Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

How Does A Nitrogen Gas Cylinder Manifold System Work?

- Pressure Regulator Valve Manufacturer

- best stainless steel gas cylinder manifold system manufacturer, Cylinder Gas Packs And Manifolds, Cylinder Manifold Nitrogen Gas Supplier, Gas Cylinder Manifold And Pipeline, Gas Cylinder Manifold And Pipeline Russia, Gas Cylinder Manifold And Pipeline System, Gas Cylinder Manifold Malaysia, Gas Cylinder Manifold Manufacturer, Gas Cylinder Manifold Manufacturer from Thane, Gas Cylinder Manifold Manufacturer Malaysia, gas regulator manifold, gas regulator manifold China, gas regulator manifold manufacturer, Gas Spring Manifold Systems, High Pressure Nitrogen Gas Manifold System, Manifold Solutions for Medical Gas Systems, Medical Gas Manifold Systems, Multi Gas Cylinder Manifold, N2 Gas Regulator Manifold Gas Supply Manifolds System, nitrogen gas cylinder manifold system manufacturer, nitrogen gas cylinder manifold system manufacturer in china, Nitrogen Gas Manifold Systems, Nitrogen Gas Manifold Systems China, Oxygen Nitrogen And Hydrogen Cylinder Manifold, stainless steel gas cylinder manifold system, stainless steel gas cylinder manifold system manufacturer, stainless steel gas cylinder manifold system manufacturer in russia, Stainless Steel Gas Cylinder Manifold Systems

- No Comments

How Does A Nitrogen Gas Cylinder Manifold System Work?

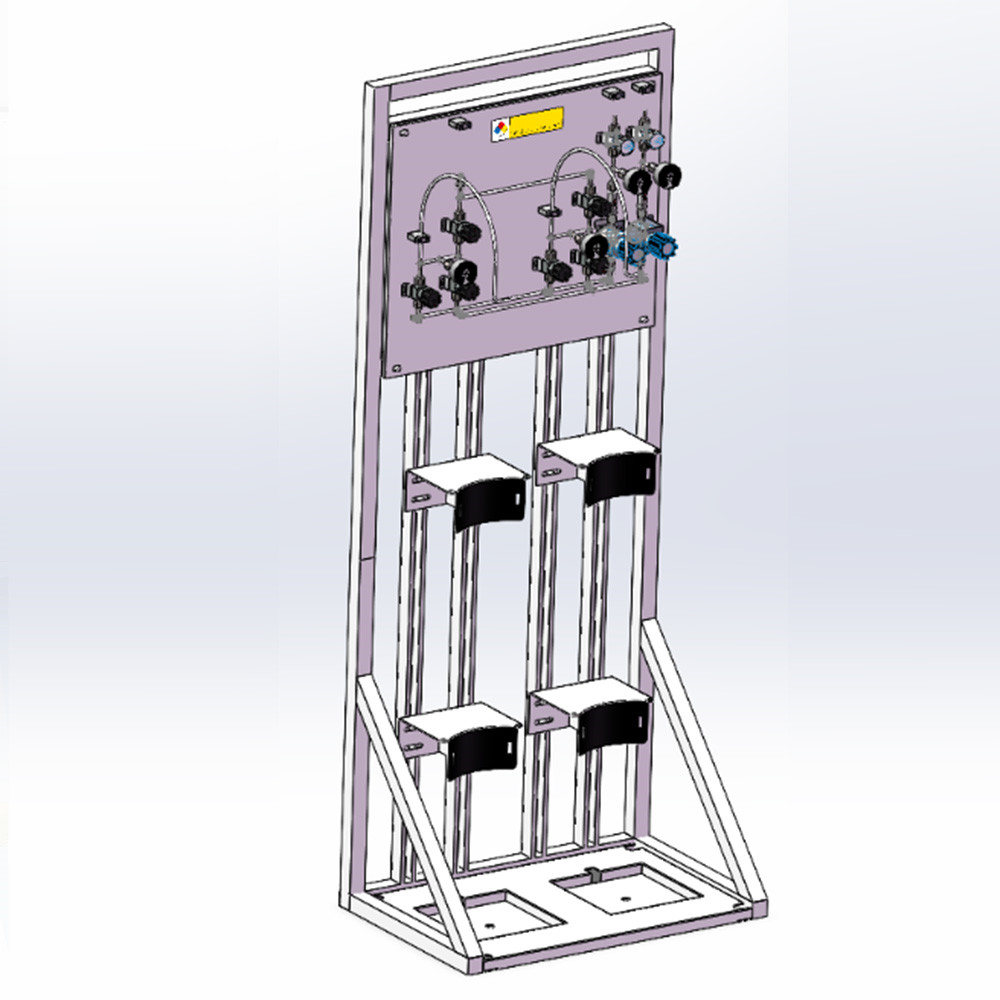

Nitrogen gas is a cornerstone in numerous industries, valued for its inert properties that make it ideal for applications such as preserving food freshness, shielding welds from oxidation, and providing an inert atmosphere in chemical processes. However, the effectiveness of nitrogen in these roles depends on a consistent and uninterrupted supply, which is where the nitrogen gas cylinder manifold system comes into play. This sophisticated system connects multiple gas cylinders to a single outlet, ensuring a seamless flow of nitrogen even as individual cylinders deplete. Its importance lies in its ability to enhance operational efficiency and safeguard processes that cannot tolerate interruptions in gas supply.

This article provides an in-depth exploration of how a nitrogen gas cylinder manifold system works. We will cover its key components, operational mechanics, types, applications, safety considerations, and maintenance requirements. By the end, you’ll have a comprehensive understanding of this critical system and its role across various sectors.

Components of a Nitrogen Gas Cylinder Manifold System

A nitrogen gas cylinder manifold system is composed of several essential components, each playing a vital role in its operation:

– Gas Cylinders: These are high-pressure vessels, typically made of steel or aluminum, designed to store nitrogen gas at pressures often exceeding 2000 psi. Each cylinder features a valve to control gas release and a protective cap to shield the valve during transport and storage.

– Manifold: The manifold is the central hub of the system, connecting multiple cylinders to a single outlet. It can range from a simple pipe with multiple inlets to a complex assembly equipped with valves and regulators. The manifold ensures that gas from any connected cylinder can flow to the point of use.

– Regulators: These devices reduce the high pressure from the cylinders to a safe, usable level for specific applications. Regulators also maintain consistent pressure, which is crucial for processes requiring precise gas flow.

– Valves: The system includes various valves:

– Shut-off Valves: Allow isolation of individual cylinders or the entire system for maintenance or emergencies.

– Check Valves: Prevent gas backflow, ensuring unidirectional flow.

– Relief Valves: Release excess pressure to prevent system damage or explosions.

– Pressure Gauges: Positioned on cylinders and the manifold, these gauges monitor pressure levels, alerting operators to low supply or anomalies.

– Safety Features: Essential for safe operation, these include:

– Burst Disks: Rupture at a set pressure to vent gas safely during overpressurization.

– Alarms: Notify operators of low pressure or system issues.

Together, these components form a robust system capable of delivering nitrogen gas reliably and safely.

Operation of a Nitrogen Gas Cylinder Manifold System

The operation of a nitrogen gas cylinder manifold system is designed to be both efficient and reliable. Here’s how it works:

Basic Setup and Gas Flow

Multiple cylinders are connected to the manifold using flexible pigtails or rigid piping. When a cylinder’s valve is opened, nitrogen gas flows into the manifold, then passes through the regulator, which adjusts the pressure to the required level. The gas is then delivered to the application site, such as a welding torch or a food packaging line.

Manual Operation

In a manual manifold system, typically two or more cylinders are connected, but only one—the primary cylinder—is active at a time. The operator monitors the pressure gauge on the primary cylinder. When the pressure drops, indicating depletion, the operator manually closes the primary cylinder’s valve and opens the valve of a reserve cylinder. This switch ensures continuous supply. The empty cylinder can then be replaced, becoming the new reserve.

For example, imagine a welding operation: the primary cylinder supplies nitrogen as a shielding gas. As it nears depletion, the operator switches to the reserve, avoiding interruptions in the welding process.

Automatic Switchover Operation

Automatic switchover systems enhance efficiency by eliminating manual intervention. These systems use sensors or pressure-sensitive valves to monitor the primary cylinder. When the pressure falls below a preset threshold, the system automatically switches to the reserve cylinder. This seamless transition is vital in critical applications like medical facilities or laboratories. Indicators or alarms often signal the switch, prompting operators to replace the empty cylinder.

Advanced Configurations

In larger setups, multiple cylinder banks may be connected to the manifold. The system can switch between banks automatically, offering greater redundancy. Additional equipment, such as purifiers, can also be integrated to meet specific purity standards.

This operational flexibility ensures that nitrogen gas is available whenever and wherever it’s needed, tailored to the demands of the application.

Types of Nitrogen Gas Cylinder Manifold Systems

There are two primary types of manifold systems, each suited to different needs:

– Manual Manifold Systems:

– Description: Require manual switching between cylinders.

– Advantages: Simple, cost-effective, and easy to maintain.

– Disadvantages: Demand constant monitoring and operator intervention, risking delays in high-demand settings.

– Best For: Small-scale operations or budget-conscious environments.

– Automatic Switchover Manifold Systems:

– Description: Automatically switch to a reserve cylinder when the primary is depleted.

– Advantages: Offer reliability and convenience with minimal human error.

– Disadvantages: More complex and expensive.

– Best For: Critical applications requiring uninterrupted supply, such as hospitals or large manufacturing plants.

The choice between these types depends on factors like operational scale, budget, and the importance of supply continuity.

Applications of Nitrogen Gas Cylinder Manifold Systems

Nitrogen gas cylinder manifold systems are vital across diverse industries due to nitrogen’s versatility:

– Welding and Metal Fabrication: Nitrogen serves as a shielding gas, preventing oxidation during welding. A manifold system ensures uninterrupted supply, maintaining weld quality and productivity.

– Food and Beverage: Nitrogen displaces oxygen in packaging, extending shelf life for products like snacks and beverages. Continuous supply from a manifold system keeps production lines running smoothly.

– Chemical Manufacturing: Used as an inert blanket, nitrogen prevents reactions with oxygen or moisture. Manifold systems provide a steady flow, ensuring process safety and consistency.

– Laboratories: Nitrogen supports applications like gas chromatography and cryopreservation. A reliable manifold system prevents disruptions in sensitive experiments.

– Medical and Pharmaceutical: Nitrogen is used for preserving biological samples and inerting in drug production. The system’s reliability is critical in these high-stakes environments.

These examples highlight the manifold system’s role in enhancing efficiency and reliability across sectors.

Safety Considerations

Handling nitrogen gas and high-pressure systems requires strict safety measures:

– Asphyxiation Risk: Nitrogen can displace oxygen in confined spaces, leading to suffocation. Proper ventilation and oxygen monitors with alarms are essential in work areas.

– High-Pressure Hazards: A cylinder rupture or system failure could release gas violently. Safety devices like relief valves and burst disks mitigate this risk by venting excess pressure.

– Storage and Handling: Cylinders must be secured upright, away from heat or impact, to prevent falls or valve damage. Protective caps should remain in place during storage.

– Leak Detection: Regular inspections using leak detection solutions or electronic devices help identify and fix leaks promptly, preventing gas loss and hazards.

– Training: Personnel must be trained in system operation, emergency procedures, and PPE use (e.g., safety glasses, gloves). Proper connection/disconnection techniques reduce risks.

– Regulatory Compliance: Adherence to standards from bodies like the Compressed Gas Association (CGA) or OSHA ensures safety through regular inspections and proper protocols.

These precautions protect both personnel and equipment, making safety a top priority.

Maintenance of Nitrogen Gas Cylinder Manifold Systems

Routine maintenance ensures the system’s longevity and safety:

– Inspections: Check pressure gauges and regulators for accuracy, and inspect valves and connections for leaks or wear. Address issues immediately.

– Component Replacement: Replace degrading parts like hoses or pigtails periodically, using only compatible replacements to maintain system integrity.

– Record Keeping: Maintain logs of maintenance and inspections to track system health and plan future upkeep.

– Manufacturer Guidelines: Follow specific recommendations to ensure optimal performance and preserve warranties.

Proactive maintenance minimizes downtime and enhances safety, keeping the system in top condition.

Conclusion

The nitrogen gas cylinder manifold system is a vital tool that ensures a continuous, reliable supply of nitrogen gas across industries. By connecting multiple cylinders to a single outlet, it eliminates supply interruptions, supporting critical processes in welding, food packaging, chemical production, and beyond. Its components—cylinders, manifold, regulators, and safety features—work in harmony to deliver gas efficiently, while manual and automatic variants cater to diverse needs. Safety and maintenance are integral to its operation, protecting users and extending system life.

As technology advances, we can anticipate smarter manifold systems with enhanced automation and monitoring, further optimizing nitrogen use. Understanding how these systems work underscores their importance in modern industry, where reliability and efficiency are paramount.

For more about how does a nitrogen gas cylinder manifold system work, you can pay a visit to Jewellok at https://www.jewellok.com/what-is-specialty-gas-semi-automatic-changeover-manifold-systems/ for more info.

Recent Posts

How a Gas Pressure Regulator Works

Adjustable Low Pressure Propane Regulator

Pressure Control Valve Manufacturers

High Flow Needle Valves manufacturers

Tags

Recommended Products

-

High Purity Chemical Dispense System & Packing System For Semiconductors JW-200L-CDM & JW-1000L-CDM

-

DPR1 Ultra High Purity Two Stage Dual Stage Pressure Reducing Regulator Semiconductor Grade Regulators

-

775L Bulkhead Reducing Union | Stainless Steel High Purity Double Ferrule Bulkhead Reducing Unions

-

Stainless Steel Single Stage Semiconductor Grade Pressure Control Module Pressure Control Panels JSP-6A Series

-

Stainless Steel High-Purity High Temperature Metal Seated Ball Valves JBV3 Series

-

739LF High Purity Female Adapter Tube To Pipe Fittings And Connectors

-

772 LF Female Branch Tee | Stainless Steel Tube Fitting Female Branch Tee 1/2 in. Tube OD x 1/2 in. Tube OD x 3/8 in. Female NPT

-

Fully Automated Gas Cabinet For Precise UHP Gas Delivery And High Purity Gas Delivery Systems JW-300-GC