Blog

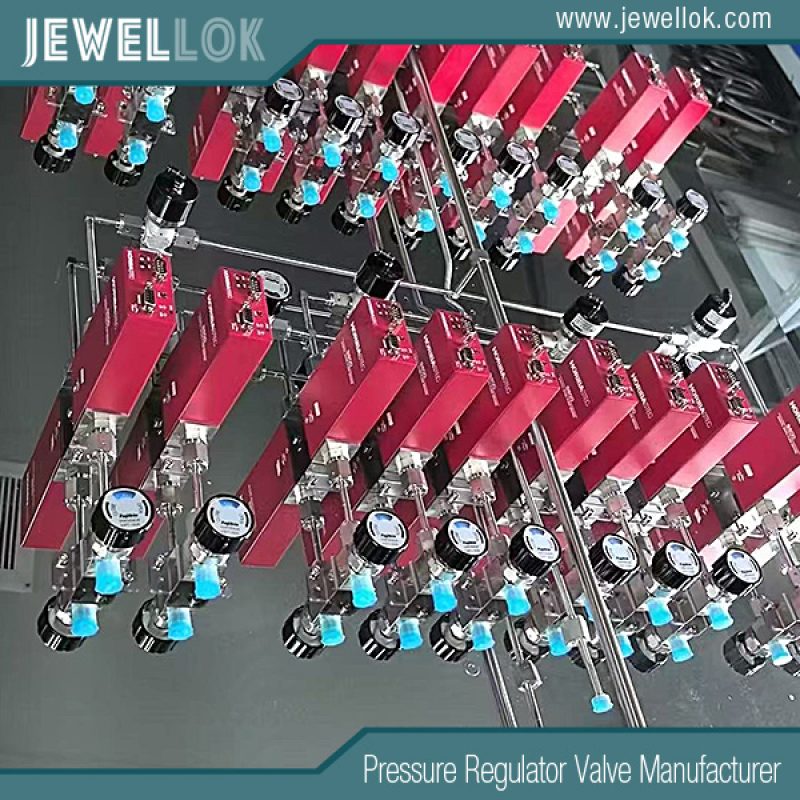

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Analysis of the Market Prospect of Ultra High Purity Diaphragm Valves

- Pressure Regulator Valve Manufacturer

- 1inch of water, 2 inch irrigation valve, 6mm compression fitting, adjustable low pressure propane regulator, air compressor non return valve, argon hose connector, argon hose fittings, compression fitting 6mm, electric water valve 12v, ferrule connector, fire arrestor, fluid system components, gas semiconductor, high purity regulators, how a gas pressure regulator works, how a pressure regulator works, how do pressure regulators work, how do regulators work, how often should pressure relief valves be replaced, how solenoid works, humming propane regulator, male fitting for argon hose, oxygen cylinder manifold, pressure relief valve vs safety valve, propane adjustable pressure regulator, propane manifold with valves, purpose of flame arrester, safety or relief valves, safety relief valve vs safety valve, safety valve vs pressure relief valve, second stage propaneregulator, solenoid valve for ammonia gas 2 inch pipe, timer water valve, two stage pressure regulator

- No Comments

Analysis of the Market Prospect of Ultra High Purity Diaphragm Valves

Ultra high purity diaphragm valves, as indispensable key components in fields with extremely high requirements for fluid purity, their market prospects are influenced by a multitude of intertwined factors. Judging from the current industry dynamics and future development trends, the market for ultra high purity diaphragm valves harbors tremendous development potential.

In terms of the growth trend of the market scale, the market for ultra high purity diaphragm valves is showing a positive expansion trend. According to relevant market research data, the global market size of ultra-high purity (UHP) diaphragm valves reached several billion yuan in 2023, and it is expected to continue growing at a certain compound annual growth rate during the period from 2024 to 2030. This growth is not accidental but the result of the combined action of various driving factors.

In terms of application fields, the semiconductor industry is one of the important application markets for ultra high purity diaphragm valves. With the continuous progress of semiconductor technology, the chip manufacturing process is becoming increasingly refined, putting forward extremely high requirements for the purity and control accuracy of fluids in the production process. In key processes of semiconductor manufacturing such as etching, thin film deposition, and ion implantation, ultra high purity diaphragm valves are used to control the flow of ultra pure gases and chemicals, ensuring a highly clean production environment and the precision of the manufacturing process, which plays a crucial role in improving the performance and yield of chips. Taking the current advanced chip manufacturing process as an example, as the line width of chips continues to shrink, more precise fluid control is required. Ultra high purity diaphragm valves can meet this demand for high precision, ensuring that ultra pure gases and chemicals are not contaminated during the transportation process, thus guaranteeing the quality of chip manufacturing. With the continuous development of the global semiconductor industry, especially the increasing investment in the semiconductor field by emerging economies, the demand for ultra high purity diaphragm valves will also rise accordingly. For example, China has been vigorously developing the semiconductor industry in recent years and has built numerous semiconductor manufacturing plants, which has brought broad development space for the market of ultra high purity diaphragm valves.

The pharmaceutical industry also has a large demand for ultra high purity diaphragm valves. In the process of pharmaceutical production, ensuring the purity and safety of drugs is of utmost importance. Ultra high purity diaphragm valves can prevent drugs from being contaminated by external impurities during the production and transportation processes, ensuring the stability and uniformity of drug quality. For example, in the field of biopharmaceuticals, ultra high purity diaphragm valves are used to control the flow of biological culture media, pharmaceutical raw materials and other fluids, avoiding microbial contamination and cross-contamination, and meeting the strict quality standards of pharmaceutical production. With the continuous increase in people’s attention to medical health and the continuous growth of the demand for high-quality drugs, the expansion of the pharmaceutical industry will also drive the development of the ultra high purity diaphragm valve market.

In the food processing industry, under the trend of pursuing high-quality food, ultra high purity diaphragm valves are being increasingly applied. In the production process of beverages, dairy products and other foods, in order to ensure the taste, quality and safety of the food, it is necessary to precisely control the production water, food raw materials and other fluids to prevent the mixing of impurities. Ultra high purity diaphragm valves, with their good sealing performance and pollution-free characteristics, can meet the strict requirements of the food processing industry for hygiene and purity. For example, in the production of high-end dairy products, ultra high purity diaphragm valves ensure the purity of milk and other raw materials during the processing process, avoiding the influence of external factors on the product quality.

In terms of technological innovation, ultra high purity diaphragm valves are also constantly making breakthroughs. On the one hand, the progress of materials science has provided new opportunities for the development of ultra high purity diaphragm valves. The application of new materials, such as materials with higher purity, better corrosion resistance and stability, has significantly improved the performance of ultra high purity diaphragm valves. For example, the use of special stainless steel alloy materials or high-performance plastic materials can enhance the tolerance of diaphragm valves to highly corrosive chemicals, extend the service life of the valves, and at the same time ensure that the purity of the fluid is not affected. On the other hand, the improvement of manufacturing processes has also increased the precision and reliability of ultra high purity diaphragm valves. Advanced processing technologies can achieve more precise part manufacturing and assembly, ensuring the stability and sealing performance of the valves during long-term use. Some manufacturers use advanced numerical control processing technologies and automated assembly production lines, which improve the consistency and quality stability of products.

In addition, the integration of automation and intelligent technologies is also an important development trend of ultra high purity diaphragm valves. With the continuous improvement of industrial automation levels, the integration degree of ultra high purity diaphragm valves and automation control systems is getting higher and higher. Through intelligent control, ultra high purity diaphragm valves can achieve functions such as remote monitoring and automatic flow regulation, improving the efficiency and accuracy of the production process. In some large semiconductor manufacturing plants, ultra high purity diaphragm valves are connected to the automation control system, which can adjust the opening of the valves in real time according to the requirements of the production process to achieve precise control of the fluid flow. At the same time, they can also timely feedback the working status of the valves, which is convenient for maintenance and management.

However, the ultra high purity diaphragm valve market also faces some challenges. On the one hand, the market competition is fierce, and many domestic and foreign enterprises are competing in the ultra high purity diaphragm valve market. Some well-known international brands, such as Swagelok, Kitz SCT, etc., occupy an important position in the market by virtue of their advanced technology, high-quality products and good brand reputation. Although domestic enterprises have made certain development in recent years, there is still a certain gap in technological research and development and brand influence compared with international enterprises. On the other hand, the fluctuation of raw material prices and the increase in production costs have also had a certain impact on the ultra high purity diaphragm valve market. The instability of raw material prices may lead to fluctuations in product prices, affecting market demand; while the increase in production costs has compressed the profit margins of enterprises, bringing certain pressure to the production and operation of enterprises.

In terms of geographical distribution, the ultra high purity diaphragm valve market presents different development trends globally. North America and Europe, due to their advanced technology and mature industrial foundation in industries such as semiconductors and pharmaceuticals, have a relatively stable demand for ultra high purity diaphragm valves and dominate the high-end product field. In the Asian region, especially in China, Japan and South Korea, with the rapid rise of industries such as semiconductors and electronics, the demand for ultra high purity diaphragm valves is growing rapidly, becoming the main driving force for the growth of the global ultra high purity diaphragm valve market. As one of the largest semiconductor consumer markets in the world, and with the continuous development of industries such as pharmaceuticals and food processing, China has huge potential demand for ultra high purity diaphragm valves in the future.

conclusion

The market prospect of ultra high purity diaphragm valves is broad. Although facing challenges such as market competition and cost pressure, driven by the continuous development of industries such as semiconductors, pharmaceuticals and food processing, as well as the drive of technological innovation, the ultra high purity diaphragm valve market is expected to achieve continuous and stable growth in the future. Enterprises need to continuously increase investment in technological research and development, improve product quality and performance, and strengthen brand building to cope with market competition, seize market opportunities, and achieve better development in the ultra high purity diaphragm valve market.

For more about analysis of the market prospect of ultra high purity diaphragm valves, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Choose a Gas Cylinder Manifold System

Pressure Reducing Regulator VS Back Pressure Reducing Valve

The Inner Workings of a 316L VIM-VAR Stainless Steel Pressure Regulator

How Ultra-High Purity Stainless Steel Tubing Powers Critical Industries

How Does a UHP 316L Stainless Steel Bellows Valve Work?

Tags

Recommended Products

-

High Pressure High-Purity Welded Check Valves And Low Cracking Pressure Check Valve JCV1 Series

-

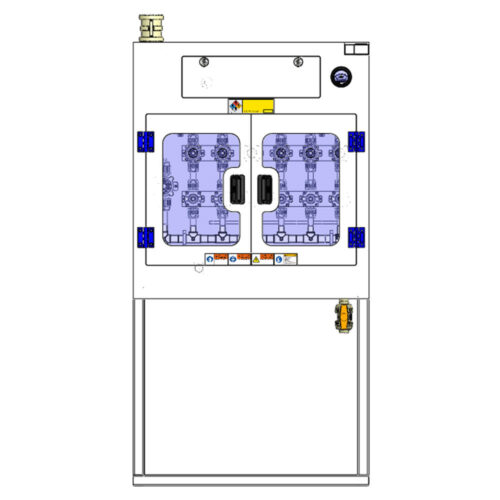

Semi Automatic Gas Cabinet Gas Panels High Purity Gas Delivery Systems JW-200-GC

-

Stainless Steel High Pressure Specialty Gas Changeover Manifold For High Purity Oxygen Nitrogen Argon Helium Hydrogen Co2

-

Stainless Steel Mini Elbow Mini Tee Mini Cross Mini Tribow Ultrahigh Purity Mini Butt Weld Fittings

-

High Purity Configurable Systems VMB Valve Manifold Box JW-200-VMB-C & JW-100-VMB-C

-

High Purity High Pressure Stainless Steel Needle Valve Natural Gas Flow Control Valve JNV Series

-

DPR1 Ultra High Purity Two Stage Dual Stage Pressure Reducing Regulator Semiconductor Grade Regulators

-

High Purity High Flow Pressure Control Regulators & Valves Gas Stick Assemblies JSR-2TG Series