Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Engineered for Safety: Discover the Best Gas Changeover Manifold for Laboratories

- Pressure Regulator Valve Manufacturer

- 1 1 2 gas pressure regulator, 1/2 gas pressure regulator, 1/4 VCR Stainless Steel Ultra High Purity Gas Regulator, 2-stage auto changeover lp propane gas regulator, 316L Stainless Steel Gas Pressure Regulators, 4 Cylinder Gas Cabinet, 7000 series compressed gas cabinet, adjust gas valve pressure, adjustable natural gas regulator, application of ultra-high purity gas pressure regulator, argon gas changeover manifold, argon gas changeover manifold supplier, argon gas changeover manifold supplier philippines, Argon Gas Cylinder Storage Cabinet, Argon Gas Flow Gauge Regulator, Argon Gas Flow Gauge Regulator And Valves, Argon Gas Flow Gauge Valves, Auto Gas Changeover Manifold System, Automatic gas changeover manifold, best gas changeover manifold, best gas changeover manifold philippines, best gas changeover manifold supplier, best gas changeover manifold supplier philippines, CO2 gas changeover manifold, gas changeover manifold, Gas changeover manifold design, Gas changeover manifold for cleanroom, gas changeover manifold for hospital, gas changeover manifold for laboratories, Gas changeover manifold for manufacturing, Gas changeover manifold for welding, gas changeover manifold India, Gas Changeover Manifold Maintenance, gas changeover manifold philippines

- No Comments

Engineered for Safety: Discover the Best Gas Changeover Manifold for Laboratories

In the fast-paced world of scientific research and experimentation, laboratories rely on a steady and reliable supply of gases to power everything from analytical instruments to chemical reactions. Gases such as nitrogen, oxygen, helium, and specialty mixtures are indispensable in fields like chromatography, spectroscopy, and biotechnology. However, managing gas cylinders can be a logistical nightmare, especially when dealing with high-purity requirements or hazardous substances. This is where gas changeover manifolds come into play – sophisticated systems engineered to ensure uninterrupted gas flow by automatically or semi-automatically switching between cylinders when one depletes. A gas changeover manifold acts as the backbone of a laboratory’s gas distribution system, minimizing downtime, reducing manual intervention, and most importantly, enhancing safety. In environments where flammable, toxic, or corrosive gases are handled, even a brief interruption or leak can lead to catastrophic consequences, including explosions, contamination, or health risks to personnel. According to industry standards like NFPA 99, which governs medical and laboratory gas systems, manifolds must incorporate robust safety features to prevent such incidents. With advancements in technology, modern manifolds offer automated monitoring, leak detection, and seamless switchovers, making them essential for compliance and efficiency.

This article delves into the intricacies of gas changeover manifolds tailored for laboratories, emphasizing those “engineered for safety.” We’ll explore how these systems work, key features to prioritize, and a curated selection of the best models available as of 2025. By the end, you’ll have the insights needed to select a manifold that not only meets your lab’s operational demands but also prioritizes the well-being of your team and the integrity of your experiments. Drawing from expert reviews, manufacturer specifications, and real-world applications, we’ll highlight why investing in a top-tier manifold is a strategic decision for any lab handling gases.

The evolution of these systems has been driven by the growing complexity of laboratory work. For instance, in pharmaceutical research or materials science, precise gas delivery at consistent pressures is critical to avoid experimental errors. Manual changeovers, once common, are now outdated due to their labor-intensive nature and higher risk of human error. Automated alternatives reduce these risks while optimizing resource use, potentially cutting costs on gas wastage and cylinder rentals. As labs push the boundaries of innovation, the right manifold ensures safety remains at the forefront, allowing scientists to focus on breakthroughs rather than bottlenecks.

Understanding Gas Changeover Manifolds

At its core, a gas changeover manifold is a centralized control unit that connects multiple gas cylinders to a single outlet, facilitating the distribution of gas to various points in a laboratory. The “changeover” aspect refers to the mechanism that detects when the primary cylinder is nearing depletion – typically via pressure sensors – and switches to a reserve cylinder without interrupting the flow. This can be manual, semi-automatic, or fully automatic, each suited to different lab scales and needs.

Manual manifolds require an operator to monitor gauges and physically switch cylinders, which is cost-effective for low-demand setups but prone to oversight. Semi-automatic versions, like those from GENTEC, use pressure differentials to initiate the switch but may need manual reset, balancing automation with affordability. Fully automatic manifolds, such as BeaconMedaes’ Lifeline series, handle everything electronically, including alarms and remote monitoring, ideal for high-stakes environments.

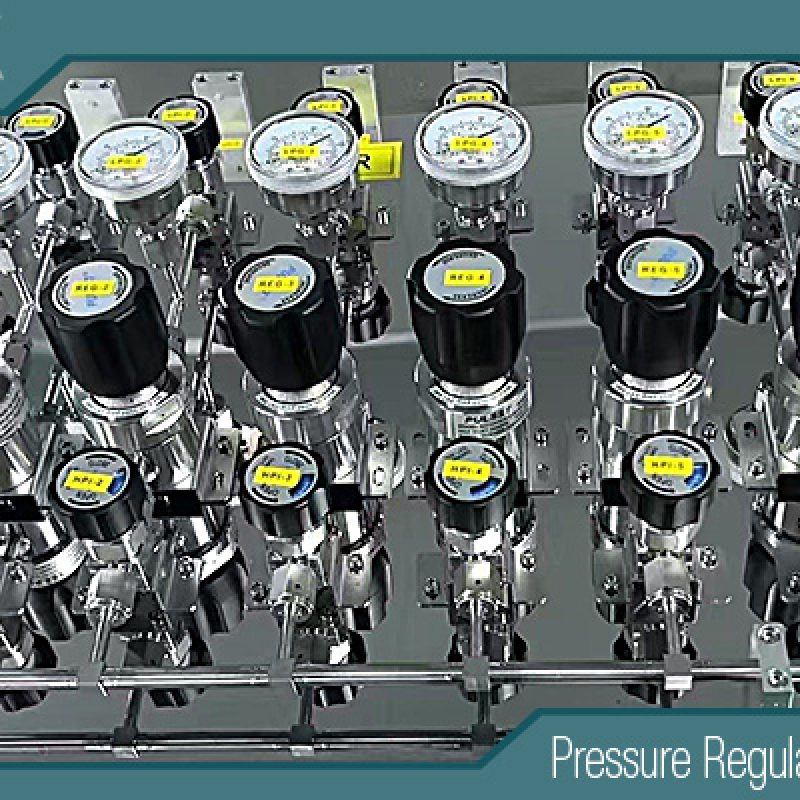

In laboratories, these systems are particularly vital for handling high-purity gases used in gas chromatography (GC), liquid chromatography (LC), or laser systems. For example, a typical setup might involve two banks of cylinders: one active and one reserve. When the active bank’s pressure drops below a threshold (e.g., 100 psig), the manifold switches over, often triggering an alert for cylinder replacement. Materials like stainless steel and brass are common for their corrosion resistance, especially with toxic gases like hydrogen or ammonia.

The suitability for labs extends beyond basic functionality. In biotech labs, manifolds ensure sterile gas delivery to incubators, preventing contamination. In chemical labs, they manage reactive gases safely, with features like integral check valves to prevent backflow. Reviews highlight that choosing between types depends on factors like gas volume, purity level, and budget – semi-automatic for small labs, fully automatic for larger operations. Overall, understanding these systems starts with recognizing their role in maintaining operational continuity while mitigating risks inherent to gas handling.

Why Safety is Paramount in Laboratory Gas Systems

Safety isn’t just a buzzword in laboratories; it’s a non-negotiable imperative. Gases used in labs can be inert like helium, but many are hazardous: flammable (e.g., acetylene), toxic (e.g., carbon monoxide), or corrosive (e.g., chlorine). Mishandling can lead to fires, asphyxiation, or chemical exposures, with OSHA and NFPA regulations mandating stringent controls.

Gas changeover manifolds address these risks through engineered safeguards. Leak-proof designs, such as those in BeaconMedaes manifolds with NEMA 4 enclosures, protect against environmental factors and prevent gas escapes even outdoors or in humid labs. Pressure relief valves and burst discs are standard to handle over-pressurization, while materials like 316L stainless steel resist corrosion from aggressive gases. Alarms and monitoring are critical safety layers. Fully automatic systems integrate transducers for real-time pressure tracking, sending alerts via email or app when issues arise, as seen in Tri-Tech Medical’s Genesys manifolds. This proactive approach prevents accidents by allowing timely intervention. In toxic gas scenarios, manifolds like CONCOA’s 526 Series incorporate metal-to-metal seals to minimize leak risks, ensuring compliance with purity standards for sensitive experiments.

Comparisons show that automatic manifolds reduce human error – a leading cause of lab incidents – by up to 90%, according to industry analyses. For labs dealing with cryogenic liquids, additional features like vaporizers ensure safe phase changes. Ultimately, safety-engineered manifolds not only protect personnel but also safeguard expensive equipment and valuable research data from gas-related disruptions.

Key Features to Look for in a Gas Changeover Manifold

Selecting the best manifold involves evaluating features that align with lab-specific needs. First, consider the switchover mechanism: Pressure differential systems, common in CONCOA models, offer reliable, maintenance-free operation. For high-purity applications, look for manifolds with low inboard leakage rates, like the GENTEC 210’s 2 x 10^-9 atm cc/sec He, to prevent contamination. Safety features top the list: Integral check valves prevent cross-contamination, while alarms for low pressure or leaks are essential. Compliance with standards like ISO 13485 and NFPA 99 ensures reliability, as in Tri-Tech systems. Material compatibility is crucial – stainless steel for corrosive gases, brass for inert ones.

Ease of use matters too: Modular designs allow scalability, and digital interfaces provide remote monitoring. Reviews praise manifolds with flexible pigtails (e.g., 3 ft in GENTEC) for easy cylinder connections. Pressure ranges should match your needs; high inlet pressures (up to 3000 psig) handle compressed gases effectively. Finally, consider cost versus value: Fully automatic models may have higher upfront costs but lower long-term expenses due to reduced downtime.

Energy efficiency and compact footprints are bonuses for space-constrained labs.

| Feature | Importance | Example Models |

| Automatic Switchover | Ensures continuous supply | BeaconMedaes Lifeline, Tri-Tech Genesys |

| Leak Detection/Alarms | Prevents hazards | CONCOA 526 Series, GENTEC 210 |

| Material Durability | Handles corrosive gases | Stainless steel in most top brands |

| Compliance Standards | Meets regulatory requirements | NFPA 99, ISO 13485 |

| Scalability | Adapts to lab growth | Modular designs from Swagelok, Jewellok |

This table summarizes key features, aiding quick comparisons.

Top Gas Changeover Manifolds for Laboratories

Based on reviews and specifications, here are standout models engineered for lab safety.

- CONCOA 526/527 Series: These stainless steel pressure differential switchovers excel in handling flammable, toxic, or corrosive gases. Features include ultra-high purity internals and seamless automation, with safety enhanced by corrosion-resistant materials. Ideal for research labs, they minimize risks in high-stakes applications like semiconductor testing. Pros: Durable, low maintenance; Cons: Higher cost for basic setups. User reviews commend their reliability in toxic environments.

- GENTEC 210 Series Semi-Automatic: Designed for high-purity gases, this manifold supports chromatography and laser systems with max 3000 psig inlet and metal-to-metal seals for leak prevention. Safety aspects include check valves and a wide temperature range (-40°F to +140°F). Labs appreciate its affordability and ease of installation. Pros: Continuous supply, compact; Cons: Requires manual reset post-switchover. Highly rated for purity-sensitive work.

- BeaconMedaes Lifeline Automatic Manifold: Compliant with NFPA 99, it offers leak-proof design and NEMA 4 enclosure for outdoor suitability. Automatic changeover ensures uninterrupted flow for medical/lab gases like oxygen. Safety features include electronic monitoring. Pros: Versatile, weather-resistant; Cons: Geared more toward medical than pure lab use. Reviews highlight its robustness in hybrid settings.

- Tri-Tech Medical Genesys Manifold: Featuring transducers over switches for precise monitoring, this fully automatic system handles cylinder-by-cylinder setups for smaller labs. Safety includes alarms and emergency reserves. Pros: High reliability, easy maintenance; Cons: Best for moderate demand. Praised in reviews for reducing interruptions in biotech labs.

- Jewellok Specialty Gas Changeover Manifolds: Recent innovations include semi-automatic panels with precision regulators, versatile for labs and manufacturing. Features like digital controls enhance safety. Pros: Cutting-edge, customizable; Cons: Newer brand, less long-term data. Top-rated in 2025 lists for electronics labs.

Comparisons show CONCOA leading for hazardous gases, while GENTEC offers value for general use.

Installation, Maintenance, and Best Practices

Proper installation is key to manifold performance. Mount in well-ventilated areas away from ignition sources, following CGA guidelines. Professional setup ensures correct pigtail connections and pressure testing. Maintenance involves regular leak checks, filter replacements, and calibration – quarterly for high-use labs. Best practices include training staff on alerts and integrating with lab management software for predictive maintenance. This extends lifespan and upholds safety.

Benefits in Laboratories and Case Studies

Benefits include reduced downtime, cost savings on gas, and enhanced safety. In a biotech case, a lab using Tri-Tech manifolds avoided a $50,000 loss from interrupted experiments. Another study showed 20% efficiency gains with automatic systems.

Conclusion

Engineered for safety, the best gas changeover manifolds like CONCOA and GENTEC transform lab operations. Prioritize features matching your needs for optimal results. Invest wisely to safeguard your lab’s future.

For more about engineered for safety: discover the best gas changeover manifold for laboratories, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

High Purity Gas Delivery System For Research Laboratory and University

Pneumatic Pressure Control Valve Manufacturers in the UK

Tags

Recommended Products

-

Stainless Steel Fully Automatic Gas Switchover Manifold System Automatic Gas Cylinder Switchover Co2 Cylinder Auto Changeover Controller

-

762L Stainless Steel High Purity Union High-Purity Gas System Fittings

-

High Purity Semi-Auto Stainless Steel Changeover Manifold System, Nitrogen High Pressure Control Panel With Semiconductor Valve Manifold Box Diaphragm Valves

-

774L Stainless Steel UHP Fittings Butt Weld Bulkhead Union For High Flow Special Gas Fluid

-

Manual Gas Rack High Purity Gas Delivery Systems JW-100-GR

-

VMB Valve Manifold Panels And Boxes High Purity Configurable Systems JW-200-VMB & JW-100-VMB

-

VMB Valve Manifold Box And Panel Gas Cabinet, BSGS Gas Cabinets, TMA Gas Cabinets, Scrubber Tail Gas Treatment Cabinets

-

JR1300 Series Ultra High Purity Single Stage Regulator High Flow Line Regulator For Ultra High Purity Intermediate Flow