Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

How Do Ultra High Purity Gas Delivery Systems Contribute to the Medical Industry?

- Pressure Regulator Valve Manufacturer

- Best uhp gas delivery systems, gas delivery system in medical industry, gas delivery system in semiconductor, hospital oxygen manifold system, Malaysia Ultra High Purity Gas Delivery Systems, medical gas pipeline system in hospitals, medical gas system components, Semiconductor Gas Delivery Systems, UHP gas delivery systems, ultra high purity gas delivery systems in brazil, ultra high purity gas delivery systems in thailand, Ultra High Purity Gas Delivery Systems in USA, Ultra High Purity Gas Delivery Systems Malaysia, ultra high purity gas delivery systems vietnam, Ultra-High-Purity Gas Delivery Systems

- No Comments

How Do Ultra High Purity Gas Delivery Systems Contribute to the Medical Industry?

In the intricate and highly regulated world of healthcare, precision and safety are non-negotiable. Ultra high purity (UHP) gas delivery systems play a vital yet often overlooked role in meeting these standards. Designed to provide gases with exceptionally low levels of impurities, these systems are essential across a range of medical applications—from patient care and laboratory diagnostics to sterilization and pharmaceutical manufacturing. This article explores how UHP gas delivery systems contribute to the medical industry, ensuring that healthcare providers can deliver safe, effective, and high-quality care.

Understanding Ultra High Purity Gas Delivery Systems

UHP gas delivery systems are engineered to supply gases that meet stringent purity requirements, often with impurity levels below 1 part per million (ppm). In medical contexts, even trace contaminants—such as moisture, particulates, or unwanted gases—can compromise patient safety, diagnostic accuracy, or product quality. These systems incorporate advanced components to maintain gas purity, including:

Purifiers: Remove specific impurities like water vapor or oxygen.

Filters: Trap particulates that could contaminate the gas stream.

Regulators: Control pressure and flow for consistent delivery.

Manifolds and Valves: Enable safe distribution and switching of gas sources.

By integrating these elements, UHP gas delivery systems ensure that gases remain uncontaminated from production to their point of use, whether that’s a hospital ward, a laboratory, or a manufacturing facility.

1. Ensuring Patient Safety in Medical Gas Supply

Medical gases like oxygen, nitrous oxide, and nitrogen are indispensable in patient care, and their purity directly impacts treatment outcomes. UHP gas delivery systems ensure these gases meet the highest safety standards, minimizing risks to patients.

Oxygen for Respiratory Support

Oxygen is a lifeline for patients with respiratory conditions, such as chronic obstructive pulmonary disease (COPD) or acute respiratory distress syndrome (ARDS). Impurities like carbon monoxide or particulates in oxygen can worsen breathing difficulties or introduce new health risks. UHP oxygen, typically with a purity of 99.5% or higher, ensures that patients receive clean, safe gas. Regulatory bodies like the U.S. Food and Drug Administration (FDA) set strict limits on impurities—such as carbon dioxide and moisture—and UHP systems consistently exceed these requirements.

Nitrous Oxide for Anesthesia

Nitrous oxide, often called “laughing gas,” is widely used as an anesthetic during surgeries and dental procedures. Contaminants in nitrous oxide could reduce its effectiveness or cause adverse reactions, such as improper sedation levels. UHP gas delivery systems guarantee that this gas remains pure, providing reliable pain management and sedation for patients.

Nitrogen in Cryosurgery

In cryosurgery, nitrogen is used to freeze and destroy abnormal tissues, such as tumors or warts. The precision of this procedure depends on the purity of the nitrogen, as impurities could disrupt the freezing process or contaminate the surgical site. UHP nitrogen ensures controlled, effective treatment with minimal risk.

Real-World Impact

A hospital in California demonstrated the value of UHP gas delivery when it upgraded its oxygen system. Previously, aging infrastructure occasionally allowed impurities to enter the oxygen supply, leading to respiratory complications in some patients. After installing a modern UHP system, the hospital reported a 30% reduction in such incidents, highlighting how purity translates to improved patient safety.

2. Enhancing Accuracy in Laboratory Analysis

Medical laboratories depend on precise analytical techniques to diagnose diseases, monitor health, and advance research. Techniques like gas chromatography (GC), mass spectrometry (MS), and high-performance liquid chromatography (HPLC) rely on UHP gases to deliver accurate results.

Gas Chromatography

In GC, carrier gases such as helium or nitrogen transport samples through a column to separate and analyze compounds. Impurities in these gases—such as oxygen or moisture—can interfere with the separation process, leading to inaccurate readings or misdiagnoses. UHP gases, with their near-zero impurity levels, ensure reliable separation and detection, critical for diagnosing conditions like diabetes or cancer.

Mass Spectrometry

MS uses gases like argon or nitrogen in ionization processes to identify molecules based on their mass-to-charge ratio. Contaminants can disrupt ionization efficiency, skewing results and potentially leading to incorrect identification of substances. UHP gas delivery systems maintain the integrity of these analyses, supporting accurate diagnostics and research.

Calibration Standards

Laboratories also use UHP gases as calibration standards to verify the accuracy of their instruments. Impure calibration gases could introduce systematic errors, undermining the reliability of all subsequent tests. By providing consistent, pure gases, UHP systems uphold the precision required in medical testing.

Technical Benefit

In GC, oxygen or moisture in the carrier gas can degrade the column over time, shortening its lifespan and increasing costs. UHP gases mitigate this issue, extending equipment durability while ensuring consistent performance—key factors in busy medical labs where downtime is not an option.

3. Improving Sterilization Efficiency

Sterilization is a critical process in healthcare, ensuring that medical equipment and instruments are free of microbial contamination. Ethylene oxide (EtO) gas is a common sterilizing agent, and its effectiveness depends on its purity, which UHP gas delivery systems guarantee.

Ethylene Oxide Sterilization

EtO penetrates packaging and equipment to eliminate bacteria, viruses, and fungi, making it ideal for heat-sensitive items like surgical tools and implants. However, impurities in EtO—such as moisture—can reduce its sterilizing power or form toxic byproducts like ethylene glycol, which could remain on equipment and pose risks to patients. UHP EtO ensures thorough sterilization without harmful residues, safeguarding patient health.

Regulatory Compliance

The FDA and other regulatory agencies set strict purity standards for EtO used in sterilization. UHP gas delivery systems help healthcare facilities and manufacturers meet these requirements, ensuring that sterilized products are safe for use. This compliance is especially critical in operating rooms, where contaminated instruments could lead to postoperative infections.

4. Supporting Quality in Pharmaceutical Manufacturing

Pharmaceutical production demands precise control over every aspect of the process, and UHP gases play a key role in maintaining product quality and safety.

Freeze-Drying (Lyophilization)

Freeze-drying is used to preserve vaccines, biologics, and other sensitive drugs. Nitrogen, often supplied via UHP systems, creates an inert atmosphere that prevents degradation during this process. Impurities in the nitrogen could compromise the stability or efficacy of the final product, potentially rendering it ineffective or unsafe.

Blanketing and Purging

Inert gases like nitrogen or argon are used to displace oxygen and moisture in reactors and storage tanks, protecting active pharmaceutical ingredients (APIs) from oxidation or contamination. UHP gases ensure that these protective environments remain pristine, preserving the integrity of high-value compounds.

Aerosol Propellants

In inhalers and other aerosolized medications, UHP gases serve as propellants to deliver consistent doses. Contaminants in these gases could introduce impurities into the patient’s respiratory system, undermining the treatment’s safety and efficacy. UHP systems eliminate this risk, ensuring reliable drug delivery.

Industry Example

A pharmaceutical company producing inhalable insulin relies on UHP nitrogen to maintain an oxygen-free production environment. Even trace oxygen could degrade the insulin, reducing its potency. By achieving a 99.9% purity level with a UHP gas delivery system, the company ensures that its product remains stable and effective for patients with diabetes.

Overcoming Challenges in Gas Purity

Maintaining ultra high purity from production to application is not without challenges. Contamination risks arise during transportation, storage, or at the point of use, but UHP gas delivery systems address these issues with advanced solutions.

Transportation and Storage: Gases can pick up moisture or particulates from cylinders or piping if not properly maintained. UHP systems use high-integrity materials, like electropolished stainless steel, to minimize contamination risks.

Point of Use: Final connection points, such as valves or connectors, can introduce impurities if mishandled. Point-of-use purifiers installed near the application remove any contaminants introduced downstream.

Monitoring: Modern UHP systems feature automated sensors that continuously monitor gas purity, alerting operators to deviations and enabling rapid corrections.

These innovations ensure that gases remain pure throughout their journey, protecting the integrity of medical processes.

The Future of UHP Gas Delivery in Medicine

As medical science advances, the demand for UHP gases is set to increase. Emerging fields like regenerative medicine, personalized therapies, and advanced diagnostics will rely on even higher purity levels to support their complex requirements.

Regenerative Medicine: In stem cell research and tissue engineering, UHP gases create controlled environments for cell growth. Impurities could affect cell viability, making purity essential for successful outcomes.

Personalized Therapies: Tailored treatments require precise manufacturing conditions, where UHP gases will ensure the quality of individualized drugs.

Advanced Diagnostics: Techniques like next-generation sequencing or proteomics may use UHP gases for sample preparation, demanding exceptional purity for accurate results.

Future advancements in gas purification—such as improved adsorbents or on-site gas generation—will further enhance the capabilities of UHP systems, reducing contamination risks and meeting the evolving needs of healthcare.

Conclusion

Ultra high purity gas delivery systems are a cornerstone of modern medicine, quietly but powerfully contributing to patient safety, diagnostic accuracy, sterilization efficiency, and pharmaceutical quality. By delivering gases free of harmful impurities, these systems uphold the rigorous standards of the medical industry, ensuring that treatments, tests, and products perform as intended. As healthcare continues to innovate, the role of UHP gas delivery systems will grow, supporting breakthroughs that enhance patient care and save lives. In a field where precision is paramount, their importance cannot be overstated.

For more about how do ultra high purity gas delivery systems contribute to the medical industry, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Pneumatic Actuated Ball Valve

Industrial Diaphragm Valve

Needle Valve 10000 psi Manufacturers

Best High-Pressure Gas Regulators For Industrial Use

Tags

Recommended Products

-

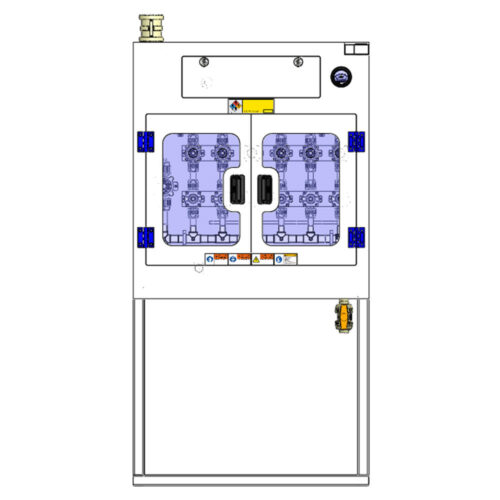

T-BOX JW-TB-C Special Gas Delivery System Gas Valve Manifold Boxes

-

768LN Stainless Steel Male Pipe Tube Butt Weld Connector And Tube Fittings Supplier

-

739 High Purity LMR Male Adapter Tube To Pipe Fittings And Adapters

-

High Purity Configurable Systems VMB Valve Manifold Box JW-200-VMB-C & JW-100-VMB-C

-

JR1000 Series UHP Ultra High Purity Single Stage Pressure Reducing Regulator And Low To Intermediate Flow

-

774L Stainless Steel UHP Fittings Butt Weld Bulkhead Union For High Flow Special Gas Fluid

-

Semi Automatic Gas Cabinet Gas Panels High Purity Gas Delivery Systems JW-200-GC

-

775L Bulkhead Reducing Union | Stainless Steel High Purity Double Ferrule Bulkhead Reducing Unions