Blog

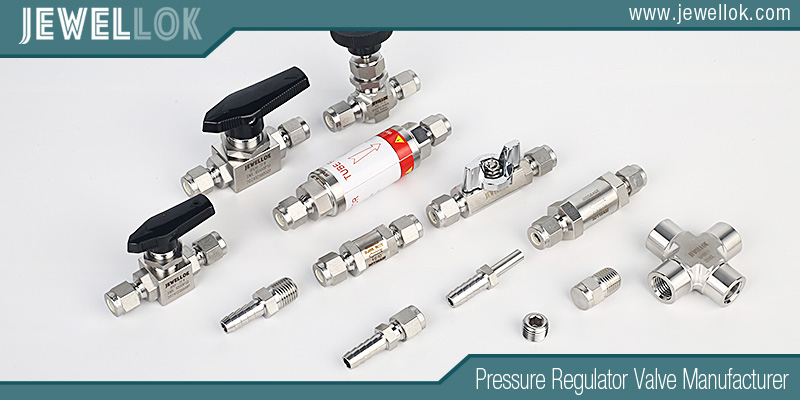

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

How to Choose the Right Check Valve for Your Industrial Application?

- Pressure Regulator Valve Manufacturer

- 1/2 gas pressure regulator, adjustable air pressure regulator, adjustable hydraulic pressure regulator, adjustable low pressure propane regulator, Adjustable Pressure Regulators, adjustable propane pressure regulator, air compressor pressure regulator, air pressure regulator electronic control, air pressure regulator valve with gauge, air pressure regulator with gauge, air pressure regulator with relief valve, compression fitting 6mm, Extra high pressure Regulators, fluid system components, high pressure regulator, High pressure regulator for very high flow, High Pressure Regulator Gas Regulator Thailand, high pressure regulator manufacturer, high pressure regulator supplier, high pressure regulator vs low pressure regulator, how a gas pressure regulator works, Medical oxygen high pressure regulator, oxygen cylinder manifold, pressure regulator, pressure relief valve vs safety valve, propane manifold with valves, safety or relief valves, safety relief valve vs safety valve, second stage propaneregulator, Single stage high pressure regulator for very high flow, Top High Pressure Regulators Products In India

- No Comments

How to Choose the Right Check Valve for Your Industrial Application?

Check valves, also known as non-return valves, are critical components in industrial systems, ensuring unidirectional flow of fluids (liquids or gases) while preventing backflow. They are essential in industries such as oil and gas, chemical processing, hydrogen energy, water treatment, pharmaceuticals, power generation, and food and beverage, where backflow can cause equipment damage, safety hazards, or process inefficiencies. Selecting the right check valve for a specific application requires careful consideration of factors like valve type, material compatibility, pressure and flow requirements, environmental conditions, installation constraints, and regulatory standards. An incorrect choice can lead to system failures, increased maintenance costs, or non-compliance with industry regulations. This article provides a step-by-step guide to choosing the right check valve for your industrial application, exploring key criteria, practical considerations, and emerging trends to optimize performance, safety, and efficiency.

Understanding Check Valves and Their Role

A check valve is a mechanical device that allows fluid to flow in one direction while automatically closing to prevent reverse flow. It operates without external actuation, relying on the pressure differential created by the fluid’s flow.

Check valves are used to:

- Protect pumps and compressors from backflow damage.

- Prevent contamination in systems handling sensitive fluids (e.g., pharmaceuticals).

- Maintain pressure in pipelines or vessels.

- Ensure safety in hazardous systems (e.g., hydrogen or chemical processing).

Common types of check valves include:

- Swing Check Valves: Use a hinged disc that swings open with forward flow and closes against backflow.

- Ball Check Valves: Employ a ball that lifts with flow and seals against a seat to prevent backflow.

- Lift Check Valves: Feature a disc or piston that lifts with flow and reseats to block reverse flow.

- Diaphragm Check Valves: Use a flexible diaphragm to allow forward flow and seal against backflow, ideal for slurries or viscous fluids.

- Dual-Plate Check Valves: Have two spring-loaded plates that open and close quickly, reducing water hammer.

- Stop-Check Valves: Combine check and isolation functions, allowing manual closure.

Choosing the right check valve involves aligning its design, materials, and performance with the application’s specific needs. Below, we outline a structured approach to guide this process.

Step 1: Define Application Requirements

The first step is to understand the application’s operational and environmental requirements, which dictate the valve’s type, materials, and specifications.

1.1 Fluid Type and Compatibility

The fluid being handled (gas, liquid, or slurry) determines the valve’s material and design:

- Corrosive Fluids: Chemicals like chlorine, ammonia, or acids require corrosion-resistant materials such as 316L stainless steel, Hastelloy, or PTFE-lined valves.

- Non-Corrosive Fluids: Water, air, or nitrogen may allow carbon steel or brass valves, which are less expensive but less resistant to corrosion.

- Viscous or Slurry Fluids: Diaphragm or ball check valves prevent clogging, unlike swing check valves, which are better for clean fluids.

- Hazardous Gases: Flammable (e.g., hydrogen) or toxic (e.g., phosphine) gases demand leak-tight valves with materials resistant to embrittlement or chemical reactions.

- Hygienic Fluids: Food-grade or pharmaceutical fluids require sanitary valves with polished surfaces (e.g., 316L stainless steel, Ra < 0.4 µm).

- Action: Create a fluid profile specifying composition, corrosiveness, viscosity, and cleanliness requirements, and ensure valve materials are compatible.

1.2 Flow and Pressure Requirements

The system’s flow and pressure characteristics influence valve selection:

- Flow Rate: Ensure the valve’s size and design accommodate the expected flow rate without excessive pressure drop. For example, swing check valves suit high-flow systems, while ball check valves are better for low-flow applications.

- Pressure Rating: Select a valve with a pressure rating exceeding the system’s maximum allowable working pressure (MAWP). For instance, a system operating at 100 bar requires a valve rated for at least 150 bar.

- Cracking Pressure: The minimum pressure required to open the valve. Low-cracking-pressure valves (e.g., 0.1 bar) are ideal for low-pressure systems, while higher values suit high-pressure applications.

- Backpressure: Ensure the valve can seal against expected backpressure without leaking.

- Action: Compile a datasheet with flow rate, operating pressure, maximum pressure, and backpressure, and match these to the valve’s specifications.

1.3 Application Context

Consider the industry and specific use case:

- Oil and Gas: Requires high-pressure, corrosion-resistant valves (e.g., 316L stainless steel swing check valves) for pipelines or refineries.

- Hydrogen Energy: Needs valves for ultra-high-pressure hydrogen (e.g., 700 bar) with materials resistant to embrittlement (e.g., austenitic stainless steel).

- Pharmaceuticals: Demands sanitary valves with clean-in-place (CIP) compatibility and polished surfaces.

- Water Treatment: Uses valves for moderate pressures and corrosion resistance against chlorinated water.

- Power Generation: Requires robust valves for steam or cooling water systems, often swing or lift check valves.

- Action: Define the industry, application (e.g., pump protection, pipeline isolation), and any regulatory or hygienic requirements.

Step 2: Select the Appropriate Valve Type

The check valve type impacts performance, maintenance, and suitability for the application.

2.1 Swing Check Valves

- Design: A hinged disc swings open with forward flow and closes against backflow.

- Advantages: Low pressure drop, suitable for high-flow systems, simple design.

- Disadvantages: Slower closing can cause water hammer, not ideal for low-flow or pulsating systems.

- Applications: Oil and gas pipelines, water treatment, power generation.

2.2 Ball Check Valves

- Design: A ball lifts with flow and seals against a seat to prevent backflow.

- Advantages: Low cracking pressure, compact, suitable for viscous fluids or slurries.

- Disadvantages: Higher pressure drop, limited to smaller sizes.

- Applications: Chemical processing, wastewater, low-flow systems.

2.3 Lift Check Valves

- Design: A disc or piston lifts with flow and reseats to block backflow.

- Advantages: Reliable sealing, suitable for high-pressure systems.

- Disadvantages: Higher pressure drop, requires vertical installation for gravity-assisted closure.

- Applications: Steam systems, high-pressure gas systems (e.g., hydrogen).

2.4 Diaphragm Check Valves

- Design: A flexible diaphragm opens with flow and seals against backflow.

- Advantages: Handles slurries, viscous fluids, or corrosive media; hygienic design.

- Disadvantages: Limited pressure range, higher cost.

- Applications: Pharmaceuticals, food and beverage, chemical processing.

2.5 Dual-Plate Check Valves

- Design: Two spring-loaded plates open and close quickly.

- Advantages: Fast closing reduces water hammer, compact, versatile.

- Disadvantages: Higher cost, spring wear over time.

- Applications: Oil and gas, water distribution, HVAC systems.

- Action: Choose the valve type based on flow rate, pressure, fluid type, and installation constraints (e.g., swing for high-flow pipelines, diaphragm for hygienic systems).

Step 3: Choose the Right Materials

Material selection ensures compatibility, durability, and compliance.

3.1 Body and Trim Materials

- 316L Stainless Steel: Ideal for corrosive fluids (e.g., acids, chlorine) and hygienic applications (e.g., pharmaceuticals).

- Carbon Steel: Cost-effective for non-corrosive fluids (e.g., oil, water) but unsuitable for aggressive media.

- Brass: Economical for low-pressure, non-corrosive gases (e.g., air, nitrogen).

- Hastelloy/Monel: For extreme corrosion (e.g., seawater, hydrofluoric acid).

- PTFE/Polymer-Lined: For highly corrosive or hygienic applications.

3.2 Seal Materials

- PTFE: Chemical resistance for acids and solvents.

- Viton: Suitable for oils and hydrocarbons.

- EPDM: Ideal for water and steam.

- Metal-to-Metal: For high-pressure or high-temperature applications (e.g., steam).

- Action: Select body and seal materials based on fluid compatibility, temperature, and pressure, prioritizing 316L stainless steel for corrosive or hygienic systems.

Step 4: Consider Environmental and Installation Factors

Environmental conditions and installation practices affect valve performance and longevity.

4.1 Environmental Conditions

- Corrosive Atmospheres: Coastal or chemical plant environments require 316 stainless steel or coated valves to resist salt or acid exposure.

- Temperature Extremes: Ensure materials withstand fluid and ambient temperatures (e.g., -40°C to 200°C for stainless steel).

- Ingress Protection: IP65 or higher for outdoor or washdown environments (e.g., food processing).

- Vibration: Spring-loaded or dual-plate valves reduce chatter in vibrating systems (e.g., near pumps).

- Action: Specify materials and designs to match environmental conditions, using spring-loaded valves for vibration-prone areas.

4.2 Installation Considerations

- Orientation: Swing and lift check valves often require specific orientations (e.g., horizontal for swing, vertical for lift) for proper operation.

- Space Constraints: Compact valves (e.g., ball or dual-plate) suit tight spaces.

- Flow Direction: Ensure correct installation to align with flow direction, marked on the valve body.

- Maintenance Access: Install valves in accessible locations for inspection and replacement.

- Action: Follow manufacturer installation guidelines, ensuring proper orientation and accessibility.

Step 5: Ensure Regulatory and Safety Compliance

Compliance with industry standards and safety requirements is critical, especially in regulated industries.

5.1 Key Standards

- ASME B16.34: Specifies valve design, materials, and testing for industrial applications.

- API 598: Defines valve inspection and testing, including check valves.

- ISO 17292: Governs metal ball valves, applicable to some check valve designs.

- FDA/3-A: Require hygienic designs for food and pharmaceutical valves.

- NFPA 56: Mandates safe materials for hydrogen systems, including embrittlement-resistant valves.

- ATEX/IECEx: Ensure valves are intrinsically safe for explosive atmospheres (e.g., oil and gas).

5.2 Safety Features

- Anti-Slam Design: Dual-plate or spring-loaded valves reduce water hammer.

- Leak-Tight Sealing: Metal-to-metal or soft seals prevent backflow leaks.

- Pressure Relief: Some designs include bypass features for over-pressure protection.

- Action: Verify compliance with relevant standards (e.g., ASME, FDA) and select valves with safety features for hazardous applications.

Step 6: Evaluate Performance and Maintenance Needs

The valve’s performance and maintenance requirements impact long-term reliability and cost.

6.1 Performance Criteria

- Pressure Drop: Minimize pressure loss with low-drop designs (e.g., swing check valves).

- Sealing Reliability: Ensure tight closure to prevent backflow, critical for hazardous fluids.

- Response Time: Fast-closing valves (e.g., dual-plate) reduce water hammer in dynamic systems.

- Action: Request performance data (e.g., pressure drop, closing speed) from suppliers and prioritize reliability for critical systems.

6.2 Maintenance and Lifespan

- Maintenance Frequency: Simple designs (e.g., swing check valves) require less maintenance than complex ones (e.g., stop-check valves).

- Ease of Repair: Choose valves with replaceable seats or seals for quick maintenance.

- Lifespan: Stainless steel valves last longer in corrosive environments, reducing replacement costs.

- Action: Establish a maintenance schedule based on application criticality and manufacturer recommendations, and maintain spare parts for repairs.

6.3 Total Cost of Ownership (TCO)

- Upfront Cost: Stainless steel valves cost more than brass but offer durability.

- Maintenance Costs: Low-maintenance designs reduce long-term expenses.

- Downtime Costs: Reliable valves minimize system disruptions.

- Action: Calculate TCO by factoring in purchase price, maintenance, and lifespan, prioritizing quality for critical systems.

Step 7: Partner with Reliable Suppliers

The supplier’s expertise, quality, and support are crucial for selecting the right valve.

7.1 Supplier Evaluation

- Reputation: Choose suppliers with a track record in your industry (e.g., Swagelok, Parker, or Flowserve).

- Certifications: Ensure valves meet ISO 9001, ASME, or industry-specific standards.

- Customization: Select suppliers offering tailored solutions (e.g., specific materials, sizes).

7.2 Support Services

- Technical Support: Access to engineers for selection and troubleshooting.

- Testing Services: Pressure and leak testing to verify performance.

- Warranty: Look for warranties covering defects or failures (e.g., 1–5 years).

- Action: Request supplier references, certifications, and service details, and negotiate terms for support and warranties.

Challenges and Solutions

- Challenge: Over-specifying valves, increasing costs.

- Solution: Match valve specifications to application needs (e.g., brass for non-corrosive fluids vs. stainless steel for corrosive ones).

- Challenge: Water hammer in high-flow systems.

- Solution: Use dual-plate or spring-loaded valves to reduce slam.

- Challenge: Regulatory compliance.

- Solution: Work with suppliers to ensure valves meet standards like ASME or FDA.

- Challenge: Installation errors.

- Solution: Train personnel and follow manufacturer guidelines for orientation and flow direction.

Emerging Trends

Innovations are enhancing check valve performance:

- Smart Valves: IoT-enabled valves with sensors monitor flow, pressure, and wear, enabling predictive maintenance.

- Sustainable Materials: Eco-friendly manufacturing and recyclable materials align with green goals.

- Compact Designs: Miniaturized valves support space-constrained systems (e.g., medical devices).

- Advanced Coatings: PTFE or ceramic coatings improve corrosion resistance and sealing.

- Impact: These trends enhance reliability, sustainability, and usability, supporting modern industrial needs.

Conclusion

Choosing the right check valve for an industrial application requires a systematic approach, considering fluid compatibility, flow and pressure requirements, valve type, materials, environmental conditions, regulatory compliance, and maintenance needs. By defining application requirements, selecting the appropriate valve type, ensuring material compatibility, and partnering with reliable suppliers, organizations can optimize valve performance, enhance safety, and reduce costs. Check valves, ranging from swing and ball to diaphragm and dual-plate designs, offer versatile solutions for industries like oil and gas, pharmaceuticals, and hydrogen energy. Emerging trends like smart valves and sustainable materials further enhance their value, supporting efficiency and innovation. By following the steps outlined in this article, stakeholders can confidently select the right check valve, ensuring reliable flow control and operational success in critical industrial systems.

For more about how to choose the right check valve for your industrial application, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Tags

Recommended Products

-

High Pressure High Temperature Pneumatic Ultrahigh Purity Stainless Steel Diaphragm Valves

-

774L Stainless Steel UHP Fittings Butt Weld Bulkhead Union For High Flow Special Gas Fluid

-

Clean Connection Cabinet JW-300-CCB Valve Manifold Box And Control Valve Box

-

Stainless Steel Ultra High Purity Mini Butt Weld Mini Tee Reducer MTRW Series Fittings

-

High Purity And Industria Gas Stick Assemblies Precise Pressure Control Gas Systems JSR-1ETG-BV Series

-

771L Male Run Tee | Stainless Steel High Quality High Purity Male Run Tee Branch Tee Pipe Fittings

-

768L Stainless Steel Male Tube Butt Weld Connector | Clean Weld Fittings And Ultra-High Purity Fittings

-

7121L Plug High Purity Plug Fitting And Blanking Plug