Blog

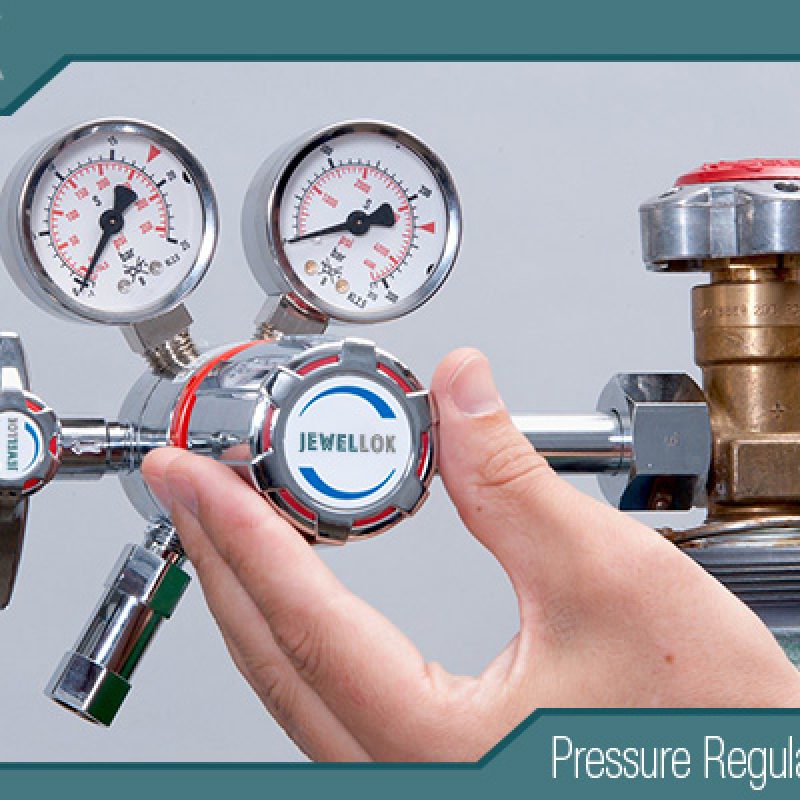

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Needle Valve 10000 psi Manufacturers

- Pressure Regulator Valve Manufacturer

- 10000 Psi Needle Valve Manufacturer, 316 SS ball valves manufacturer, back pressure regulator manufacturers, best needle valve 10000 psi manufacturers, China Customized Needle Valve Manufacturers, china high pressure air regulator valve manufacturer, china high pressure hydraulic needle valve, china high pressure needle valve manufacturer, China High Pressure Needle Valve Suppliers, China Needle Valve Factory, china needle valves high pressure, China Needle Valves Stainless steel, China Top 10 High Pressure Needle Valve, Diaphragm Valve Manufacturers, Double Block and Bleed valve manufacturers, Female Needle Valve Factory China, high flow needle valve manufacturer, high pressure 6000psi needle valve, High Pressure and High Temperature Stainless Steel Needle Valve, high pressure ball valve manufacturer, high pressure hydraulic needle valve manufacturer, high purity valves manufacturers, low pressure valve manufacturer, Needle Valve, needle valve 10000 psi, needle valve 10000 psi manufacturers, pressure control valve manufacturers, pressure gauge manufacturers, pressure reducing valve manufacturers, ss diaphragm valve manufacturers, Stainless Steel Diaphragm Valve Manufacturer

- No Comments

Needle Valve 10000 psi Manufacturers

Needle valves are critical components in industrial systems requiring precise flow control, particularly in high-pressure environments. A needle valve rated for 10,000 psi (pounds per square inch) is engineered to handle extreme pressures, making it indispensable in industries such as oil and gas, chemical processing, and hydraulics. This article explores the world of needle valve 10,000 psi manufacturers, delving into their offerings, technical specifications, applications, and the importance of quality and reliability. Spanning approximately 2,000 words, this guide aims to provide a thorough understanding of these specialized valves and the companies that produce them.

Introduction to Needle Valves and the 10,000 psi Rating

Needle valves are precision instruments designed to regulate fluid flow with exceptional accuracy. Unlike ball or gate valves, which are typically used for on/off control, needle valves feature a slender, tapered stem that allows for fine adjustments to flow rates. This makes them ideal for applications where even minor changes in flow can significantly impact system performance.

The 10,000 psi rating indicates that these valves are built to operate under extreme pressure conditions—up to 10,000 pounds per square inch. Such a capability requires robust design, high-quality materials, and meticulous manufacturing processes to ensure safety and reliability. Industries that rely on high-pressure systems, such as oil and gas exploration, chemical synthesis, and hydraulic machinery, depend on these valves to prevent leaks, maintain system integrity, and ensure operational efficiency.

In this article, we will examine the leading manufacturers of 10,000 psi needle valves, explore the technical specifications that define their performance, and highlight the applications where they excel. We will also discuss the critical role of quality assurance and provide real-world examples of their use, offering a comprehensive resource for anyone seeking to understand or procure these vital components.

Leading Manufacturers of 10,000 psi Needle Valves

The market for 10,000 psi needle valves is populated by several reputable manufacturers, each offering products tailored to meet the demands of high-pressure applications. Below, we profile some of the key players, detailing their offerings and distinguishing features.

- Trupply

Trupply is a trusted supplier of industrial valves, including needle valves rated for 10,000 psi. These valves are designed for rugged environments like oil and gas facilities, where durability is non-negotiable. Constructed from high-grade materials, Trupply’s needle valves are engineered to resist corrosion and wear, ensuring long-term performance. Their products are available for purchase online, making them accessible to a wide range of customers.

- DuraChoice

DuraChoice specializes in stainless steel (316) needle valves with a 10,000 psi rating. Featuring a packed bonnet design, these valves provide enhanced sealing to prevent leaks under extreme pressure. Available in various sizes, from 1/4″ upwards, DuraChoice’s offerings are versatile and meet stringent industry standards, making them a popular choice for applications requiring reliability and precision.

- Seal Fast, Inc.

Seal Fast, Inc. offers a diverse catalog of full-size needle valves made from 316 stainless steel, all rated for 10,000 psi. Their valves come in multiple styles, allowing customers to select designs that best suit their specific needs. Known for precision engineering, Seal Fast ensures that each valve delivers consistent performance, even in the harshest conditions.

- S-Lok

S-Lok manufactures high-pressure needle valves, including a widely used 3/8″ stainless steel model rated for 10,000 psi. These valves are designed for precision flow control, making them ideal for industries like petrochemicals and instrumentation. S-Lok’s reputation for reliability has made it a go-to choice for applications where accuracy is paramount.

- FAV Fittings

FAV Fittings produces carbon steel needle valves for 10,000 psi applications, with the advantage of rapid availability for urgent needs. This responsiveness is a boon for industries that cannot tolerate downtime. Beyond needle valves, FAV offers complementary products like gate and ball valves, all built to withstand high-pressure environments.

- Titan Fittings

Titan Fittings focuses on hydraulics, offering a 3/4″ male-to-female NPT needle valve rated for 10,000 psi. Engineered for high-performance applications, these valves are integral to hydraulic systems where precision and durability are critical. Titan’s products are designed to maintain system stability under intense pressure.

- Hy-Lok

Hy-Lok stands out for its versatility, producing needle valves from materials such as stainless steel, carbon steel, brass, and alloy 400, all rated for 10,000 psi. These valves can operate at temperatures up to 1,200°F, making them suitable for extreme conditions in industries like power generation and chemical processing. Hy-Lok’s commitment to innovation ensures its products meet diverse customer needs.

- Balon

Balon manufactures needle valves for various applications, including a metal-seated, stainless steel model with a threaded body rated for 10,000 psi. These valves are designed for ease of installation and exceptional durability, making them a reliable choice for critical systems in the oil and gas sector.

These manufacturers represent a cross-section of the industry, each bringing unique strengths to the table. Whether it’s material versatility, rapid delivery, or precision engineering, they collectively cater to the diverse requirements of high-pressure applications.

Technical Specifications of 10,000 psi Needle Valves

Understanding the technical specifications of 10,000 psi needle valves is essential for selecting the right product for a given application. These specifications dictate the valve’s performance, compatibility, and longevity.

- Pressure Rating: The defining feature of these valves is their ability to withstand pressures up to 10,000 psi. This requires robust construction, often achieved through thick-walled bodies and reinforced components.

- Material: Material choice is critical for performance. Stainless steel (316 SS) is favored for its corrosion resistance and strength, while carbon steel offers durability at a lower cost. Specialized alloys like Monel or alloy 400 are used for highly corrosive or extreme environments, as seen in Hy-Lok’s offerings.

- Connection Types: Valves are available with connection types such as NPT (National Pipe Thread), BSPP (British Standard Pipe Parallel), or others, ensuring compatibility with existing piping systems. A secure connection is vital to prevent leaks under high pressure.

- Temperature Range: Some valves, like those from Hy-Lok, can operate at temperatures up to 1,200°F, while others are designed for more moderate conditions. Temperature tolerance is a key consideration for applications with thermal fluctuations.

- Flow Control: The tapered stem design allows for precise flow adjustments, a hallmark of needle valves. This precision is crucial in applications requiring fine control, such as instrumentation or hydraulic systems.

- Sealing Mechanisms: A packed bonnet or similar sealing system ensures leak-free operation. These mechanisms must be adjustable and durable to maintain performance over time.

- Certifications: Many valves comply with standards like ISO, API, or ASME, providing assurance of safety and quality. Certifications are particularly important in regulated industries.

These specifications guide the selection process, ensuring that the chosen valve meets the operational demands of its intended use.

Applications of 10,000 psi Needle Valves

The ability to handle extreme pressures makes 10,000 psi needle valves essential across multiple industries. Here are some key applications:

- Oil and Gas: Used in wellhead control and drilling operations, these valves regulate the flow of hydrocarbons and drilling fluids, preventing blowouts and ensuring safety.

- Chemical Processing: In plants handling corrosive or hazardous fluids, needle valves provide precise control, enhancing safety and product quality during reactions.

- Hydraulic Systems: High-pressure hydraulic equipment, such as presses or heavy machinery, relies on these valves for accurate pressure and flow regulation.

- Instrumentation: Laboratories and testing facilities use needle valves to control gases and liquids in high-pressure experiments, ensuring accurate results.

- Power Generation: In steam or fluid-based power systems, these valves manage flow and pressure, contributing to efficient and safe operations.

These applications underscore the valves’ versatility and importance in maintaining precision and safety under extreme conditions.

Quality Assurance and Reliability

In high-pressure environments, the reliability of needle valves is non-negotiable. Manufacturers employ rigorous quality assurance practices to ensure their products perform flawlessly:

- Material Selection: High-strength, corrosion-resistant materials are chosen based on application needs, ensuring durability and performance.

- Precision Manufacturing: Advanced machining techniques achieve tight tolerances, ensuring smooth operation and reliable sealing.

- Testing: Valves undergo hydrostatic and leak testing, often at pressures exceeding their rated capacity, to verify integrity.

- Quality Control: From raw materials to final assembly, strict oversight minimizes defects and ensures consistency.

- Certifications: Compliance with industry standards provides third-party validation of quality and safety.

These measures reduce the risk of failure, protecting both personnel and equipment in critical applications.

Real-World Examples

To illustrate their impact, consider these scenarios:

- Offshore Drilling: A 10,000 psi needle valve controls drilling mud flow, stabilizing the wellbore and preventing catastrophic blowouts in deepwater operations.

- Chemical Plant: In a high-pressure reactor, needle valves regulate reactant flow, ensuring consistent synthesis and minimizing safety risks.

- Hydraulic Press: A manufacturing facility uses needle valves to fine-tune pressure, producing precise metal components without damage.

These examples highlight the valves’ role in enabling safe, efficient, and precise industrial processes.

Conclusion

Needle valves rated for 10,000 psi are vital for high-pressure applications, offering unmatched precision and reliability. Manufacturers like Trupply, DuraChoice, Seal Fast, S-Lok, FAV Fittings, Titan Fittings, Hy-Lok, and Balon provide a range of solutions, each tailored to specific needs. By understanding technical specifications, applications, and quality standards, users can select valves that ensure safety and performance. As industries continue to demand robust solutions for extreme conditions, these manufacturers will remain at the forefront, delivering the tools needed for success.

For more about the best needle valve 10000 psi manufacturers, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Pneumatic Actuated Ball Valve

Industrial Diaphragm Valve

Needle Valve 10000 psi Manufacturers

Best High-Pressure Gas Regulators For Industrial Use

Tags

Recommended Products

-

Ultra High Purity Gas Delivery Systems And Liquid Chemical Delivery Systems JW-300-LDS

-

Pressure Control Panels For High Purity Gas Control System JSP-3AE Series From Pressure Control Panels Suppliers And Manufacturer

-

FT-BOX JW-FTB-C Valve Manifold Panels And Boxes With High Purity Configurable Systems

-

316L Stainless Steel Tube Butt Weld Reducing Fittings Union Reducer RW Series Ultrahigh Purity Process

-

Fully Automated Gas Cabinet Gas Rack Gas Delivery Systems JW-300-GR

-

UHP Metal Gasket Face Seal Fittings Vacuum Coupling Metal Face Seal Join Long Gland And Short Gland

-

Long Gland LG Series For Ultra High Purity Gas And Chemical Delivery Systems

-

JF Series In-Line Gas Filters | High Purity High Precision High Flow Semiconductor Gas Filter Gas Filtration & Purification