Blog

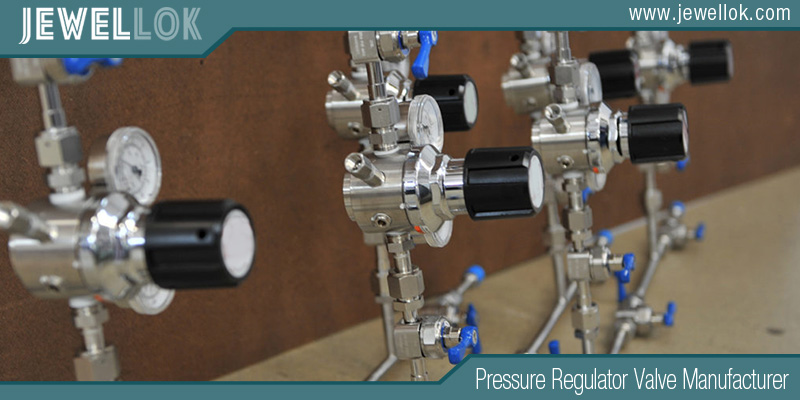

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

The Best High Flow UHP Gas Pressure Regulator Industry in Italy

- Pressure Regulator Valve Manufacturer

- 1 1 2 gas pressure regulator, 1/2 gas pressure regulator, 2 inch irrigation valve, adjustable low pressure propane regulator, air compressor non return valve, application of ultra-high purity gas pressure regulator, argon gas pressure regulator, argon gas pressure regulator manufacturer, argon gas pressure regulator supplier, argon gas pressure regulator supplier factory, argon hose connector, best high flow UHP gas pressure regulator industry, best high flow UHP gas pressure regulator industry in Italy, best high purity gas pressure regulator, China Natural Gas Pressure Regulator, China Single Stage Gas Pressure Regulator Manufacturers, China Suppliers Instrument Gas Pressure Regulator, China Wholesale Nitrogen Gas Pressure Regulator, gas pressure regulator, gas semiconductor, high flow UHP gas pressure regulator, high flow UHP gas pressure regulator industry, high purity regulators, humming propane regulator, pressure regulator valve leaking, pressure relief valve vs safety valve, propane adjustable pressure regulator, propane manifold with valves, purpose of flame arrester, relief valve safety valve difference, safety or relief valves, safety relief valve vs safety valve, safety valve vs pressure relief valve, second stage propaneregulator, timer water valve, two stage pressure regulator, UHP gas pressure regulator

- No Comments

The Best High Flow UHP Gas Pressure Regulator Industry in Italy

High flow ultra high purity (UHP) gas pressure regulators are critical devices designed to manage the pressure and flow of gases in applications where both exceptional purity and substantial gas volumes are required. These regulators ensure that gases maintain purity levels of 99.999% (grade 5.0) or higher, meaning impurities are kept to a minimum—often less than a few parts per million. At the same time, they are capable of delivering high flow rates, typically exceeding 200 standard liters per minute (std L/min), making them ideal for processes that demand rapid and large gas delivery. This combination of purity and flow capacity sets them apart from standard regulators, positioning them as essential tools in industries such as semiconductor manufacturing, pharmaceuticals, and advanced research.

In Italy, a country renowned for its engineering expertise and industrial strength, high flow UHP gas pressure regulators play a pivotal role. With a robust presence in sectors like automotive, aerospace, pharmaceuticals, and electronics, Italy has both a demand for these precision instruments and the capability to produce them. Italian manufacturers and suppliers leverage their technical know-how to serve domestic industries and compete in the global market. This article delves into the world of high flow UHP gas pressure regulators in Italy, exploring their importance across various sectors, the dynamics of the Italian market, key players, technological innovations, and the challenges and opportunities shaping this specialized industry.

Importance of High Flow UHP Gas Pressure Regulators

High flow UHP gas pressure regulators are indispensable in applications where gas purity and precise control are critical to success. Their ability to deliver large volumes of ultra-pure gas without introducing contaminants or pressure instability makes them vital across multiple industries.

Semiconductor Manufacturing

The semiconductor industry relies heavily on UHP gases like nitrogen, argon, and hydrogen for processes such as etching, chemical vapor deposition (CVD), and wafer cleaning. These processes require high flow rates to ensure uniform application across large surfaces, but even trace impurities—such as moisture, oxygen, or particulates—can cause defects in microchips, leading to significant financial losses. High flow UHP regulators maintain stable pressure and purity under demanding conditions, ensuring that production runs smoothly. For instance, in CVD, where thin films are deposited onto silicon wafers, these regulators supply precursor gases at high volumes while preventing contamination that could compromise film quality.

Pharmaceuticals and Biotechnology

In the pharmaceutical and biotechnology sectors, UHP gases are used to create controlled environments, prevent contamination, and ensure product safety. Nitrogen, for example, is often employed to displace oxygen in drug manufacturing or packaging, preserving the integrity and shelf life of sensitive compounds. High flow UHP regulators are essential here, as they deliver large quantities of gas quickly while adhering to strict purity standards mandated by regulatory bodies like the European Medicines Agency (EMA). A failure in gas purity could result in product spoilage or health risks, making these regulators a cornerstone of pharmaceutical production.

Scientific Research and Laboratories

Research laboratories conducting experiments in fields like chemistry, physics, and materials science depend on UHP gases for precision and reproducibility. In gas chromatography, for example, the purity and consistent flow of the carrier gas directly impact the accuracy of analytical results. High flow UHP regulators provide the necessary control, allowing researchers to scale experiments or work with high-throughput systems without sacrificing gas quality. This is particularly crucial in cutting-edge fields like nanotechnology or quantum computing, where even minor variations in gas composition can alter experimental outcomes.

Additional Applications

Beyond these core industries, high flow UHP regulators find use in aerospace for fuel cell testing and in the food and beverage sector for nitrogen-based packaging and preservation. In each case, their ability to combine high flow with ultra-purity ensures operational efficiency and product quality, highlighting their versatility and importance across diverse applications.

Italian Market Overview

Italy’s industrial ecosystem, marked by its strength in high-value manufacturing and innovation, creates a fertile ground for the high flow UHP gas pressure regulator market. The country’s economic landscape and regulatory framework further shape its role in this niche sector.

Market Size and Trends

While precise statistics on Italy’s high flow UHP regulator market are not widely available, the broader industrial gas and equipment market provides context. The global gas pressure regulator market is expected to grow due to rising demand for high-purity gases in advanced manufacturing, and Italy, as part of the European industrial gas sector, mirrors this trend. Italy’s industrial gas market has seen steady growth, fueled by investments in technology and infrastructure, which in turn supports the demand for sophisticated gas control equipment like UHP regulators. The country’s focus on precision industries suggests a promising outlook for this market segment.

Regulatory Framewor

kAs an EU member state, Italy adheres to stringent regulations that influence the design, production, and use of UHP gas regulators. Standards such as ISO 9001 (quality management) and ISO 14644 (cleanroom specifications) ensure that manufacturers maintain high levels of quality and cleanliness. The EU’s REACH regulation also governs the materials used in regulators, requiring them to be free of substances that could contaminate gas streams. These standards elevate the reliability of Italian-made regulators and ensure compliance with both domestic and international requirements, giving Italian companies a competitive edge.

Driving Factors

Several key drivers underpin the demand for high flow UHP regulators in Italy:

- Industrial Expansion: Italy’s automotive and aerospace industries, led by companies like Stellantis and Leonardo S.p.A., are adopting advanced manufacturing techniques that require precise gas control.

- Pharmaceutical Growth: With major players like Menarini and Chiesi Farmaceutici, Italy’s pharmaceutical sector is a significant consumer of UHP gases, necessitating reliable regulators.

- Research Excellence: Institutions like the Italian Institute of Technology (IIT) drive demand through their use of UHP gases in innovative research.

- Sustainability Goals: Efforts to improve energy efficiency and reduce emissions align with the use of high flow UHP regulators to optimize gas delivery and minimize waste.

Key Manufacturers and Suppliers in Italy

Italy hosts a mix of local manufacturers and international companies with a strong presence, all contributing to the supply of high flow UHP gas pressure regulators. Below are some notable players:

- Pietro Fiorentini

Pietro Fiorentini, an Italian leader in gas control systems, is known for its high-quality pressure regulators. While primarily focused on natural gas, the company also offers solutions for industrial gases, including UHP applications. Their regulators are celebrated for precision and durability, catering to industries needing high flow and purity. Pietro Fiorentini’s innovation focus makes it a significant contributor to Italy’s gas equipment market.

- GCE Group Italy

GCE Group, a global specialist in gas control, operates in Italy through GCE Group Italy. Their UHP regulators, such as the APTECH series, are designed for clean industries like semiconductors, featuring low outgassing and diffusion properties. GCE Group Italy provides both standard and tailored solutions, serving a wide range of Italian industries with high-purity needs.

- Swagelok Italy

Swagelok, a worldwide leader in fluid system components, has a strong foothold in Italy via Swagelok Italy. Their high-flow UHP regulators, like the HF series, support flow rates up to 300 std L/min and are built with corrosion-resistant materials and advanced pressure-sensing technology. These products are widely used in Italy’s semiconductor and pharmaceutical sectors.

- Parker Hannifin Italy

Parker Hannifin, another global giant, operates in Italy and offers UHP regulators tailored for precision and safety. Their products cater to pharmaceuticals, electronics, and other high-purity applications, known for their robustness and versatility. Parker’s Italian operations bolster the local supply chain with top-tier gas control solutions.

- Local Innovators

Beyond these major players, Italy is home to smaller, specialized firms that produce custom or niche UHP regulators. These companies leverage Italy’s engineering heritage to address specific industry needs, adding diversity and innovation to the market.

Technological Advancements

The high flow UHP regulator sector is evolving rapidly, with Italian manufacturers and suppliers embracing cutting-edge technologies to meet industry demands.

- Advanced MaterialsTo maintain gas purity, regulators are constructed from materials like 316L stainless steel, which resists corrosion and minimizes outgassing. Some companies are also using alloys like Hastelloy for corrosive gases, while techniques like electropolishing smooth surfaces to reduce contamination risks.

- Digital IntegrationThe advent of Industry 4.0 has brought digital enhancements to regulators. Sensors now monitor pressure, flow, and purity in real time, enabling predictive maintenance and process optimization. Italian firms are integrating these smart features to enhance performance and compliance.

- Compact and Modular DesignsModern regulators are becoming smaller and more modular, allowing easier integration into complex systems. For example, Swagelok’s HF series offers high flow in a compact footprint, ideal for space-limited applications.

- Improved Sealing TechnologiesAdvanced sealing, such as tied diaphragm designs, enhances leak prevention and purity maintenance. These innovations are increasingly standard in Italian-made UHP regulators, ensuring long-term reliability.

Challenges and Opportunities

The Italian market for high flow UHP regulators faces hurdles but also offers substantial growth potential.

Challenges

- Cost Barriers: The high price of UHP regulators, driven by precision engineering and premium materials, can deter smaller firms.

- Maintenance Needs: Regular calibration and upkeep are essential but resource-intensive, posing challenges for large-scale users.

- Global Competition: Italian companies compete with powerhouses from Germany, the U.S., and Japan, requiring constant innovation to stay ahead.

Opportunities

- Rising Demand: Growth in Italy’s tech-driven industries boosts the need for UHP regulators.

- Innovation Potential: Advances in materials and digital systems offer chances to lead the market with novel solutions.

- Sustainability Focus: Developing efficient regulators aligns with environmental goals, opening new avenues for growth.

- Niche Markets: Custom solutions for specialized fields like quantum computing provide untapped opportunities.

Conclusion

High flow UHP gas pressure regulators are vital to Italy’s industrial and research landscape, supporting sectors that demand purity and precision. With companies like Pietro Fiorentini, GCE Group Italy, Swagelok Italy, and Parker Hannifin Italy driving the market, Italy is a hub of expertise and innovation. Technological strides in materials, digitalization, and design are propelling the industry forward, despite challenges like cost and competition. As Italy’s high-tech industries grow and sustainability becomes a priority, the future of high flow UHP regulators looks bright, promising continued advancements and market expansion.

For more about the best high flow UHP gas pressure regulator industry in Italy, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Types of Specialty Gas Changeover Systems

Top High-Pressure Diaphragm Valve Suppliers in Mexico

Tags

Recommended Products

-

Stainless Steel High-Purity High Temperature Metal Seated Ball Valves JBV3 Series

-

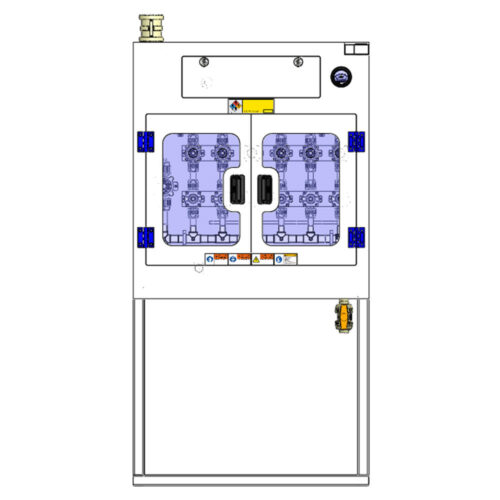

High Purity Configurable Systems VMB Valve Manifold Box JW-200-VMB-C & JW-100-VMB-C

-

765LR Reducing Tee | Stainless Steel 316 High Purity Butt Weld Fittings Metal Face Seal For Welding Pipe Fitting Reducing Tee

-

775L Bulkhead Reducing Union | Stainless Steel High Purity Double Ferrule Bulkhead Reducing Unions

-

Pressure Control Panels For High Purity Gas Control System JSP-3AE Series From Pressure Control Panels Suppliers And Manufacturer

-

JR1000 Series UHP Ultra High Purity Single Stage Pressure Reducing Regulator And Low To Intermediate Flow

-

High Purity High Flow Pressure Control Regulators & Valves Gas Stick Assemblies JSR-2TG Series

-

762L Stainless Steel High Purity Union High-Purity Gas System Fittings