Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

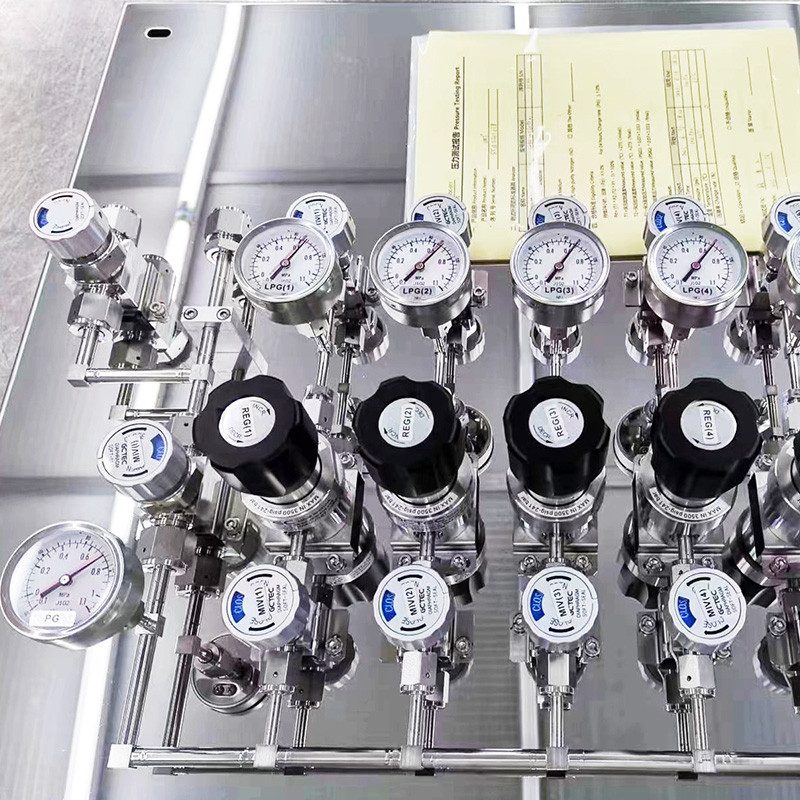

Understanding Fully Automated Manifold Design with Ultra High Purity Manifolds

- Pressure Regulator Valve Manufacturer

- Automatic LED-type Oxygen Manifold System, Automatic Manifold Systems, Automatic Medical Gas Manifold, Custom hydraulic manifold blocks, Custom Manifold Assembly, Digital Automatic Manifold Systems, fully automated manifold design, Fully Automatic Manifold High Pressure Cylinders, Fully Automatic Medical Gas Manifolds, fully-automatic touch screen hybrid manifold systems, High Purity Semi-Auto Stainless Steel Changeover Manifolds, hydraulic manifold manufacturers, Integrated Manifold Design Tool, LCD Automatic Oxygen Manifold, Manifolds for Industrial Gas Supply System, Semi-Automatic Manifold Systems, UHP Ultra High Purity Gas Regulator Panels Manifolds, UHP Valve Panel, ultra high purity manifolds, Ultra High Purity Valves Diaphragm and Bellows Manifold

- No Comments

Understanding Fully Automated Manifold Design with Ultra High Purity Manifolds

In today’s advanced industrial and laboratory environments, the precise and reliable distribution of fluids and gases is a cornerstone of operational success. At the heart of these distribution systems are manifolds—complex assemblies of pipes, valves, and components engineered to control and direct material flow. As industries like semiconductor manufacturing, pharmaceuticals, and biotechnology demand ever-higher levels of precision and purity, the evolution of manifold technology has led to the development of fully automated systems designed for ultra high purity (UHP) applications. This article explores the intricacies of fully automated manifold design, focusing on how these systems achieve ultra high purity, their real-world applications, and the challenges and benefits they bring to modern industries.

What Are Manifolds and Why Do They Matter?

A manifold, in its simplest form, is a network of interconnected pipes, valves, and fittings that manages the flow of liquids or gases from a source to multiple destinations—or vice versa. Think of it as the circulatory system of an industrial process, ensuring that materials reach their intended points efficiently and accurately. In everyday contexts, manifolds might be found in HVAC systems or automotive engines, but in high-stakes industries, their role becomes far more critical.

In sectors such as semiconductor production or pharmaceutical manufacturing, manifolds are not just about flow—they’re about maintaining absolute control over that flow while preventing contamination. A single impurity, even at the level of parts per billion (ppb), can ruin a batch of microchips or compromise a drug’s safety. This is where ultra high purity manifolds shine, and when paired with full automation, they elevate performance to meet the exacting standards of modern technology.

The Rise of Fully Automated Manifolds

Automation has transformed industries across the globe, and manifold systems are no exception. A fully automated manifold operates with minimal human intervention, relying on advanced technologies like programmable logic controllers (PLCs), sensors, and software to manage its functions. This shift from manual to automated operation brings a host of advantages that are particularly valuable in high-purity environments.

Key Features of Automation

– Precision and Consistency: Automated manifolds can execute complex sequences—such as opening and closing valves or adjusting flow rates—with pinpoint accuracy. This eliminates the variability introduced by human operators, ensuring consistent delivery of materials.

– Safety Enhancements: By reducing manual handling, automation lowers the risk of errors that could lead to leaks, contamination, or safety hazards. Real-time monitoring and automated alerts allow the system to respond instantly to issues, such as pressure drops or valve malfunctions.

– Operational Efficiency: Automation speeds up processes like gas switching or system purging, reducing downtime between production runs. This not only boosts productivity but also minimizes wear on components, extending the system’s lifespan.

In a fully automated setup, operators can monitor and control the manifold remotely, often through a user-friendly interface. Features like self-diagnostic tools or predictive maintenance alerts further enhance reliability, making these systems ideal for continuous, high-stakes operations.

Ultra High Purity: The Design Imperative

Ultra high purity manifolds are engineered to deliver fluids or gases with contaminant levels so low they’re measured in ppb or even parts per trillion (ppt). Achieving this requires a meticulous approach to every aspect of design, from the materials used to the layout of the system itself.

Material Selection

The backbone of a UHP manifold is its material. Stainless steel, particularly grade 316L, is a go-to choice due to its excellent corrosion resistance and durability. This alloy contains low carbon levels, reducing the risk of carbide precipitation that could introduce contaminants. In some cases, even stricter specifications—like low-sulfur stainless steel—are required to meet extreme purity demands.

Beyond the raw material, surface treatment is critical. Two common processes stand out:

– Electropolishing: This electrochemical technique removes a thin layer of material, creating a smooth, mirror-like finish. It reduces microscopic imperfections where particles could lodge, making the surface easier to clean and less prone to contamination.

– Passivation: This chemical process forms a protective oxide layer on the steel, enhancing its resistance to corrosion and further minimizing the risk of impurities leaching into the system.

Valves and Fittings

In UHP manifolds, every component must uphold the system’s integrity. Valves, for instance, are often diaphragm-style, prized for their leak-tight seals and minimal internal crevices where contaminants could hide. Fittings, meanwhile, rely on high-integrity connections like orbital welds, which create seamless joints that reduce leak potential and simplify cleaning.

System Layout

The physical design of a UHP manifold is as important as its components. Engineers aim to:

– Minimize Dead Legs: These are stagnant zones where fluid can pool, potentially harboring contaminants. A well-designed manifold reduces pipe lengths and eliminates unnecessary bends or branches.

– Optimize Flow Paths: Shorter, straighter paths with fewer connections lower the risk of contamination and make purging more effective.

– Enable Cleaning: Automated purge valves or integrated cleaning systems ensure the manifold can be flushed of residual materials quickly and thoroughly.

Together, these elements create a system capable of maintaining ultra high purity under demanding conditions.

Real-World Applications

Fully automated UHP manifolds are not theoretical—they’re workhorses in some of the world’s most advanced industries. Here’s how they’re applied in practice.

Semiconductor Manufacturing

The production of microchips is a marvel of precision, and ultra-pure gases like nitrogen, argon, and hydrogen play a starring role. These gases, used in processes like chemical vapor deposition or etching, must be delivered without a trace of moisture, oxygen, or particulates that could ruin the tiny circuits.

Fully automated UHP manifolds manage this task with finesse. They switch between gas sources seamlessly, purge lines to remove residuals, and monitor pressure and flow in real time. In a semiconductor fab, where downtime can cost millions, this automation ensures both purity and productivity.

Pharmaceutical Production

In pharmaceuticals, sterility is king. Whether it’s manufacturing injectable drugs or biologics, the gases and fluids used must be free of microbes and impurities. UHP manifolds deliver sterile compressed air, nitrogen, or oxygen to maintain aseptic conditions during production.

Automation takes this a step further by handling tasks like sterilization cycles or system validation without human input. This reduces contamination risks from manual intervention and keeps the process compliant with stringent regulatory standards.

Biotechnology and Research

In labs developing cutting-edge therapies or conducting sensitive experiments, UHP manifolds provide the controlled environments needed for success. Automation allows researchers to focus on their work, not on managing gas delivery, while ultra high purity ensures experimental integrity.

Challenges in Implementation

For all their benefits, fully automated UHP manifolds come with challenges that must be addressed.

– Complexity: The integration of automation and high-purity design requires sophisticated engineering. Systems may include dozens of sensors, valves, and control units, all of which must work in harmony.

– Maintenance: Maintaining ultra high purity demands a cleanroom-like approach to repairs or servicing. Components may need replacement rather than repair to avoid contamination, driving up costs.

– Training: Operators need specialized skills to manage these systems, from programming PLCs to interpreting diagnostic data. This can increase onboarding time and operational overhead.

Despite these hurdles, the payoff—improved quality, safety, and efficiency—makes the investment worthwhile for industries where failure is not an option.

Benefits That Drive Adoption

The advantages of fully automated UHP manifolds are compelling:

– Unmatched Purity: Contaminant levels in the ppb range ensure product quality in even the most sensitive applications.

– Reduced Downtime: Faster purging, automated switching, and predictive maintenance keep operations running smoothly.

– Enhanced Safety: Real-time monitoring and reduced human involvement lower the risk of accidents or errors.

– Scalability: Automated systems can adapt to growing production demands, making them future-proof investments.

These benefits translate directly to the bottom line, whether through higher yields in semiconductor plants or safer drugs in pharmaceutical facilities.

The Future of UHP Manifold Design

As technology advances, so will fully automated UHP manifolds. Emerging trends include:

– Artificial Intelligence: AI could predict maintenance needs or optimize flow patterns, pushing efficiency even further.

– Advanced Sensors: Next-generation sensors might monitor purity in real time, providing instant feedback on system performance.

– Modular Designs: Flexible, scalable manifolds could allow industries to adapt quickly to new processes or requirements.

These innovations promise to keep UHP manifolds at the cutting edge of industrial technology.

Conclusion

Fully automated ultra high purity manifolds represent a fusion of precision engineering and advanced automation, tailored to meet the demands of industries where purity and reliability are paramount. From the careful selection of materials like electropolished stainless steel to the seamless integration of PLCs and sensors, these systems are designed to deliver exceptional performance in the most challenging environments.

In semiconductor fabs, pharmaceutical plants, and beyond, they ensure that gases and fluids flow with unparalleled cleanliness and efficiency. While their complexity poses challenges, the benefits—improved product quality, reduced downtime, and enhanced safety—make them indispensable tools for modern industry. As technology continues to evolve, fully automated UHP manifolds will remain at the forefront, driving innovation and upholding the highest standards of excellence.

For more about fully automated manifold design with ultra high purity manifolds, you can pay a visit to Jewellok at https://www.jewellok.com/product-category/gas-changeover-manifold/ for more info.

Recent Posts

Types of Specialty Gas Changeover Systems

Top High-Pressure Diaphragm Valve Suppliers in Mexico

Tags

Recommended Products

-

Line And Panel Mounting Adjustable Low Pressure Propane And Nitrogen Pressure Regulator JSR-3L & JSR-3LP Series

-

High Pressure High Flow Specialty Gas Control Panel With Diaphragm Valve , 3000Psig Oxygen Control Medical Changeover Manifold Panel

-

739 High Purity LMR Male Adapter Tube To Pipe Fittings And Adapters

-

VMB Valve Manifold Panels And Boxes High Purity Configurable Systems JW-200-VMB & JW-100-VMB

-

Stainless Steel Low Pressure Seal Pneumatic Diaphragm Control Valve For For HP & UHP Gases

-

765LR Reducing Tee | Stainless Steel 316 High Purity Butt Weld Fittings Metal Face Seal For Welding Pipe Fitting Reducing Tee

-

Ultra High Purity Oxygen Pressure Gauge For Semiconductor Gases JG Series Pressure Instruments For Semiconductor Manufacturing

-

Ultra High Purity Stainless Steel Compressed Gas Changeover Manifold Panel System For Integrated Gas Supply System