Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

What Do Top Reliability Engineers Know About Gas Changeover Manifold Maintenance That You Don’t?

- Pressure Regulator Valve Manufacturer

- Application-Based Keywords, argon gas changeover manifold, argon gas changeover manifold supplier, argon gas changeover manifold supplier philippines, Auto Gas Changeover Manifold System, Automatic gas changeover manifold, Automatic gas switchover system, best gas changeover manifold, best gas changeover manifold philippines, best gas changeover manifold supplier, best gas changeover manifold supplier philippines, BURSAN Gas Changeover Manifold, CO2 gas changeover manifold, Dual-stage gas regulator manifold, gas changeover manifold, Gas changeover manifold design, Gas changeover manifold for cleanroom, gas changeover manifold for hospital, Gas changeover manifold for manufacturing, Gas changeover manifold for welding, gas changeover manifold India, Gas Changeover Manifold Maintenance, gas changeover manifold philippines, gas changeover manifold supplier in the philippines, Gas changeover manifold system, Gas changeover manifold troubleshooting, gas changeover manifold Turkey, Gas changeover system for food and beverage, Gas changeover system for fuel ce, Gas cylinder changeover system, Gas distribution manifold, Gas manifold backflow prevention, Gas manifold for aquaculture oxygen supply, Gas manifold for chemical processing, Gas manifold for gas chromatography, Gas manifold for high-pressure cylinders, Gas manifold for medical oxygen supply, Gas manifold for pharmaceutical industry, Gas manifold pressure control, Gas manifold pressure sensors, Gas manifold safety valves, gas manifold system, gas regulator manifold, Gas supply manifold, High-pressure gas manifold, Industrial gas changeover system, Industrial gas manifold, IoT gas changeover manifold, Medical gas manifold, Technical and Feature-Based Keywords

- No Comments

What Do Top Reliability Engineers Know About Gas Changeover Manifold Maintenance That You Don’t?

In the high-stakes world of industrial operations, where downtime can cost thousands of dollars per hour and safety is non-negotiable, gas changeover manifolds serve as the unsung heroes of continuous gas supply. These systems—whether automatic, semi-automatic, or manual—seamlessly switch between gas cylinders or banks to prevent interruptions in processes ranging from semiconductor manufacturing to hospital oxygen delivery. But what separates a well-functioning manifold from a catastrophic failure? It’s not just routine checks; it’s the nuanced, often overlooked maintenance strategies employed by top reliability engineers. Reliability engineers, those guardians of system uptime in fields like oil and gas, pharmaceuticals, and renewable energy, approach manifold maintenance with a blend of data-driven precision and proactive foresight. They know that a manifold isn’t just plumbing—it’s a dynamic system susceptible to pressure fluctuations, contamination, and wear that can lead to leaks, freezes, or complete shutdowns. According to industry experts, improper maintenance accounts for up to 70% of gas system failures, leading to safety hazards and financial losses. Yet, many operators stick to basic inspections, missing the advanced techniques that ensure 99.9% reliability.

What do these elite engineers know that you don’t? It’s a combination of predictive analytics, tailored schedules, and cutting-edge tools that go beyond the manual. For instance, they integrate remote monitoring to catch issues before they escalate, use ultra-high purity protocols to combat contamination, and apply reliability-centered maintenance (RCM) principles to optimize interventions. This article uncovers these secrets, drawing from best practices in reliability engineering as of 2025. We’ll explore common pitfalls, advanced techniques, and real-world applications, empowering you to elevate your maintenance game. By the end, you’ll understand why top engineers treat manifolds not as equipment, but as critical assets demanding strategic care. In an era of smart factories and IoT integration, ignoring these insights could mean the difference between seamless operations and emergency shutdowns. Let’s dive into the knowledge that keeps the gas flowing—and the risks at bay.

The Hidden Foundations: Beyond Basic Manifold Mechanics

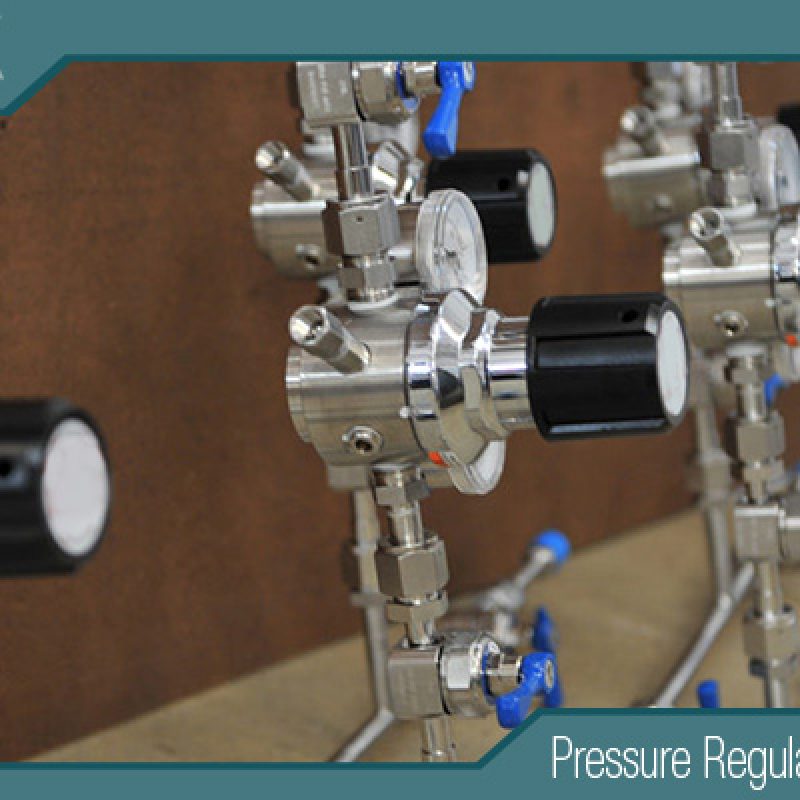

Top reliability engineers start with a deep understanding of manifold anatomy, but they don’t stop at the obvious. A typical gas changeover manifold includes regulators, valves, sensors, pigtails (flexible hoses), and sometimes electronic controllers for automatic switching. While entry-level maintainers might focus on visible wear, experts dissect the system into failure modes: mechanical (e.g., valve seizures), environmental (e.g., corrosion from moisture), and operational (e.g., pressure creep). One key insight is the role of material compatibility. Engineers know that using brass for corrosive gases like ammonia can lead to rapid degradation, opting instead for stainless steel or specialized alloys. They also emphasize the importance of staggered regulator set points in automatic systems, which allow seamless transitions without pressure drops— a technique that prevents turbulence from upstream fittings like elbows or meters. But here’s where they excel: integrating reliability engineering principles like Failure Mode and Effects Analysis (FMEA). Before installation, they map potential failures, assigning risk priority numbers to prioritize maintenance. For example, in high-flow environments, they anticipate freezing from Joule-Thomson cooling and incorporate heated regulators or heat jackets. This proactive mapping isn’t standard; it’s a tool borrowed from aerospace that top engineers adapt to gas systems.

Moreover, they tailor maintenance to the gas type. For specialty gases in semiconductor fabs, purity is paramount, so they implement two-stage regulation and regular inert gas purges at shutdown to flush contaminants. In contrast, for LPG in industrial welding, the focus shifts to excess-flow valves to prevent surges. Engineers also advocate for modular designs with minimal threaded connections, reducing leak points by up to 50%. Daily inspections? Sure, but experts elevate them with calibrated gauges for precise pressure consistency checks, spotting anomalies like weak flames or yellowing (indicating incomplete combustion) early. They know that ignoring these “hidden foundations” leads to creep—the internal leak where gas seeps past the seat, causing over-pressurization. By mastering these basics with an advanced lens, they achieve longevity that others only dream of.

Common Pitfalls: The Traps That Catch the Unwary

Even seasoned operators fall into traps that top reliability engineers sidestep with ease. One prevalent issue is neglecting environmental factors. In cold climates or high-moisture settings, regulators can freeze during high-flow operations, leading to failure. Engineers counter this by monitoring ambient conditions and using insulated enclosures or anti-freeze additives where applicable. Another common failure: the “creep” phenomenon, where internal seats wear, allowing gas to leak internally and build pressure. This manifests as hissing, popping, or uneven flames—signs often dismissed as minor until they cause shutdowns. Top pros conduct bi-monthly leak tests with soapy water or electronic detectors, catching creeps before they escalate.

Valve mishandling is a killer. Opening cylinder valves too quickly can trip excess-flow valves, disrupting supply. Engineers train teams on slow, controlled openings and incorporate automatic reset features in modern manifolds. Incompatibility woes—using regulators for wrong gases or pressures—lead to catastrophic bursts. They mitigate by strict labeling and compatibility charts. Contamination ranks high too. Dust, moisture, or particulates in lines cause blockages or corrosion. Experts purge systems with inert gas post-maintenance and install inline filters. Power dependency in electric auto-changeovers? Outages cause failures, so they favor hybrid or non-electric backups for critical apps. Overdue inspections per G 607 standards for mobile systems like motorhomes highlight regulatory pitfalls. Engineers use digital logs for compliance, avoiding fines. Low pressure from depleted tanks or leaks? They install smart sensors for real-time alerts. By anticipating these pitfalls, they turn potential disasters into routine fixes, saving time and resources.

Advanced Techniques: Tools of the Trade in 2025

Here’s where top reliability engineers shine: deploying 2025’s cutting-edge techniques for manifold maintenance. Remote monitoring via IoT is a game-changer. Systems like Jewellok’s manifolds feature apps that track pressure, usage, and anomalies in real-time, sending alerts for predictive interventions. This allows engineers to forecast failures, reducing unplanned downtime by 40%. Sensor technology has evolved. Advanced manifolds use high-precision transducers for pressure and flow, integrated with AI algorithms to detect subtle deviations—like early creep or contamination. In solar module manufacturing, automatic changeovers ensure purity with minimal human input, optimizing gas usage. Ultra-high purity protocols involve electropolished surfaces and orbital welding to minimize contamination risks. Engineers apply these in specialty gas setups, conducting helium leak tests at 10^-9 atm-cc/s sensitivity—far beyond standard soap tests.

SMART fully automatic systems provide data analytics for maintenance optimization. Using proprietary software, engineers analyze trends to adjust schedules, extending component life. For pipelines, reliability-based models optimize inspections for corrosion and stress. Heated regulators prevent freezing, while modular panels facilitate quick swaps. In medical gases, seamless auto-switchovers with compact designs ensure uptime. Engineers also use RCM to classify assets, focusing efforts on high-impact areas. Tailored plans consider process environments—harsh for oil/gas, precise for fabs. They perform functional tests under flow conditions, not static. These techniques aren’t luxuries; they’re essentials for 2025’s demanding operations.

Predictive Strategies and Case Studies

Predictive maintenance is the crown jewel. Using vibration analysis and thermography, engineers spot wear in valves before failure. In one case, a brewery implemented IoT monitoring, catching a creeping regulator and averting a $50,000 downtime. Another: In semiconductor plants, AI-driven manifolds reduced gas waste by 20% through optimized switchovers. These stories illustrate how predictive tools turn knowledge into action.

Conclusion

Top reliability engineers know that manifold maintenance is about foresight, not reaction. By mastering pitfalls, advanced tech, and predictive strategies, they ensure safety and efficiency. Adopt these insights—your operations will thank you.

For more about what do top reliability engineers know about gas changeover manifold maintenance that you don’t?, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Tags

Recommended Products

-

Stainless Steel Low Pressure Seal Pneumatic Diaphragm Control Valve For For HP & UHP Gases

-

High Purity High Pressure Specialty Gas Pressure Regulators Specialty Gases Pipeline Engineering Equipments Manufacturer And Supplier

-

Semi Automatic And Automatic Switching Speicialty Gas Changeover Manifold Panel With Semiconductor Valve Manifold Box Gas Pressure Regulators

-

Semi Automatic Gas Changeover Manifold System Manual Changeover Manifold Panel Single Stage Automatic Switchover Board

-

Semi Automatic Gas Cabinet Gas Panels High Purity Gas Delivery Systems JW-200-GC

-

Stainless Steel Ultra Clean Welding Joint Fittings TW Series TRW Series & CW Series

-

771LF Female Run Tee | Stainless Steel Tube Fitting Compression Fittings 1/4 In 3-Way Tee Female Run Tee

-

Stainless Steel Fully Automatic Gas Switchover Manifold System Automatic Gas Cylinder Switchover Co2 Cylinder Auto Changeover Controller