Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

316L VIM-VAR UHP High Pressure Diaphragm Sealed Valve: Advancements in Ultrahigh-Purity Fluid Control

- Pressure Regulator Valve Manufacturer

- 316l stainless steel diaphragm valve, 316L stainless steel VIM-VAR process, 316l vim var stainless steel gas pressure reducing regulator, 316L VIM-VAR UHP High Pressure Diaphragm Sealed Valve, ASME BPE compliant valve, Diaphragm seal maintenance tips, Diaphragm sealed valve semiconductor, Electropolished 316L valve, Helium leak tested diaphragm valve, High cycle pressure valve durability, High pressure fluid control valve, High pressure sealed valve applications, Low particle generation UHP valve, low pressure gas regulator 316l stainless, Modular diaphragm valve design, Outgassing reduction in UHP valves, pneumatic actuated diaphragm valve, uhp 316l stainless steel bellows valves, uhp 316l stainless steel diaphragm valves, uhp 316l stainless steel gas pressure regulators, UHP gas delivery system valve, UHP valve pharmaceutical manufacturing, Ultrahigh-purity diaphragm valve, Vacuum Induction Melting VAR steel, VCR fitting high pressure valve

- No Comments

316L VIM-VAR UHP High Pressure Diaphragm Sealed Valve: Advancements in Ultrahigh-Purity Fluid Control

In the realm of ultrahigh-purity (UHP) fluid systems, the demand for reliable, contamination-free components has never been higher. Industries such as semiconductor manufacturing, pharmaceuticals, and biotechnology require valves that can handle extreme pressures while maintaining the utmost purity levels. The 316L VIM-VAR UHP high pressure diaphragm sealed valve stands out as a pinnacle of engineering in this field. This valve, constructed from specially processed 316L stainless steel using Vacuum Induction Melting followed by Vacuum Arc Remelting (VIM-VAR), offers exceptional performance in high-pressure environments. Its diaphragm-sealed design ensures zero leakage and minimal particle generation, making it indispensable for critical applications where even trace contaminants can compromise product quality or process integrity.

The core material of the 316L VIM-VAR UHP high pressure diaphragm sealed valve is 316L stainless steel, enhanced through the VIM-VAR process. Vacuum Induction Melting involves melting the alloy in a vacuum to remove impurities and gases, resulting in a highly homogeneous material. This is followed by Vacuum Arc Remelting, where the ingot is remelted using an electric arc in a vacuum, further refining the microstructure and eliminating inclusions. The outcome is a steel with superior cleanliness, corrosion resistance, and mechanical properties compared to standard 316L. In UHP systems, where purity levels must exceed 99.9999%, this material prevents outgassing and surface reactions that could introduce contaminants like oxygen, moisture, or particulates into the fluid stream.

The diaphragm-sealed mechanism is a key feature that differentiates this valve from traditional designs. Unlike stem-sealed valves, which rely on packing materials that can wear and generate particles, the diaphragm acts as a flexible barrier between the process fluid and the actuator. Typically made from multilayered Elgiloy or Hastelloy, the diaphragm provides a hermetic seal, ensuring no fluid escapes or external contaminants enter. This design is particularly advantageous in high-pressure scenarios, where the valve can withstand pressures up to 3500 psig (241 bar) while maintaining a low internal volume to minimize dead space. The high-pressure variant of the 316L VIM-VAR UHP high pressure diaphragm sealed valve is engineered for demanding conditions, with reinforced body construction and precise machining to handle cyclic stresses without fatigue.

Available in various configurations, such as 1/4-inch or 6 mm tube fittings, VCR face seal fittings, or butt weld ends, the valve offers versatility in integration. For instance, the VCR fitting provides a metal-to-metal seal that is helium leak-tested to rates below 4 x 10^-9 std cm³/s, ensuring reliability in vacuum or pressurized systems. The valve’s body is electropolished to a surface finish of 10 Ra or better, reducing adhesion sites for contaminants and facilitating easy cleaning. Actuation options include manual handles for precise control or pneumatic actuators for automated processes, with normally closed or normally open configurations to suit safety requirements.

In semiconductor fabrication, where gases like silane or ammonia are handled at high pressures, the 316L VIM-VAR UHP high pressure diaphragm sealed valve plays a crucial role in gas delivery systems. It prevents back-diffusion of impurities that could lead to defects in wafer production. Similarly, in pharmaceutical manufacturing, it ensures sterile fluid transfer in bioreactors and filling lines, complying with standards like ASME BPE. The valve’s low actuation torque and bubble-tight shutoff enhance operational efficiency, reducing downtime and maintenance costs.

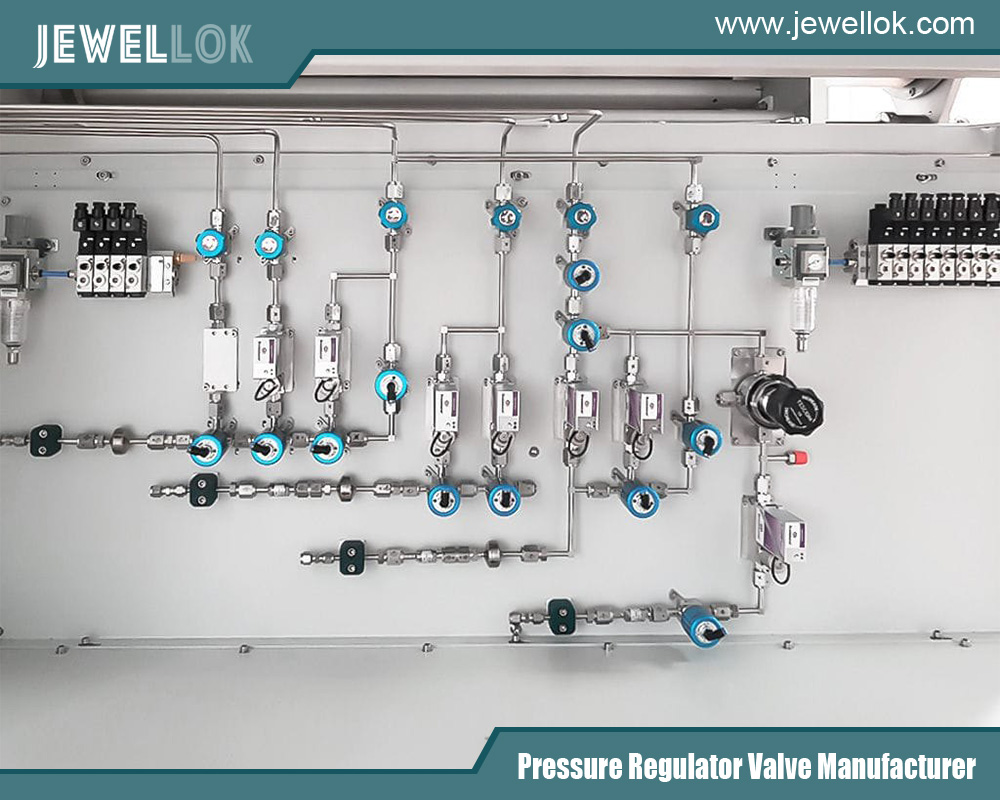

Technical specifications of the 316L VIM-VAR UHP high pressure diaphragm sealed valve highlight its robustness. The operating temperature range spans from -10°F to 150°F (-23°C to 65°C), with extensions possible using specialized diaphragms. Flow coefficients (Cv) vary from 0.10 to 0.27 depending on port size, allowing for controlled flow rates in precision applications. The valve undergoes rigorous testing, including pressure cycling up to 100,000 cycles and helium leak detection, to certify its durability. Its compact design, often with a height under 3 inches, facilitates installation in space-constrained environments like gas cabinets or manifold boxes.

One of the primary advantages of this valve is its contribution to system purity. In UHP environments, particle counts must be kept below 0.1 particles per cubic foot for sizes over 0.5 microns. The diaphragm seal eliminates dynamic seals that could shed particles, while the VIM-VAR material minimizes metallic ion leaching. Comparative studies show that valves using standard 316L may exhibit higher outgassing rates, leading to increased moisture levels in purge cycles. In contrast, the 316L VIM-VAR variant demonstrates up to 50% lower outgassing, as measured by residual gas analysis.

Installation and maintenance of the 316L VIM-VAR UHP high pressure diaphragm sealed valve require adherence to best practices to preserve its integrity. During installation, tools should be clean and free of lubricants to avoid contamination. Torque specifications for fittings must be followed precisely to prevent over-tightening, which could damage the seal. For maintenance, the valve’s modular design allows for diaphragm replacement without removing the body from the line, minimizing system exposure. Regular inspections for actuator wear and leak testing are recommended, especially in high-cycle applications.

The evolution of the 316L VIM-VAR UHP high pressure diaphragm sealed valve reflects broader trends in materials science and fluid dynamics. Advances in melting technologies have enabled the production of steels with inclusion contents below 1 ppm, pushing the boundaries of purity. Future developments may incorporate smart sensors for real-time monitoring of seal integrity or advanced coatings to extend temperature ranges. As industries pursue smaller feature sizes in semiconductors or more complex biologics in pharma, the need for such valves will only intensify.

In conclusion, the 316L VIM-VAR UHP high pressure diaphragm sealed valve represents a fusion of advanced metallurgy and innovative design, tailored for the rigors of ultrahigh-purity high-pressure systems. Its ability to maintain purity, withstand pressure, and integrate seamlessly makes it a cornerstone in modern industrial processes. By choosing this valve, engineers ensure not only compliance with stringent standards but also enhanced reliability and efficiency in their operations.

For more about 316l vim-var uhp high pressure diaphragm sealed valve: advancements in ultrahigh-purity fluid control, you can pay a visit to Jewellok at https://www.specialtygasregulator.com/product-category/ultra-high-purity-diaphragm-valves/ for more info.

Recent Posts

The Inner Workings of a 316L VIM-VAR Stainless Steel Pressure Regulator

How Ultra-High Purity Stainless Steel Tubing Powers Critical Industries

How Does a UHP 316L Stainless Steel Bellows Valve Work?

How Does a 316 Stainless Steel Pipe Fitting Work?

A Comprehensive Guide to 316L VIM VAR UHP Gas Regulator

Tags

Recommended Products

-

FT-BOX JW-FTB-C Valve Manifold Panels And Boxes With High Purity Configurable Systems

-

High Purity High Pressure Stainless Steel Needle Valve Natural Gas Flow Control Valve JNV Series

-

Stainless Steel High-Purity High Temperature Metal Seated Ball Valves JBV3 Series

-

316L Stainless Steel Tube Butt Weld Reducing Fittings Union Reducer RW Series Ultrahigh Purity Process

-

Ultra High Purity Oxygen Pressure Gauge For Semiconductor Gases JG Series Pressure Instruments For Semiconductor Manufacturing

-

Clean Connection Cabinet JW-300-CCB Valve Manifold Box And Control Valve Box

-

Bulk Specialty Gas Systems (BSGS) Gas Cabinets And Scrubber Tail Gas Treatment Cabinets For High Purity Bulk Specialty Gas Delivery

-

VMB Valve Manifold Panels And Boxes High Purity Configurable Systems JW-200-VMB & JW-100-VMB