Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

How Does A GC Semi-Automatic Special Gas Cabinet Work?

- Pressure Regulator Valve Manufacturer

- Argon Gas Cylinder Storage Cabinet, China Chemical gas cylinder safety cabinet Manufacturers, China Lab Storage Cabinet Manufacturers, China Safety Storage Cabinet, China Special Gas Cabinet Manufacturer, China Special Gas Cabinet Supplier, gas cabinets semiconductor, gas cylinder cabinet manufacturer, gas cylinder cabinet manufacturer in china, Gas Cylinder Cabinet Price, Gas Cylinder Cabinet Wholesale Factory, Gas cylinder cabinets for indoor storage, Gas Cylinder Storage Cabinets, Gas Delivery Cabinet Systems, Gas Delivery Systems Gas Cabinets, Laboratory Gas Cylinder Storage Cabinet, Semi Automatic Gas Cabinet, semi-automatic special gas cabinet, Semiconductor Gas Storage and Delivery, vertical gas cylinder cabinet

- No Comments

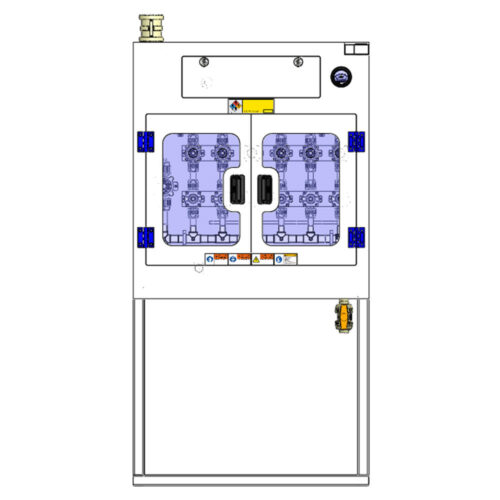

How Does A GC Semi-Automatic Special Gas Cabinet Work?

Gas chromatography (GC) is a cornerstone technique in analytical chemistry, used to separate and analyze volatile compounds with precision. Central to its operation is the need for a reliable supply of high-purity gases—such as helium, nitrogen, or hydrogen—which serve as carrier gases or fuel for detectors. Managing these gases, particularly when they are hazardous or require exact pressure control, demands specialized equipment. Enter the GC semi-automatic special gas cabinet: a sophisticated system designed to store, regulate, and deliver these gases safely and efficiently to GC instruments. This article explores how such a cabinet functions, delving into its components, operational mechanisms, safety features, applications, and maintenance requirements, providing a comprehensive understanding of its role in laboratory settings.

Introduction

In analytical laboratories, the precision of gas chromatography relies heavily on the consistent delivery of special gases. These gases, often stored under high pressure in cylinders, can be flammable, toxic, or simply require meticulous handling to maintain their purity. The GC semi-automatic special gas cabinet addresses these challenges by offering a controlled environment for gas storage and distribution. The term “semi-automatic” highlights its hybrid design: it automates key processes like pressure regulation and cylinder switchover while requiring manual intervention for tasks such as cylinder replacement. This balance enhances both safety and usability, making the cabinet an indispensable tool for GC operations.

The cabinet’s primary functions are to ensure a steady gas supply to the GC system and to protect laboratory personnel from potential hazards. Whether it’s delivering helium as a carrier gas or hydrogen for a flame ionization detector, the cabinet must perform reliably under varying conditions. In this article, we’ll break down its workings step-by-step, starting with its components, followed by its operational workflow, safety mechanisms, practical applications, and upkeep. By the end, you’ll have a clear picture of how this equipment supports critical analytical tasks.

Components of the Gas Cabinet

To understand how a GC semi-automatic special gas cabinet operates, we first need to examine its key components. Each part is engineered to contribute to the system’s overall functionality, ensuring safe and efficient gas delivery.

1. Gas Cylinders

The gas cylinders are the core of the system, housing the special gases required for GC. Typically made of high-strength steel or aluminum, these cylinders store gases at pressures up to 2000 psi or more. The cabinet is designed to accommodate multiple cylinders—often a primary and a secondary—to guarantee a continuous supply. Each cylinder is fitted with a valve that controls gas release, which the user manually operates during setup.

2. Pressure Regulators

High-pressure gas from the cylinders must be reduced to a usable level for the GC instrument, typically 50-100 psi. Pressure regulators perform this task with precision, maintaining a stable output pressure regardless of the cylinder’s internal pressure. These devices are critical for ensuring consistent gas flow, which directly impacts the accuracy of GC analyses.

3. Valves

Several types of valves are integrated into the cabinet to manage gas flow:

Shut-off Valves: Allow isolation of individual cylinders or sections of the system for maintenance or safety.

Check Valves: Prevent backflow, ensuring gas moves only toward the GC instrument.

Purge Valves: Enable the system to be flushed with an inert gas (e.g., nitrogen) to remove contaminants or residual gases.

4. Manifold System

The manifold is a piping network that connects the cylinders to the delivery line. It often includes a switchover mechanism, a hallmark of the semi-automatic design, which shifts the gas source from the primary to the secondary cylinder when the primary runs low. This ensures uninterrupted operation without user intervention at the moment of depletion.

5. Control Panel

The control panel is the user’s interface with the cabinet. It typically includes:

Pressure Gauges: Show the pressure in each cylinder and the output line.

Selector Switches: Let the user choose the active cylinder or gas type (if multiple gases are present).

Alarm Indicators: Signal events like low pressure or switchovers.

Control Knobs/Buttons: Allow adjustment of output pressure or initiation of purge cycles.

6. Sensors and Alarms

Sensors monitor critical parameters such as pressure, flow, and gas leaks. If an anomaly is detected—say, a drop in pressure or a gas escape—an alarm (visual or audible) alerts the user. In some cases, these sensors trigger automated responses, enhancing safety.

7. Ventilation System

A built-in ventilation system removes any leaked gas from the cabinet, preventing hazardous buildup. This is especially vital for flammable or toxic gases, with exhaust typically routed to the laboratory’s external ventilation.

8. Enclosure

The cabinet’s enclosure is constructed from durable, often fire-resistant materials to contain potential hazards. It features lockable doors to restrict access to trained personnel, adding an extra layer of security.

These components collectively enable the cabinet to store and deliver gases safely, with the semi-automatic features emerging from their interplay.

Operation of the Semi-Automatic Gas Cabinet

The operation of a GC semi-automatic special gas cabinet blends automation with manual oversight, creating a workflow that’s both efficient and user-controlled. Here’s how it works, step by step.

1. Initial Setup

Cylinder Installation: The process starts with the user placing gas cylinders into the cabinet’s holders, securing them, and connecting them to the manifold with proper fittings.

Valve Opening: The user manually opens each cylinder’s valve, releasing gas into the system. This step requires care to avoid pressure surges.

2. Gas Selection and Pressure Setting

Control Panel Use: Via the control panel, the user selects the desired gas (e.g., helium) and sets the output pressure needed for the GC instrument.

Automatic Regulation: The regulators take over, automatically adjusting the gas pressure to the specified level and maintaining it consistently.

3. Automatic Switchover

Pressure Monitoring: Sensors track the primary cylinder’s pressure. When it falls below a threshold (indicating it’s nearly empty), the switchover mechanism activates.

Switchover Execution: The manifold closes the primary cylinder’s valve and opens the secondary’s, seamlessly transitioning the gas source.

User Alert: The control panel signals the switchover with lights or sounds, notifying the user to replace the empty cylinder.

4. Manual Cylinder Replacement

Removal: The user closes the empty cylinder’s valve, disconnects it, and removes it from the cabinet.

Replacement: A new cylinder is installed, connected, and its valve opened.

System Reset: The user resets the system via the control panel, ensuring the new cylinder is recognized.

5. Continuous Monitoring and Safety

Leak Detection: Sensors watch for leaks, triggering alarms or shut-offs if needed.

Pressure Stability: Regulators adjust dynamically to maintain output pressure.

Emergency Protocols: In severe cases (e.g., a major leak), the system can shut down entirely, isolating the gas supply.

This workflow showcases the semi-automatic design: automation handles routine tasks like switchovers and regulation, while manual steps like cylinder changes keep the user engaged in critical operations.

Safety Features

Handling high-pressure or hazardous gases demands robust safety measures. The GC semi-automatic special gas cabinet incorporates several features to mitigate risks.

1. Leak Detection and Alarms

Sensors: Gas detectors inside the cabinet identify leaks quickly, even at low concentrations.

Alerts: Alarms notify users of issues, sometimes prompting automatic shut-offs.

2. Automatic Shut-Off

Pressure Triggers: Abnormal pressure readings can close valves to stop gas flow.

Emergency Button: A manual stop button allows instant shutdown.

3. Ventilation System

Air Circulation: Continuously removes leaked gases.

Exhaust Link: Connects to lab ventilation for safe gas disposal.

4. Fire Suppression

Materials: Fire-resistant enclosure contains potential fires.

Systems: Some models include extinguishers for flammable gases.

5. Secure Enclosure

Locks: Restrict access to authorized users.

Durability: Withstands impacts to prevent leaks.

6. Purge System

Inert Gas Flush: Clears residual gases during cylinder changes, preventing contamination or reactions.

These features ensure the cabinet operates safely, protecting both equipment and personnel.

Applications

The GC semi-automatic special gas cabinet is tailored for gas chromatography but has broader relevance:

Carrier Gases: Supplies helium or nitrogen for sample transport in GC columns.

Detector Gases: Provides hydrogen or air for detectors like FID.

Specialty Gases: Manages calibration or reactive gases for specific analyses.

While focused on GC, similar cabinets may support other techniques requiring precise gas control, such as mass spectrometry.

Maintenance

Regular maintenance keeps the cabinet functioning optimally:

Component Checks: Inspect cylinders, regulators, and valves for wear or leaks.

Sensor Calibration: Ensure pressure and leak sensors remain accurate.

Safety Tests: Verify alarms and shut-offs work correctly.

Ventilation Care: Replace filters and check fans.

Records: Log all maintenance for compliance and troubleshooting.

A consistent maintenance routine ensures reliability and safety.

Conclusion

The GC semi-automatic special gas cabinet is a vital tool in analytical labs, merging automation with manual control to deliver special gases safely and efficiently. Its components work together to store, regulate, and switch gas sources, while safety features protect against hazards. By understanding its operation and upkeep, lab personnel can leverage this equipment to support precise GC analyses, ensuring both scientific accuracy and workplace safety.

For more about how does a GC semi-automatic special gas cabinet work, you can pay a visit to Jewellok at https://www.jewellok.com/product-category/gas-cabinet/ for more info.

Recent Posts

Five Key Considerations When Choosing a TMA Gas Changeover Manifold

How to Prevent Contamination in High Purity Xenon Gas Systems

Regulators for High Purity Krypton in Laser and Lighting Applications

Tags

Recommended Products

-

316L Stainless Steel Tube Butt Weld Reducing Fittings Union Reducer RW Series Ultrahigh Purity Process

-

High Purity Configurable Systems VMB Valve Manifold Box JW-200-VMB-C & JW-100-VMB-C

-

768L Stainless Steel Male Tube Butt Weld Connector | Clean Weld Fittings And Ultra-High Purity Fittings

-

Scrubber Gas Cabinet Scrubber Tail Gas Treatment Cabinet Vent Gas Scrubber System Heat-Filter Burn Box Gas Scrubber/Abatement System

-

High Pressure High Temperature Pneumatic Ultrahigh Purity Stainless Steel Diaphragm Valves

-

7108L Cylinder Cap Connectors For Ultra High Purity Gases

-

JR1000 Series UHP Ultra High Purity Single Stage Pressure Reducing Regulator And Low To Intermediate Flow

-

Single Stage Wall And Cabinet Mounting Pressure Control Panels JSP-2E Series For High Purity Gases