Blog

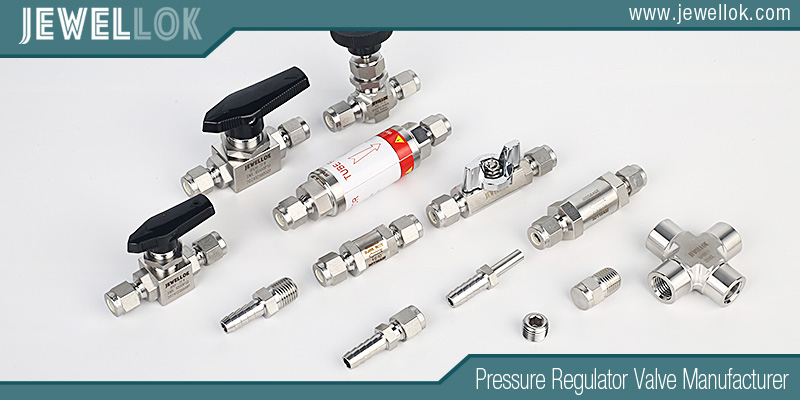

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Medical Oxygen Pressure Gauge: Precision Instruments Powering Healthcare

- Pressure Regulator Valve Manufacturer

- 1 1 2 gas pressure regulator, 1 2 gas regulator, 1 2 propane regulator, 12v electric valve, adjustable propane pressure regulator, argon gas pressure regulator, automatic switching valve, electric water valve, gas manifold system, gas pipeline valve, gas pipeline valves, gas regulator, gases used in semiconductor manufacturing, high flow co2 regulator, high pressure argon regulator, high purity regulator, high purity valves, how does a needle valve work, industrial regulators, irrigation timer valve, laboratory gas valves, low pressure gas regulator, medical oxygen pressure gaug, medical oxygen pressure gauge factory, medical oxygen pressure gauge manufacturer, medical oxygen pressure gauge supplier, oxygen regulator gauge, pressure regulator, pressure safety valve vs relief valve, propane pressure regulator valve, relief valve and safety valve difference, safety valve and relief valve, safety valve vs relief valve, semiconductor gas, single stage pressure regulator, solenoid valve working, timed water valve, valve manifold box

- No Comments

Medical Oxygen Pressure Gauge: Precision Instruments Powering Healthcare

In the fast-paced world of healthcare, where every second counts, the reliable delivery of medical oxygen can mean the difference between life and death. At the heart of this critical process lies a small but mighty device: the medical oxygen pressure gauge. These precision instruments, crafted by specialized manufacturers, play a pivotal role in ensuring that patients receive the oxygen they need, when they need it. As the demand for high-quality medical equipment continues to rise, the importance of these manufacturers cannot be overstated. This article delves into the world of medical oxygen pressure gauge manufacturers, exploring their vital role, the intricacies of their craft, and the future of this essential industry.

The Critical Role of Medical Oxygen Pressure Gauges

Medical oxygen pressure gauges are indispensable tools in healthcare settings, from bustling hospital wards to quiet home care environments. Their primary function is to measure and display the pressure of oxygen within storage tanks, delivery systems, and other medical apparatus. This seemingly simple task carries profound implications for patient care and safety.

Why Pressure Gauges Matter

- Ensuring Patient Safety: Accurate pressure readings allow healthcare providers to monitor the oxygen supply, preventing interruptions that could jeopardize a patient’s well-being. For patients with respiratory conditions, such as chronic obstructive pulmonary disease (COPD) or pneumonia, a consistent oxygen flow is non-negotiable.

- Optimizing Oxygen Delivery: By tracking pressure, medical staff can adjust flow rates to match a patient’s specific needs, ensuring effective therapy without waste. This precision is especially critical in intensive care units (ICUs) where oxygen levels must be tightly controlled.

- Preventing Equipment Failure: Regular pressure monitoring can reveal potential issues—like leaks or blockages—before they escalate into dangerous malfunctions. This proactive approach protects both patients and healthcare workers.

Given these essential functions, the reliability and accuracy of medical oxygen pressure gauges are paramount. Manufacturers of these devices are tasked with producing instruments that healthcare professionals can trust implicitly, day in and day out.

The Role of Manufacturers in Ensuring Quality and Compliance

Manufacturers of medical oxygen pressure gauges operate in a highly regulated landscape where precision and accountability are not optional—they are mandated. These companies must adhere to stringent standards set by international and national bodies to guarantee that their products are safe, reliable, and effective.

Standards and Regulations

- ISO 13485: This international standard outlines requirements for a quality management system tailored to medical devices. It ensures that manufacturers maintain consistency in design, development, production, and delivery—cornerstones of dependable medical equipment.

- FDA Regulations: In the United States, medical oxygen pressure gauges fall under the purview of the Food and Drug Administration (FDA). Classified as medical devices, they must comply with regulations such as premarket notification (510(k)) and good manufacturing practices (GMP), which dictate rigorous safety and performance benchmarks.

- Calibration Standards: To deliver accurate readings, gauges must be calibrated to precise standards, often aligned with guidelines from national metrology institutes like the National Institute of Standards and Technology (NIST). This calibration ensures that a gauge reading 100 psi (pounds per square inch) is truly reflecting that pressure.

Navigating this regulatory maze requires significant investment in testing, documentation, and quality assurance. Compliance is not just a legal obligation; it’s a commitment to patient safety and a foundation for trust with healthcare providers.

Challenges and Responsibilities

Manufacturing medical oxygen pressure gauges is no small feat. Producers face a unique set of challenges:

- Precision Engineering: These gauges must deliver accurate readings across a wide range of pressures and environmental conditions—whether in a humid hospital room or a freezing ambulance. Even minor deviations can have serious consequences.

- Material Selection: Components must be crafted from materials that are durable, corrosion-resistant, and compatible with medical-grade oxygen. Any degradation or contamination could compromise the gauge’s performance or the oxygen’s purity.

- Cost Management: High-quality materials and meticulous manufacturing processes come at a price. Manufacturers must balance these costs with market demands to keep their products accessible without sacrificing quality.

Beyond these technical hurdles, manufacturers carry the weighty responsibility of innovation. They must continually refine their designs and processes to enhance gauge performance, usability, and longevity—ensuring that their products remain at the forefront of medical technology.

The Manufacturing Process: Precision and Innovation

Creating a medical oxygen pressure gauge is a complex, multi-step process that marries advanced engineering with uncompromising quality control. While techniques may differ slightly among manufacturers, the core stages are universally rigorous.

Design and Engineering

- CAD Modeling: The journey begins with computer-aided design (CAD) software, which allows engineers to craft detailed, three-dimensional models of the gauge. This digital blueprint specifies exact dimensions and tolerances, laying the groundwork for precision.

- Simulation and Testing: Before physical production, virtual simulations test the gauge’s performance under various pressures and conditions. This step identifies potential weaknesses, ensuring the design is robust before it’s brought to life.

Material Selection

- Stainless Steel: A mainstay in gauge construction, stainless steel offers strength and resistance to corrosion—critical for withstanding the reactive nature of oxygen over time.

- Brass and Alloys: Often used for internal components like Bourdon tubes (the pressure-sensing element), brass and specialized alloys provide durability and oxygen compatibility.

- Specialized Coatings: Some manufacturers apply protective coatings to enhance resistance to wear, contamination, or environmental stressors, extending the gauge’s lifespan.

Machining and Assembly

- Precision Machining: Computer numerical control (CNC) machines carve components with microscopic accuracy, ensuring each part meets exact specifications. This precision is vital for the gauge’s functionality.

- Assembly: Skilled technicians meticulously assemble the gauge, fitting together components like the dial, needle, and pressure-sensing mechanism. A single misstep here could skew readings or cause failure.

Calibration and Testing

- Calibration: Each gauge is calibrated against a known pressure standard, fine-tuning it to deliver accurate readings. For example, a gauge might be adjusted to align perfectly at 50 psi and 200 psi, ensuring reliability across its range.

- Leak Testing: To prevent oxygen loss—a safety and efficiency concern—gauges undergo rigorous leak tests, often using helium or pressure decay methods.

- Environmental Testing: Some manufacturers simulate extreme conditions (e.g., high humidity or low temperatures) to verify performance in real-world scenarios.

Quality Control

- Inspection: Both visual checks and automated systems scan for defects—cracks, misalignments, or irregularities—that could compromise the gauge.

- Documentation: Comprehensive records track each gauge’s production journey, from raw materials to final testing, providing traceability and proof of compliance.

This painstaking process ensures that every medical oxygen pressure gauge is a paragon of reliability, ready to serve its life-saving purpose.

Types of Medical Oxygen Pressure Gauges and Their Applications

Not all medical oxygen pressure gauges are created equal. Manufacturers produce a variety of types, each tailored to specific needs and settings within healthcare.

Analog Gauges

- Description: These classic gauges feature a needle and dial, offering a visual representation of pressure.

- Advantages: They’re straightforward, durable, and often more affordable than digital options. No batteries or electronics mean fewer points of failure.

- Applications: Analog gauges are staples in hospitals, ambulances, and home oxygen setups, prized for their simplicity and reliability.

Digital Gauges

- Description: Equipped with electronic displays, digital gauges provide precise, numeric pressure readings.

- Advantages: They boast superior accuracy, easy-to-read screens, and extras like data logging or alarms—perfect for detailed monitoring.

- Applications: Digital gauges shine in critical care units, research labs, and settings where exact measurements are paramount.

Specialized Gauges

- Neonatal Gauges: Designed for newborns, these gauges feature finer scales and heightened accuracy to accommodate the low oxygen flows required in neonatal care.

- High-Altitude Gauges: Used in mountain rescues or air ambulances, these are calibrated to adjust for atmospheric pressure changes, ensuring consistent readings at elevation.

Manufacturers must deeply understand these diverse applications to craft gauges that excel in their intended roles, meeting the nuanced demands of healthcare providers.

The Future of Medical Oxygen Pressure Gauge Manufacturing

As healthcare evolves and technology advances, the medical oxygen pressure gauge industry stands on the cusp of transformation. Emerging trends and innovations are poised to redefine how these critical devices are designed and produced.

Smart Technology Integration

- IoT Connectivity: The Internet of Things (IoT) could enable gauges to transmit real-time pressure data to healthcare systems, allowing remote monitoring and instant alerts for low oxygen levels.

- Predictive Maintenance: Smart gauges might use algorithms to predict when maintenance is needed, minimizing downtime and enhancing safety.

Advanced Materials

- Lightweight Composites: New materials could yield gauges that are lighter yet just as durable, improving portability and ease of use.

- Biocompatible Coatings: Cutting-edge coatings might further reduce contamination risks, ensuring oxygen purity and extending gauge life.

Sustainability and Efficiency

- Eco-Friendly Manufacturing: Manufacturers are exploring greener practices—like reducing waste or using recyclable materials—to align with global sustainability goals.

- Energy-Efficient Designs: For digital gauges, low-power displays or solar options could cut energy use, especially valuable in remote or resource-scarce settings.

Customization and Flexibility

- Modular Designs: Future gauges might feature interchangeable parts, letting users adapt them to specific needs or upgrade components as technology improves.

- 3D Printing: Additive manufacturing could enable rapid, on-demand production of custom gauges, tailored to unique patient or equipment requirements.

These advancements promise to elevate the functionality, reliability, and accessibility of medical oxygen pressure gauges, ultimately enhancing patient outcomes.

Conclusion

Medical oxygen pressure gauge manufacturers are unsung heroes of the healthcare ecosystem, crafting the precision tools that ensure oxygen reaches patients safely and effectively. Through adherence to rigorous standards, mastery of intricate manufacturing processes, and a forward-looking embrace of innovation, these companies uphold the highest levels of quality and trust. As the industry evolves—driven by smart technology, advanced materials, and sustainable practices—it will continue to meet the growing and changing demands of modern medicine. In doing so, manufacturers not only advance medical technology but also safeguard the health and lives of countless individuals who depend on their expertise every day.

For more about medical oxygen pressure gauge: precision instruments powering healthcare, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Safely Operate a TMA Gas Changeover Manifold

How to Choose an Ultra High Purity CO2 Pressure Reducing Valve

The Top High-Pressure Argon Gas Regulator Manufacturer in China

How to Choose a Gas Cylinder Manifold System

Tags

Recommended Products

-

High Purity High Flow Pressure Control Regulators & Valves Gas Stick Assemblies JSR-2TG Series

-

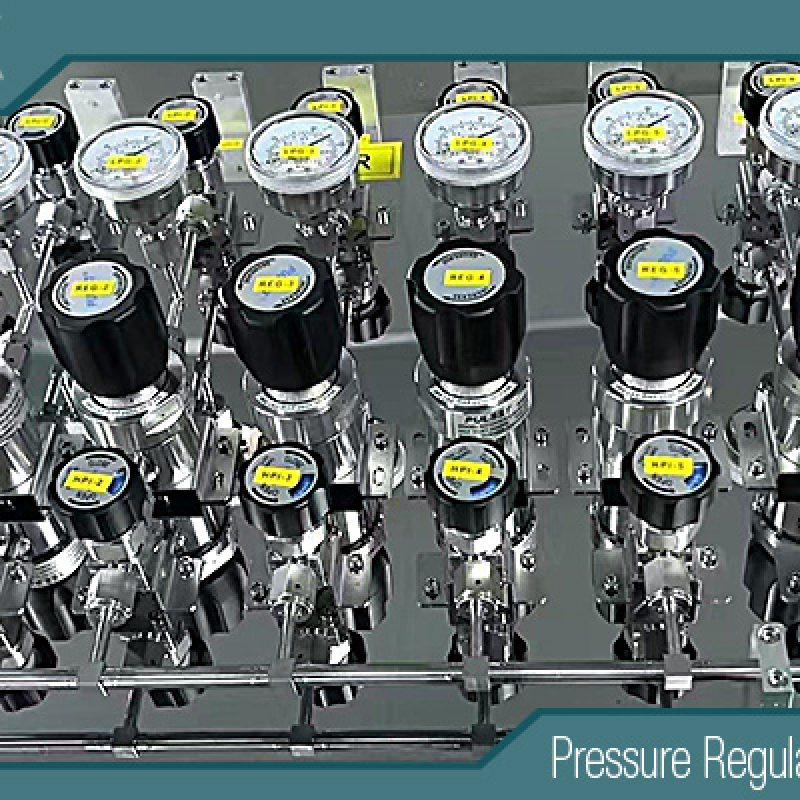

Medical Oxygen Single Stage Manual Gas Changeover Manifold Panel High-Purity Two-Stage Manual Gas Manifold Gas Pressure Control Panels

-

Semi Automatic And Automatic Switching Speicialty Gas Changeover Manifold Panel With Semiconductor Valve Manifold Box Gas Pressure Regulators

-

High Pressure High-Purity Welded Check Valves And Low Cracking Pressure Check Valve JCV1 Series

-

771LF Female Run Tee | Stainless Steel Tube Fitting Compression Fittings 1/4 In 3-Way Tee Female Run Tee

-

High Purity High Pressure Gas Cylinder Pressure Regulators Pressure Reducing Valve JSR-1E Series

-

7108L Cylinder Cap Connectors For Ultra High Purity Gases

-

Pressure Control Panels For High Purity Gas Control System JSP-3AE Series From Pressure Control Panels Suppliers And Manufacturer