Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

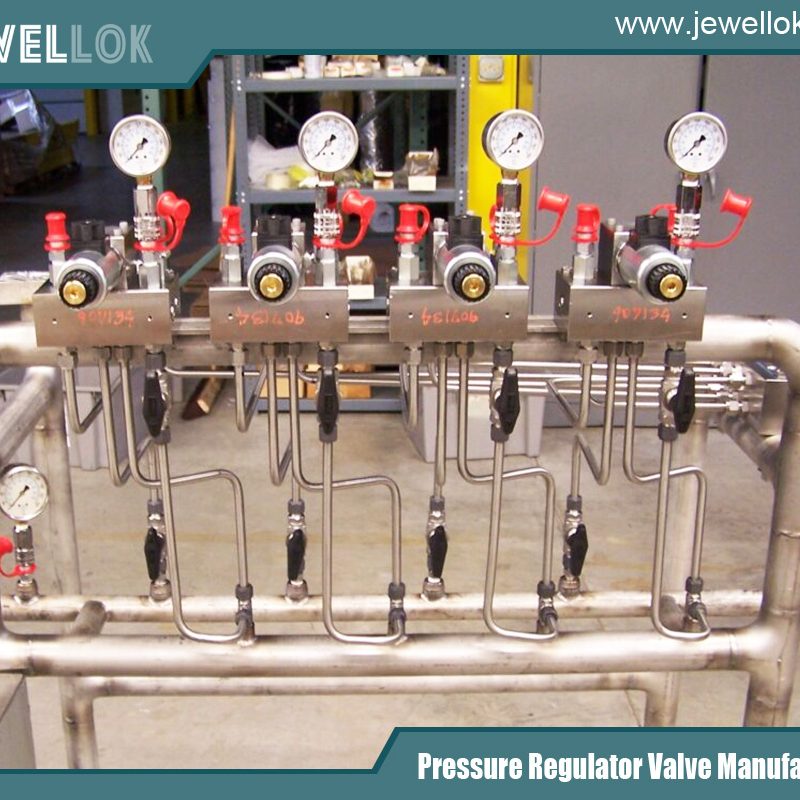

Stainless Steel Pressure Regulator: Precision and Durability for Critical Applications

- Pressure Regulator Valve Manufacturer

- 1inch of water, 2 inch irrigation valve, 316l stainless steel pressure regulator, 316l stainless steel pressure regulator manufacturer, adjustable low pressure propane regulator, air compressor non return valve, argon hose connector, argon hose fittings, ba grade stainless steel pressure regulator, China Stainless Steel Pressure Regulator, fire arrestor, fluid system components, gas pipeline valve, gas pipeline valves, gases used in semiconductor manufacturing, high grade stainless steel pressure regulator, High Pressure Co2 Stainless Steel Pressure Regulator, High Pressure Stainless Steel Pressure Regulator, high purity valves, humming propane regulator, irrigation timer valve, laboratory gas valves, male fitting for argon hose, pressure regulator, pressure regulator valve leaking, pressure relief valve vs safety valve, propane adjustable pressure regulator, propane manifold with valves, regulator valve alibaba international market, safety relief valve vs safety valve, safety valve vs pressure relief valve, second stage propaneregulator, single stage pressure regulator, Stainless Steel Pressure Regulator, Stainless Steel Pressure Regulator Supplier, stainless steel pressure regulators, stainless steel pressure regulators manufacturer, stainless steel pressure regulators wholesale, timed water valve, timer water valve, valve timer water

- No Comments

Stainless Steel Pressure Regulator: Precision and Durability for Critical Applications

In industries where precise control of gas or fluid pressure is critical, stainless steel pressure regulators stand out as indispensable components. These robust devices ensure stable pressure delivery while withstanding harsh environments, making them a cornerstone of applications in oil and gas, pharmaceuticals, water treatment, and more. Crafted from corrosion-resistant stainless steel, they offer unparalleled durability and reliability, even under demanding conditions. As industries continue to prioritize efficiency, safety, and longevity, the demand for high-quality stainless steel pressure regulators has surged, with the global market for pressure regulators projected to grow significantly in the coming years.This 2,000-word guide explores the world of stainless steel pressure regulators, detailing their functionality, types, applications, key features, selection criteria, leading manufacturers, emerging trends, and practical considerations. Whether you’re an engineer designing a system, a procurement specialist sourcing components, or a business seeking reliable solutions, this article will equip you with the knowledge to make informed decisions about stainless steel pressure regulators.

What is a Stainless Steel Pressure Regulator?

A stainless steel pressure regulator is a mechanical device designed to maintain a consistent output pressure of a gas or liquid, regardless of fluctuations in the input pressure or flow demand. It achieves this by balancing the force of the incoming fluid against a spring or diaphragm mechanism, throttling the flow to achieve the desired downstream pressure. The use of stainless steel—typically grades like 316L or 304—sets these regulators apart, offering superior corrosion resistance, durability, and compatibility with aggressive media.How It WorksThe regulator’s core components include a diaphragm or piston, a spring, and a valve assembly. When the upstream pressure exceeds the set point, the valve restricts flow, reducing the downstream pressure. Conversely, if demand increases, the valve opens to maintain stability. Stainless steel construction ensures the regulator can handle corrosive fluids, high temperatures, or harsh environments without degrading, making it ideal for critical applications.Why Stainless Steel?Stainless steel’s unique properties make it the material of choice for pressure regulators in demanding settings:

- Corrosion Resistance: Resists rust and degradation from chemicals, seawater, or acidic gases.

- Durability: Withstands high pressures and temperatures, ensuring long-term performance.

- Hygienic Properties: Non-porous surfaces prevent contamination, critical for pharmaceuticals and food processing.

- Aesthetic and Functional: Maintains integrity in extreme conditions, from desert heat to sterile labs.

These qualities make stainless steel pressure regulators a preferred choice across industries.

Types of Stainless Steel Pressure Regulators

Stainless steel pressure regulators come in various designs, each tailored to specific applications. Below are the primary types:1. Single-Stage Pressure Regulators

- Description: Reduces pressure in one step, suitable for systems with stable inlet pressures.

- Features: Compact, cost-effective, and precise for low-to-medium pressure applications.

- Applications: Laboratory gas systems, analytical instruments, and low-pressure gas distribution.

- Example: Swagelok’s KPR series, designed for pressures up to 600 psig.

- Two-Stage Pressure Regulators

- Description: Reduces pressure in two steps, minimizing the impact of inlet pressure fluctuations.

- Features: Enhanced stability, ideal for high-purity or critical applications.

- Applications: Semiconductor manufacturing, pharmaceutical gas systems, and high-purity gas delivery.

- Example: Tescom’s 44-1300 series, offering precise control for corrosive gases.

- Back Pressure Regulators

- Description: Maintains upstream pressure by venting excess fluid, ideal for systems requiring constant backpressure.

- Features: High flow capacity, compatibility with harsh environments.

- Applications: Chemical reactors, pipeline systems, and offshore oil platforms.

- Example: ControlAir’s Type 700BP, with a flow capacity up to 50 scfm.

- Pilot-Operated Regulators

- Description: Uses a pilot valve to control a larger main valve, offering high flow and precision.

- Features: Large orifice designs, suitable for high-pressure applications.

- Applications: Natural gas transmission, industrial gas systems, and city gate stations.

- Example: Emerson’s Fisher 627 series, with a 1500 psig inlet rating.

- Ultra-High Purity (UHP) Regulators

- Description: Designed for applications requiring minimal contamination, such as semiconductor fabrication.

- Features: Electropolished 316L stainless steel, low dead volume, high leak integrity.

- Applications: High-purity gas systems, pharmaceutical production, and microelectronics.

- Example: APTech’s AK1000 series, optimized for grade 6.0 gases.

Each type addresses specific operational needs, from precision control to high-flow applications.

Applications of Stainless Steel Pressure Regulators

Stainless steel pressure regulators are used across a wide range of industries due to their versatility and reliability. Key applications include:

- Oil and Gas: Regulating pressure in pipelines, wellheads, and refineries to prevent blowouts and ensure safety. Stainless steel’s resistance to sour gases makes it ideal for offshore platforms.

- Pharmaceuticals and Biotechnology: Maintaining precise pressure in sterile gas and fluid systems to prevent contamination, critical for drug production.

- Water Treatment and Desalination: Controlling pressure in reverse osmosis systems and water distribution networks, leveraging stainless steel’s corrosion resistance to seawater.

- Semiconductor Manufacturing: Delivering ultra-pure gases for processes like chemical vapor deposition, where even trace impurities can ruin yields.

- Food and Beverage: Ensuring hygienic pressure control in systems handling gases or liquids, meeting FDA standards.

- HVAC and Industrial Systems: Managing compressed air or gas in commercial buildings, where durability is key.

These applications highlight the critical role of stainless steel pressure regulators in maintaining safety and efficiency.

Key Features of Stainless Steel Pressure Regulators

When selecting a stainless steel pressure regulator, certain features ensure optimal performance:1. Corrosion-Resistant Materials

- Benefit: Grades like 316L stainless steel withstand aggressive media, extending service life.

- Example: NACE MR0175-compliant regulators for sour gas environments.

- High-Pressure Capability

- Benefit: Handles pressures from 100 to 10,000 psig, suitable for diverse applications.

- Example: Pressure Tech’s regulators for high-pressure subsea systems.

- Precision Control

- Benefit: Low droop and tight regulation ensure stable downstream pressure.

- Example: Swagelok’s RHPS series with minimal supply pressure effect.

- Hygienic Design

- Benefit: Electropolished surfaces and low dead volume meet stringent cleanliness standards.

- Example: APTech’s UHP regulators for semiconductor applications.

- Customization Options

- Benefit: Tailored pressure ranges, materials, or port configurations meet specific needs.

- Example: Tescom’s custom regulators for specialty gases.

- Environmental Sealing

- Benefit: IP65 or higher ratings protect against dust and water ingress.

- Example: ControlAir’s Type 360 for harsh outdoor conditions.

How to Choose a Stainless Steel Pressure Regulator

Selecting the right regulator requires careful consideration of several factors:1. Application Requirements

- Match the regulator’s pressure range, flow capacity, and media compatibility to your system’s needs.

- Tip: For high-purity applications, choose UHP models with electropolished surfaces.

- Material Compatibility

- Ensure the regulator’s materials (e.g., 316L stainless steel, Hastelloy) are compatible with the fluid or gas.

- Tip: Check for NACE compliance in corrosive environments.

- Environmental Conditions

- Consider temperature, humidity, and exposure to chemicals or saltwater.

- Tip: Opt for sealed regulators for outdoor or marine use.

- Precision Needs

- For applications requiring tight control, choose regulators with low droop and high accuracy.

- Tip: Two-stage regulators offer better stability for fluctuating inlet pressures.

- Certifications and Standards

- Look for compliance with industry standards like ISO 9001, NACE, or SEMI.

- Tip: Request material test reports to verify quality.

- Supplier Support

- Choose manufacturers with strong technical support and local availability.

- Tip: Check for warranty, calibration, and spare parts services.

Leading Manufacturers of Stainless Steel Pressure Regulators

Several companies excel in producing high-quality stainless steel pressure regulators, particularly in the USA, a hub for precision engineering. Here are some key players:1. Swagelok

- Overview: Based in Solon, Ohio, Swagelok is renowned for fluid system components.

- Key Products: KPR and RHPS series, offering precise control for pressures up to 6000 psig.

- Strengths: High-quality materials, customization, and global support.

- Applications: Semiconductors, pharmaceuticals, and oil and gas.

- Emerson (TESCOM Brand)

- Overview: Headquartered in St. Louis, Missouri, Emerson’s TESCOM brand specializes in precision regulators.

- Key Products: 44-1300 and 26-2000 series, designed for high-purity and corrosive gases.

- Strengths: Modular designs, extensive certifications, and technical expertise.

- Applications: Aerospace, pharmaceuticals, and industrial gases.

- APTech (Advanced Pressure Technology)

- Overview: Located in Napa, California, APTech focuses on high and ultra-high purity regulators.

- Key Products: AK1000 series for UHP applications, with pressures up to 3500 psig.

- Strengths: Cleanroom assembly, helium leak testing, and specialty gas expertise.

- Applications: Semiconductors, solar cells, and laboratories.

- ControlAir

- Overview: Based in Amherst, New Hampshire, ControlAir offers precision regulators for industrial use.

- Key Products: Type 360 and 700BP, designed for high flow and harsh environments.

- Strengths: Cost-effective, rugged designs, and NACE compliance.

- Applications: Oil and gas, chemical processing, and HVAC.

- Parker Hannifin (Veriflo Division)

- Overview: Headquartered in Cleveland, Ohio, Parker’s Veriflo division excels in high-purity regulators.

- Key Products: Veriflo regulators for specialty gases, with tied-diaphragm designs.

- Strengths: Compact size, high flow, and customization options.

- Applications: Semiconductors, pharmaceuticals, and research labs.

These manufacturers lead the industry with innovative, reliable solutions tailored to diverse needs.

Emerging Trends in Stainless Steel Pressure Regulators

The pressure regulator industry is evolving to meet modern demands:

- Smart Regulators: IoT-enabled sensors monitor pressure and predict maintenance needs.

- Advanced Materials: Alloys like Hastelloy or titanium enhance corrosion resistance.

- Compact Designs: Smaller regulators maintain performance in space-constrained systems.

- Eco-Friendly Solutions: Low-emission designs align with sustainability goals.

- High-Purity Focus: Increased demand for UHP regulators in semiconductors and pharmaceuticals.

These trends ensure regulators remain cutting-edge and adaptable.

Practical Considerations for Using Stainless Steel Pressure Regulators

To maximize performance, follow these best practices:

- Proper Installation: Follow manufacturer guidelines to avoid stress on components.

- Regular Calibration: Ensure accuracy with periodic checks.

- Maintenance: Inspect seals, diaphragms, and valves for wear.

- Environmental Protection: Use enclosures in harsh conditions to prolong life.

- Training: Ensure operators understand the regulator’s specifications and limits.

Conclusion

Stainless steel pressure regulators are critical components for industries requiring precision, durability, and safety. Their corrosion resistance, high-pressure capabilities, and hygienic design make them ideal for applications from oil and gas to semiconductors. By understanding the types, features, and selection criteria, businesses can choose regulators that meet their specific needs. Leading manufacturers like Swagelok, Emerson, APTech, ControlAir, and Parker Hannifin offer innovative solutions backed by quality and support. As trends like smart technology and eco-friendly designs shape the future, these regulators will continue to drive efficiency and reliability. Invest in a stainless steel pressure regulator today to ensure your systems perform at their best, now and in the future.

For more about the stainless steel pressure regulator: precision and durability for critical applications, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Five Key Considerations When Choosing a TMA Gas Changeover Manifold

How to Prevent Contamination in High Purity Xenon Gas Systems

Regulators for High Purity Krypton in Laser and Lighting Applications

Tags

Recommended Products

-

Ultra High Purity Trimethylaluminum TMA Gas Cabinet Liquid Delivering Cabinet Used For Specialty Gas Delivery System In Semiconductor

-

774L Stainless Steel UHP Fittings Butt Weld Bulkhead Union For High Flow Special Gas Fluid

-

766L High Purity Female Connector UHP Fitting Female Connector

-

775L Bulkhead Reducing Union | Stainless Steel High Purity Double Ferrule Bulkhead Reducing Unions

-

Fully Automated Gas Cabinet Gas Rack Gas Delivery Systems JW-300-GR

-

Bulk Specialty Gas Systems (BSGS) Gas Cabinets And Scrubber Tail Gas Treatment Cabinets For High Purity Bulk Specialty Gas Delivery

-

Stainless Steel Single Stage Semiconductor Grade Pressure Control Module Pressure Control Panels JSP-6A Series

-

Stainless Steel Ultra Clean Welding Joint Fittings TW Series TRW Series & CW Series