Blog

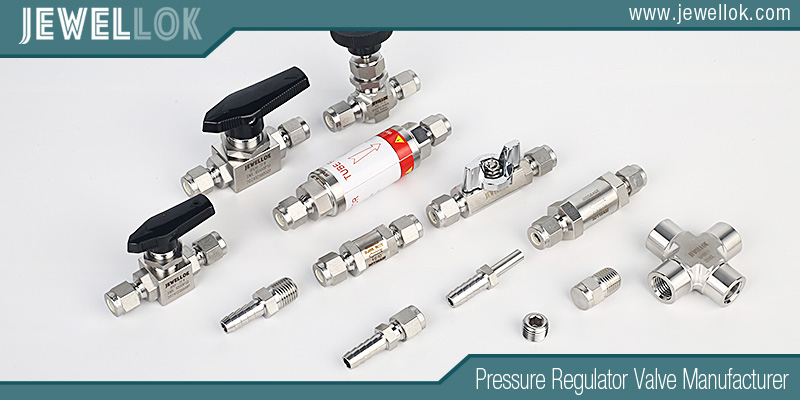

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

High Polish High Purity Tube Fittings: Essential Components for Critical Industries

- Pressure Regulator Valve Manufacturer

- 316 stainless steel pipe fittings, compression fitting on gas pipe, compression plumbing fittings, compression tube fittings, high performance fittings manufacturer, high polish high purity tube fittings, high pressure compression fittings, high pressure stainless steel tubing, high purity stainless steel tubing, hydrogen pipe valves and fittings, latest design stainless steel reducer fittings, metal gasket face seal fittings, precision high pressure fittings supplier, stainless compression fittings, stainless steel 1/4 in. pressure gauge fitting, stainless steel 1/4 in. pressure gauge fitting - 3/8 qc, stainless steel butt weld pipe fittings, stainless steel compression fittings, ultra high purity fittings, ultra high purity stainless steel tubing, vcr metal gasket face seal fittings

- No Comments

High Polish High Purity Tube Fittings: Essential Components for Critical Industries

Introduction

In the realm of modern manufacturing and processing, where precision and purity are paramount, high polish high purity tube fittings stand out as indispensable components. These specialized fittings are designed to ensure the seamless, contamination-free transfer of fluids and gases in environments that demand the utmost cleanliness. High polish refers to the exceptionally smooth surface finish achieved through advanced polishing techniques, while high purity denotes the minimal risk of introducing impurities into the system. Together, these attributes make high polish high purity tube fittings ideal for industries such as semiconductors, pharmaceuticals, biotechnology, and food processing, where even microscopic contaminants can lead to catastrophic failures or compromised product quality.

The evolution of these fittings has been driven by the growing complexity of industrial processes. For instance, in semiconductor fabrication, ultra-pure gases and chemicals must be delivered without any particulates or residues that could affect wafer production. Similarly, in pharmaceutical manufacturing, fittings must comply with stringent regulations to prevent bacterial growth or chemical leaching. This article delves into the characteristics, manufacturing processes, applications, benefits, and future trends of high polish high purity tube fittings, highlighting their role in maintaining system integrity and efficiency. By exploring these aspects, we underscore why investing in such fittings is not just a choice but a necessity for high-stakes operations.

What Are High Polish High Purity Tube Fittings?

High polish high purity tube fittings are precision-engineered connectors used to join tubes in fluid and gas handling systems. Unlike standard tube fittings, which may suffice for general industrial use, these variants are optimized for environments requiring ultra-clean conditions. The “high polish” aspect typically involves surface finishes with roughness averages (Ra) as low as 5-10 microinches (μin), achieved through electropolishing or mechanical polishing. This smoothness reduces the potential for particle adhesion and facilitates easier cleaning. High purity, on the other hand, ensures that the materials and construction minimize outgassing, corrosion, and extractables—substances that could leach into the conveyed media.

Common materials include 316L stainless steel, known for its low carbon content and excellent corrosion resistance, as well as fluoropolymers like PVDF or PFA for chemical inertness. These fittings come in various configurations, such as elbows, tees, reducers, unions, and caps, often featuring metal gasket face seals or weld connections for leak-tight performance. For example, metal gasket face seal fittings use nickel or stainless steel gaskets to create a reliable seal under vacuum or high pressure.

Compared to standard fittings, high polish high purity tube fittings undergo rigorous cleaning and packaging in cleanrooms to meet standards like SEMI F20 or ISO 14644-1. They are electropolished to remove surface imperfections, passivated to enhance corrosion resistance, and tested for helium leaks at rates as low as 10^-10 std cm³/sec. This level of refinement distinguishes them from off-the-shelf options, making them suitable for ultra-high purity (UHP) applications where purity levels exceed 99.9999%.

Key Characteristics of High Polish High Purity Tube Fittings

The efficacy of high polish high purity tube fittings lies in their meticulously engineered characteristics. Surface finish is a cornerstone: electropolishing, an electrochemical process, dissolves a thin layer of material to achieve Ra values of 10 μin or less, creating a mirror-like surface that resists bacterial adhesion and particulate buildup. This is crucial in preventing contamination in sensitive systems.

Material purity is equally vital. Most fittings are crafted from 316L stainless steel, with chemical compositions tightly controlled—chromium (16-18 wt.%), nickel (10-15 wt.%), and molybdenum (2-3 wt.%)—to ensure durability and minimal reactivity. Sulfur content is kept low (0.005-0.017 wt.%) to avoid pitting. Gaskets may use nickel for enhanced sealing. These materials comply with ASTM A269, ASME SA213, and EN 1.4404 standards.

Leak-tight seals are achieved through designs like metal-to-metal contacts, O-rings, or automatic butt welds. Weld fittings, such as reducing unions or elbows without shoulders, minimize dead spaces where contaminants could accumulate. High flow variants support larger volumes without pressure drops.

Cleanroom manufacturing ensures purity: fittings are assembled in ISO Class 4 environments, rinsed with 18 MΩ·cm deionized water at 60°C, and purged with filtered nitrogen. Packaging involves heat-sealed polyethylene bags to maintain cleanliness. Traceability is maintained via certificates of conformance, covering surface roughness, dimensional tolerances, and purity tests like SEM for pits and XPS for oxide ratios.

Compliance with industry standards, including ASME B31.3 for pressure ratings and CGA G4.1 for residue levels, further bolsters their reliability. Pressure ratings can reach 5100 psig for 1/4-inch OD tubing at ambient temperatures.

Applications of High Polish High Purity Tube Fittings

High polish high purity tube fittings find extensive use across industries where purity is non-negotiable. In semiconductor manufacturing, they are integral to gas delivery systems for processes like chemical vapor deposition (CVD) and etching. Here, fittings ensure ultra-pure gases reach wafers without impurities that could cause defects. Rotarex’s UHP fittings, for instance, support vacuum-to-high-pressure applications with leak-free performance, essential for maintaining process integrity.

In pharmaceuticals and biotechnology, these fittings are used in water for injection (WFI) systems and sterile fluid handling. Their smooth, electropolished surfaces prevent biofilm formation, complying with FDA and USP standards. Cardinal UHP’s electropolished coil tubing, available in lengths up to 300ft, reduces welds and installation time in bioprocessing lines.

The food and beverage sector employs them for hygienic processing, such as in dairy or beverage lines, to avoid bacterial growth and ensure product safety. Aerospace and laboratory applications benefit from their corrosion resistance in handling reactive chemicals or reagents.

In solar and TFT/LCD production, Valex’s fittings up to NPS 24 support large-scale fluid systems, ensuring purity in chemical handling. Heated tubing variants from Cardinal maintain temperatures up to 180°C for viscous media. Coaxial designs provide dual containment for hazardous substances, enhancing safety.

Overall, these fittings enable miniaturization in systems like Swagelok’s Micro-Fit, where flow ratings match larger welds despite compact sizes. Their versatility extends to medical devices and chemical processing, underscoring their broad applicability.

Manufacturing and Quality Control Processes

Manufacturing high polish high purity tube fittings begins with material selection: 316L stainless steel bars or forgings compliant with ASME SA-479 and ASTM A-276. Fabrication involves precision machining, forging, and orbital welding to create shapes like elbows or tees.

Surface treatment is critical: electropolishing removes burrs and passivates the surface, achieving Ra <10 μin. Cleaning follows, with DI water rinsing and nitrogen purging in ISO Class 4 cleanrooms. Valex integrates electropolishing into their process for tubes from 1/8″ to 24″ NPS.

Quality control includes helium leak testing, dimensional inspections, and purity analyses. Cardinal’s ISO 9001:2015 certification ensures traceability. Rotarex monitors parameters with SPC and CAQS for full traceability. Packaging in Class 10 cleanrooms prevents recontamination.

Benefits of High Polish High Purity Tube Fittings

The primary benefit is contamination prevention: smooth surfaces and pure materials reduce particulates and extractables, enhancing yield in semiconductors. Reliability stems from leak-tight seals and high pressure ratings, minimizing downtime.

Cleanability is improved, with electropolishing facilitating sterilization. Maintenance is reduced due to corrosion resistance, leading to cost savings. Compliance with standards like ASTM G93 ensures regulatory adherence. Durability in harsh environments extends service life.

Challenges and Considerations

Despite advantages, challenges include high initial costs due to specialized manufacturing. Installation requires skilled technicians and tools like orbital welders. Maintenance demands cleanroom protocols.

Selecting the right supplier is key; factors like traceability and certifications mitigate risks.

Future Trends in High Purity Tube Fittings

Advancements include smarter materials with enhanced thermoplastics for better chemical resistance. Automation in electropolishing will improve consistency. Demand from biopharma and renewables will drive innovations like integrated sensors for real-time monitoring.

Sustainability efforts may focus on recyclable materials and energy-efficient processes.

Conclusion

High polish high purity tube fittings are the backbone of purity-critical systems, offering unmatched performance in contamination control and reliability. As industries evolve, these fittings will remain essential. Partnering with reputable manufacturers ensures optimal results, safeguarding operations and innovation.

For more about high polish high purity tube fittings: essential components for critical industries, you can pay a visit to Jewellok at https://www.jewellok.com/product-category/compression-tube-fittings/ for more info.

Recent Posts

Five Key Considerations When Choosing a TMA Gas Changeover Manifold

How to Prevent Contamination in High Purity Xenon Gas Systems

Regulators for High Purity Krypton in Laser and Lighting Applications

Tags

Recommended Products

-

High Purity High Pressure Specialty Gas Pressure Regulators Specialty Gases Pipeline Engineering Equipments Manufacturer And Supplier

-

High Pressure High-Purity Welded Check Valves And Low Cracking Pressure Check Valve JCV1 Series

-

Stainless Steel Low Pressure Seal Pneumatic Diaphragm Control Valve For For HP & UHP Gases

-

Hydrogen Manifold Argon Gas Manifold System Oxygen Manifold Propane Gas Manifold With Valves In Gas Manifold Changeover System

-

High Purity And Industria Gas Stick Assemblies Precise Pressure Control Gas Systems JSR-1ETG-BV Series

-

7121L Plug High Purity Plug Fitting And Blanking Plug

-

Ultra High Purity Gas Delivery Systems And Liquid Chemical Delivery Systems JW-300-LDS

-

Stainless Steel High-Purity High Temperature Metal Seated Ball Valves JBV3 Series