Bulk Specialty Gas Systems (BSGS) Gas Cabinets And Scrubber Tail Gas Treatment Cabinets For High Purity Bulk Specialty Gas Delivery

Bulk Specialty Gas Systems (BSGS) Gas Cabinets And Scrubber Tail Gas Treatment Cabinets For High Purity Bulk Specialty Gas Delivery

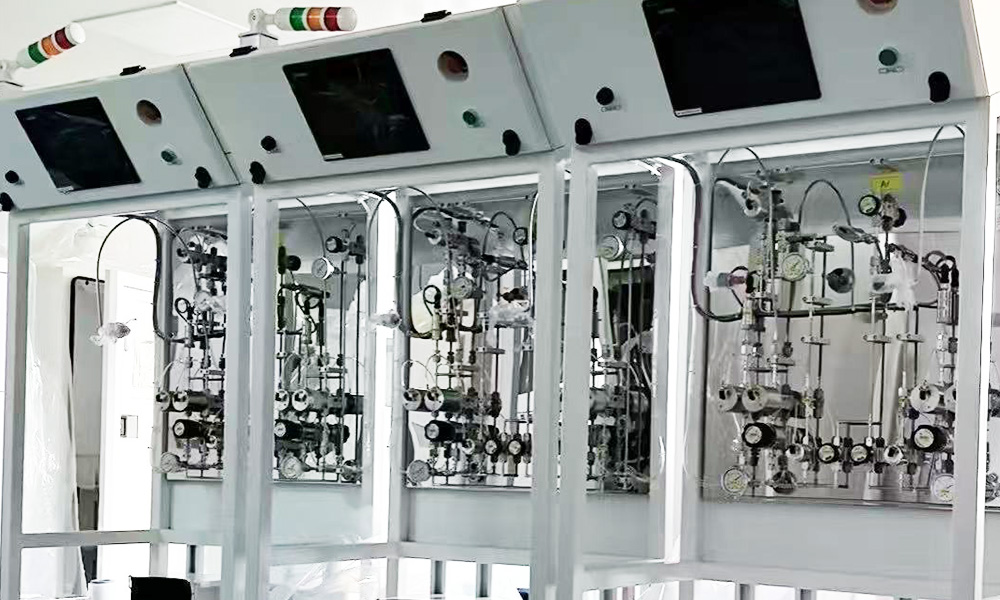

Jewellok specializes in fully automatic and semi-automatic GC gas cabinets, BSGS gas cabinets, VMB gas cabinets, TMA gas cabinets, Scrubber tail gas treatment cabinets, gas distribution cabinets, VDB gas cabinets, and VDP gas cabinets, suitable for gases such as SiH4, NF3, NH3, N2O, and HCI.

Bulk Specialty Gas Systems (BSGS) are critical for delivering high-purity specialty gases in industries like semiconductor manufacturing, pharmaceuticals, and chemical processing. These systems ensure safe, efficient, and contamination-free gas delivery through specialized gas cabinets and scrubber tail gas treatment cabinets.

Gas Cabinets in BSGS

Gas cabinets are engineered enclosures designed to store and deliver high-purity specialty gases, such as silane, ammonia, or hydrogen chloride, used in sensitive processes. They feature robust safety mechanisms, including automated shut-off valves, leak detection sensors, and ventilation systems to mitigate risks associated with hazardous gases. The cabinets maintain gas purity by using high-grade materials like stainless steel and advanced filtration systems to prevent contamination. Automated control systems monitor pressure, flow, and purity levels, ensuring consistent delivery to the point of use. Regular maintenance and compliance with safety standards, such as SEMI S2, are essential to prevent leaks and ensure operational reliability.

Scrubber Tail Gas Treatment Cabinets

Scrubber tail gas treatment cabinets are integral for managing exhaust gases from BSGS. These systems neutralize and remove toxic, corrosive, or environmentally harmful byproducts before release. Wet scrubbers use liquid solutions to capture and neutralize acidic or reactive gases, while dry scrubbers employ chemical media to adsorb or react with hazardous compounds. Advanced designs incorporate real-time monitoring to optimize efficiency and ensure compliance with environmental regulations, such as EPA standards. These cabinets reduce emissions, protect equipment, and safeguard personnel and the environment.

BSGS gas cabinets and scrubber tail gas treatment cabinets work together to deliver high-purity gases safely and sustainably. Their advanced design and monitoring capabilities ensure operational efficiency, safety, and environmental compliance in high-stakes industrial applications.

Technical Data

| Model | JW-300-BSGS |

| Specification | W800*D633*H2172 |

| Special gas cabinet size | Control power supply: 220VAC, 50HZ, 500W, heating power supply: 220VAC, 50HZ, 1-6KW |

| Control cabinet power supply | PN2,1/4”MVCR |

| Purge | HPN2,1/4”MVCR |

| High pressure holding | GN2.1/4” MVCR |

| Vacuum | 1/2” MVCR |

| VENT drain pipe | CDA driver, 1/4″ SWG |

| Pneumatic air source | OD 150MM, silane 810m/hr; others 204m3/hr |

| Cabinet ventilation | Automatic switching, automatic purging, explosion-proof and anti-leaving cabinet, explosion-proof self-locking door, explosion-proof glass observation window, leakage alarm, remote cut-off, negative pressure alarm |

| Operation interface | 10″ color touch screen |

Optional

*UV/IR Flame Detector

*Cylinder Shutboy

*Panel heating

*Ethernet communication module

*Weight Scale

*Excess Flow Switch