Scrubber Tail Gas Treatment Cabinet Waste Gas Treatment Wet Scrubber Exhaust Gas Treatment Spray Tower

Scrubber Tail Gas Treatment Cabinet Waste Gas Treatment Wet Scrubber Exhaust Gas Treatment Spray Tower Gas Scrubbing Systems For Drying And Cleaning Processes

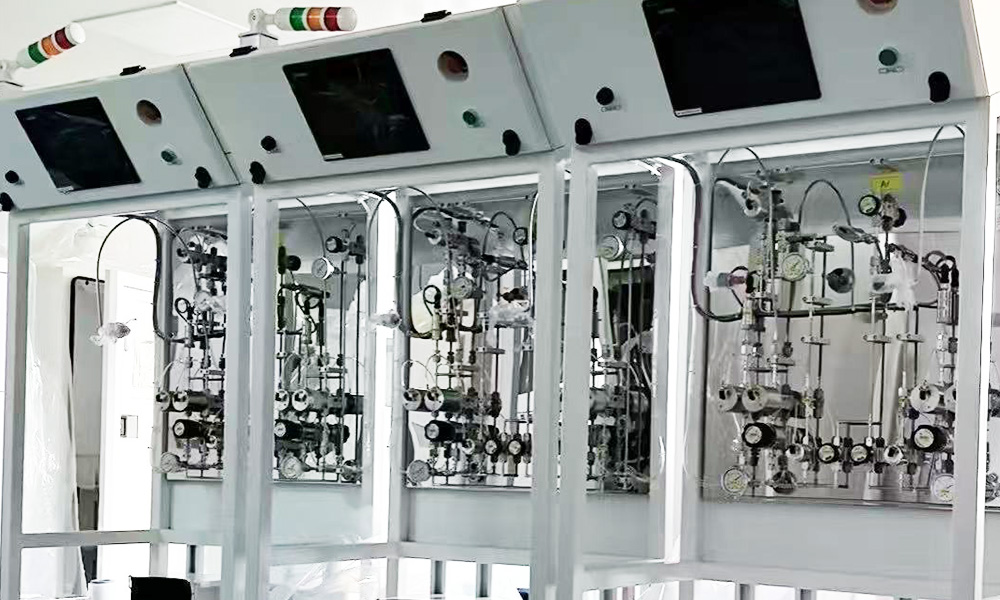

Scrubber tail gas treatment systems are specialized equipment designed to remove pollutants and harmful gases from industrial exhaust streams, ensuring compliance with environmental regulations and improving air quality. These systems are critical in industries such as chemical manufacturing, pharmaceuticals, and power generation, where drying and cleaning processes generate hazardous emissions.

A scrubber tail gas treatment cabinet integrates gas scrubbing technology to capture and neutralize contaminants like particulate matter, volatile organic compounds (VOCs), and acidic gases (e.g., SO₂, HCl). The system typically consists of a compact, enclosed cabinet housing key components: a scrubbing chamber, liquid spray nozzles, packing media, and exhaust fans. The contaminated gas passes through the scrubbing chamber, where it contacts a liquid solution (often water or a chemical absorbent) that traps or chemically neutralizes pollutants. The cleaned gas is then released, while the contaminated liquid is collected for treatment or disposal.

For drying processes, scrubbers remove moisture-laden gases and fine particulates generated during material processing. In cleaning processes, they eliminate chemical residues and odors, ensuring safe working environments. The cabinet design optimizes space, making it suitable for facilities with limited room, and often includes automated controls for efficient operation and monitoring.

Key benefits include high pollutant removal efficiency (up to 99% for some contaminants), reduced environmental impact, and compliance with stringent emission standards. Regular maintenance, such as cleaning nozzles and replacing packing media, ensures consistent performance. Advanced systems may incorporate energy-saving features or recover valuable byproducts from the gas stream.

In summary, scrubber tail gas treatment cabinets are essential for managing emissions in drying and cleaning processes. They provide a reliable, compact solution for industries aiming to minimize environmental footprints while maintaining operational efficiency and regulatory compliance.

Technical Data

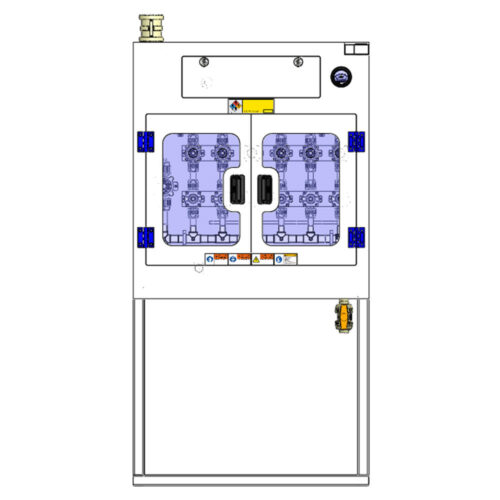

| Model | JW-FTB-C |

| Physical dimension | FT-BOX: W700*D460*H246 Can be specially customized according to user requirements |

| Control cabinet power supply | The electronic control part of TBOX/FTBOX can be connected with the factory central control system |

| Waste outlet | Drain,PP DN20 Fusion Socket |

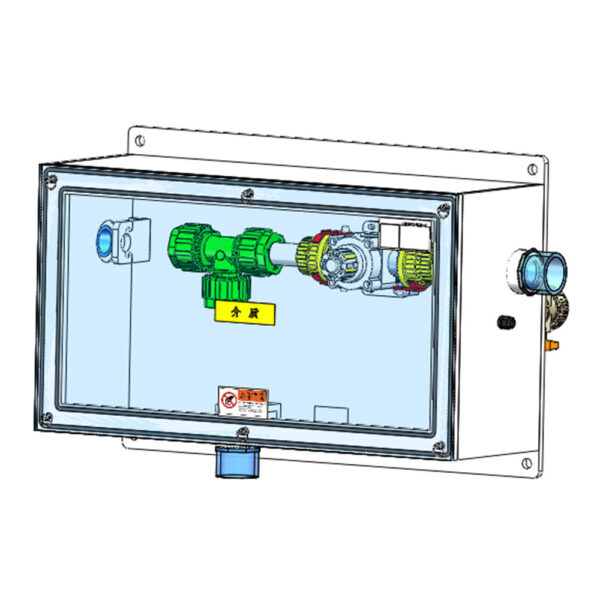

| Standard equipment | PP shell+transparent PVC observation window+PFA internal pipe valve components, leakage alarm, |

Optional

*Door Sensor