Integrated Gas System (IGS) Modular Integrated Gas Systems (TMS) Integrated Gas Supply System For Semiconductor And Laboratory

Integrated Gas System (IGS) Modular Integrated Gas Systems (TMS) Integrated Gas Supply System For Semiconductor And Laboratory

Shenzhen Jewellok Technology Co., Ltd. specializes in specialty gas pipeline engineering, laboratory gas pipeline engineering, specialty gas pipeline engineering construction, and gas pipeline engineering installation. We are a specialty gas pipeline engineering installation company that undertakes laboratory specialty gas pipeline engineering manufacturers, scrubber exhaust gas treatment system engineering, secondary gas distribution pipelines, high-purity gas pipelines, gas pressure reducing valves, gas busbars, gas proportioners, purifiers, specialty gas cabinets, busbars, distribution cabinets, VMB cabinets, VDB cabinets, VDP cabinets, BSGS systems, exhaust gas treatment equipment, etc.

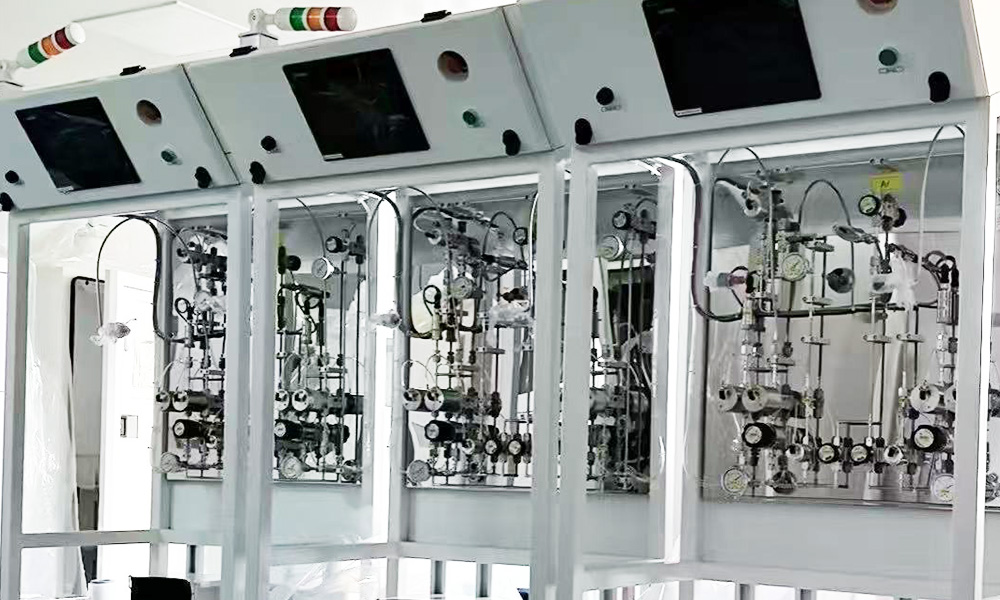

Integrated Gas Systems (IGS) are critical for delivering high-purity gases in semiconductor manufacturing and laboratory environments. These systems ensure precise, safe, and efficient gas delivery for processes like wafer fabrication, chemical vapor deposition, and analytical testing. IGS integrates components such as gas cylinders, regulators, valves, and monitoring systems into a cohesive setup, minimizing contamination risks and ensuring operational reliability.

Modular Integrated Gas Systems (TMS) enhance IGS by offering a flexible, scalable design. TMS allows for easy configuration and expansion to meet specific process requirements. Its modular nature simplifies installation, maintenance, and upgrades, reducing downtime in semiconductor fabs and labs. Each module can handle different gases, pressures, or flow rates, enabling customization while maintaining safety and purity standards. TMS is particularly valued in dynamic environments where process needs evolve rapidly.

The Integrated Gas Supply System is the backbone of gas management in these settings. It encompasses gas storage, purification, distribution, and monitoring, ensuring uninterrupted supply to tools and experiments. For semiconductors, it supports processes requiring ultra-high-purity gases like nitrogen, argon, or hydrogen, where even trace contaminants can ruin yields. In laboratories, it facilitates precise gas delivery for analytical instruments like gas chromatographs.

These systems prioritize safety with features like leak detection, pressure regulation, and automated shutoffs. They also comply with strict industry standards, such as SEMI regulations for semiconductors. By integrating advanced sensors and controls, IGS and TMS enable real-time monitoring, ensuring optimal performance and traceability. Their compact designs save space, critical in cleanrooms, while reducing operational costs through efficient gas usage. Together, IGS, TMS, and integrated gas supply systems are vital for precision, safety, and efficiency in high-tech applications.

Technical Data

| Model | JW-300-BSGS |

| Specification | W800*D633*H2172 |

| Special gas cabinet size | Control power supply: 220VAC, 50HZ, 500W, heating power supply: 220VAC, 50HZ, 1-6KW |

| Control cabinet power supply | PN2,1/4”MVCR |

| Purge | HPN2,1/4”MVCR |

| High pressure holding | GN2.1/4” MVCR |

| Vacuum | 1/2” MVCR |

| VENT drain pipe | CDA driver, 1/4″ SWG |

| Pneumatic air source | OD 150MM, silane 810m/hr; others 204m3/hr |

| Cabinet ventilation | Automatic switching, automatic purging, explosion-proof and anti-leaving cabinet, explosion-proof self-locking door, explosion-proof glass observation window, leakage alarm, remote cut-off, negative pressure alarm |

| Operation interface | 10″ color touch screen |

Features:

Functionality: Specially designed for flammable, toxic, or corrosive gases such as hydrogen, ammonia, and chlorine.

Applications: Critical environments such as semiconductor fabs, special gas labs, and research institutions with stringent safety requirements.

Control Method: Fully automated with PLC control, including gas sensors, exhaust fan interlocks, fire control systems, and access control.

Safety Features:

1)Explosion-proof electrical components

2)Ventilation and exhaust control

3)Combustible/toxic gas detection and alarm interlocks

4)Emergency shut-off valves

5)Optional fire suppression or gas purification modules

Optional

*UV/IR Flame Detector

*Cylinder Shutboy

*Panel heating

*Ethernet communication module

*Weight Scale

*Excess Flow Switch

Jewellok specializes in fully automatic and semi-automatic GC gas cabinets, BSGS gas cabinets, VMB gas cabinets, TMA gas cabinets, Scrubber tail gas treatment cabinets, gas distribution cabinets, VDB gas cabinets, and VDP gas cabinets, suitable for gases such as SiH4, NF3, NH3, N2O, and HCI.