Blog

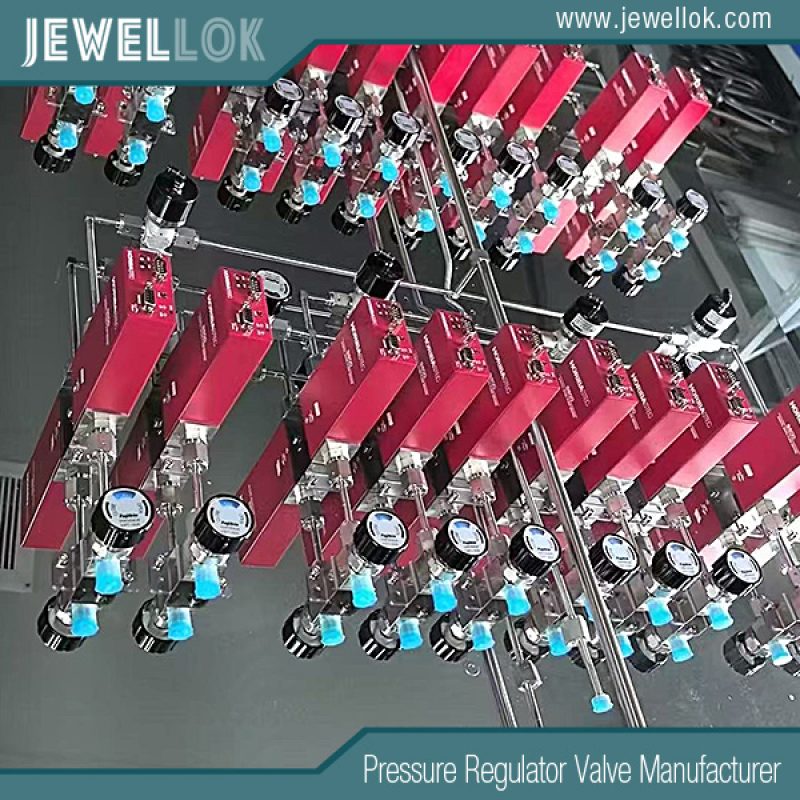

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Gas Changeover Manifold: An Essential Component in Modern Gas Supply Systems

- Pressure Regulator Valve Manufacturer

- argon gas manifold system, argon manifold system, Automatic Changeover Gas Manifold, automatic changeover manifold, automatic gas switchover manifold system, Best Gas Switchover Manifolds for Gas Management, best manifold valve manufacturers in india, custom hydraulic manifolds, gas cylinder changeover manifold, gas cylinder changeover manifold malaysia, gas manifold system, gas switchover manifold, High Pressure Nitrogen Gas Manifold System, how does a gas changeover valve work, hydrogen valve manifold, nitrogen gas manifold system, pressure valve manifold manufacturers, semi-automatic gas switchover manifold panel system, stainless steel manifold manufacturers, Stainless Steel Semi-automatic Changeover Gas Manifold, welding gas manifold system

- No Comments

Gas Changeover Manifold: An Essential Component in Modern Gas Supply Systems

Introduction

In the realm of gas supply and distribution, ensuring a continuous and uninterrupted flow of gas is paramount, especially in critical applications such as medical facilities, industrial processes, and laboratory environments. The gas changeover manifold serves as a pivotal device in achieving this reliability. A gas changeover manifold is an automated or semi-automated system designed to switch between multiple gas cylinders or sources seamlessly when the primary supply depletes. This prevents downtime, maintains pressure stability, and enhances operational efficiency.

The concept of the gas changeover manifold has evolved significantly since its inception in the mid-20th century, driven by advancements in automation and safety standards. Today, these manifolds are integral to sectors where gas purity, pressure consistency, and safety are non-negotiable. This article delves into the technical intricacies of gas changeover manifolds, exploring their design, functionality, applications, and maintenance. By understanding the gas changeover manifold’s role, engineers and technicians can better appreciate its contribution to modern infrastructure.

At its core, a gas changeover manifold consists of regulators, valves, sensors, and piping that monitor and control gas flow from two or more cylinders. When the pressure in the active cylinder drops below a predetermined threshold, the manifold automatically activates the reserve cylinder, alerting operators to replace the empty one. This mechanism not only ensures continuity but also minimizes human intervention, reducing the risk of errors.

Components and Design of Gas Changeover Manifolds

A typical gas changeover manifold is engineered with precision to handle various gases, including oxygen, nitrogen, argon, and specialty gases like helium or carbon dioxide. The design must account for gas properties such as corrosiveness, flammability, and pressure requirements.

Key components include:

– Inlet Connections: These are the points where gas cylinders connect to the manifold. Usually, they feature high-pressure flexible hoses or pigtails equipped with check valves to prevent backflow and contamination.

– Pressure Regulators: Dual-stage regulators are common in gas changeover manifolds to step down high cylinder pressures (often exceeding 200 bar) to usable levels (typically 4-10 bar). The first stage reduces pressure significantly, while the second fine-tunes it for the application.

– Changeover Valve or Switch: This is the heart of the gas changeover manifold. In automatic models, it’s often a solenoid or pneumatically actuated valve that shifts flow based on pressure sensors. Manual versions require operator intervention but are simpler and cost-effective for less critical uses.

– Pressure Gauges and Sensors: Analog or digital gauges display inlet and outlet pressures. Advanced sensors integrate with control systems to trigger alarms or automated switches. For instance, differential pressure switches detect when the primary side’s pressure falls below the secondary.

– Outlet Manifold and Piping: Downstream from the changeover mechanism, a distribution manifold directs gas to end-users. Materials like stainless steel or brass are chosen for compatibility with the gas to avoid reactions.

– Safety Devices: Relief valves, burst discs, and filters are incorporated to protect against overpressure or impurities.

Design considerations for a gas changeover manifold emphasize modularity and scalability. For example, a basic two-cylinder setup can expand to multi-bank systems with dozens of cylinders, using headers to group them. Computational fluid dynamics (CFD) simulations are often employed during design to optimize flow paths and minimize pressure drops.

In terms of standards, gas changeover manifolds comply with regulations like ISO 7396 for medical gases or CGA (Compressed Gas Association) guidelines in North America. Materials must be non-reactive; for oxygen, oxygen-compatible lubricants are mandatory to prevent ignition risks.

Working Principle of Gas Changeover Manifolds

The operational principle of a gas changeover manifold revolves around pressure monitoring and automated switching. Let’s break it down step-by-step.

Initially, two or more gas cylinders are connected: one as primary (active) and others as reserves. The manifold’s control unit sets the primary side to supply gas. As gas is consumed, the pressure in the primary cylinder decreases.

Pressure transducers continuously monitor both sides. When the primary pressure reaches a setpoint (e.g., 5 bar), the system activates the changeover. In an automatic gas changeover manifold, this involves:

- Closing the valve on the depleted side.

- Opening the valve on the reserve side.

- Signaling an alarm (visual, audible, or digital) to indicate the need for cylinder replacement.

During the switch, a brief overlap or bleed-down ensures no interruption in supply. Some advanced models use proportional control valves for smoother transitions, maintaining outlet pressure within ±0.1 bar.

For semi-automatic variants, the switch is manual, but indicators guide the operator. In fully automatic systems, integration with PLC (Programmable Logic Controllers) allows remote monitoring via SCADA (Supervisory Control and Data Acquisition) systems.

Mathematically, the switching logic can be represented as:

If P_primary < P_threshold and P_reserve > P_minimum, then initiate changeover.

Where P_primary is the pressure on the active side, P_threshold is the switch point, and P_reserve ensures the backup is viable.

Efficiency is enhanced by features like economizers, which allow partial use of the depleted cylinder’s remaining gas before full switchover, optimizing resource utilization.

Types of Gas Changeover Manifolds

Gas changeover manifolds are classified based on automation level, gas type, and configuration.

– Manual Gas Changeover Manifolds: These require human intervention to switch cylinders. They are economical and suitable for low-demand applications like small labs. A simple lever or knob changes the flow path.

– Semi-Automatic Manifolds: Feature automatic detection but manual reset. Once the primary depletes, an alarm sounds, and the operator manually switches while the system maintains flow from a buffer.

– Fully Automatic Manifolds: No manual input needed; the system handles everything. Ideal for 24/7 operations, such as hospitals where oxygen supply cannot falter.

By gas type:

– Inert Gas Manifolds: For nitrogen or argon, focusing on purity maintenance.

– Medical Gas Manifolds: Compliant with stringent health standards, often with dual lines for redundancy.

– Industrial Gas Manifolds: Robust designs for high-volume use, like in welding or chemical processing.

Configuration-wise, wall-mounted, cabinet-enclosed, or floor-standing models exist. Multi-stage manifolds handle cascading switches across banks, ensuring scalability.

Applications of Gas Changeover Manifolds

The versatility of gas changeover manifolds makes them indispensable across industries.

In healthcare, medical gas changeover manifolds supply oxygen, nitrous oxide, and medical air to operating rooms and ICUs. They ensure compliance with HTM 02-01 standards, preventing supply failures that could endanger lives.

Industrial applications include manufacturing, where manifolds manage shielding gases in welding or cutting processes. For instance, in automotive assembly, a gas changeover manifold maintains consistent argon flow for MIG welding, reducing defects.

Laboratories use them for analytical instruments like gas chromatographs, where precise pressure is crucial for accurate readings. In semiconductor fabrication, ultra-high purity manifolds handle specialty gases without contamination.

Other uses include food and beverage (CO2 for carbonation), pharmaceuticals (nitrogen for inerting), and even aquaculture (oxygen for fish farms).

Case studies highlight their impact: A hospital upgrading to an automatic gas changeover manifold reduced cylinder change incidents by 70%, enhancing patient safety.

Installation and Maintenance

Proper installation of a gas changeover manifold is critical for performance and safety.

Site preparation involves assessing space, ventilation, and proximity to cylinders. Cylinders should be secured in racks, away from heat sources.

Installation steps:

- Mount the manifold securely.

- Connect inlet hoses, ensuring torque specifications to prevent leaks.

- Install regulators and calibrate gauges.

- Wire electrical components for automatic models.

- Pressure test the system per ASME standards.

Maintenance is ongoing. Daily checks include visual inspections for leaks and gauge readings. Monthly, clean filters and test alarms. Annually, overhaul valves and replace seals.

Predictive maintenance uses IoT sensors in modern gas changeover manifolds to monitor wear, predicting failures via data analytics.

Common issues: Leakage from fittings (resolved by torque wrenches) or sensor drift (calibrated with certified tools).

Safety Considerations in Gas Changeover Manifolds

Safety is paramount in gas handling. Gas changeover manifolds incorporate multiple safeguards.

– Overpressure Protection: Relief valves vent excess pressure.

– Backflow Prevention: Check valves stop reverse flow.

– Material Compatibility: Avoids reactions, e.g., no copper with acetylene.

– Alarm Systems: For low pressure or failures.

Operators must be trained in handling, with PPE like gloves and goggles. In flammable gas setups, explosion-proof enclosures are used.

Regulatory compliance, such as OSHA guidelines, mandates regular audits.

Advantages and Disadvantages

Advantages of gas changeover manifolds:

– Continuous supply minimizes downtime.

– Automation reduces labor costs.

– Enhanced safety through built-in features.

– Scalability for growing needs.

Disadvantages:

– Initial cost can be high for automatic models.

– Requires skilled maintenance.

– Potential for electronic failures in harsh environments.

Despite drawbacks, benefits outweigh them in most scenarios.

Future Trends in Gas Changeover Manifolds

Emerging technologies are transforming gas changeover manifolds. IoT integration enables remote monitoring and AI-driven predictive maintenance. Sustainable designs focus on energy-efficient components and recyclable materials.

Hydrogen economy demands manifolds for fuel cell applications, with enhanced sealing for the small-molecule gas.

Miniaturization for portable uses, like in drones or medical devices, is on the rise.

Conclusion

The gas changeover manifold stands as a cornerstone of reliable gas supply systems, blending engineering precision with practical utility. From its components and principles to diverse applications, it exemplifies innovation in fluid control. As industries evolve, the gas changeover manifold will continue to adapt, ensuring seamless operations in an increasingly demanding world.

For more about gas changeover manifold: an essential component in modern gas supply systems, you can pay a visit to Jewellok at https://www.jewellok.com/product-category/gas-changeover-manifold/ for more info.

Recent Posts

Five Key Considerations When Choosing a TMA Gas Changeover Manifold

How to Prevent Contamination in High Purity Xenon Gas Systems

Regulators for High Purity Krypton in Laser and Lighting Applications

Tags

Recommended Products

-

Fully Automated Gas Cabinet For Precise UHP Gas Delivery And High Purity Gas Delivery Systems JW-300-GC

-

FT-BOX JW-FTB-C Valve Manifold Panels And Boxes With High Purity Configurable Systems

-

774L Stainless Steel UHP Fittings Butt Weld Bulkhead Union For High Flow Special Gas Fluid

-

Fully Automated Gas Cabinet Gas Rack Gas Delivery Systems JW-300-GR

-

High Purity High Pressure Stainless Steel Needle Valve Natural Gas Flow Control Valve JNV Series

-

JF Series In-Line Gas Filters | High Purity High Precision High Flow Semiconductor Gas Filter Gas Filtration & Purification

-

Ultra High Purity Oxygen Pressure Gauge For Semiconductor Gases JG Series Pressure Instruments For Semiconductor Manufacturing

-

Semi Automatic Gas Cabinet Gas Panels High Purity Gas Delivery Systems JW-200-GC