Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Specialty Gas Regulators: Precision Control in High-Purity Gas Delivery Systems

- Pressure Regulator Valve Manufacturer

- Best specialty gas regulators, Biotech gas delivery systems, Calibration gas regulators, CGA gas regulator fittings, Chemical vapor deposition regulators, Corrosion-resistant gas regulators, Electronic gas pressure regulators, Environmental monitoring gas regulators, Gas chromatography regulators, Gas control systems, Gas flow control, gas pressure regulators, Gas regulators for aerospace, Gas regulators for analytical chemistry, Gas regulators for food industry, Gas regulators for mass spectrometry, Gas regulators for pharmaceutical applications, Hastelloy gas regulators, High Purity Gas Regulators, High-flow gas regulators for industry, High-purity gas regulators for laboratory, High-quality gas pressure regulators, Hydrogen fuel cell regulators, Low-pressure specialty gas regulators, Pharmaceutical gas control systems, PID control gas regulators, Precision gas regulators, pressure control valves, Regulators for inert gas delivery, Semiconductor gas regulators, specialty gas equipment, Specialty gas regulator suppliers, Specialty Gas Regulators, Specialty gas regulators for hydrogen, Specialty gas regulators for semiconductor, Stainless steel 316L regulators, Stainless steel gas regulators, Top gas regulator manufacturers, Two-stage gas regulators for chromatography, Ultra High Purity Regulators

- No Comments

Specialty Gas Regulators: Precision Control in High-Purity Gas Delivery Systems

Introduction

In the realm of industrial and scientific applications, the precise control of gas flow and pressure is paramount. Specialty gas regulators stand at the forefront of this technology, ensuring that high-purity gases are delivered safely and accurately to various processes. These devices are engineered to handle gases that require exceptional purity levels, often exceeding 99.999%, and are critical in sectors such as semiconductor manufacturing, pharmaceuticals, and analytical chemistry. Unlike standard gas regulators used for common applications like welding or HVAC systems, specialty gas regulators are designed with advanced features to prevent contamination, maintain stability, and accommodate corrosive or reactive gases.

The evolution of specialty gas regulators has been driven by the increasing demand for precision in modern industries. As processes become more sophisticated, the need for regulators that can deliver gases at ultra-low pressures or in minute quantities has grown. This article delves into the technical aspects of specialty gas regulators, exploring their design, functionality, types, applications, and best practices for selection and maintenance. By understanding these components, engineers and technicians can optimize system performance, enhance safety, and reduce operational costs.

Understanding Specialty Gas Regulators

Specialty gas regulators are pressure-reducing devices specifically tailored for handling specialty gases, which include inert gases like helium and argon, reactive gases such as chlorine and ammonia, and ultra-high purity gases used in calibration and research. The primary function of a regulator is to reduce the high pressure from a gas cylinder or supply line to a lower, usable pressure while maintaining a consistent output.

At their core, these regulators consist of several key components: the inlet connection, pressure-reducing mechanism (often a diaphragm or piston), outlet connection, gauges for monitoring inlet and outlet pressures, and safety features like relief valves. The diaphragm, typically made from materials like stainless steel or elastomers, isolates the gas from the mechanical parts, preventing contamination. In specialty applications, the regulator must minimize dead space—areas where gas can stagnate and lead to impurities.

One distinguishing feature is their compatibility with high-purity standards. For instance, regulators for semiconductor gases must comply with SEMI (Semiconductor Equipment and Materials International) standards, ensuring leak-tight integrity and minimal particle generation. The internal surfaces are often electropolished to achieve a smoothness that reduces adhesion of contaminants. Flow rates can range from as low as 0.1 liters per minute (LPM) to several hundred LPM, depending on the model.

Types of Specialty Gas Regulators

Specialty gas regulators come in various configurations to suit different needs. The most common types include single-stage, two-stage, and line regulators.

Single-stage regulators reduce pressure in one step and are suitable for applications where the inlet pressure remains relatively constant. They are simpler and more cost-effective but can experience outlet pressure fluctuations as the cylinder pressure drops. For example, in laboratory settings where short-term use is common, a single-stage regulator for nitrogen might suffice.

Two-stage regulators, on the other hand, provide greater stability by reducing pressure in two sequential steps. The first stage drops the pressure to an intermediate level, and the second stage fine-tunes it to the desired output. This design minimizes the “supply pressure effect,” where outlet pressure varies with inlet changes. They are ideal for critical applications like gas chromatography, where consistent pressure is essential for accurate results.

Line regulators are installed in gas distribution systems downstream from the primary regulator. They maintain pressure in pipelines and are often used in manifold systems for continuous supply. Specialized variants include high-flow regulators for bulk gas delivery and low-pressure regulators for vacuum-assisted processes.

Additionally, there are corrosion-resistant regulators for handling aggressive gases. These feature bodies made from materials like Monel or Hastelloy, which resist chemical attack. Electronic regulators integrate sensors and controls for automated pressure adjustment, linking to PLC systems for real-time monitoring.

Working Principles of Specialty Gas Regulators

The operation of a specialty gas regulator relies on a balance of forces. In a diaphragm-type regulator, gas enters the inlet at high pressure and pushes against a spring-loaded diaphragm. The diaphragm is connected to a poppet valve that controls the flow. When the outlet pressure drops below the set point, the spring force overcomes the gas pressure on the diaphragm, opening the valve to allow more gas in. Conversely, if the outlet pressure rises, the diaphragm moves to close the valve.

Mathematically, this can be described by the force balance equation: F_spring = P_outlet * A_diaphragm + F_friction, where F_spring is the spring force, P_outlet is the outlet pressure, and A_diaphragm is the diaphragm area. Friction forces are minimized in specialty designs through low-friction materials.

For piston-type regulators, a piston replaces the diaphragm, offering higher pressure capabilities but potentially introducing more contamination if not sealed properly. In high-purity models, pistons are often Teflon-coated.

Flow dynamics play a crucial role. The regulator must handle laminar or turbulent flow regimes without introducing vibrations or pressure spikes. Droop, the decrease in outlet pressure with increasing flow, is a key performance metric. Specialty regulators aim for low droop, often less than 1 psi per 100 psi change in inlet pressure.

Safety mechanisms include burst disks that rupture at excessive pressures and integral filters to capture particles. In electronic versions, feedback loops use PID (Proportional-Integral-Derivative) control to maintain setpoint accuracy within 0.1%.

Materials and Construction Considerations

The choice of materials in specialty gas regulators is critical to ensure compatibility, durability, and purity. Stainless steel 316L is the standard for bodies and wetted parts due to its corrosion resistance and low outgassing. For ultra-high purity, surfaces are passivated or electropolished to Ra values below 10 microinches.

Seals and diaphragms vary by gas type. For inert gases, Viton or Buna-N elastomers suffice, but for reactive gases, Kalrez or Chemraz perfluoroelastomers are used for their chemical inertness. Metal-to-metal seals eliminate organic materials altogether in some designs, reducing permeation risks.

Construction techniques include orbital welding to minimize crevices and helium leak testing to verify integrity down to 10^-9 atm-cc/sec. Regulators for cryogenic gases incorporate insulated components to prevent frost buildup.

In terms of standards, regulators must meet CGA (Compressed Gas Association) connection specifications, ensuring the correct fitting for each gas to prevent mix-ups. For example, CGA-580 for nitrogen and CGA-350 for hydrogen.

Applications in Various Industries

Specialty gas regulators find extensive use across multiple sectors. In the semiconductor industry, they control dopant gases like arsine and phosphine in CVD (Chemical Vapor Deposition) processes, where even trace impurities can ruin wafer yields.

In pharmaceuticals, regulators handle gases for sterilization, such as ethylene oxide, or for inert blanketing in drug formulation to prevent oxidation. Analytical laboratories rely on them for calibration gases in mass spectrometry and chromatography, ensuring ppm-level accuracy.

The aerospace sector uses them for fuel cell testing with hydrogen and oxygen, while environmental monitoring employs regulators for trace gas analysis in air quality stations. In food and beverage, CO2 regulators maintain carbonation levels in bottling lines.

Emerging applications include hydrogen fuel cells, where regulators manage high-pressure storage tanks, and biotech for cell culture incubators requiring precise CO2/O2 mixtures.

Selection Criteria for Specialty Gas Regulators

Selecting the right regulator involves several factors. First, gas compatibility: ensure materials won’t react or degrade. Pressure requirements dictate the type—high inlet pressures favor piston designs.

Flow rate needs match the application’s demand; oversized regulators can lead to instability. Purity level influences the choice of electropolished vs. standard finishes.

Environmental conditions, like temperature extremes or hazardous locations, require ATEX or FM approvals for explosion-proof models.

Budget considerations balance initial cost with long-term reliability. Consulting manufacturer data sheets for Cv (flow coefficient) values helps predict performance.

Maintenance and Safety Practices

Proper maintenance extends regulator life and ensures safety. Regular inspections check for leaks using soap solutions or electronic detectors. Diaphragms should be replaced per schedule, typically every 1-2 years for high-use applications.

Cleaning involves purging with inert gas and avoiding solvents that could contaminate. Storage in clean, dry environments prevents corrosion.

Safety protocols include using regulators only for intended gases, installing in ventilated areas, and training personnel on emergency shutdowns. Overpressure protection via relief valves is mandatory.

Common issues like creeping (slow pressure rise) indicate diaphragm failure, while chattering suggests improper sizing.

Future Trends in Specialty Gas Regulators

Advancements in IoT integration allow remote monitoring and predictive maintenance. Smart regulators with embedded sensors can alert to anomalies via apps.

Materials research focuses on nanocomposites for lighter, stronger components. Sustainability drives designs for recyclable materials and lower energy use.

As hydrogen economy grows, regulators for 700 bar systems are emerging, incorporating advanced composites.

Miniaturization for portable analyzers and integration with microfluidics for lab-on-chip devices represent cutting-edge developments.

Conclusion

Specialty gas regulators are indispensable for precision gas handling in demanding applications. Their sophisticated design ensures purity, stability, and safety, underpinning advancements in technology and science. By selecting, maintaining, and innovating these devices, industries can achieve higher efficiency and reliability. As demands evolve, so too will these regulators, continuing to play a vital role in our technological landscape.

For more about specialty gas regulators: precision control in high-purity gas delivery systems, you can pay a visit to Jewellok at https://www.jewellok.com/specialty-gas-regulator-manual-a-comprehensive-guide/ for more info.

Recent Posts

How to Safely Operate a TMA Gas Changeover Manifold

How to Choose an Ultra High Purity CO2 Pressure Reducing Valve

The Top High-Pressure Argon Gas Regulator Manufacturer in China

How to Choose a Gas Cylinder Manifold System

Tags

Recommended Products

-

Flow Control Stainless Steel Low Pressure Manual Diaphragm Valve For High Purity And Ultra High Purity Gases

-

775L Bulkhead Reducing Union | Stainless Steel High Purity Double Ferrule Bulkhead Reducing Unions

-

Semi Automatic Oxygen Nitrogen Helium Argon Gas Changeover Manifold Manual Gas Changeover Manifold Panel For Gas Cylinders

-

High Purity High Pressure 316 Stainless Steel Ball Valves JBV1 Series From High Pressure Ball Valve Manufacturer And Supplier In China

-

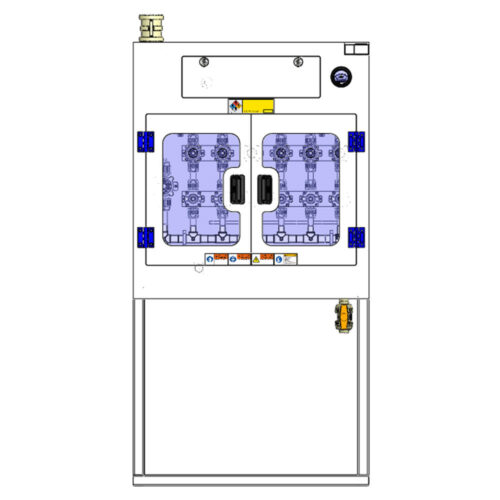

High Purity Configurable Systems VMB Valve Manifold Box JW-200-VMB-C & JW-100-VMB-C

-

Fully Automated Gas Cabinet Gas Rack Gas Delivery Systems JW-300-GR

-

764L Stainless Steel Union Tee High Purity Fitting Union Tee Reducing Tubing Connection

-

Scrubber Gas Cabinet Scrubber Tail Gas Treatment Cabinet Vent Gas Scrubber System Heat-Filter Burn Box Gas Scrubber/Abatement System