Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

You Can Understand the Components of a Gas Changeover Manifold in Seconds

- Pressure Regulator Valve Manufacturer

- 0-10 psi air pressure regulator with gauge, 1 1 2 gas pressure regulator, 1 2 gas regulator, 1 2 propane regulator, 1/2 gas pressure regulator, 316L Stainless Steel Gas Pressure Regulators, 316l stainless steel pressure regulator, adjustable air pressure regulator, adjustable hydraulic pressure regulator, adjustable propane pressure regulator, air compressor pressure regulator, Air pressure Regulator for Pneumatic, Air Pressure Regulator Manufacturer, argon gas changeover manifold, argon gas changeover manifold supplier, argon gas changeover manifold supplier philippines, Auto Gas Changeover Manifold System, Automatic gas changeover manifold, best gas changeover manifold, Best gas changeover manifold for laboratories, best gas changeover manifold philippines, best gas changeover manifold supplier, best gas changeover manifold supplier philippines, BURSAN Gas Changeover Manifold, CO2 gas changeover manifold, Components of a gas changeover manifold, gas changeover manifold, Gas changeover manifold design, Gas changeover manifold for cleanroom, gas changeover manifold for hospital, Gas changeover manifold for industrial applications, gas changeover manifold for laboratories, Gas changeover manifold for manufacturing, gas pressure regulator, justable propane pressure regulator, pressure regulator, Stainless Steel Gas Pressure Regulators

- No Comments

You Can Understand the Components of a Gas Changeover Manifold in Seconds

Gas changeover manifolds are critical systems in industries and facilities that depend on a continuous supply of compressed gases, such as hospitals, laboratories, chemical plants, welding operations, and semiconductor manufacturing. These manifolds ensure seamless switching between gas cylinder banks when one depletes, preventing interruptions that could lead to operational downtime, safety hazards, or compromised processes. The effectiveness of a gas changeover manifold hinges on its components, each designed to perform specific functions, from pressure regulation to safety monitoring. Understanding these components is essential for engineers, facility managers, and procurement specialists to select, install, and maintain manifolds that meet their operational and safety requirements.

This 2000-word article provides a comprehensive exploration of the components of a gas changeover manifold, detailing their functions, types, materials, importance, and applications in industrial and medical settings. We’ll also cover installation considerations, maintenance practices, regulatory standards, emerging trends, and practical tips for selecting manifolds. By the end, you’ll have a thorough understanding of how these components work together to ensure reliable and safe gas delivery.

What Is a Gas Changeover Manifold?

A gas changeover manifold is a centralized system that connects multiple gas cylinders or tanks to a single outlet line, enabling automatic or manual switching between primary and reserve sources to maintain uninterrupted gas flow. It is used for gases like oxygen (medical and industrial), nitrogen (inerting and labs), argon (welding), hydrogen (energy), and CO2 (beverage and manufacturing). The manifold monitors pressure levels and switches to the reserve bank when the primary bank depletes, ensuring continuous supply without manual intervention in automated systems.

The manifold’s components work in harmony to regulate flow, maintain pressure, prevent contamination, and ensure safety. Each component is engineered for durability, compatibility with specific gases, and compliance with standards like NFPA 55, CGA P-1, and ISO 7396. Below, we dive into the key components, their roles, and their significance in industrial and medical applications.

Key Components of a Gas Changeover Manifold

A gas changeover manifold comprises several critical components, each contributing to its functionality, safety, and reliability. Here’s a detailed breakdown:

- Cylinder Headers

- Function: Headers connect multiple gas cylinders into a single bank, allowing simultaneous use of several cylinders to meet high flow demands.

- Description: A header is a rigid or flexible manifold pipe with multiple inlet ports, each connected to a cylinder via a pigtail. Headers are typically organized into primary and reserve banks.

- Materials: Stainless steel for corrosive gases (e.g., chlorine), brass for non-corrosive gases (e.g., nitrogen), or aluminum for lightweight setups.

- Importance: Enables scalability by accommodating multiple cylinders, reducing the frequency of changes in high-demand settings like chemical plants.

- Applications: Used in hospitals for oxygen banks or in welding shops for argon supply.

- Example: Pattons Medical manifolds feature headers with up to 10 cylinder connections, compliant with NFPA 99.

- Pigtails (Flexible Hoses)

- Function: Connect individual cylinders to the header, allowing gas to enter the manifold system.

- Description: Flexible hoses with fittings (e.g., CGA-compliant) to match cylinder valves. They often include check valves to prevent backflow.

- Materials: Stainless steel for high-pressure or corrosive gases, Teflon-lined for UHP applications, or reinforced rubber for low-pressure gases.

- Importance: Ensures safe and leak-free connections, with flexibility to accommodate cylinder placement variations.

- Applications: Critical in laboratories for UHP gases like helium to prevent contamination.

- Example: Middlesex Gases’ pigtails use stainless steel braiding for durability.

- Isolation Valves

- Function: Allow individual cylinders or banks to be shut off for replacement or maintenance without stopping the entire system.

- Description: Manual or automatic valves (ball or needle) installed at each cylinder connection or header inlet.

- Materials: Stainless steel or brass, with PTFE or Viton seals for gas compatibility.

- Importance: Enhances safety by isolating depleted cylinders, preventing exposure to high-pressure gas during changes.

- Applications: Essential in hospitals for safe oxygen cylinder swaps.

- Example: Amico manifolds include ball valves for easy isolation, per NFPA standards.

- Pressure Sensors/Transducers

- Function: Monitor gas pressure in each bank to detect depletion and trigger changeover.

- Description: Electronic transducers or mechanical gauges that measure pressure (e.g., 0-3000 psi) and send signals to the control unit.

- Materials: Stainless steel or corrosion-resistant alloys for sensor housings.

- Importance: Ensures timely switching to prevent supply interruptions, critical in time-sensitive applications like semiconductor manufacturing.

- Applications: Used in automated manifolds for real-time pressure monitoring.

- Example: Genstar Technologies’ manifolds use high-accuracy transducers for precise detection.

- Changeover Valve/Switch

- Function: The core mechanism that switches gas flow from the primary to the reserve bank.

- Description: Can be a mechanical valve (pressure-differential type) or a solenoid valve in automatic systems. It activates when pressure sensors detect a low threshold.

- Materials: Stainless steel or brass, with robust seals to prevent leaks.

- Importance: Ensures seamless transition without flow disruption, vital for continuous processes like welding or medical gas delivery.

- Applications: Found in all manifold types, from manual to fully automatic.

- Example: Swagelok’s changeover valves offer low dead volume for UHP gases.

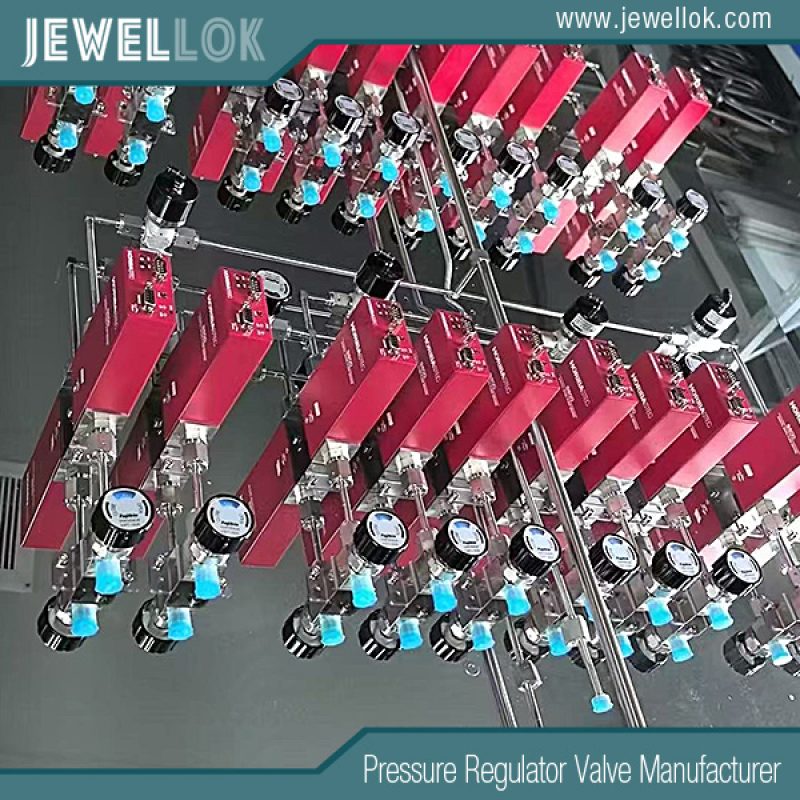

- Pressure Regulators

- Function: Reduce high cylinder pressure (e.g., 2000 psi) to a safe, usable level (e.g., 50-150 psi) for downstream equipment.

- Description: Single-stage or dual-stage regulators with diaphragms or pistons, often one per bank to maintain consistent outlet pressure.

- Materials: Stainless steel (316L for corrosive gases) or brass, with elastomer seals.

- Importance: Prevents equipment damage and ensures stable flow, critical in precise applications like gas chromatography.

- Applications: Used in chemical plants for nitrogen or hydrogen delivery.

- Example: Tescom regulators in manifolds ensure ±1 psi accuracy.

- Control Panel

- Function: Provides an interface for monitoring and controlling the manifold, including alarms and status indicators.

- Description: Includes digital or analog displays for pressure, LED indicators for bank status, and alarms (audible/visual) for low pressure or faults.

- Materials: Durable plastic or metal enclosures, often IP65-rated for dust and water resistance.

- Importance: Enhances operator awareness, reducing response time to issues like depletion or leaks.

- Applications: Critical in hospitals for 24/7 monitoring of oxygen manifolds.

- Example: Airgas manifolds feature digital panels with remote alarm capabilities.

- Safety Relief Valves

- Function: Vent excess pressure to prevent over-pressurization, which could cause cylinder rupture or system failure.

- Description: Spring-loaded valves or burst discs that open at a set pressure (e.g., 1.5 times working pressure) and reseat or rupture.

- Materials: Stainless steel or brass, with corrosion-resistant coatings.

- Importance: Protects against pressure spikes from temperature changes or regulator failures, crucial for flammable gases like hydrogen.

- Applications: Mandatory in high-pressure systems like hydrogen fuel cell plants.

- Example: Pattons Medical manifolds include NFPA-compliant relief valves.

- Check Valves

- Function: Prevent backflow of gas from one bank to another or from the outlet to the inlet.

- Description: One-way valves (ball or poppet) integrated into pigtails or headers.

- Materials: Stainless steel or brass, with elastomer seals.

- Importance: Avoids contamination or mixing of incompatible gases, reducing explosion or corrosion risks.

- Applications: Essential in semiconductor manufacturing for UHP gases.

- Example: CK Supply manifolds use check valves in pigtails.

- Filters

- Function: Remove impurities like dust, moisture, or particles from the gas stream.

- Description: Sintered metal or membrane filters, often in-line or at the outlet.

- Materials: Stainless steel for UHP systems, brass for general use.

- Importance: Maintains gas purity, preventing equipment damage or process contamination.

- Applications: Used in pharmaceutical production for sterile gases.

- Example: Jewell Instruments manifolds include 0.01-micron filters for high-purity applications.

- Piping and Fittings

- Function: Connect the manifold to downstream equipment.

- Description: Seamless or welded pipes with fittings (e.g., compression or threaded).

- Materials: Stainless steel for corrosive gases, copper for medical oxygen.

- Importance: Ensures leak-free delivery to end-use points.

- Applications: Found in all manifold installations, from welding to labs.

- Alarms and Remote Monitoring

- Function: Alert operators to low pressure, changeover events, or faults.

- Description: Audible buzzers, flashing LEDs, or digital alerts via SMS/email.

- Materials: Integrated into control panels.

- Importance: Ensures rapid response to issues, critical in hospitals or chemical plants.

- Applications: Used in fully automatic manifolds for real-time monitoring.

Importance of Each Component

Each component plays a specific role:

- Headers and pigtails enable scalability and safe cylinder connections.

- Isolation valves and check valves enhance maintenance safety and prevent contamination.

- Sensors and changeover valves ensure uninterrupted supply.

- Regulators and relief valves maintain safe pressure levels.

- Filters protect downstream equipment, while alarms provide operational awareness.

Together, they ensure reliability, safety, and efficiency.

Applications of Gas Changeover Manifolds

Manifolds are used in:

- Welding: Continuous argon/CO2 supply for defect-free welds.

- Chemical Processing: Nitrogen for inerting reactors.

- Semiconductors: UHP gases like silane for fabrication.

- Food and Beverage: CO2 for carbonation.

- Hospitals: Oxygen for patient care.

- Energy: Hydrogen for fuel cells.

These applications highlight the manifold’s versatility.

Installation Considerations

Proper installation ensures component functionality:

- Site: Ventilated, secure area away from ignition sources.

- Mounting: Wall or floor mounts for stability.

- Connections: Use CGA-compliant fittings.

- Testing: Conduct pressure and leak tests per ASME B31.3.

- Electrical: Wire alarms and controls to BMS.

- Compliance: Follow NFPA 55, CGA P-1, or ISO 7396.

Professional installation is recommended.

Maintenance Practices

Maintenance preserves components:

- Daily: Check gauges and alarms.

- Weekly: Inspect pigtails and valves.

- Monthly: Clean filters, test changeover.

- Annual: Calibrate sensors, pressure test.

- Cylinder Handling: Follow CGA guidelines.

Keep logs for compliance.Regulatory Standards

Standards governing components include:

- NFPA 55: Requires relief valves and alarms.

- CGA P-1: Specifies pigtail and check valve design.

- ASME B31.3: Governs piping and fittings.

- ISO 7396: For medical gas manifolds.

- OSHA 1910.101: Ensures safe gas handling.

Compliance ensures safety and reliability.

Emerging Trends in Manifold Components

Trends include:

- IoT Sensors: Real-time pressure monitoring via apps.

- High-Purity Materials: Electropolished stainless for UHP gases.

- Smart Alarms: AI-driven fault prediction.

- Eco-Friendly Designs: Recyclable materials.

- Compact Components: Smaller regulators for space savings.

These trends enhance performance and safety.

Practical Tips for Selecting a Manifold

- Gas Type: Match materials to gas properties (e.g., stainless for corrosive).

- Demand: Size headers for flow rate.

- Automation: Fully automatic for critical applications.

- Supplier: Choose brands like Swagelok or Pattons Medical.

- Budget: Balance cost with TCO.

Case Studies

- Chemical Plant (USA): Manifold with stainless headers reduced downtime by 95%.

- Semiconductor Fab (Taiwan): UHP filters ensured contamination-free gas delivery.

- Welding Shop (Germany): Automatic changeover valves improved efficiency.

Conclusion

The components of a gas changeover manifold—headers, pigtails, valves, sensors, regulators, and alarms—work together to ensure continuous, safe, and efficient gas delivery. From welding to medical applications, these components are critical for reliability and compliance with standards like NFPA and CGA. Proper installation, maintenance, and selection based on gas type and demand are essential. As trends like IoT and high-purity designs evolve, manifolds will become even more advanced. Invest in a quality manifold with robust components to optimize your industrial or medical operations.

For more about beginners can understand components of a gas changeover manifold in seconds, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Select the Right Valve Manifold Box for Your Application

316L Stainless Steel Ultra High Purity Regulator for PH3 Service

How to Safely Operate a TMA Gas Changeover Manifold

How to Choose an Ultra High Purity CO2 Pressure Reducing Valve

Tags

Recommended Products

-

771LF Female Run Tee | Stainless Steel Tube Fitting Compression Fittings 1/4 In 3-Way Tee Female Run Tee

-

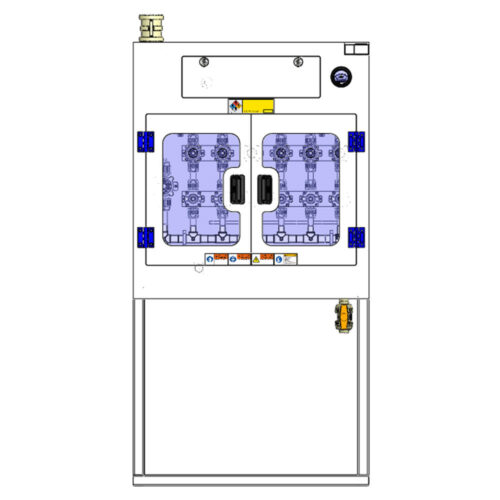

Semiconductor High Purity High Pressure Specialty Gas Bottle Gas Cylinder Storage Cabinet And Gas Pressure Regulating Cabinet

-

Stainless Steel High Pressure Specialty Gas Changeover Manifold For High Purity Oxygen Nitrogen Argon Helium Hydrogen Co2

-

High Purity Stainless Steel Mini Tube Butt Weld Fittings For Semiconductor

-

VMB Valve Manifold Box And Panel Gas Cabinet, BSGS Gas Cabinets, TMA Gas Cabinets, Scrubber Tail Gas Treatment Cabinets

-

High Purity Gas Cylinder Semi Automatic Changeover Manifold Regulator Panel 3000psig Stainless Steel Gas Control Panel 1/8 Npt With Gauge

-

High Purity Configurable Systems VMB Valve Manifold Box JW-200-VMB-C & JW-100-VMB-C

-

High Purity High Pressure Specialty Gas Pressure Regulators Specialty Gases Pipeline Engineering Equipments Manufacturer And Supplier