Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

How Does a Specialty Gas Regulator Work?

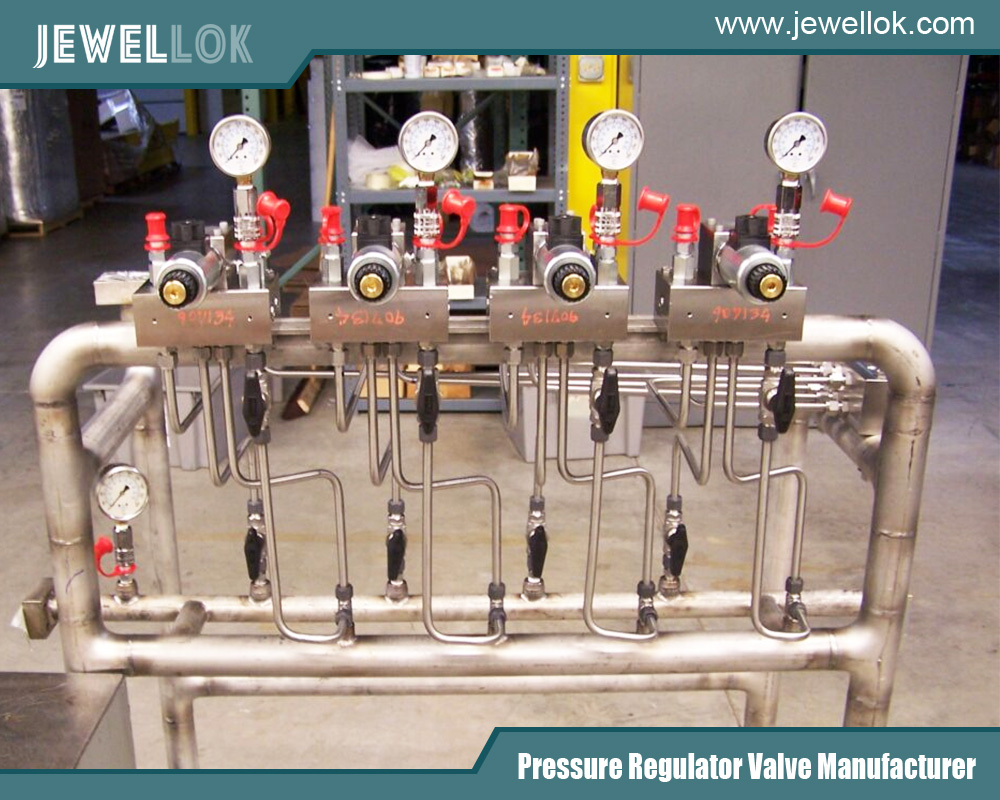

- Pressure Regulator Valve Manufacturer

- Best specialty gas regulator manufacturers, Best specialty gas regulators, Best specialty gas regulators manufacturer in india, best top 10 specialty gas regulators suppliers, Gas regulator for laboratory use, Gas regulator for semiconductor manufacturing, Low-pressure specialty gas regulators, Pressure relief valve gas regulator, products specialty gas regulator manual, Single Stage Small Body Specialty Gas Regulator, Single-stage vs two-stage gas regulator, Specialty gas regulator, specialty gas regulator brands in brazil, specialty gas regulator companies in brazil, specialty gas regulator company in philippines, specialty gas regulator in brazil, specialty gas regulator manual, specialty gas regulator manufacturer, specialty gas regulator manufacturer in brazil, Specialty gas regulator manufacturers usa, Specialty gas regulator suppliers, Specialty gas regulator working principle, Specialty Gas Regulators, Types of specialty gas regulators

- No Comments

How Does a Specialty Gas Regulator Work?

Introduction

Specialty gas regulators are essential devices in various industrial, medical, and laboratory settings where precise control of gas pressure is critical. Unlike standard gas regulators used for everyday applications like propane grills or home heating systems, specialty gas regulators are designed to handle high-purity gases such as oxygen, nitrogen, argon, helium, carbon dioxide, and even corrosive or toxic gases. These regulators ensure that the gas is delivered at a consistent, safe pressure, preventing equipment damage, ensuring process accuracy, and enhancing user safety.

At their core, specialty gas regulators function by reducing the high pressure from a gas source—typically a compressed gas cylinder or pipeline—to a lower, usable outlet pressure. This pressure reduction is vital because gas cylinders can store gases at pressures exceeding 2,000 pounds per square inch (psi), which is far too high for most applications. Without proper regulation, this could lead to leaks, explosions, or inconsistent performance in sensitive processes like semiconductor manufacturing, pharmaceutical production, or analytical instrumentation.

The importance of specialty gas regulators cannot be overstated. In laboratories, they maintain the purity of gases used in chromatography or spectroscopy, where even minor contaminants can skew results. In medical environments, they control the flow of oxygen or anesthesia gases to patients, where precision directly impacts health outcomes. Industrially, they support welding, calibration, and chemical processing by providing stable pressure despite fluctuations in the source.

This article delves into the intricacies of how specialty gas regulators work. We will explore the basic principles of pressure regulation, key components, types of regulators, the detailed working mechanism, applications, maintenance practices, and safety considerations. By understanding these elements, users can better select, operate, and maintain these devices for optimal performance.

Specialty gas regulators differ from general-purpose ones in their construction materials and design features. They often use corrosion-resistant materials like stainless steel or brass to handle reactive gases, and incorporate features like metal diaphragms to minimize contamination. The working principle relies on a balance of forces—inlet pressure, outlet pressure, and loading mechanisms—to achieve precise control. As we proceed, we’ll break this down step by step.

Basic Principles of Pressure Regulation

Pressure regulation in gases is governed by fundamental physical principles, primarily involving the control of fluid dynamics and force equilibrium. A gas regulator acts as a valve that automatically adjusts to maintain a set outlet pressure, regardless of changes in inlet pressure or flow demand.

The process begins with the high-pressure gas entering the regulator from the source. Inside the regulator, a sensing element detects the outlet pressure and compares it to a reference force, typically provided by a spring. If the outlet pressure drops below the set point—due to increased demand downstream—the regulator opens to allow more gas to flow, increasing the pressure. Conversely, if the pressure rises above the set point, the regulator closes to restrict flow, reducing the pressure.

This feedback loop is what makes regulators “self-regulating.” It’s based on the principle of equilibrium between opposing forces: the force from the inlet gas trying to close the valve, the outlet gas pressure pushing back, and the adjustable loading force opening the valve. In specialty applications, this must be highly precise because even small variations can affect purity or reaction rates.

There are two main categories of pressure reduction: single-stage and multi-stage. In a single-stage regulator, pressure is reduced in one step, which is efficient but can lead to variations as the source pressure decreases (known as “droop”). Multi-stage regulators, common in specialty uses, reduce pressure in sequential steps, providing more stable output.

Materials play a crucial role in these principles. For specialty gases, regulators use diffusion-resistant materials to prevent contaminants from entering the gas stream. Seals and diaphragms are often made from elastomers like Viton or PTFE, which resist chemical attack and outgassing— the release of trapped gases that could impure the stream.

Temperature also influences regulation. Gases expand or contract with temperature changes, affecting pressure. Specialty regulators may include compensators or be rated for specific temperature ranges to maintain accuracy.

In summary, the basic principle is pressure reduction through balanced forces, ensuring safe and consistent delivery. This foundation allows specialty regulators to handle unique challenges like high purity and corrosivity, setting them apart from standard models.

Key Components of Specialty Gas Regulators

A specialty gas regulator comprises several interconnected components, each designed for durability, precision, and compatibility with specialty gases. Understanding these parts is key to grasping how the device operates as a whole.

The inlet connection is the entry point where the regulator attaches to the gas cylinder or pipeline. It must withstand high pressures, often up to 3,000 psi or more, and features standardized fittings like CGA (Compressed Gas Association) connections specific to the gas type to prevent mismatches. Safety elements, such as check valves or burst discs, are integrated here to prevent backflow or over-pressurization.

Next is the pressure-reducing valve, the heart of the regulator. This valve, often a poppet or needle type, controls the gas flow by opening or closing an orifice. In single-stage designs, it’s spring-loaded; in two-stage, there are sequential valves for stepped reduction.

The diaphragm or piston serves as the sensing element. Diaphragms, typically made of stainless steel or elastomers, flex in response to pressure changes, providing high sensitivity for low-pressure applications. Pistons are used for higher pressures, offering ruggedness but less precision. This component isolates the high-pressure side from the low-pressure side, preventing leaks and contamination.

The loading mechanism, usually an adjustable spring controlled by a knob or screw, sets the desired outlet pressure. By compressing the spring, the user increases the force on the sensing element, which in turn opens the valve wider to achieve higher output.

Gauges are essential for monitoring. Most regulators have two: an inlet gauge showing source pressure and an outlet gauge for delivery pressure. These are typically Bourdon tube types, calibrated in psi or bar, and help users detect issues like leaks or depleting cylinders.

Relief valves protect against over-pressurization by venting excess gas if pressure exceeds safe limits. Purge devices, often valved systems on the inlet, allow flushing of residual gases during cylinder changes to maintain purity.

Flow meters, while not always integral, are common add-ons. They measure flow rates using rotameters or electronic sensors, aiding in precise delivery.

Filters and purifiers remove particulates or impurities, crucial for high-purity gases. Valves like diaphragm packless types provide on/off control without packing glands that could leak.

Finally, the body and bonnet house these components, made from materials like brass for general use or stainless steel for corrosive gases. Seals ensure airtight operation.

These components work in harmony, with materials chosen to resist corrosion, minimize diffusion, and ensure longevity in demanding environments.

Types of Specialty Gas Regulators

Specialty gas regulators come in various types, each tailored to specific needs based on pressure range, precision, and application.

Single-stage regulators reduce pressure in one step, making them simple and cost-effective. They are ideal for applications with stable inlet pressures, like pipeline systems or liquefied gases, but require adjustments as cylinder pressure drops. In specialty contexts, they suit intermittent use where precision isn’t paramount, such as basic welding with argon.

Two-stage regulators, also called dual-stage, are the most common for specialty gases. They perform reduction in two phases: the first stage lowers pressure to an intermediate level (around 350-500 psi), and the second adjusts to the final output. This design minimizes droop, providing constant pressure even as the source depletes. They are essential for high-precision tasks like gas chromatography or calibration standards.

Precision regulators offer enhanced accuracy, often with finer adjustment mechanisms and low-droop characteristics. Used in laboratories or medical devices, they can maintain pressures within fractions of a psi, incorporating features like metal diaphragms for purity.

High-pressure regulators handle inlet pressures up to 6,000 psi or more, used for gases like hydrogen in fuel cells. They feature robust pistons and reinforced bodies.

Corrosion-resistant regulators are built for reactive gases like chlorine or ammonia, using materials like Monel or Hastelloy.

Line regulators control pressure in distribution lines, often single-stage with only an outlet gauge.

Hose-end regulators are compact, portable versions for fieldwork, attaching directly to hoses.

Pressure-relief regulators include built-in vents for safety in overpressure scenarios.

Three-stage regulators extend the concept for ultra-high pressures, maintaining low outputs stably.

Selection depends on gas type, pressure requirements, flow rates, and environmental factors. For instance, oxygen requires non-sparking materials to prevent ignition.

Working Mechanism

The working mechanism of a specialty gas regulator involves a dynamic balance of forces to achieve precise pressure control. Let’s break it down step by step.

First, the regulator is connected to the gas source via the inlet. The cylinder valve is opened slowly, allowing high-pressure gas (e.g., 2,000 psi) to enter the high-pressure chamber. At this point, the adjusting knob is turned counterclockwise to minimize spring tension, keeping the valve closed.

To set the pressure, the user turns the knob clockwise, compressing the range spring. This loading force pushes on the diaphragm or piston, which in turn moves the valve stem to open the orifice. Gas flows into the low-pressure chamber, building outlet pressure.

The sensing element (diaphragm/piston) monitors this outlet pressure. As pressure rises, it exerts force against the spring, attempting to close the valve. Equilibrium is reached when the outlet pressure force equals the spring force plus any inlet pressure influence, maintaining the set pressure.

Key forces at play:

– Inlet pressure force: Pushes to close the poppet, preventing uncontrolled flow.

– Outlet pressure force: Acts on the sensing element to balance and adjust.

– Loading mechanism force: Opposes the others, opening the valve as needed.

In single-stage regulators, as cylinder pressure decreases, delivery pressure rises slightly, requiring readjustment. Two-stage models mitigate this: the first stage reduces to a fixed intermediate pressure, and the second handles fine control, ensuring stability.

For specialty gases, additional mechanisms like purge valves are used. During setup, purging flushes air or residues to preserve purity. Relief valves activate if pressure exceeds limits, venting gas safely.

Flow demand affects operation. Increased downstream flow drops outlet pressure, causing the diaphragm to flex, opening the valve more until balance restores. This “droop” is minimized in high-quality regulators.

Lock-up occurs when flow stops; the valve closes tightly, with a slight pressure rise above set point to ensure seal.

In corrosive applications, the mechanism includes inert coatings to prevent degradation.

Overall, this interplay of components and forces allows specialty regulators to deliver gas reliably, adapting to variations while safeguarding purity and safety.

Applications

Specialty gas regulators find use across diverse fields. In laboratories, they control gases for analytical instruments like mass spectrometers, ensuring consistent flow for accurate readings. Medical applications include regulating oxygen for ventilators or nitrous oxide for anesthesia, where precision is life-critical.

Industrially, they support semiconductor fabrication with ultra-pure gases, preventing contamination in cleanrooms. In welding, regulators handle argon or helium for shielding, maintaining arc stability. Calibration labs use them for standard gases in metrology.

Environmental monitoring employs regulators for sampling gases like methane. In pharmaceuticals, they aid in synthesis processes requiring inert atmospheres.

Aerospace and fuel cell technologies rely on them for hydrogen delivery, handling high pressures safely.

These applications highlight the regulators’ role in enabling advanced technologies through precise gas management.

Maintenance and Safety

Proper maintenance extends the life of specialty gas regulators and ensures safety. Regular inspections check for corrosion, leaks, or wear using soapy water for bubble tests. Clean external surfaces with non-abrasive cloths; internal cleaning requires disassembly per manufacturer guidelines.

Lubricate moving parts with compatible greases. Replace worn seals, diaphragms, or springs promptly. For high-purity models, avoid contaminants during handling.

Safety practices include wearing protective gear, never exceeding pressure ratings, and venting systems before disconnection. Use only for intended gases to prevent reactions. Install in well-ventilated areas, especially for toxic gases.

Periodic pressure testing and calibration maintain accuracy. Store regulators in clean, dry environments.

Adhering to these ensures reliable operation and minimizes risks like explosions or exposures.

Conclusion

Specialty gas regulators are sophisticated devices that reduce and control gas pressure through balanced forces and precise components. From single-stage to multi-stage types, they cater to demanding applications while prioritizing purity and safety. Understanding their workings empowers users to optimize performance in critical fields.

For more about how does a specialty gas regulator work, you can pay a visit to Jewellok at https://www.jewellok.com/product-category/high-purity-gas-system/ for more info.

Recent Posts

How to Select the Right Valve Manifold Box for Your Application

316L Stainless Steel Ultra High Purity Regulator for PH3 Service

How to Safely Operate a TMA Gas Changeover Manifold

How to Choose an Ultra High Purity CO2 Pressure Reducing Valve

Tags

Recommended Products

-

Semi Automatic Gas Changeover Manifold System Manual Changeover Manifold Panel Single Stage Automatic Switchover Board

-

770L Female Elbow | Stainless Steel High Purity Weld Fittings Female Micro Elbow Fittings

-

Automatic Gas Switchover System Automatic Switchover Manifold Automatic Gas Cylinder Switchover

-

739 High Purity LMR Male Adapter Tube To Pipe Fittings And Adapters

-

High Pressure High-Purity Welded Check Valves And Low Cracking Pressure Check Valve JCV1 Series

-

Semi Automatic Gas Cabinet Gas Panels High Purity Gas Delivery Systems JW-200-GC

-

High Pressure High Flow Specialty Gas Control Panel With Diaphragm Valve , 3000Psig Oxygen Control Medical Changeover Manifold Panel

-

Ultra High Purity Trimethylaluminum TMA Gas Cabinet Liquid Delivering Cabinet Used For Specialty Gas Delivery System In Semiconductor