Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

What is the Difference Between Integrated Gas System (IGS) and Modular Integrated Gas Systems (TMS)

- Pressure Regulator Valve Manufacturer

- integrated gas system, Integrated Gas System (IGS), Integrated Gas System China, integrated gas system china supplier, Integrated Gas System in Semiconductor, Integrated Gas System in the Semiconductor Companies, integrated gas system in the semiconductor market, integrated gas system manufacturer, integrated gas system manufacturer China, integrated gas system manufacturer in china, integrated gas system manufacturer in india, integrated gas system supplier, Integrated Gas Systems in the Semiconductor, integrated gas technologies, Modular Integrated Gas Systems, Modular Integrated Gas Systems (TMS)

- No Comments

What is the Difference Between Integrated Gas System (IGS) and Modular Integrated Gas Systems (TMS)

Introduction

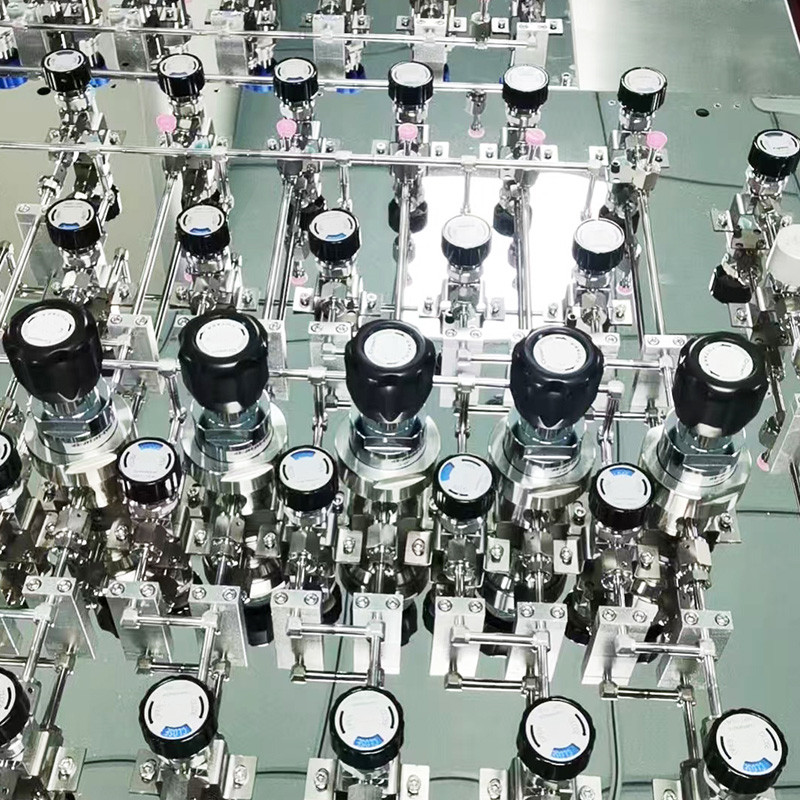

In the rapidly evolving semiconductor industry, the precise control and delivery of high-purity gases are critical for manufacturing processes such as etching, deposition, and cleaning. Gas delivery systems ensure that specialty gases like nitrogen, argon, hydrogen, and various reactive gases are supplied safely, efficiently, and without contamination. Among these systems, Integrated Gas Systems (IGS) and Modular Integrated Gas Systems (TMS) represent key technologies that have transformed how gases are managed in fabrication facilities.

IGS refers to integrated platforms that combine valves, fittings, regulators, and other components into a unified system for gas control. These systems emerged as a response to the need for higher purity, reliability, and compactness in semiconductor production. On the other hand, TMS, often associated with advanced modular designs like the Talon Modular System, builds upon the IGS foundation by emphasizing modularity, configurability, and scalability. While both aim to optimize gas delivery, their differences lie in design philosophy, installation ease, maintenance requirements, and overall performance.

This article explores the fundamentals of IGS and TMS, highlighting their features, applications, and key distinctions. By understanding these differences, engineers and facility managers can make informed decisions to enhance productivity, reduce downtime, and lower operational costs in high-tech manufacturing environments. We will delve into the technical aspects, benefits, and potential drawbacks, providing a comprehensive comparison to guide practical implementation.

Overview of Integrated Gas Systems (IGS)

Integrated Gas Systems (IGS) are engineered solutions designed to streamline the handling of gases in industrial settings, particularly in semiconductor fabrication. These systems integrate multiple components—such as manual and pneumatic valves, pressure regulators, filters, flow controllers, and transducers—into a single, cohesive unit. The primary goal is to minimize leaks, ensure gas purity, and maintain consistent flow rates under varying process conditions.

Key Features of IGS

IGS typically feature a surface-mount architecture compliant with standards like those from the Semiconductor Equipment and Materials International (SEMI). This design allows components to be mounted directly onto a base substrate, reducing the number of connections and potential failure points. For instance, systems often use metal-to-metal seals, such as W-seals or C-seals, to achieve hermetic integrity and prevent contamination from atmospheric gases or particles.

Technical specifications vary by manufacturer, but common attributes include:

– Operating pressures up to 1 MPa (approximately 145 psi).

– Temperature ranges from -10°C to 80°C, suitable for handling special material gases.

– Compact dimensions, with series like 1.125W or 1.5W offering footprints as small as 1.125 inches for standard flow paths.

– Materials like stainless steel (SUS316L) for corrosion resistance and ultra-high purity.

The basic concepts behind IGS emphasize performance enhancement through technological improvements, compactness to fit into space-constrained cleanrooms, and reliability via robust sealing mechanisms. For example, some IGS incorporate leak ports and detachable parts that facilitate quick inspections without disrupting the entire system.

Applications in the Semiconductor Industry

In semiconductor manufacturing, IGS are indispensable for processes requiring precise gas mixtures. They are used in chemical vapor deposition (CVD), plasma etching, and ion implantation, where even minor impurities can lead to defects in microchips. Beyond semiconductors, IGS find applications in pharmaceuticals, aerospace, and chemical processing, where controlled gas environments are essential.

Benefits of IGS

Compared to older, non-integrated systems, IGS offer several advantages:

– Improved uptime by reducing maintenance times through integrated diagnostics and fewer welds or joints.

– Enhanced safety with built-in pressure relief and monitoring features.

– Cost savings from standardization, which allows for easier scaling and replacement of parts.

– Better gas efficiency due to shorter flow paths that minimize dead volumes and purging times.

However, traditional IGS can sometimes be rigid in configuration, requiring custom engineering for specific setups, which may increase lead times and initial costs.

Overview of Modular Integrated Gas Systems (TMS)

Modular Integrated Gas Systems (TMS) represent an evolution of IGS, focusing on modularity to address the limitations of more rigid integrated designs. TMS, exemplified by systems like the Talon Modular System, allows for customizable configurations where individual modules can be added, removed, or rearranged without overhauling the entire setup. This modularity is achieved through standardized interfaces and interchangeable components, making TMS highly adaptable to changing process requirements.

Key Features of TMS

TMS builds on IGS principles but incorporates advanced modular architecture. Key elements include:

– Configurable seal types, supporting Face Seal, C-Seal, and W-Seal connections in various sizes (e.g., 1.125-inch standard flow to 1.50-inch high flow).

– Manifold integration where seals are embedded into components, reducing the number of bolts and seals needed.

– Dual-level manifolding for complex gas mixing and distribution.

– Integrated heating options to maintain gas temperatures and prevent condensation.

– Gas stick pitches of 1.4 inches for compact 1.125-inch systems and 1.7 inches for larger 1.500-inch high-flow variants.

Technical specifications often include:

– Wetted paths of 0.18 inches for standard flow and 0.30 inches for high flow, using 0.250-inch or 0.375-inch outer diameter tubes.

– Compatibility with all major industry standards, ensuring interoperability with existing equipment.

– Top-side accessibility for components, simplifying assembly and leak testing.

The design philosophy of TMS prioritizes field reconfigurability, allowing engineers to add future gas lines or modify flows on-site. This is particularly useful in dynamic environments where production lines evolve frequently.

Applications in the Semiconductor Industry

TMS is widely adopted in semiconductor fabs for its flexibility in handling diverse gas recipes. It supports advanced nodes in chip manufacturing, where rapid prototyping and process adjustments are common. Additionally, TMS is used in medical device production, power generation, and aerospace, where modular upgrades can extend system lifespans without major investments.

Benefits of TMS

TMS offers enhanced benefits over standard IGS:

– Significant space savings with a smaller, lighter footprint, ideal for crowded cleanrooms.

– Faster installation and reconfiguration, reducing assembly time by integrating manifolds and minimizing connections.

– Higher reliability through reduced service times and the ability to perform maintenance without shutting down the entire system.

– Cost efficiencies from inventory availability and shorter lead times, as modular components can be stocked and swapped easily.

One notable advantage is the improved purging efficiency due to shorter gas paths, which can cut process cycle times and gas consumption.

Key Differences Between IGS and TMS

While IGS and TMS share the common objective of efficient gas delivery, their differences stem from design approach, functionality, and operational impact. Below, we outline the primary distinctions.

Design and Architecture

IGS typically features a more fixed integration, where components are assembled into a unified panel with predefined layouts. This provides robustness but limits flexibility. In contrast, TMS employs a modular framework, allowing components to be stacked or arranged in custom sequences. For example, TMS systems integrate the manifold seal directly into the component seal, eliminating extra hardware and simplifying the structure. This results in fewer potential leak points—often reducing seal and bolt counts by half compared to traditional IGS.

Installation and Configuration

Installing an IGS often involves custom welding or fitting, which can be time-consuming and require specialized tools. TMS, however, supports plug-and-play modularity with standardized interfaces like C-seals and W-seals. This enables quick assembly from the top side, speeding up leak checks and initial setup. In practice, TMS can reduce installation time by 30-50% compared to IGS, making it preferable for facilities with frequent line changes.

Maintenance and Uptime

Maintenance in IGS may require disassembling parts of the system, potentially leading to longer downtimes. TMS excels here with detachable modules and field-reconfigurable designs, allowing individual components to be replaced without affecting others. This modularity improves uptime, a critical metric in semiconductors where even brief halts can cost thousands per minute. Additionally, TMS often includes integrated diagnostics for proactive maintenance, a feature less common in basic IGS.

Performance and Efficiency

Both systems ensure high-purity gas delivery, but TMS offers superior efficiency through shorter flow paths and optimized purging. For instance, TMS high-flow configurations handle larger volumes with minimal pressure drops, supporting advanced processes. IGS, while reliable, may have longer paths in non-modular setups, increasing gas waste during changes. Quantitatively, TMS can achieve space savings of up to 40% and reduce purging times by 20-30%, translating to operational cost reductions.

Cost Implications

Initial costs for IGS can be lower for simple applications due to standardized designs. However, TMS provides better long-term value through scalability and reduced maintenance expenses. The modular nature allows for incremental upgrades, avoiding full system replacements. In high-volume production, TMS’s productivity gains often offset higher upfront investments.

Scalability and Adaptability

IGS is scalable but often requires redesign for expansions. TMS’s modularity inherently supports growth, with options to add manifolds or heating elements as needed. This adaptability is crucial in industries like semiconductors, where technology nodes shrink and gas requirements evolve rapidly.

Advantages and Disadvantages

Advantages of IGS

– Proven reliability in standard applications.

– Lower complexity for basic setups.

– Cost-effective for static processes.

Disadvantages of IGS

– Limited flexibility for changes.

– Potentially higher maintenance downtimes.

– Larger footprints in non-optimized designs.

Advantages of TMS

– High configurability and scalability.

– Reduced space and installation time.

– Enhanced uptime and efficiency.

Disadvantages of TMS

– Higher initial costs due to advanced features.

– Requires training for modular handling.

– Dependency on compatible components.

Case Studies and Practical Examples

Consider a semiconductor fab upgrading from traditional gas panels to IGS. Initially, adopting IGS reduced leaks by 50% and improved purity levels. However, as production scaled, the fixed design hindered quick adjustments. Switching to TMS allowed reconfiguring gas sticks in hours, boosting throughput by 15%.

In another scenario, an aerospace manufacturer used TMS for its compact profile, fitting complex gas mixtures into limited spaces while maintaining reliability under extreme conditions.

Future Trends

As semiconductor nodes advance below 2nm, demand for ultra-precise gas control will grow. IGS and TMS will evolve with smart sensors for real-time monitoring and AI-driven predictive maintenance. Hybrid systems combining IGS stability with TMS modularity may emerge, further blurring lines but enhancing overall performance. Sustainability will also drive designs minimizing gas waste and energy use.

In conclusion, while IGS provides a solid foundation for integrated gas management, TMS offers superior modularity and efficiency, making it ideal for dynamic environments. Choosing between them depends on specific needs, but TMS is increasingly the choice for future-proofing operations in high-tech industries.

For more about what is the difference between integrated gas system (igs) and modular integrated gas systems (tms), you can pay a visit to Jewellok at https://www.jewellok.com/best-top-10-integrated-gas-system-manufacturers-and-suppliers-in-india/ for more info.

Recent Posts

How a Gauged Two-Stage Propane Gas Pressure Regulator Works

The Best Natural Gas Pressure Regulators Manufacturers in USA

How to Choose the Right Laboratory Gas Valves

The Top High Pressure Hydraulic Needle Valve Manufacturer in 2025

Why the Top Companies Choose Ultra-High Purity Diaphragm Valves

How to Choose the Material Properties of Ball Valve Core?

Tags

Recommended Products

-

Semi-Automatic VMB Gas Cabinet With Semiconductor Valve Manifold Box Diaphragm Valves And Gas Pressure Regulators

-

772 LF Female Branch Tee | Stainless Steel Tube Fitting Female Branch Tee 1/2 in. Tube OD x 1/2 in. Tube OD x 3/8 in. Female NPT

-

765L Stainless Steel Union Elbow Reducing High Purity Fitting Tubing Extension Tubing Connection

-

Stainless Steel 316L Single Stage Regulator Pressure Control Panels JSP-1E Series For Semiconductor Fluid Control

-

High Pressure High-Purity Welded Check Valves And Low Cracking Pressure Check Valve JCV1 Series

-

Flow Control Stainless Steel Low Pressure Manual Diaphragm Valve For High Purity And Ultra High Purity Gases

-

Ultra High Purity Trimethylaluminum TMA Gas Cabinet Liquid Delivering Cabinet Used For Specialty Gas Delivery System In Semiconductor

-

768L Stainless Steel Male Tube Butt Weld Connector | Clean Weld Fittings And Ultra-High Purity Fittings