Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Best Top 10 Stainless Steel Ball Valve Manufacturers and Suppliers in China

- Pressure Regulator Valve Manufacturer

- 316 SS ball valves manufacturer, 316 stainless steel ball valves, actuated ball valve manufacturers, ball valve supplier malaysia, china 10000 psi ball valves, china stainless steel ball valve, europe pneumatic actuated ball valve, europe pneumatic actuated ball valve factory, europe pneumatic actuated ball valve manufacturer, europe pneumatic actuated ball valve supplier, high pressure ball valve factory, high pressure ball valves, high pressure ball valves distributors, high pressure ball valves manufacturers, high pressure ball valves suppliers, high purity ball valve, high purity ball valves, high temperature ball valve, high temperature ball valves, high temperature high pressure ball valves, pneumatic actuated ball valve manufacturer, pneumatic actuator ball valve, stainless steel ball valve china, stainless steel ball valve from china manufacturer, stainless steel ball valve manufacturer

- No Comments

Best Top 10 Stainless Steel Ball Valve Manufacturers and Suppliers in China

Introduction

Stainless steel ball valves are essential components in fluid control systems across a wide array of industries, renowned for their durability, corrosion resistance, and reliable performance under demanding conditions. A ball valve operates on a simple yet effective principle: a spherical disc, or “ball,” with a bore drilled through its center rotates within the valve body to control the flow of liquids or gases. When the bore aligns with the pipeline, the valve is open, allowing unobstructed flow; when perpendicular, it shuts off completely, providing a tight seal. The use of stainless steel, particularly grades like 304 and 316, enhances these valves’ suitability for harsh environments. Stainless steel 304 offers excellent formability and weldability with good corrosion resistance in mild atmospheres, while 316 provides superior protection against pitting and crevice corrosion in chloride-rich settings, making it ideal for marine, chemical, and pharmaceutical applications.

Technically, stainless steel ball valves come in various configurations to meet diverse operational needs. Floating ball designs, where the ball is free to move with line pressure to enhance sealing, are common for lower-pressure systems up to 1000 PSI. Trunnion-mounted variants, supported by upper and lower stems, excel in high-pressure scenarios exceeding 6000 PSI, reducing torque requirements and wear on seats. Two-piece and three-piece constructions allow for easy maintenance, with the latter enabling full in-line repair without system shutdown. Key features include full-port designs for minimal flow restriction (characterized by a Cv value close to that of the pipe), reduced-port for cost efficiency, and options for automation via pneumatic or electric actuators. Seals typically employ reinforced PTFE or metal-to-metal for fire-safe compliance per API 607 standards, ensuring integrity during emergencies.

The global demand for these valves is driven by sectors such as oil and gas, where they manage high-pressure hydrocarbons; water treatment, for hygienic flow control; and petrochemicals, for corrosive media handling. With rising infrastructure projects and a shift toward sustainable manufacturing, the market is projected to grow at a CAGR of 5.2% through 2030. China stands as the undisputed leader in this domain, producing over 60% of the world’s valves due to its robust supply chain, advanced CNC machining capabilities, and competitive pricing without compromising quality. Wenzhou, Zhejiang Province, alone hosts thousands of specialized factories, benefiting from proximity to raw material suppliers and export ports.

Selecting the best manufacturers requires a multifaceted approach. Factors include adherence to international standards like ISO 9001 for quality management, API 6D for pipeline valves, and CE marking for European compliance. Production capacity, innovation in low-emission designs, and after-sales support are crucial. This article evaluates the top 10 based on these criteria, drawing from their technical prowess, market reputation, and contributions to valve technology. These companies not only dominate domestic output but also export to over 100 countries, embodying China’s evolution from volume producer to precision engineer.

Criteria for Selection

To identify the premier stainless steel ball valve manufacturers in China, a rigorous evaluation framework was applied, emphasizing technical excellence and operational reliability. Primary considerations include certifications such as ISO 9001:2015 for quality assurance, API 607 for fire safety, and API 6D for design and testing, ensuring valves withstand pressures from 150 PSI to 10,000 PSI and temperatures from -196°C to 650°C. Material traceability via spectrometry and non-destructive testing (e.g., ultrasonic and radiographic) is mandatory to guarantee SS304/316 integrity.

Production capacity assesses annual output (targeting >2000 tons), facility size (>20,000 m²), and automation levels, including CNC lathes for ±0.01 mm precision and automated welding for seam-free bodies. Innovation metrics cover R&D investment, with preferences for low-torque designs reducing actuator size by 30% and eco-friendly coatings minimizing VOC emissions. Customer-centric factors like lead times (<4 weeks), global service networks, and customization (e.g., sanitary tri-clamp ends per ASME BPE) were weighed. Market share, export volume (>50% of sales), and client testimonials from Fortune 500 firms further validated rankings. This holistic approach ensures selections represent leaders in reliability, where a single valve failure could cost millions in downtime.

1. Newsway Valve Co., Ltd. (NSW Valve)

Newsway Valve Co., Ltd., established over two decades ago in Wenzhou, has solidified its position as a vanguard in stainless steel ball valve production. With a sprawling 20,000 m² facility equipped with state-of-the-art CNC machining centers and automated assembly lines, the company annualizes over 3,000 tons of valves, catering to oil & gas, chemical processing, and water sectors. Their stainless steel ball valves, forged from SS304 and SS316, feature floating and trunnion-mounted designs with pressure ratings up to 10,000 PSI. A hallmark is the precision-engineered ball-seat interface, achieving bubble-tight shutoff at Class VI leakage rates per API 598.

Key innovations include multi-port configurations for complex flow diversion, reducing system components by 20%, and pneumatic actuation integration for SCADA compatibility. Certifications abound: API 607 fire-safe, ISO 9001, CE, and TS for pressure equipment. NSW’s in-house testing lab employs hydrostatic and pneumatic trials at 1.5x rated pressure, ensuring 100% traceability via QR-coded serialization. Their commitment to sustainability shines through low-emission casting processes, aligning with EU RoHS directives. Globally exported to 80+ countries, Newsway’s valves power refineries from ExxonMobil to Sinopec, underscoring their blend of affordability and engineering rigor that sets benchmarks in Chinese manufacturing.

2. Xinhai Valve Co., Ltd.

As one of China’s top five industrial valve producers, Xinhai Valve Co., Ltd., founded in 1986 in Wenzhou, excels in bespoke stainless steel ball valves for petrochemical and marine applications. Spanning 35,000 m² with a workforce of 500, their annual capacity exceeds 5,000 tons, leveraging robotic welding for seamless SS316 bodies resistant to 316L’s enhanced molybdenum content for superior chloride resistance. Products range from 1/2″ to 48″ diameters, supporting ANSI Class 150-2500 pressures and -50°C to 500°C temperatures.

Technically, Xinhai’s trunnion-mounted series incorporates self-relieving seats that purge trapped media, preventing over-pressurization and extending seat life by 50%. Actuator-ready stems with blowout-proof shoulders comply with ISO 5211 mounting pads, facilitating quick retrofits. Holding API 6D, ISO 14001 environmental, and ABS type approvals, their valves undergo 100% PMI (positive material identification) and dye penetrant inspections. Innovation extends to low-emission packing per API 6FA, reducing fugitive emissions below TA-Luft standards. Serving clients like BP and Shell, Xinhai’s 40+ years of expertise translate to 70% export ratio, making them a cornerstone for high-stakes fluid control in corrosive regimes.

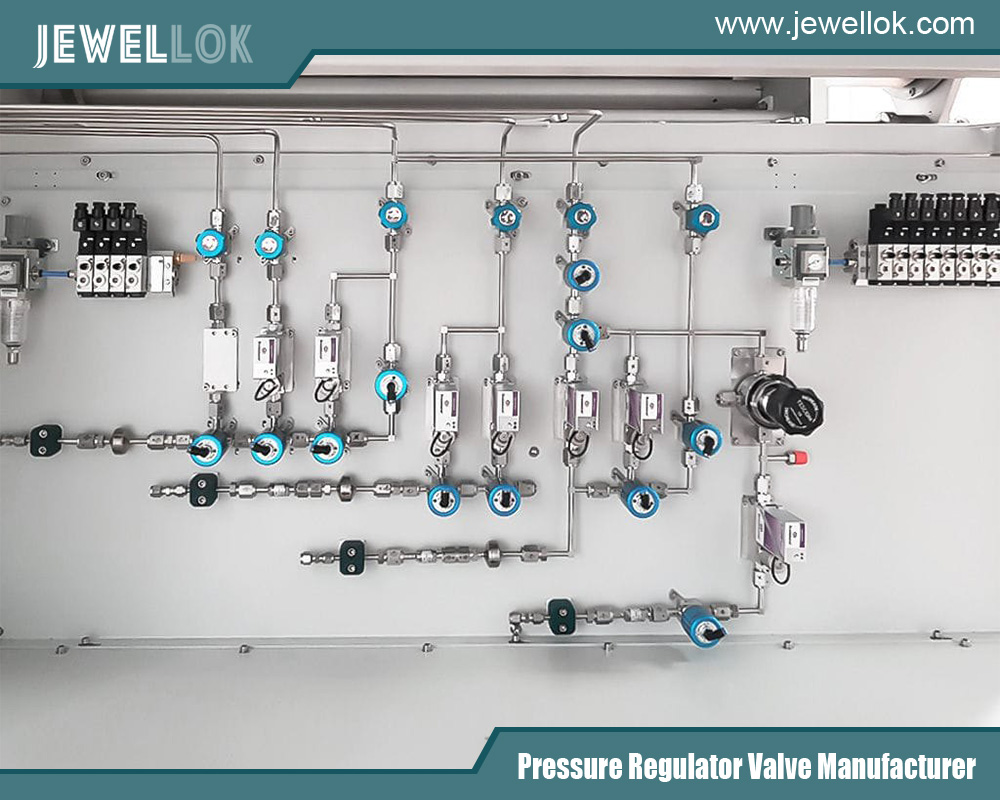

3. Shenzhen Jewellok Technology Co., Ltd

Jewellok provides laboratory, photovoltaic, semiconductor, petrochemical, and new energy industries with high-purity pressure regulating valves, high-purity pressure reducing valves, high-purity diaphragm valves, specialty gas diaphragm valves, VCR connectors, micro-welding connectors, micro-welding tees, micro-welding elbows, specialty gas pressure reducing valves, specialty gas pressure reducing valves, EP pressure reducing valves, EP pressure regulating valves, vacuum connection face seal connectors, VCR five-piece kits, VCR three-piece kits, VCR sealing gaskets, high-pressure pneumatic diaphragm valves, low-pressure pneumatic diaphragm valves, high-pressure manual diaphragm valves, low-pressure manual diaphragm valves, ultra-clean welded connectors, GC specialty gas cabinets, VMB manifolds, high-purity gas valve discs, ultra-high-purity pressure gauges, and prefabricated valve components for semiconductor equipment. VCR long welded pipes, VCR short welded pipes, VCR female nuts, and VCR male nuts.

Jewellok specializes in fully automatic and semi-automatic GC gas cabinets, BSGS gas cabinets, VMB gas cabinets, TMA gas cabinets, Scrubber tail gas treatment cabinets, gas distribution cabinets, VDB gas cabinets, and VDP gas cabinets, suitable for gases such as SiH4, NF3, NH3, N2O, and HCI.

4. Wenzhou Leader Flow Control Equipment Co., Ltd.

Wenzhou Leader Flow Control, a 2007 spin-off from Leader Valve Group in Yueqing, Zhejiang, specializes in precision stainless steel ball valves with a 3,000 m² facility yielding 2,500 tons annually. Focused on forged designs, their SS316 products span 1/4″ to 12″ in three-piece configurations, enduring 6,000 PSI and -29°C to 425°C, perfect for hydraulic and instrumentation duties.

Leader’s forged floating series employs anti-static grounding paths per ATEX directives, with flexible graphite seals for zero leakage at Class VIII. Key tech includes blowout-proof stems with dual O-rings and self-cleaning balls via hydrodynamic grooves, boosting cycle life to 1 million operations. Certified under API 6D/607, CE, and China’s Special Equipment License, they feature in-line spectrometric testing for alloy purity. R&D emphasizes compact actuators, cutting energy use by 25%. With 20+ years in exports to North America and Europe, Leader’s professional sales engineering ensures tailored solutions, like custom port angles, cementing their status as a nimble leader in high-reliability valves.

5. Tanggong Valve Group Co., Ltd.

Tanggong Valve Group, headquartered in Wenzhou, pioneers stainless steel ball valves for power generation and water treatment, with a 40,000 m² campus producing 6,000 tons yearly via automated CNC and heat treatment lines. Their SS304/316 lineup includes full-port 3-way diverters up to 24″ and 4,000 PSI, with extended bonnet options for cryogenic service.

Technological prowess shines in their low-torque trunnion designs, incorporating live-loaded packing to maintain seal compression amid thermal cycling, compliant with MSS SP-72. Features like position indicators and locking handles enhance safety in automated loops. Holding ISO 9001, API 600/602, and SIL 3 functional safety ratings, Tanggong’s valves pass 150% overpressure hydrotests. Innovation includes PEEK seats for chemical inertness, extending service life in acidic media. Serving 500+ global clients with 24/7 support, their 100-strong technical team drives customizations like sanitary polish to Ra 0.8 μm, making Tanggong a top choice for precision and scalability in China’s export-driven market.

6. Plumberstar Valve Co., Ltd.

Plumberstar Valve, based in Taizhou, Zhejiang, has risen as a specialist in residential and light industrial stainless steel ball valves since 2007, with a 15,000 m² facility outputting 2,000 tons annually. Their compact SS304 series, from 1/2″ to 2″, handles 1,000 PSI for plumbing and HVAC, featuring threaded NPT/BSP ends for easy integration.

Plumberstar’s two-piece designs incorporate floating balls with reinforced PTFE seats for 500 PSI steam service, achieving full flow with minimal pressure drop (ΔP < 0.5 bar). Anti-siphon features prevent backflow, per ASSE 1011. Certified ISO 9001 and WRAS for potable water, they undergo salt spray testing per ASTM B117 for 1,000 hours corrosion resistance. R&D focuses on lead-free alloys, aligning with NSF/ANSI 61. With exports to 50 countries and OEM partnerships, Plumberstar’s affordable, high-volume production—over 500 varieties—delivers reliable shutoff in everyday applications, underscoring their niche dominance.

7. Yongjia Zhenghong Valve Co., Ltd.

Yongjia Zhenghong Valve Co., Ltd., in Wenzhou’s Yongjia County since 2005, fabricates robust stainless steel ball valves for oilfield and marine use, with a 20,000 m² plant at 3,500 tons capacity. SS316L products range 1″ to 36″, Class 150-900, with bolted bodies for field servicing.

Their trunnion-mounted valves use metal-seated balls for high-temperature throttling up to 650°C, with torque coefficients under 1.0 for efficient actuation. Emergency shutdown (ESDV) compliance per API 6FA includes spring-return fail-safe. Certifications: API 6D, ISO 15848 Class A leakage, and DNV GL for offshore. Ultrasonic thickness gauging ensures wall integrity > schedule 40. Innovation in cavity pressure relief vents mitigates hydro-locking. Exporting 60% to Middle East projects, Zhenghong’s valves in Aramco pipelines highlight their engineering depth and cost-effectiveness.

8. Wenzhou Best Valve & Pipe Fitting Co., Ltd.

Wenzhou Best Valve, established 2010 in Wenzhou, integrates valve and fitting production in a 18,000 m² site, yielding 2,800 tons of stainless steel ball valves yearly. Their SS304/316 low-pressure series (up to 600 PSI) suits water and gas distribution, with grooved ends per AWWA C606.

Best’s multi-turn designs feature adjustable stem nuts for precise alignment, reducing wear by 30%. Fire-rated per UL 1091, with graphoil packing. ISO 9001, FM approved, and EPDM seals for -20°C to 150°C. In-house flow bench testing verifies Kv ratings within 5%. Custom quick-joint integrations streamline installations. With 40% exports to Americas, Best’s holistic solutions position them as a versatile mid-tier leader.

9. Wenzhou Zhongtou Valve Co., Ltd.

Leveraging Wenzhou’s stainless ecosystem, Zhongtou Valve Co., Ltd. (2012) operates a 12,000 m² facility producing 1,800 tons of SS ball valves annually for pharma and food processing. Sanitary tri-clamp models in SS316L meet 3A standards, 1/2″ to 4″, 150 PSI.

Zhongtou’s electropolished surfaces (Ra <0.5 μm) prevent bacterial adhesion, with SIP/CIP compatibility. Cavity-free designs eliminate dead zones. CE, FDA compliant, with helium leak tests at 10^-8 mbar l/s. R&D in PFA liners enhances chemical resistance. Exports to EU biotech firms underscore their hygienic expertise.

10. Wenzhou Yuzheng Valve Co., Ltd.

Wenzhou Yuzheng Valve, founded 2008, specializes in high-pressure stainless steel ball valves from its 10,000 m² plant, at 1,500 tons capacity. SS316 two-piece units up to 10,000 PSI for instrumentation.

Yuzheng’s needle-integrated valves offer fine throttling, with micrometer stems for ±0.1° control. API 602 forged bodies, NACE MR0175 sour service. Pressure-balanced designs cut actuator torque 40%. ISO 9001, with RTJ flanged ends. Serving aerospace exports, Yuzheng excels in compact, ultra-reliable solutions.

Conclusion

China’s top stainless steel ball valve manufacturers exemplify a fusion of tradition and technology, delivering products that rival global standards while driving cost efficiencies. From Newsway’s high-volume precision to Yuzheng’s niche innovations, these firms propel industrial advancement, ensuring secure fluid management worldwide.

For more about the best top 10 stainless steel ball valve manufacturers and suppliers in china, you can pay a visit to Jewellok at https://www.jewellok.com/product-category/high-purity-gas-system/ball-valves/ for more info.

Recent Posts

How to Choose the Krypton Gas Ultra High Purity (UHP) Regulator

Troubleshooting Common Failures in TMA Gas Changeover Manifolds

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

Tags

Recommended Products

-

Hydrogen Manifold Argon Gas Manifold System Oxygen Manifold Propane Gas Manifold With Valves In Gas Manifold Changeover System

-

762L Stainless Steel High Purity Union High-Purity Gas System Fittings

-

Fully Automated Gas Cabinet For Precise UHP Gas Delivery And High Purity Gas Delivery Systems JW-300-GC

-

Clean Connection Cabinet JW-300-CCB Valve Manifold Box And Control Valve Box

-

768LN Stainless Steel Male Pipe Tube Butt Weld Connector And Tube Fittings Supplier

-

Stainless Steel Ultra Clean Welding Joint Fittings TW Series TRW Series & CW Series

-

High Purity Stainless Steel Mini Tube Butt Weld Fittings For Semiconductor

-

Specialty Gas Valves Ultra High Purity Gas Valves Ultra High Purity Gas Cylinder Valves UHP Cylinder Valve Ultra High Purity Gas Regulator