Blog

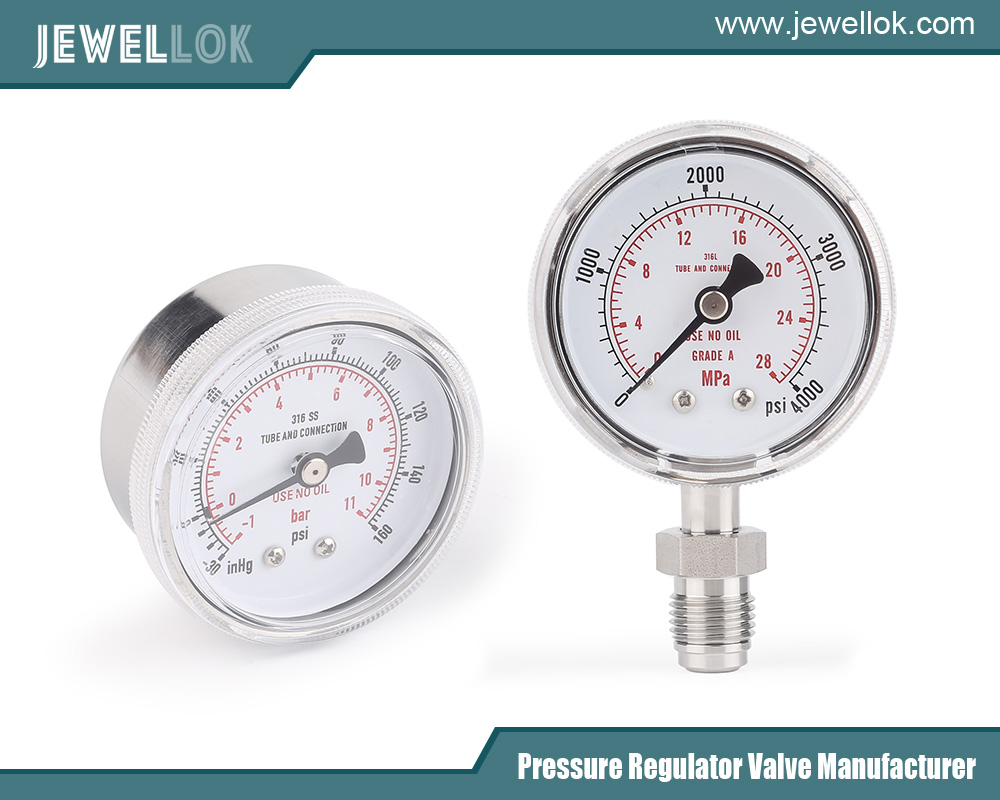

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

How to Choose High Purity Diaphragm Valves That Are Hassle-Free and Efficient

- Pressure Regulator Valve Manufacturer

- 1/4 VCR Stainless Steel Ultra High Purity Gas Regulator, 316L Stainless Steel Seamless High Purity System Tube, adjustable propane pressure regulator, adjustable propane regulator, application of ultra-high purity gas pressure regulator, BA grade high purity ball valves, BA Grade High Purity Gas Pressure Regulators, ba grade high purity pressure regulator, BA Grade Stainless High Purity Ball Valve, BA Series high purity ball valves, best high purity gas pressure regulator, best high purity gas pressure regulators manufacturer, Best high purity stainless steel gas fittings, best high purity valves, Best Ultra-High Purity Specialty Gases, Brass High Purity Single Stage Pressure Regulators, China High purity gas regulator Manufacturer, China High Purity Gas System Manufacturer, high pressure argon regulator, high purity diaphragm valves, high purity diaphragm valves in brazil, high purity diaphragm valves manufacturer, high purity diaphragm valves supplier, high purity regulator, hydraulic regulator, low pressure gas regulator, pressure safety valve vs relief valve, stainless pressure regulator, Ultra High Purity Diaphragm Valves, ultra high purity diaphragm valves manufacturer

- No Comments

How to Choose High Purity Diaphragm Valves That Are Hassle-Free and Efficient

In industries where contamination can lead to catastrophic failures, such as pharmaceuticals, biotechnology, semiconductors, and food processing, the selection of valves is not just a matter of functionality but a critical decision impacting product integrity, safety, and operational efficiency. High purity diaphragm valves stand out in these environments due to their unique design that isolates the process fluid from the valve’s mechanical components, minimizing the risk of leaks, corrosion, and particle generation. These valves are engineered to handle ultra-clean fluids, ensuring that no impurities compromise the end product—whether it’s a life-saving drug, a cutting-edge microchip, or a safe beverage.

But what makes a diaphragm valve “high purity”? Typically, it refers to valves constructed with materials and finishes that meet stringent standards for cleanliness, such as electropolished stainless steel surfaces with low roughness averages (Ra) to prevent bacterial adhesion. Hassle-free operation implies minimal maintenance needs, quick actuation, and easy integration into automated systems, while efficiency encompasses optimal flow rates, low pressure drops, and energy-saving features. Choosing the right one isn’t straightforward; it requires balancing factors like material compatibility, regulatory compliance, and long-term performance.

This article serves as a comprehensive guide to navigating these choices. Drawing from industry insights, we’ll explore the fundamentals of diaphragm valves, key selection criteria, real-world applications, and best practices to avoid common pitfalls. By the end, you’ll be equipped to select valves that enhance your processes without unnecessary downtime or costs. With the global market for high purity valves projected to grow significantly due to advancements in biotech and semiconductors, making informed decisions now can future-proof your operations.

The importance of these valves cannot be overstated. In semiconductor manufacturing, even microscopic contaminants can ruin wafers worth thousands of dollars, while in pharmaceuticals, purity ensures compliance with regulations like those from the FDA or EMA. Efficient valves reduce energy consumption in pumping systems, and hassle-free designs cut labor costs for maintenance. As we delve deeper, remember that the goal is not just to pick a valve but to integrate one that aligns seamlessly with your system’s demands.

Understanding High Purity Diaphragm Valves

Diaphragm valves operate on a simple yet ingenious principle: a flexible diaphragm, typically made from elastomers like PTFE (polytetrafluoroethylene) or EPDM (ethylene propylene diene monomer), acts as a barrier between the fluid path and the actuator. When the valve is closed, the diaphragm presses against a weir or seat in the valve body, creating a hermetic seal. Opening the valve lifts the diaphragm, allowing fluid to flow through. This design eliminates crevices where fluids could stagnate, making it ideal for high purity applications where sterility is paramount.

There are two primary types: weir-type and straight-through (or full-bore) designs. Weir-type valves, common in hygienic processes, feature a raised weir that the diaphragm seals against, offering excellent shutoff but potentially higher pressure drops. Straight-through valves provide unobstructed flow paths, reducing turbulence and improving cleanability, which is crucial for viscous media or high-flow scenarios. Materials play a pivotal role; valve bodies are often forged from 316L stainless steel for its low carbon content and corrosion resistance, while diaphragms must be selected based on chemical compatibility—PTFE for aggressive chemicals, EPDM for water-based solutions.

High purity variants go further with ultra-high purity (UHP) features, such as vacuum-baked components to remove outgassing risks in semiconductor fabs or biocompatible materials certified under USP Class VI for biotech. Actuation options include manual, pneumatic, or electric, with pneumatic being favored for automation in cleanrooms due to its reliability and speed. Efficiency in these valves is measured by Cv (flow coefficient), which indicates how much fluid can pass at a given pressure drop—higher Cv means better efficiency.

Maintenance ease is a hallmark of hassle-free designs. Modern valves like those with quick-release bonnets allow diaphragm replacement in minutes without tools, reducing downtime. Surface finishes are critical; an Ra of 0.4 μm or better ensures easy cleaning via CIP (Clean-In-Place) or SIP (Sterilize-In-Place) processes. Understanding these basics sets the foundation for selection, as mismatched valves can lead to inefficiencies like excessive energy use or frequent failures.

n essence, high purity diaphragm valves bridge the gap between robust industrial needs and delicate purity requirements. Their evolution from basic shutoff devices to sophisticated, sensor-integrated components reflects industry demands for smarter, more efficient systems.

Key Factors in Selecting High Purity Diaphragm Valves

Selecting the right high purity diaphragm valve involves a multifaceted evaluation to ensure it meets your application’s demands for purity, efficiency, and minimal hassle. Start with material selection, as it’s the frontline defense against contamination and degradation.

Materials and Compatibility

The valve body, diaphragm, and seals must withstand the process media without leaching impurities. Stainless steel 316L is the gold standard for its corrosion resistance and low extractables, especially in electropolished form to achieve sub-micron surface smoothness. For diaphragms, PTFE offers broad chemical resistance and high purity, ideal for acids and solvents in semiconductor processes, while EPDM suits neutral pH fluids in biotech. NBR (nitrile butadiene rubber) is cost-effective for oils but less common in high purity due to potential swelling. Always consult compatibility charts; mismatched materials can cause diaphragm rupture, leading to contamination.

Consider temperature and pressure ratings too. Diaphragms have limits—PTFE handles up to 150°C, but EPDM maxes at 120°C. For UHP applications, opt for metal-free wetted parts to avoid ion contamination.

Design and Efficiency Features

Design impacts flow efficiency and cleanability. Weir-type valves excel in throttling but may introduce dead legs; straight-through designs minimize pressure drops for efficient flow, crucial in high-volume biotech fermenters. Look for self-draining angles (at least 2-3 degrees) to prevent pooling, enhancing CIP efficiency.

Efficiency is quantified by low Cv variance and minimal actuation energy. Pneumatic actuators with positioners ensure precise control, reducing overshoot and energy waste. For hassle-free operation, choose valves with modular designs allowing in-line maintenance without pipeline removal. Integrated sensors for leak detection or flow monitoring add efficiency by enabling predictive maintenance.

Size matters—oversized valves waste space and increase costs, while undersized ones cause high pressure drops, straining pumps. Calculate required Cv based on flow rate, viscosity, and delta P using formulas like Q = Cv √(ΔP / SG), where Q is flow, ΔP is pressure drop, and SG is specific gravity.

Certifications and Compliance

High purity demands certifications. Seek ASME BPE compliance for bioprocessing, ensuring hygienic design. FDA 21 CFR 177 for materials in food/pharma contact, and 3-A Sanitary Standards for dairy applications.

USP Class VI tests biocompatibility, vital for injectables. EHEDG certification confirms cleanability. For semiconductors, SEMI standards address particle control.

Reputable manufacturers provide traceability, like material certificates (3.1 or 3.2 EN 10204), ensuring batch purity.

Maintenance and Hassle-Free Aspects

Hassle-free valves minimize interventions. Opt for designs with fewer parts—e.g., one-piece diaphragms reduce assembly errors. Quick-change mechanisms cut downtime from hours to minutes. Predictive maintenance via IoT integration flags wear before failure.

Efficiency ties into longevity; valves with reinforced diaphragms last 1-5 million cycles. Factor in total ownership cost: initial price vs. maintenance savings.

Supplier and Customization

Choose suppliers with proven track records, like those offering custom configurations for unique processes. Evaluate warranties, support, and lead times. Testing prototypes in your system verifies performance.

By prioritizing these factors, you ensure valves that are pure, efficient, and low-maintenance, optimizing your operations.

Applications in High-Tech Industries

High purity diaphragm valves shine in demanding sectors. In pharmaceuticals and biotech, they control sterile fluids in bioreactors, chromatography, and filling lines, preventing cross-contamination. Their aseptic design supports SIP at 135°C, ensuring sterility.

In semiconductors, UHP valves manage ultrapure water (UPW) and chemicals like hydrofluoric acid in etching processes, where ppb-level purity is essential to avoid defects. Efficiency here means high flow with minimal particles.

Food and beverage industries use them for hygienic transfer of juices or dairy, complying with 3-A standards to prevent bacterial growth. In water treatment, they handle corrosive agents efficiently.

Emerging applications include hydrogen production and battery manufacturing, where purity prevents catalyst poisoning. Versatile and adaptable, these valves enable innovation across industries.

Common Mistakes and Best Practices

Avoid pitfalls like ignoring media viscosity, leading to inefficient flow—always model your system. Overlooking certifications can cause regulatory failures; verify early.

Neglecting maintenance schedules shortens life—implement routine inspections for cracks or hardening. Choosing cheap materials invites corrosion; invest in quality.

Best practices: Conduct risk assessments, consult experts, and pilot test. Train staff on proper operation to avoid over-torquing. Use 3-way divert valves for complex routing to boost efficiency.

Stay updated on innovations like smart valves for real-time monitoring.

Conclusion

Choosing high purity diaphragm valves that are hassle-free and efficient boils down to thorough evaluation of materials, design, certifications, and application fit. By focusing on these, you secure reliable performance, cost savings, and compliance. As industries evolve, selecting the right valve today ensures tomorrow’s success. Consult specialists and prioritize quality for optimal results.

For more about how to choose high purity diaphragm valves that are hassle-free and efficient, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

The Inner Workings of a 316L VIM-VAR Stainless Steel Pressure Regulator

How Ultra-High Purity Stainless Steel Tubing Powers Critical Industries

How Does a UHP 316L Stainless Steel Bellows Valve Work?

How Does a 316 Stainless Steel Pipe Fitting Work?

A Comprehensive Guide to 316L VIM VAR UHP Gas Regulator

Tags

Recommended Products

-

BSGS Large Flow Specialty Gas Supply Cabinet 3 Cylinder Gas Storage Cabinet Fully Automated PLC Control Bulk Specialty Gas Systems (BSGS) Gas Cabinets

-

765L Stainless Steel Union Elbow Reducing High Purity Fitting Tubing Extension Tubing Connection

-

Stainless Steel 316L Single Stage Regulator Pressure Control Panels JSP-1E Series For Semiconductor Fluid Control

-

Clean Connection Cabinet JW-300-CCB Valve Manifold Box And Control Valve Box

-

772 LF Female Branch Tee | Stainless Steel Tube Fitting Female Branch Tee 1/2 in. Tube OD x 1/2 in. Tube OD x 3/8 in. Female NPT

-

Low Pressure High Flow Line Pressure Regulators And Control Valves JSR-4L Series For Laboratory Pressure Control

-

764L Stainless Steel Union Tee High Purity Fitting Union Tee Reducing Tubing Connection

-

VMB Valve Manifold Box And Panel Gas Cabinet, BSGS Gas Cabinets, TMA Gas Cabinets, Scrubber Tail Gas Treatment Cabinets