Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

China Ball Valves Manufacturers: A Comprehensive Overview

- Pressure Regulator Valve Manufacturer

- 316 SS ball valves manufacturer, 316 ss ball valves manufacturer Thailand, BA grade high purity ball valves, BA Series high purity ball valves, ball valve supplier malaysia, best 316 SS ball valves manufacturer, china ball valves manufacturers, China High Temperature Ball Valves, China Pneumatic Actuator Ball Valve Manufacturers, china stainless steel ball valve, europe pneumatic actuated ball valve factory, high pressure ball valve china, high pressure ball valve factory, high pressure ball valves, high pressure ball valves manufacturers, high pressure ball valves suppliers, high pressure ball valves suppliers in turkey, high purity ball valves, High Purity Ball Valves Malaysia, High Purity Ball Valves Manufacturer, high temperature ball valve, High temperature ball valve manufacturer, high temperature ball valves china, high temperature high pressure ball valves, pneumatic actuated ball valve manufacturer, pneumatic actuator ball valve, pneumatic actuator ball valve manufacturers, pneumatic actuator ball valve working principle, stainless steel ball valve china, Ultra-high Temperature Ball Valves

- No Comments

China Ball Valves Manufacturers: A Comprehensive Overview

Introduction

In the world of industrial fluid control, ball valves stand out as one of the most reliable and versatile components. These devices, characterized by a spherical disc that controls the flow of liquids or gases through a pipeline, have become indispensable in sectors ranging from oil and gas to water treatment, chemical processing, and manufacturing. The ball inside the valve has a hole through its center, and when aligned with the flow path, it allows passage; a quarter-turn rotation seals it shut. This simple yet effective mechanism ensures minimal leakage, quick operation, and durability under high pressure and temperature conditions.

China has emerged as a global powerhouse in the production of ball valves, dominating the market with its vast manufacturing capabilities, technological advancements, and cost-effective solutions. As one of the largest exporters of industrial valves, China ball valves manufacturers supply products to over 100 countries, contributing significantly to the global supply chain. The keyword “China ball valves manufacturers” encapsulates this thriving industry, where innovation meets affordability. With a focus on quality standards like ISO 9001, API, and CE certifications, these manufacturers have transformed from imitators of foreign designs to leaders in customized, high-performance valves.

The rise of China ball valves manufacturers can be attributed to several factors. First, the country’s robust infrastructure and skilled workforce enable mass production without compromising quality. Second, ongoing investments in research and development have led to innovations such as trunnion-mounted ball valves, floating ball valves, and automated pneumatic versions. Third, China’s strategic position in global trade allows for efficient logistics and competitive pricing. This article delves into the history, top players, advantages, and market trends of China ball valves manufacturers, providing a detailed insight into why they are the go-to choice for industries worldwide. By exploring these aspects, we can appreciate how China has positioned itself at the forefront of this essential sector.

Ball valves from China are not just products; they represent a blend of tradition and modernity. From basic brass models used in plumbing to advanced stainless steel variants for offshore drilling, the diversity is remarkable. As environmental concerns grow, many manufacturers are incorporating eco-friendly materials and designs that reduce energy consumption. The industry’s growth aligns with China’s broader economic strategy, emphasizing high-tech manufacturing and exports. In 2024, the valve sector in China was valued at billions, with ball valves forming a substantial portion due to their widespread applications.

History of Ball Valves Manufacturing in China

The history of ball valves manufacturing in China is intertwined with the nation’s industrial evolution, dating back centuries but gaining momentum in the modern era. While the concept of valves can be traced to ancient China around 4000 years ago—where bamboo or cork plugs were used in water pipes for basic flow control—the ball valve as we know it emerged much later.

The global invention of the ball valve occurred in the 1950s, evolving from earlier plug valves. In China, the valve industry began to take shape in the late 19th century. Shanghai, a bustling trade hub, saw the first valve production in 1902 at the Pan Shunji Copper Workshop on Wuchang Road. Initially, these were simple gate and plug valves, but they laid the foundation for more complex designs. By the 1950s, during the early years of the People’s Republic, valve manufacturing focused on military applications, producing basic components for defense needs.

The 1960s marked a pivotal decade when China started imitating Soviet Union designs, establishing state-owned factories to produce industrial valves. This period saw the introduction of ball valves into the domestic market, primarily for petrochemical and water systems. Factories in regions like Zhejiang and Jiangsu began experimenting with brass and cast iron ball valves, though quality was inconsistent due to limited technology.

The reform and opening-up policy in 1978 revolutionized the industry. Foreign investments poured in, bringing advanced machinery and expertise. Joint ventures with Western companies introduced floating and trunnion-mounted ball valves, which offer better sealing and support for larger sizes. By the 1980s, China ball valves manufacturers were exporting basic models to Southeast Asia, marking the shift from domestic to international markets.

The 1990s witnessed rapid expansion. With the establishment of special economic zones, companies like Neway Valve and SUFA Technology emerged, focusing on high-pressure ball valves for oil and gas. The adoption of CNC machines and CAD software improved precision, reducing defects. Trunnion ball valves, which became popular for large-diameter pipelines, saw increased production in China from the late 1990s, often under licenses from U.S. brands.

Entering the 2000s, the industry boomed with China’s WTO accession in 2001. Manufacturers invested in R&D, developing automated and corrosion-resistant valves. Companies such as Oviko Group and Formen Valve specialized in fully welded and metal-seated ball valves, catering to harsh environments. The 2010s brought digital transformation, with smart valves integrating sensors for remote monitoring, aligning with Industry 4.0.

Today, China ball valves manufacturers lead in innovation, producing eco-friendly valves with low-emission designs. From humble beginnings in Shanghai workshops to global dominance, the history reflects China’s industrial prowess. Challenges like intellectual property issues in the early days have given way to original patents, with over 10,000 valve-related inventions registered annually. This evolution has made China the world’s largest producer, accounting for nearly 40% of global ball valve output.

Top China Ball Valves Manufacturers

When discussing China ball valves manufacturers, several names stand out for their quality, innovation, and market reach. These companies range from state-owned giants to private enterprises, each contributing uniquely to the industry. Below, we profile some of the top players, highlighting their specialties, history, and contributions.

1. Neway Valve Co., Ltd.: Headquartered in Suzhou, Jiangsu, Neway is one of the largest valve manufacturers globally. Founded in 1997, it specializes in trunnion-mounted and floating ball valves for oil, gas, and petrochemical sectors. With over 2,000 employees and exports to 80 countries, Neway holds API 6D and ISO certifications. Their valves withstand pressures up to 2500 psi, featuring anti-static designs and fire-safe seals.

2. SUFA Technology Industry Co., Ltd.: Based in Suzhou, this company traces its roots to 1952 as a state-owned entity. It produces high-performance ball valves, including cryogenic models for LNG applications. SUFA’s R&D center develops valves with extended bonnets for low-temperature environments. Annually, they manufacture over 100,000 units, emphasizing nuclear-grade quality.

3. Yuanda Valve Group Co., Ltd.: Located in Hebei, Yuanda was established in 1994 and focuses on cast steel ball valves for water and sewage systems. Known for affordability, their products meet ANSI standards and are exported to Europe and the Middle East. Yuanda’s innovation includes anti-corrosion coatings, extending valve lifespan in harsh conditions.

4. Xinhai Valve Manufacturing Co., Ltd.: In Wenzhou, Zhejiang—a valve manufacturing hub—Xinhai excels in stainless steel ball valves. Founded in 1986, it offers threaded, flanged, and welded types. Their emphasis on customization has won contracts for major pipelines in Asia.

5. Oviko Group Co., Ltd.: Specializing in fully welded ball valves, Oviko is based in Wenzhou and was founded in 2003. Their products are ideal for district heating and gas transmission, with zero-leakage guarantees. Oviko exports to Russia and the U.S., holding PED and ATEX certifications.

6. Formen Valve: A leading exporter, Formen produces brass and bronze ball valves for plumbing and HVAC. Established in the 2000s, they prioritize OEM services, supplying to international traders with quick turnaround times.

7. Zhejiang Liangyi Valve Co., Ltd. (LYV): In Yongjia County, LYV manufactures V-port ball valves for flow regulation. Since 2005, they’ve focused on automation, integrating pneumatic actuators for industrial processes.

8. Wenzhou Heli Automatic Meter Co., Ltd.: Known for mini ball valves, Heli caters to instrumentation markets. Their compact designs are popular in laboratories and medical equipment.

9. Taizhou Xingnuo Technology Co., Ltd.: This company produces forged steel ball valves, emphasizing high-pressure applications. Founded in 2008, they use advanced forging techniques for enhanced strength.

10. Ningbo Yuhua Industrial Co., Ltd.: Specializing in plastic-lined ball valves for chemical industries, Yuhua ensures corrosion resistance with PTFE linings.

11. ONERO Valve: A top trunnion-mounted ball valve maker, ONERO offers sizes up to 56 inches for offshore platforms.

12. NSV Valve: Focuses on exotic alloy ball valves for corrosive media, with a strong presence in Southeast Asia.

13. Tianyu Valve: Produces soft-seated ball valves for general purposes, known for cost-effectiveness.

14. Welco Valve Co., Ltd.: Experts in multi-port ball valves, allowing multiple flow directions.

15. Zhejiang Hengnuo Valve: While strong in gate valves, they also manufacture reliable ball valves for municipal projects.

These China ball valves manufacturers collectively drive the industry forward, with annual outputs exceeding millions of units. Their success stems from vertical integration—controlling everything from raw materials to final testing—ensuring consistency and competitiveness.

Advantages of Choosing China Ball Valves Manufacturers

Opting for China ball valves manufacturers offers numerous benefits, making them a preferred choice for global buyers. Foremost is cost-effectiveness; lower labor and material costs allow for prices 30-50% below Western counterparts without sacrificing quality. Mass production scales enable bulk orders with short lead times, often 4-6 weeks.

Quality has improved dramatically, with many adhering to international standards like API 6D and ASME. Advanced testing facilities ensure leak-proof performance, durability, and resistance to extreme conditions. For instance, ball valves from China feature quick quarter-turn operations, reducing wear and energy use.

Innovation is another edge; manufacturers invest in automation, producing smart valves with IoT integration for real-time monitoring. Precise engineering handles wide pressure ranges (up to 10,000 psi) and temperatures (-196°C to 650°C). Easy maintenance—requiring no special tools—lowers long-term costs.

Customization is readily available, from material choices (brass, stainless steel, alloys) to designs (pneumatic, electric actuators). Environmental advantages include low-emission valves compliant with EPA standards, supporting sustainable practices.

Supply chain reliability, bolstered by China’s logistics hubs, ensures timely delivery. Overall, these advantages position China ball valves manufacturers as strategic partners for industries seeking efficiency and value.

Market Trends for Ball Valves from China

The market for ball valves from China is experiencing robust growth, driven by global demand and technological shifts. In 2023, the global ball valves market was valued at around USD 13.6 billion, projected to reach USD 17 billion by 2028 at a 4.6% CAGR. China holds a significant share, exporting over 50% of its production.

Key trends include rising demand in Asia-Pacific, fueled by pipeline projects in China and India, increasing by 33%. Infrastructure development in oil, gas, and water sectors boosts adoption of trunnion and floating ball valves.

Sustainability is prominent; manufacturers are developing ceramic and HDPE ball valves for corrosion resistance and eco-friendliness. The shift to smart manufacturing incorporates automation, with pneumatic ball valves gaining traction for quick, durable operations.

The industrial valves market in China exceeded USD 13 billion in 2022, with ball valves comprising 17% due to their versatility. Emerging segments like cryogenic valves for LNG and high-pressure models for renewables are expanding.

Challenges include trade tensions, but opportunities in emerging markets like Africa and Latin America persist. By 2030, the market could grow at 6.5% CAGR, emphasizing innovation and quality from China ball valves manufacturers.

Conclusion

China ball valves manufacturers continue to redefine the industry through innovation, quality, and affordability. As global needs evolve, their role will only strengthen, ensuring reliable fluid control solutions worldwide.

For more about china ball valves manufacturers: a comprehensive overview, you can pay a visit to Jewellok at https://www.jewellok.com/product-category/high-purity-gas-system/ball-valves/ for more info.

Recent Posts

The Inner Workings of a 316L VIM-VAR Stainless Steel Pressure Regulator

How Ultra-High Purity Stainless Steel Tubing Powers Critical Industries

How Does a UHP 316L Stainless Steel Bellows Valve Work?

How Does a 316 Stainless Steel Pipe Fitting Work?

A Comprehensive Guide to 316L VIM VAR UHP Gas Regulator

Tags

Recommended Products

-

Stainless Steel High Purity High Temperature Pneumatic Actuated Ball Valves JBV2 Series

-

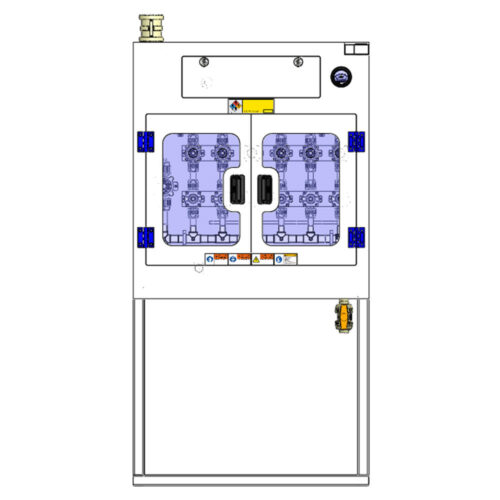

High Purity Configurable Systems VMB Valve Manifold Box JW-200-VMB-C & JW-100-VMB-C

-

Fully Automated Gas Cabinet Gas Rack Gas Delivery Systems JW-300-GR

-

Semi Automatic Gas Cabinet Gas Panels High Purity Gas Delivery Systems JW-200-GC

-

7121L Plug High Purity Plug Fitting And Blanking Plug

-

Stainless Steel 316L Single Stage Regulator Pressure Control Panels JSP-1E Series For Semiconductor Fluid Control

-

Semiconductor High Purity High Pressure Specialty Gas Bottle Gas Cylinder Storage Cabinet And Gas Pressure Regulating Cabinet

-

739 High Purity LMR Male Adapter Tube To Pipe Fittings And Adapters