Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Let’s Further Explore How a Needle Valve Works from the Perspectives of its Working Principle and Applications

- Pressure Regulator Valve Manufacturer

- 10000 Psi Needle Valve Manufacturer, ba series high pressure valve, best high flow needle valves manufacturers, best high pressure needle valve, best high-pressure hydraulic needle valve, best needle valve 10000 psi manufacturers, China Customized Needle Valve Manufacturers, china good quality high pressure valve supplier, china high pressure hydraulic needle valve, china high pressure needle valve, china high pressure needle valve manufacturer, China High Pressure Needle Valve Suppliers, china instrument needle valve, china low pressure needle valve, China Needle Valve Factory, china needle valve manufacturer, China Needle Valve Manufacturers, china needle valve ss316, china needle valve stainless steel, China Needle Valve Suppliers, china needle valves high pressure, China Needle Valves Stainless steel, High Pressure and High Temperature Stainless Steel Needle Valve, high pressure valve china, High Pressure Valves and Fittings Manufacturer, high pressure valves manufacturer in turkey, high-pressure valve, Needle Valve, Stainless Steel Needle Valve, stainless steel needle valve 1/2, Stainless Steel Needle Valve Manufacturer, stainless steel needle valve supplier, Stainless Steel Needle Valves Manufacturer, Threaded Stainless Steel Needle Valve China, ultra high pressure valves, ultra high pressure valves manufacturer

- No Comments

Let’s Further Explore How a Needle Valve Works from the Perspectives of its Working Principle and Applications

In the world of fluid control systems, precision is paramount. Whether it’s regulating the flow of gases in a laboratory setting or controlling hydraulic fluids in industrial machinery, the ability to fine-tune flow rates can make the difference between efficiency and catastrophe. Enter the needle valve—a specialized type of valve renowned for its exceptional accuracy in flow control. But how does a needle valve work? This article delves into the intricacies of needle valves, exploring their design, operation, advantages, and applications. By the end, you’ll have a comprehensive understanding of this essential component in fluid dynamics.

Needle valves derive their name from the long, tapered needle-like plunger that serves as the core mechanism for flow regulation. Unlike standard globe or gate valves, which are better suited for on-off operations, needle valves excel in throttling applications where gradual adjustments are needed. They are commonly found in industries such as oil and gas, chemical processing, pharmaceuticals, and instrumentation systems. The global market for needle valves is projected to grow steadily, driven by advancements in automation and the demand for precise control in high-pressure environments.

To appreciate how a needle valve functions, it’s crucial to start with its historical context. The concept of needle valves dates back to the 19th century, evolving from early steam engine regulators. Today, they are engineered with modern materials and precision manufacturing techniques, ensuring reliability under extreme conditions. This article will break down the valve’s anatomy, explain its working principle step by step, discuss variations, and highlight real-world uses, all while aiming to provide a thorough, 2000-word exploration.

Basic Components of a Needle Valve

At its core, a needle valve is a simple yet ingenious device composed of several key parts that work in harmony. Understanding these components is essential to grasping the valve’s operation.

The body forms the outer shell of the valve, typically machined from durable materials like stainless steel, brass, or carbon steel. It houses the internal mechanisms and provides connection points for inlet and outlet ports. The body’s design ensures it can withstand high pressures, often up to 10,000 psi in industrial models.

Attached to the body is the bonnet, which acts as a cover and seal for the stem. The bonnet is usually threaded or bolted onto the body and contains packing material to prevent leaks. In some designs, the bonnet is integral to the body for added strength.

The stem is the movable part that connects the handle to the needle. It is threaded, allowing for precise linear movement when rotated. The stem’s threads are fine-pitched to enable minute adjustments— a hallmark of needle valves.

The needle itself is the tapered plunger at the end of the stem. Shaped like a cone or needle, it fits into the seat to control flow. The taper allows for gradual opening or closing, providing throttling capability far superior to ball valves.

The seat is the orifice within the body where the needle rests when the valve is closed. It is often made from soft materials like PTFE (polytetrafluoroethylene) for a tight seal or hard metals for durability in abrasive fluids.

Finally, the handle or actuator provides the user interface. Manual handles are common, but automated versions use pneumatic or electric actuators for remote control.

These components are assembled with precision tolerances, often measured in microns, to ensure leak-free operation. For instance, the needle’s taper angle—typically 1 to 3 degrees—directly influences the flow characteristics.

Working Principle of a Needle Valve

The magic of a needle valve lies in its ability to modulate flow with pinpoint accuracy. Let’s break down the working principle step by step.

When the valve is fully closed, the needle is seated firmly against the orifice, blocking the flow path entirely. The tapered tip creates a metal-to-metal or soft-seated seal, preventing any fluid passage. This is achieved by rotating the handle clockwise, which drives the threaded stem downward, pressing the needle into the seat.

To open the valve, the handle is turned counterclockwise. As the stem retracts, the needle lifts away from the seat, creating an annular space for fluid to pass through. The key here is the gradual taper: the flow area increases slowly with each turn, allowing for fine adjustments. For example, a single rotation might open the valve by just 0.1 mm, resulting in a minimal flow increase.

Fluid dynamics play a crucial role. The flow rate through a needle valve follows the principles of Bernoulli’s equation, where pressure drop across the valve converts to velocity. The valve’s Cv (flow coefficient) value, which measures its capacity, is low compared to other valves, emphasizing its role in low-flow, high-precision scenarios.

In operation, the valve can be adjusted to any position between fully open and closed, making it ideal for throttling. However, it’s not recommended for rapid on-off cycling, as the fine threads can wear out over time.

Consider a practical example: in a gas chromatography system, a needle valve regulates the carrier gas flow to the column. By slightly turning the handle, an operator can adjust the flow from 1 ml/min to 10 ml/min, ensuring optimal separation of compounds.

High-pressure variants incorporate additional features like anti-cavitation designs to handle fluids near their vapor pressure, preventing damage from imploding bubbles.

Types of Needle Valves

Needle valves come in various configurations to suit different applications, each with unique design tweaks.

Straight Needle Valves: The most common type, with inlet and outlet ports aligned in a straight line. Ideal for inline installations where space is not an issue.

Angle Needle Valves: These have ports at 90 degrees, useful for changing flow direction without additional fittings. They are prevalent in instrumentation panels.

Multi-Port Needle Valves: Featuring three or more ports, these allow for diversion or mixing of flows. For instance, a three-way needle valve can switch between two sources.

Miniature Needle Valves: Scaled-down versions for low-flow applications, such as medical devices or analytical instruments. They often have port sizes as small as 1/16 inch.

Motorized Needle Valves: Equipped with electric motors for automated control, integrated into PLC systems for process automation.

High-Pressure Needle Valves: Designed for extreme conditions, with reinforced bodies and exotic alloys like Hastelloy for corrosive environments.

Each type maintains the core needle mechanism but adapts it for specific needs, showcasing the valve’s versatility.

Materials and Construction

The choice of materials in needle valve construction is critical for performance and longevity.

Common body materials include:

- Stainless Steel: Resistant to corrosion, suitable for chemical and food industries.

- Brass: Cost-effective for low-pressure water or air systems.

- Monel or Inconel: For high-temperature or corrosive fluids in oil refineries.

Seats can be metal (for durability) or elastomeric (for better sealing). Packing materials around the stem, such as graphite or Viton O-rings, prevent leaks while allowing smooth movement.

Manufacturing involves CNC machining for precision, followed by pressure testing to ASME standards. Quality control ensures the valve can handle rated pressures without failure.

In harsh environments, coatings like epoxy or nickel plating enhance resistance to wear and corrosion.

Advantages and Disadvantages

Needle valves offer several advantages:

- Precision Control: Unmatched accuracy in flow regulation.

- Compact Size: Fits in tight spaces.

- Low Leakage: Tight sealing when closed.

- Versatility: Handles gases, liquids, and slurries.

However, they have drawbacks:

- Low Flow Capacity: Not suitable for high-volume applications.

- Susceptibility to Clogging: Fine orifices can block with particulates.

- Higher Cost: Precision engineering increases price.

- Slow Operation: Manual adjustments take time.

Weighing these pros and cons helps in selecting the right valve for the job.

Applications of Needle Valves

Needle valves are indispensable across industries.

In oil and gas, they control injection rates in wellheads, preventing overpressure.

In pharmaceuticals, they regulate sterile fluids in bioreactors, ensuring purity.

Instrumentation: Used in pressure gauges and flow meters for calibration.

Hydraulics: Fine-tune actuator speeds in machinery.

Aerospace: Manage fuel flows in engines.

A case study: In a natural gas pipeline, needle valves throttle flow during maintenance, allowing safe isolation without full shutdown.

Maintenance and Troubleshooting

Proper maintenance extends a needle valve’s life.

Routine checks include inspecting for leaks, lubricating threads, and replacing packing.

Common issues:

- Leakage: Often due to worn seats; solution: reseat or replace.

- Sticking Stem: Caused by debris; clean with solvent.

- Vibration Damage: Secure mounting to prevent.

Follow manufacturer guidelines for disassembly and reassembly.

Comparison with Other Valves

Compared to ball valves, needle valves offer better throttling but slower operation.

Versus globe valves, they provide finer control with less pressure drop.

Gate valves are for on-off, lacking precision.

This positions needle valves as specialists in accuracy.

Conclusion

Understanding how a needle valve works reveals its elegance in design and function. From the tapered needle’s precise movement to its role in critical industries, it’s a testament to engineering ingenuity. As technology advances, needle valves will continue evolving, perhaps with smart sensors for real-time monitoring. Whether you’re an engineer, student, or enthusiast, appreciating this valve deepens your insight into fluid control systems.

For more about let’s further explore how a needle valve works from the perspectives of its working principle and applications, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Five Key Considerations When Choosing a TMA Gas Changeover Manifold

How to Prevent Contamination in High Purity Xenon Gas Systems

Regulators for High Purity Krypton in Laser and Lighting Applications

Tags

Recommended Products

-

Fully Automated Gas Cabinet For Precise UHP Gas Delivery And High Purity Gas Delivery Systems JW-300-GC

-

Hydrogen Manifold Argon Gas Manifold System Oxygen Manifold Propane Gas Manifold With Valves In Gas Manifold Changeover System

-

High Purity High Pressure Specialty Gas Pressure Regulators Specialty Gases Pipeline Engineering Equipments Manufacturer And Supplier

-

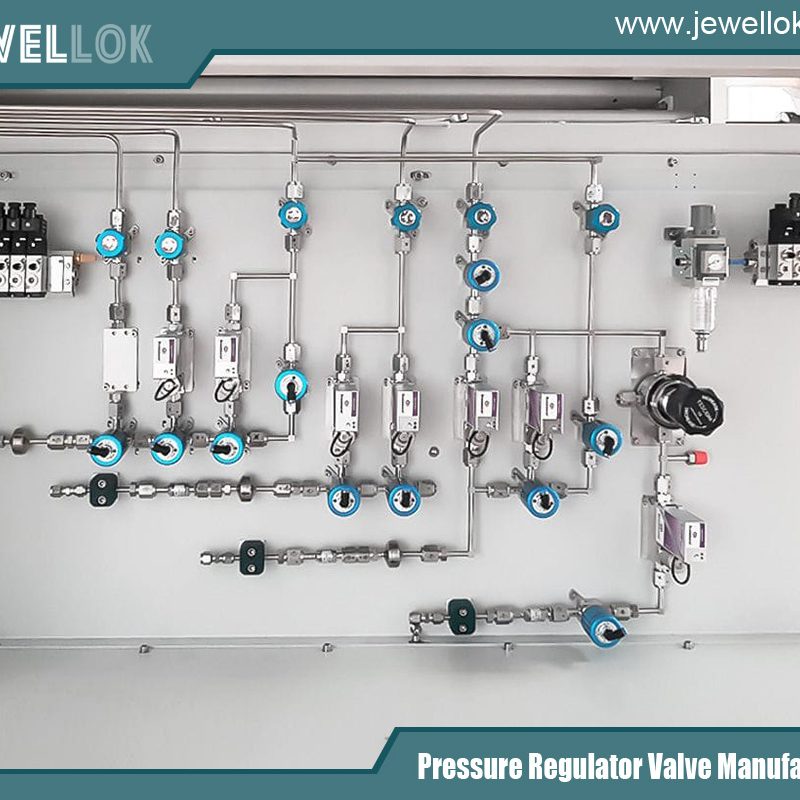

Stainless Steel Single Stage Semiconductor Grade Pressure Control Module Pressure Control Panels JSP-6A Series

-

Low Pressure High Flow Line Pressure Regulators And Control Valves JSR-4L Series For Laboratory Pressure Control

-

High Purity High Pressure Stainless Steel Needle Valve Natural Gas Flow Control Valve JNV Series

-

High Purity Chemical Dispense System & Packing System For Semiconductors JW-200L-CDM & JW-1000L-CDM

-

High Purity And Industria Gas Stick Assemblies Precise Pressure Control Gas Systems JSR-1ETG-BV Series