Blog

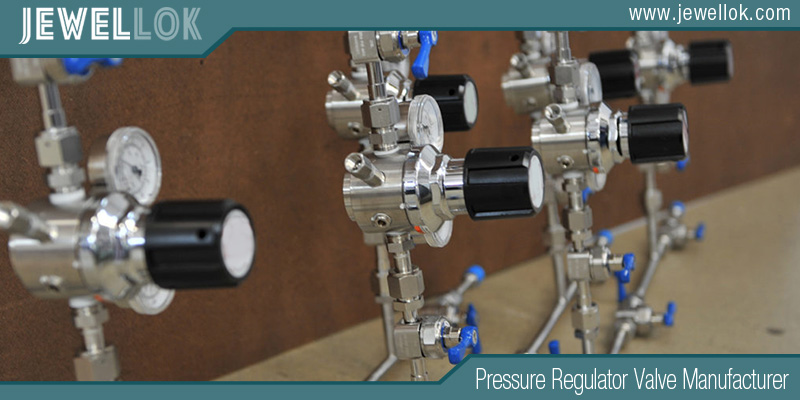

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

How to Select a High-Pressure Nitrogen Gas Regulator Suitable for Corrosive Environments

- Pressure Regulator Valve Manufacturer

- 1 1 2 gas pressure regulator, 1 2 gas regulator, 1/2 gas pressure regulator, 1/4 VCR Stainless Steel Ultra High Purity Gas Regulator, 2-stage auto changeover lp propane gas regulator, 3/4 natural gas regulator, 316L Stainless Steel Gas Pressure Regulators, 316l stainless steel pressure regulator, adjustable air pressure regulator, Adjustable Helium Single Stage High Pressure Gas Regulator, adjustable hydraulic pressure regulator, adjustable hydraulic pressure relief valve, adjustable natural gas regulator, air pressure regulator diagram, air pressure regulator electronic control, Air Pressure Regulator Manufacturer, Argon Gas Regulator Manufacturer, Argon Gas Regulators, best gas regulator in philippines, best gas regulator valve manufacturers, best high pressure nitrogen gas regulator, best high pressure nitrogen gas regulator manufacturer, Best specialty gas regulator manufacturers, Best specialty gas regulators, Best specialty gas regulators manufacturer in india, gas regulator, gas regulator manufacturers in india, high pressure gas regulator, high pressure nitrogen gas regulator, high pressure nitrogen gas regulator manufacturer, high pressure nitrogen gas regulator supplier, high pressure nitrogen regulator, high pressure regulator, low pressure nitrogen gas regulator, nitrogen gas regulator

- No Comments

How to Select a High-Pressure Nitrogen Gas Regulator Suitable for Corrosive Environments

High-pressure nitrogen gas regulators are essential devices in various industrial, scientific, and manufacturing applications where precise control of gas pressure is required. Nitrogen, an inert gas, is widely used for processes such as purging systems, blanketing in chemical storage tanks, laser cutting, food packaging, and tire inflation. A regulator’s primary function is to reduce the high pressure from a gas cylinder or supply line—often exceeding 3,000 psi—to a safer, usable outlet pressure, while maintaining stability despite fluctuations in inlet pressure or flow demand.

In corrosive environments, selecting the right regulator becomes even more critical. These settings, such as chemical processing plants, offshore oil rigs, wastewater treatment facilities, or marine applications, expose equipment to harsh elements like acids, salts, moisture, and reactive chemicals. Corrosion can lead to material degradation, leaks, pressure instability, and safety hazards, including explosions or toxic releases. According to industry guidelines, improper selection can result in premature failure, increased maintenance costs, and operational downtime. For instance, in high-pressure scenarios where nitrogen is used at pressures up to 6,000 psi, a regulator must not only handle the mechanical stress but also resist environmental attacks that could compromise its integrity.

This article provides a comprehensive guide to selecting a high-pressure nitrogen gas regulator for corrosive environments. We’ll cover key factors such as material compatibility, pressure and flow requirements, design features, standards, and maintenance practices. By understanding these elements, users can ensure reliability, safety, and longevity in challenging conditions. The selection process begins with assessing the application’s specific needs, including the type of corrosion (e.g., uniform, pitting, or stress cracking), expected pressure ranges, and regulatory compliance. Ultimately, the goal is to choose a regulator that balances performance, cost, and durability while minimizing risks associated with corrosive exposure.

Nitrogen itself is non-corrosive and non-flammable, but when used in environments with corrosive agents, the regulator’s external and internal components must be fortified. For example, in petrochemical plants, nitrogen might be employed for inerting vessels, but ambient humidity mixed with sulfur compounds can accelerate corrosion on standard brass regulators. High-pressure applications amplify these risks, as failures under elevated pressures can have catastrophic consequences. Therefore, a systematic approach to selection is indispensable, incorporating expert recommendations from manufacturers and standards bodies.

Understanding Corrosive Environments

Corrosive environments are characterized by the presence of substances that can chemically attack and degrade materials over time. These include acids (e.g., hydrochloric or sulfuric), bases, salts, oxidizing agents, and even high humidity or saltwater in coastal areas. In industrial contexts, such as fertilizer production, semiconductor manufacturing, or oil and gas extraction, nitrogen regulators may be exposed to these elements externally or through trace contaminants in the gas supply.

The impact on gas regulators is multifaceted. Corrosion can erode body materials, leading to thinning walls and potential ruptures under high pressure. It may also affect seals and diaphragms, causing leaks that compromise pressure control or introduce contaminants into the system. For high-pressure nitrogen systems, where inlet pressures can reach 3,500-6,000 psi, even minor corrosion can exacerbate stress points, increasing the likelihood of failure. Common types of corrosion include galvanic (between dissimilar metals), crevice (in tight spaces like threads), and pitting (localized holes that weaken structures).

Examples of corrosive environments include:

- Chemical plants handling ammonia or chlorine, where nitrogen is used for purging.

- Marine or offshore platforms, exposed to saltwater spray.

- Wastewater facilities with hydrogen sulfide gases.

- Mining operations with acidic runoff.

To mitigate these, regulators must be designed with corrosion-resistant features. Environmental factors like temperature extremes (e.g., -40°F to 200°F) and vibration further compound the challenges, as they can accelerate corrosion rates. Assessing the environment involves conducting a hazard analysis, including pH levels, exposure duration, and potential contaminants. Tools like corrosion resistance charts from organizations such as NACE (National Association of Corrosion Engineers) can guide initial evaluations. For nitrogen applications, since the gas is inert, the focus shifts to external protection, but internal compatibility remains vital if the system handles mixed gases.

Key Components of a Gas Regulator

A high-pressure nitrogen gas regulator consists of several interconnected components that work together to control pressure. Understanding these is crucial for selection in corrosive environments, as each part’s material and design influence overall resilience.

The main elements include:

- Body and Bonnet: The outer housing, typically made of metal, that contains internal parts. In corrosive settings, stainless steel (e.g., 316 grade) is preferred over brass or aluminum for its resistance to acids and chlorides.

- Diaphragm or Piston (Sensing Element): Detects outlet pressure changes. Diaphragms, often stainless steel or elastomer-coated, flex to adjust the valve; pistons are used for higher pressures due to their ruggedness but may introduce friction. In corrosive environments, metal diaphragms like 316 stainless steel prevent degradation from chemical exposure.

- Poppet Valve (Control Element): Regulates gas flow by opening or closing. It includes a seat (e.g., PTFE for corrosion resistance) that seals against the orifice.

- Spring (Loading Mechanism): Provides the reference force to set outlet pressure. Stainless steel springs resist corrosion better than carbon steel.

- Inlet and Outlet Ports: Connections to the gas supply and downstream system, often with CGA fittings specific to nitrogen (e.g., CGA 580 for standard, CGA 680 for high-pressure).

Regulators operate on a balance of forces: the spring pushes the poppet open, allowing gas flow until outlet pressure on the diaphragm counters it, closing the valve at the set point. In high-pressure applications, multi-stage designs (two- or three-stage) cascade reductions for stability, essential when inlet pressure drops as a cylinder empties.

For corrosive environments, components must minimize dead space to reduce contaminant buildup. Barstock construction, machined from solid metal, offers denser grain and smoother surfaces than forged bodies, enhancing purity and corrosion resistance. Additional features like purge assemblies allow inert gas flushing to prevent moisture ingress during cylinder changes, critical in humid, corrosive areas.

Material Selection

Material choice is the cornerstone of selecting a regulator for corrosive environments, as it directly determines resistance to chemical attack and longevity under high pressure.

Start with the body material. Brass is economical for non-corrosive gases but corrodes rapidly in acidic or saline conditions. Stainless steel, particularly 316 or 316L, is the standard for corrosive applications due to its chromium and molybdenum content, which forms a passive oxide layer resisting pitting and crevice corrosion. For extremely aggressive environments, exotic alloys like Hastelloy C-22 or Monel offer superior performance against strong acids like HCl or HF. Aluminum, while lightweight and corrosion-resistant in some cases, is unsuitable for strong corrosives and often requires epoxy coatings.

Diaphragms and seals demand special attention. Stainless steel diaphragms (e.g., 316) are ideal for high purity and corrosive resistance, avoiding the off-gassing and degradation of elastomers like neoprene. For seals and seats, fluoropolymers such as PTFE (Teflon), Viton, or Kalrez provide excellent chemical inertness. EPDM is suitable for bases but not acids. In high-pressure nitrogen setups, ensure seals handle temperatures from -20°F to 150°F without cracking.

Internal components like poppets and orifices should match the body material to prevent galvanic corrosion. For nitrogen, which is dry and inert, internal corrosion is less of an issue, but external exposure in corrosive atmospheres necessitates full stainless construction. High-purity applications may require electropolished surfaces to minimize particle generation and adsorption sites.

Consult chemical compatibility charts and perform tests if needed. Certifications like ASTM standards verify material properties. Cost-wise, stainless steel regulators are 2-3 times more expensive than brass but offer 5-10 times longer life in corrosive settings, reducing total ownership costs.

Pressure and Flow Considerations

High-pressure nitrogen regulators must manage inlet pressures up to 6,000 psi while delivering stable outlet pressures, often 0-500 psi or higher, depending on the application.

Determine inlet and outlet ranges first, adding a 10-20% safety margin to the maximum expected inlet. For flow, calculate maximum and minimum rates in SCFH (standard cubic feet per hour), factoring in downstream demand variations. Oversized regulators can cause droop (pressure drop with increased flow), while undersized ones restrict capacity.

Single-stage regulators suffice for stable inlets but exhibit pressure rise as cylinder pressure falls. Dual-stage models maintain constant outlet (within 1-5% accuracy) by using two reduction steps, ideal for high-pressure nitrogen from depleting cylinders. Three-stage versions handle extreme inlets (up to 3,000 psi) for portable or analytical uses.

In corrosive environments, pilot-operated designs enhance accuracy under varying conditions, as corrosion might affect mechanical parts. Consider Cv values for flow coefficients to ensure no excessive drops. Altitude adjustments are necessary, as capacity decreases 3% per 1,000 feet. For nitrogen, non-relieving regulators prevent venting inert gas, but in corrosive setups, ensure vents are protected or directed safely.

Additional Features and Specifications

Beyond basics, look for features enhancing suitability in corrosive environments. Safety options include excess flow valves to shut off during ruptures and flash arrestors for mixed gas risks. Purging systems, like tee purges, flush lines with nitrogen to exclude moisture and corrosives.

Certifications are vital: PED for pressure equipment, ATEX for hazardous areas, and CGA for connections. For high purity, opt for Class 100 clean room assembly. Mounting styles (panel, line) and adjustments (hand knob vs. T-handle) affect usability in harsh settings. Remote sensing lines improve accuracy in long runs. Vendor selection involves reputable brands like Swagelok, ControlAir, or Matheson, offering warranties and support.

Installation and Maintenance

Proper installation ensures performance: Mount upright, use straight piping (6 diameters downstream), and protect vents from elements. In corrosive areas, use protective enclosures.

Maintenance includes annual inspections, leak tests, and component replacement every 5 years. Easy-disassembly designs reduce downtime. Monitor with gauges and sensors for early detection.

Conclusion

Selecting a high-pressure nitrogen gas regulator for corrosive environments requires balancing materials, pressure capabilities, and features for optimal safety and efficiency. Prioritize stainless steel construction, multi-stage designs, and compliance standards to mitigate risks. Consult experts and test in simulated conditions for best results. With careful choice, these regulators can provide reliable service in the toughest settings.

For more about how to select a high-pressure nitrogen gas regulator suitable for corrosive environments, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Five Key Considerations When Choosing a TMA Gas Changeover Manifold

How to Prevent Contamination in High Purity Xenon Gas Systems

Regulators for High Purity Krypton in Laser and Lighting Applications

Tags

Recommended Products

-

Clean Connection Cabinet JW-300-CCB Valve Manifold Box And Control Valve Box

-

High Purity High Pressure Stainless Steel Needle Valve Natural Gas Flow Control Valve JNV Series

-

766L High Purity Female Connector UHP Fitting Female Connector

-

763L Stainless Steel High Purity Pressure Reducing Union Fittings And Tubing Pressure Reducing Valve Adjustment

-

316L Stainless Steel Tube Butt Weld Reducing Fittings Union Reducer RW Series Ultrahigh Purity Process

-

Manual Gas Rack High Purity Gas Delivery Systems JW-100-GR

-

7102L Stainless Steel 316L SS Union Cross Ultra High Purity Long Arm Union Elbow Tee Cross Butt Weld Fittings

-

JF Series In-Line Gas Filters | High Purity High Precision High Flow Semiconductor Gas Filter Gas Filtration & Purification