Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

What is the Core Difference Between Pressure Safety Valve and Relief Valve

- Pressure Regulator Valve Manufacturer

- 0-10 psi air pressure regulator with gauge, 1 1 2 gas pressure regulator, 1/2 gas pressure regulator, 10000 Psi Needle Valve Manufacturer, 12v electric valve, 3 piece ball valves in thailand, 3000psi High Pressure Stainless Steel Diaphragm Valve, 316 SS ball valves manufacturer, 316 stainless steel ball valves, 316 stainless steel tube pressure rating, 316l stainless steel ball valve manufacturer, 316l stainless steel diaphragm valve, 316L Stainless Steel Gas Pressure Regulators, 316l stainless steel pressure regulator, actuated ball valve manufacturers, adjust gas valve pressure, adjustable air pressure regulator, Adjustable Helium Single Stage High Pressure Gas Regulator, adjustable high pressure propane regulator, adjustable hydraulic pressure regulator, adjustable hydraulic pressure relief valve, adjustable low pressure propane regulator, adjustable low pressure propane regulator with gauge, adjustable propane pressure regulator, air compressor non return valve, gas cylinder, humming propane regulator, pressure regulator, pressure relief valve vs pressure safety valve, pressure safety valve, pressure safety valve vs pressure relief valve, pressure safety valve vs relief valve, relief valve, safety or relief valves, safety valve vs pressure relief valve, valve

- No Comments

What is the Core Difference Between Pressure Safety Valve and Relief Valve

In the realm of industrial engineering and process safety, pressure control devices play a pivotal role in preventing catastrophic failures, protecting equipment, and ensuring the safety of personnel. Among these devices, pressure safety valves (PSVs) and pressure relief valves (PRVs) are two of the most critical components used across various sectors such as oil and gas, chemical processing, pharmaceuticals, and power generation. While both serve the fundamental purpose of relieving excess pressure from systems to avoid overpressurization, they are often misunderstood or used interchangeably. However, understanding their core differences is essential for proper selection, installation, and maintenance.

At their essence, PSVs and PRVs differ primarily in their operational mechanisms, applications, and response to pressure changes. A PRV typically opens gradually in proportion to the pressure increase, making it suitable for controlled regulation under normal operating conditions. In contrast, a PSV opens suddenly and fully once a predetermined pressure threshold is reached, providing rapid relief in emergency scenarios. This distinction not only affects how they function but also influences their suitability for different fluids—liquids for PRVs and gases or vapors for PSVs. These differences stem from engineering principles designed to address specific safety needs, and overlooking them can lead to inefficiencies, equipment damage, or even hazardous incidents.

This article delves into the definitions, historical context, operating principles, key differences, similarities, applications, standards, selection criteria, and maintenance of PSVs and PRVs. By exploring these aspects in detail, we aim to provide a comprehensive understanding that aids engineers, technicians, and decision-makers in optimizing system safety. With industries increasingly focusing on regulatory compliance and operational efficiency, grasping these nuances is more important than ever.

Definitions

1.Pressure Relief Valve (PRV)

A pressure relief valve, often abbreviated as PRV, is a safety device engineered to limit or control pressure within a system by automatically releasing excess fluid when the internal pressure approaches or exceeds a predefined limit. Unlike manual valves, PRVs operate autonomously, relying on the system’s pressure to trigger their action. They are designed for proportional operation, meaning the valve opens incrementally as pressure rises, allowing for a controlled discharge of fluid to maintain system stability.

PRVs are commonly associated with incompressible fluids like liquids, where gradual pressure adjustments are necessary to prevent surges or thermal expansions from damaging pipelines, tanks, or pumps. For instance, in a hydraulic system, a PRV might relieve pressure caused by fluid heating, ensuring the system remains within safe operating parameters without abrupt interruptions.

A pressure safety valve, or PSV, is a specialized type of relief valve that acts as a fail-safe mechanism to protect pressure vessels and piping systems from excessive pressure buildup. It is engineered to open rapidly and fully—often referred to as “pop action”—when the pressure reaches a set point, discharging the medium (typically gas or vapor) until the pressure drops to a safe level, at which point it reseats.

PSVs are crucial in scenarios where overpressurization could lead to explosions or ruptures, such as in boilers or gas compressors. They are not intended for routine pressure control but rather for emergency relief, making them a last line of defense in high-risk environments.

Historical Background

The evolution of pressure valves traces back to the Industrial Revolution, when steam engines and boilers became widespread. Early incidents, like boiler explosions in the 19th century, highlighted the need for reliable pressure control. The first safety valves were simple weighted levers, but by the mid-1800s, spring-loaded designs emerged, pioneered by inventors like George Stephenson for locomotives.

The distinction between relief and safety valves became more pronounced in the 20th century with advancements in petrochemical industries. Organizations like the American Society of Mechanical Engineers (ASME) began standardizing these devices in the 1910s, differentiating them based on fluid types and response speeds. PRVs evolved for liquid systems in hydraulic and water applications, while PSVs were refined for compressible fluids in high-pressure gas systems. Post-World War II, with the rise of nuclear and chemical plants, regulations tightened, further clarifying their roles to enhance safety protocols.

Today, these valves incorporate advanced materials like stainless steel and exotic alloys to withstand corrosive environments, reflecting ongoing innovations driven by safety demands.

Operating Principles

1.How a PRV Works

The operation of a PRV is based on a balance between the system’s pressure and the valve’s spring force. Under normal conditions, a compressed spring holds the valve disc against its seat, preventing flow. As pressure increases, it exerts force on the disc, gradually overcoming the spring tension. This causes the valve to open proportionally—the greater the overpressure, the wider the opening—allowing fluid to escape through a discharge port.

Once the pressure decreases to the reseating point (typically 5-10% below the set pressure), the spring forces the disc back into place. This modulating action minimizes fluid loss and system disruption, making PRVs ideal for applications where precise control is needed. Blowdown, the difference between set and reseating pressures, is usually adjustable in PRVs for fine-tuning.

- How a PSV Works

PSVs operate on a similar spring-loaded principle but with a key twist: they are designed for snap-action opening. The valve remains closed until the exact set pressure is reached, at which point the disc lifts fully off the seat in a rapid “pop,” discharging a large volume of gas or vapor quickly. This is facilitated by a huddling chamber that uses the escaping fluid’s momentum to keep the valve open until pressure drops significantly.

The blowdown for PSVs is typically fixed at 3-10% of the set pressure, ensuring quick closure to prevent excessive venting. This mechanism is critical for compressible media, where pressure can build exponentially, requiring immediate intervention to avert failures.

indvalve.com

Key Differences

The core difference between PSVs and PRVs lies in their response to pressure: PSVs provide instantaneous, full-opening relief for emergency overpressurization, while PRVs offer gradual, proportional relief for controlled pressure management.

- Operation Mechanism: PRVs modulate opening based on pressure magnitude, suitable for slow-building pressures. PSVs pop open fully, handling sudden spikes.

- Fluid Compatibility: PRVs are optimized for liquids (incompressible), where volume changes are minimal. PSVs handle gases and vapors (compressible), where rapid expansion demands quick discharge.

- Activation Context: PRVs function during normal operations to maintain optimal pressure. PSVs act as backups, activating only when primary controls fail.

- Capacity and Blowdown: PSVs have higher discharge capacities with fixed blowdown, while PRVs allow adjustable blowdown for precision.

- Set Pressure and Reseating: PSVs reseat at a lower pressure to ensure complete relief, whereas PRVs reseat closer to the set point for minimal interruption.

These differences ensure each valve addresses specific risks, with PSVs prioritizing rapid safety and PRVs focusing on operational continuity.

Similarities

Despite their distinctions, PSVs and PRVs share several attributes. Both are automatic, spring-loaded devices that relieve excess pressure to protect systems from damage. They require regular maintenance, including inspections for corrosion, leaks, and spring integrity, to maintain reliability. Compliance with standards is mandatory for both, and they are integral to safety instrumented systems in hazardous industries.

Functionally, both prevent overpressurization, which could lead to ruptures or explosions, and they often incorporate similar components like nozzles, discs, and springs. In some contexts, the terms are used synonymously, especially in older literature, but modern engineering emphasizes their specialized roles.

Applications and Case Studies

PRVs are widely used in liquid-handling systems. For example, in hydraulic presses, they prevent overloads from thermal expansion. In water distribution networks, PRVs regulate pressure to avoid pipe bursts. A case study from a chemical plant showed that installing PRVs in storage tanks reduced downtime by 20% by managing routine pressure fluctuations.

PSVs find applications in gas and vapor systems, such as steam boilers in power plants, where they prevent explosions. In oil refineries, PSVs on pressure vessels safeguard against fire-induced overpressure. The 1984 Bhopal disaster underscored the need for reliable PSVs, as valve failures contributed to the tragedy. Modern implementations, like in LNG facilities, demonstrate how PSVs integrate with shutdown systems for enhanced safety.

Hybrid safety relief valves combine features of both, used in multiphase systems for versatile protection.

Standards and Regulations

Both valves must adhere to rigorous standards to ensure performance. The ASME Boiler and Pressure Vessel Code (Section VIII) mandates design, testing, and certification for pressure vessels, specifying capacity calculations and set pressures. API standards, such as API 520 and 521, guide sizing and installation for petroleum industries. ISO 4126 provides international guidelines on safety valves, emphasizing burst tests and material integrity.

Regulations like OSHA’s Process Safety Management require regular audits, while EU’s Pressure Equipment Directive enforces CE marking. Non-compliance can result in fines or shutdowns, highlighting the need for certified valves.

Selection Criteria

Choosing between a pressure safety valve (PSV) and PRV involves assessing system parameters: fluid type (gas vs. liquid), pressure dynamics (sudden vs. gradual), capacity needs, and environmental factors like temperature and corrosion. Engineers use software for sizing based on scenarios like blocked discharge or fire exposure. Cost, maintenance ease, and compatibility with existing systems also factor in.

For instance, in a high-pressure gas pipeline, a PSV is preferred for its rapid response, while a liquid fuel system benefits from a PRV’s precision.

Maintenance and Testing

Maintenance is crucial for both valves. Inspections every 6-12 months check for wear, with bench testing verifying set pressures. Common issues include spring fatigue, seat leakage, or blockage from debris. PSVs require pop tests to simulate emergencies, while PRVs undergo flow tests for proportional response.

Predictive maintenance using sensors for vibration or pressure monitoring extends lifespan. Training personnel on handling and recalibration ensures compliance and safety.

Conclusion

In summary, the core difference between a pressure safety valve and a relief valve boils down to their operational philosophy: PSVs for emergency, rapid relief in gas systems, and PRVs for controlled, gradual relief in liquid systems. While they share safety objectives, their distinct mechanisms make them indispensable in tailored applications. As industries evolve with automation and sustainability, selecting and maintaining these valves correctly will remain key to preventing accidents and optimizing performance. By prioritizing education and adherence to standards, we can enhance overall system reliability and safety.

For more about what is the core difference between pressure safety valve and relief valve, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Five Key Considerations When Choosing a TMA Gas Changeover Manifold

How to Prevent Contamination in High Purity Xenon Gas Systems

Regulators for High Purity Krypton in Laser and Lighting Applications

Tags

Recommended Products

-

JF Series In-Line Gas Filters | High Purity High Precision High Flow Semiconductor Gas Filter Gas Filtration & Purification

-

764L Stainless Steel Union Tee High Purity Fitting Union Tee Reducing Tubing Connection

-

763L Stainless Steel High Purity Pressure Reducing Union Fittings And Tubing Pressure Reducing Valve Adjustment

-

Semi Automatic Oxygen Nitrogen Helium Argon Gas Changeover Manifold Manual Gas Changeover Manifold Panel For Gas Cylinders

-

764LR Stainless Steel 316 Reducing Tee UHP Fitting Automatic Buttweld Reducing Tee

-

Scrubber Tail Gas Treatment Cabinet Waste Gas Treatment Wet Scrubber Exhaust Gas Treatment Spray Tower

-

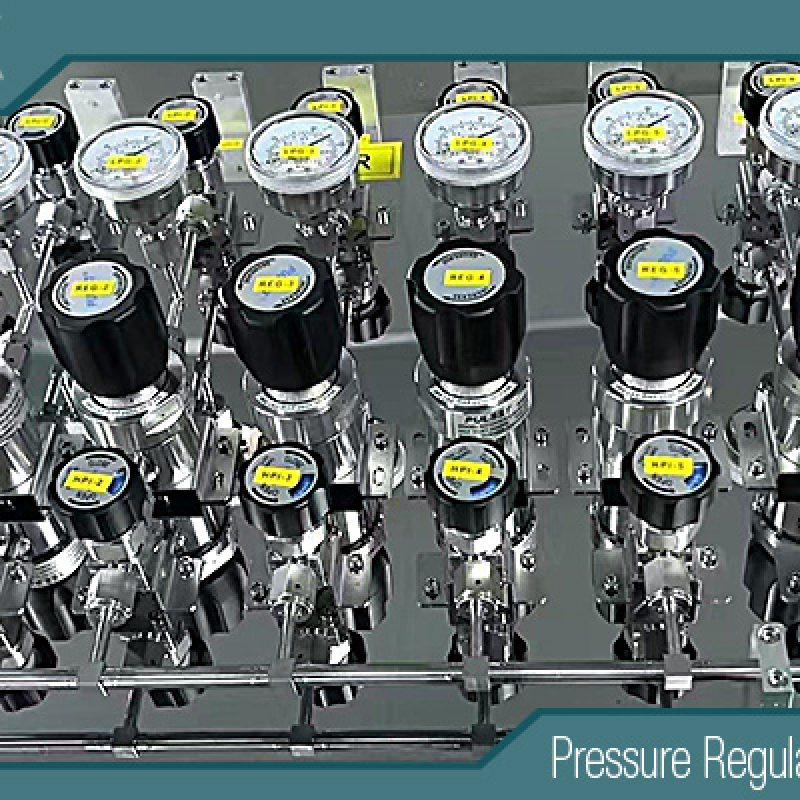

Pressure Control Panels For High Purity Gas Control System JSP-3AE Series From Pressure Control Panels Suppliers And Manufacturer

-

JR1000 Series UHP Ultra High Purity Single Stage Pressure Reducing Regulator And Low To Intermediate Flow