Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

What are the Key Technical Parameters that Define the Performance of a High-Pressure Argon Gas Regulator?

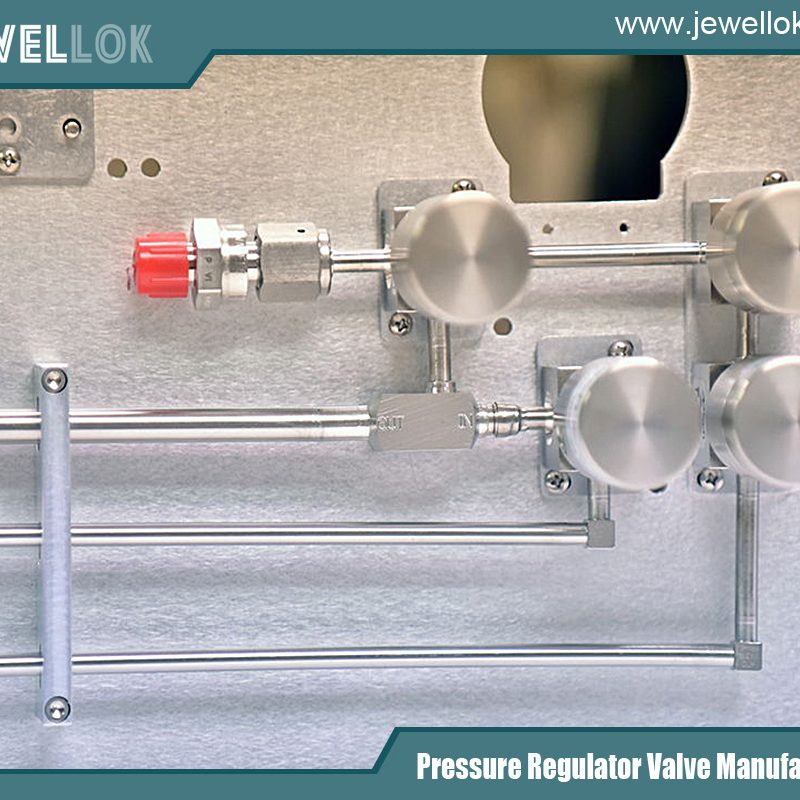

- Pressure Regulator Valve Manufacturer

- 0-10 psi air pressure regulator with gauge, 1 1 2 gas pressure regulator, 1/2 Gas Pressure Regulator manufacturer, 316 SS ball valves manufacturer, 316l stainless steel pressure regulator, adjustable air pressure regulator, adjustable high pressure regulator, adjustable hydraulic pressure regulator, Adjustable Pressure Regulators, adjustable propane pressure regulator, Air Compressor Check Valve, air pressure regulator, air pressure regulator diagram, air pressure regulator electronic control, argon gas regulator, Back Pressure Regulating Valve, back pressure regulator manufacturers, Brass Pressure Regulator, Changeover Manifold, Diaphragm Valve Manufacturers, Gas Solenoid Valve, high pressure gas regulator, high pressure regulator, high purity valves manufacturers, high-pressure argon gas regulator, high-pressure argon gas regulator factory, high-pressure argon gas regulator manufacturer, high-pressure argon gas regulator supplier, Medical Oxygen Regulator, pressure gauge manufacturers, pressure regulator, Stainless Steel Ball Valve, Stainless Steel Diaphragm Valve, Stainless Steel Diaphragm Valve Manufacturer, Stainless Steel Needle Valve, Stainless Steel Pressure Regulator, Stainless Steel Tube Fittings, Water Solenoid Valve

- No Comments

What are the Key Technical Parameters that Define the Performance of a High-Pressure Argon Gas Regulator?

High-pressure argon gas regulators are critical components in various industrial settings, serving as the gatekeepers that control the flow and pressure of argon gas from high-pressure storage cylinders to downstream applications. Argon, an inert noble gas, is widely used due to its non-reactive properties, making it ideal for processes where oxidation or contamination must be prevented. In welding, for instance, argon acts as a shielding gas to protect molten metal from atmospheric gases, while in analytical laboratories, it serves as a carrier gas in chromatography. High-pressure regulators are specifically designed to handle the elevated pressures found in argon cylinders, which can exceed 3,000 pounds per square inch gauge (psig), reducing them to safer, usable levels.

The performance of these regulators is defined by several key technical parameters, including input pressure range, output pressure accuracy, and flow capacity, among others. These parameters not only determine the regulator’s efficiency and reliability but also its compatibility with specific industrial applications. Selecting the wrong regulator can lead to inefficiencies, safety hazards, or process failures. For example, in high-stakes environments like semiconductor manufacturing, even minor fluctuations in pressure can compromise product quality. This article explores these parameters in depth, drawing on industry standards and technical insights, and examines how they influence suitability across sectors such as welding, laboratory analysis, and industrial manufacturing. By understanding these factors, engineers and technicians can make informed decisions to optimize operations.

High-pressure argon regulators come in various designs, such as single-stage and dual-stage models, each tailored to different needs. Single-stage regulators reduce pressure in one step and are simpler, while dual-stage versions provide more stable output by performing reduction in two phases. Materials like brass or stainless steel are chosen based on purity requirements, as argon is non-corrosive but applications may demand high purity to avoid contamination. The global market for gas regulators, including those for argon, is driven by industries valuing precision and safety, with advancements focusing on reducing leakage and improving flow control.

Key Technical Parameters of High-Pressure Argon Gas Regulators

- Input Pressure Range

The input pressure range, also known as inlet pressure, refers to the maximum and minimum pressures that the regulator can safely accept from the gas source, typically a cylinder. For high-pressure argon regulators, this range often spans from 0 to 10,000 psig, with standard models handling up to 3,000 psig and specialized high-pressure variants accommodating 6,000 to 7,500 psig or more. This parameter is crucial because argon cylinders are filled to high pressures to maximize storage capacity—common fillings reach 2,200 to 3,000 psig, but high-pressure options like CGA 677 or 680 connections support up to 6,000 psig.

The input pressure range affects the regulator’s structural integrity and compatibility with gas sources. Regulators must be rated above the cylinder’s maximum pressure to prevent rupture or failure. For instance, exceeding the rated input can damage internal components like the valve seat or diaphragm. Materials play a role here; forged brass bodies are common for general-purpose regulators due to their strength and cost-effectiveness, while barstock stainless steel is used for high-purity applications to withstand higher pressures without corrosion or particle generation.

In practice, the input range influences the “decaying inlet characteristic,” where delivery pressure rises as cylinder pressure drops in single-stage regulators. This requires frequent adjustments in applications with varying supply pressures. Dual-stage regulators mitigate this by maintaining stability, making them preferable for extended operations.

Temperature also interacts with input pressure; regulators are typically rated for -40°F to 165°F, as extreme conditions can alter gas density and pressure ratings.

- Output Pressure Accuracy

Output pressure accuracy measures how precisely and consistently the regulator maintains the desired delivery pressure, despite changes in flow or inlet pressure. This is quantified through metrics like droop (the drop in outlet pressure as flow increases), lockup (the slight pressure rise when flow stops), and supply pressure effect (variations due to inlet changes). High-accuracy regulators exhibit minimal droop, often less than 5-10% over their flow range, ensuring stable output.

For argon regulators, output ranges vary: low-pressure models deliver 0.1-15 psig, standard ones 0-500 psig, and high-pressure up to 6,000 psig. Accuracy is enhanced by the sensing element, typically a diaphragm made of stainless steel for high purity or elastomers like neoprene for general use. In dual-stage designs, the first stage reduces pressure to an intermediate level (e.g., three times the max working pressure), allowing the second stage to fine-tune output with greater precision.

Leakage rates are another accuracy aspect; inboard and outboard helium leak tests ensure rates below 1×10^-9 atm cc/sec He to prevent contamination. Poor accuracy can lead to process instability—for example, in welding, fluctuating pressure might cause arc instability. Regulators with tied diaphragms improve safety and accuracy for toxic or corrosive gases, though argon being inert reduces this need.

- Flow Capacity

Flow capacity, often expressed in standard cubic feet per minute (scfm) or liters per minute (slpm), indicates the volume of gas the regulator can deliver at a given pressure drop. It’s tied to the coefficient of flow (Cv), which quantifies the orifice size and efficiency. High-flow argon regulators can handle up to 250 scfm, suitable for large-scale operations, while low-flow models (e.g., 0-3 slpm) are for precise applications like calibration.

This parameter is influenced by the control element—a poppet valve that adjusts the orifice based on diaphragm feedback. As flow increases, droop occurs if capacity is exceeded, leading to pressure drops. Flow curves plot outlet pressure versus flow, showing a flat line for stable low-flow operation and a steep drop at high flows. For argon, flow capacity must match application demands; too low restricts productivity, while oversized regulators may lack precision at low flows.

Additional factors include internal volume (low dead volume designs minimize stagnant gas for purity) and preset versus variable flow options. In high-pressure models, flow is limited by safety to prevent rapid depressurization.

- Other Important Parameters

Beyond the core trio, several parameters enhance performance. Material construction ensures compatibility—brass for cost-effective non-corrosive service, stainless steel for high purity to reduce adsorption of contaminants like moisture. Seals (e.g., PTFE) prevent leaks, and CGA connections (580 for argon) standardize fittings.

Temperature range affects seals and diaphragms; extreme cold can brittle materials, while heat expands gases. Safety features like relief valves protect against overpressure, and purity levels (general <99.995%, high ≥99.995%) dictate design. Repeatability ensures consistent settings over time, vital for automated processes.

How These Parameters Affect Suitability for Different Industrial Applications

- Welding and Metal Fabrication

In TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding, argon regulators must provide stable flow (15-30 scfh typically) to shield the weld pool. Input pressure range should match cylinder ratings (2,000-3,000 psig) to handle depletion without adjustments. Output accuracy is paramount; minimal droop prevents arc wander, ensuring clean welds on metals like aluminum or stainless steel. Flow capacity needs to support continuous operation—high-flow models for industrial-scale fabrication, where low capacity could cause gas starvation and porosity.

Single-stage regulators suffice for short jobs with monitoring, but dual-stage are better for long sessions to counter decaying inlet effects. In plasma welding, higher pressures (up to 500 psig) demand robust input ranges. Poor accuracy here increases defect rates, raising costs in automotive or aerospace manufacturing.

- Laboratory and Analytical Applications

Laboratories use argon as a carrier gas in gas chromatography (GC) or for purging, requiring ultra-high purity regulators with low dead volume to avoid trace contamination. Output accuracy must be exceptional (e.g., ±0.5 psig) for consistent detector performance in FID or MSD systems. Flow capacity is often low (0.3-2.5 slpm) but precise, with minimal lockup to prevent pressure spikes that skew results.

Input range accommodates standard cylinders, but dual-stage designs are essential to maintain constant pressure as cylinders empty, critical for long analyses. In emission monitoring, high accuracy ensures regulatory compliance. Stainless steel materials prevent offgassing, making these regulators suitable where brass might introduce impurities.

- Semiconductor and High-Tech Manufacturing

Semiconductor fabs use argon for sputtering or as an inert atmosphere, demanding regulators with input ranges up to 6,000 psig for high-pressure delivery and output accuracy below 1% droop to maintain process uniformity. Flow capacity varies from low for precise etching to high for bulk purging. Ultra-high purity models with metal-to-metal seals minimize particle generation, as even ppm-level contaminants can ruin wafers.

Dual-stage and low-leakage designs are mandatory; supply pressure effects could disrupt vacuum chambers. Temperature resilience is key in cleanrooms.

- Other Industrial Applications

In food packaging (modified atmosphere), low-pressure accurate regulators extend shelf life by displacing oxygen. In chemical processing, high-flow capacity supports large reactors, with robust input ranges for pipeline supplies. For calibration standards, repeatability and low droop ensure traceable measurements.

Across applications, mismatched parameters lead to inefficiencies: oversized flow wastes gas, poor accuracy causes variability, and inadequate input range risks safety.

Conclusion

The key parameters of high-pressure argon gas regulators—input pressure range, output pressure accuracy, flow capacity, and supporting factors like materials and staging—collectively define their performance and dictate suitability for industrial uses. In welding, stability prevents defects; in labs, precision ensures data integrity; in semiconductors, purity safeguards yields. Selecting regulators involves balancing these against application demands, budget, and safety. As industries evolve, advancements in regulator technology, such as smarter sensors for real-time monitoring, will further enhance adaptability. Ultimately, thorough evaluation of these parameters ensures optimal performance, reducing downtime and enhancing productivity in argon-dependent processes.

For more about what are the key technical parameters that define the performance of a high-pressure argon gas regulator, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Choose the Krypton Gas Ultra High Purity (UHP) Regulator

Troubleshooting Common Failures in TMA Gas Changeover Manifolds

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

Tags

Recommended Products

-

Stainless Steel High-Purity High Temperature Metal Seated Ball Valves JBV3 Series

-

Stainless Steel Fully Automatic Gas Switchover Manifold System Automatic Gas Cylinder Switchover Co2 Cylinder Auto Changeover Controller

-

765LR Reducing Tee | Stainless Steel 316 High Purity Butt Weld Fittings Metal Face Seal For Welding Pipe Fitting Reducing Tee

-

High Purity Gas Cylinder Semi Automatic Changeover Manifold Regulator Panel 3000psig Stainless Steel Gas Control Panel 1/8 Npt With Gauge

-

763L Stainless Steel High Purity Pressure Reducing Union Fittings And Tubing Pressure Reducing Valve Adjustment

-

Low Pressure High Flow Line Pressure Regulators And Control Valves JSR-4L Series For Laboratory Pressure Control

-

Fully Automated Gas Cabinet For Precise UHP Gas Delivery And High Purity Gas Delivery Systems JW-300-GC

-

316L Stainless Steel Tube Butt Weld Reducing Fittings Union Reducer RW Series Ultrahigh Purity Process