Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

How Does An Acetylene Gas Changeover Manifold Work?

- Pressure Regulator Valve Manufacturer

- 1 1 2 gas pressure regulator, 1/2 gas pressure regulator, 1/2 Gas Pressure Regulator manufacturer, 316L Stainless Steel Gas Pressure Regulators, Acetylene, Acetylene Gas Changeover Manifold, acetylene gas changeover manifold work, Acetylene Gas Pressure Regulator, Acetylene Gas Pressure Regulator Manufacturer, application of ultra-high purity gas pressure regulator, argon gas changeover manifold, argon gas pressure regulator, Auto Gas Changeover Manifold System, Automatic gas changeover manifold, BA Grade High Purity Gas Pressure Regulators, Best gas changeover manifold for laboratories, best high flow UHP gas pressure regulator industry, best high flow UHP gas pressure regulator industry in Italy, best high purity gas pressure regulator, BURSAN Gas Changeover Manifold, Carbon Dioxide Gas Changeover Manifold, CO2 gas changeover manifold, Components of a gas changeover manifold, gas changeover manifold, Gas changeover manifold design, Gas changeover manifold for cleanroom, gas changeover manifold for hospital

- No Comments

How Does An Acetylene Gas Changeover Manifold Work?

Acetylene gas, known for its high flammability and use in oxy-acetylene welding and cutting, is a critical resource in industries such as metal fabrication, chemical synthesis, and construction. Stored in cylinders dissolved in acetone to prevent explosive decomposition, acetylene requires careful handling to ensure safe and continuous supply. A changeover manifold, also referred to as a switchover manifold, is a sophisticated system designed to provide an uninterrupted flow of acetylene by automatically or manually switching between multiple gas sources—typically banks of cylinders—when the primary supply depletes.

At its essence, an acetylene gas changeover manifold acts as a guardian of continuity, preventing downtime in operations where even brief interruptions can lead to significant productivity losses or safety hazards. For instance, in welding applications, a sudden halt in acetylene supply could ruin a weld or force rework, costing time and materials. These manifolds are particularly vital for acetylene due to its storage limitations: cylinders can only safely discharge about 1/10 of their capacity per hour to avoid acetone carryover, necessitating multiple cylinders connected in manifolds for higher flow rates.

The development of gas manifolds traces back to the early 20th century, coinciding with the industrialization of welding technologies. Modern designs incorporate advanced features like electronic controls and safety valves to handle acetylene’s unique properties, such as its instability above 15 psi in free state and potential for flashback. This article explores the workings of acetylene changeover manifolds in depth, covering their principles, components, operational mechanisms, types, applications, safety protocols, and maintenance. By understanding these systems, users can optimize their setups for efficiency and safety.

In a world where precision and reliability are paramount, the changeover manifold bridges the gap between finite cylinder supplies and continuous demand, embodying engineering ingenuity in gas distribution.

Basic Principles of Acetylene Gas Changeover Manifolds

The fundamental principle behind an acetylene changeover manifold is to maintain a steady gas supply by alternating between primary and reserve sources without interrupting flow. This is achieved through pressure monitoring and valve actuation, ensuring that when the primary bank’s pressure drops below a preset threshold, the system seamlessly switches to the reserve bank.

Acetylene is stored at pressures around 250-300 psi in cylinders filled with porous material soaked in acetone, which stabilizes the gas. However, safe withdrawal rates are limited to prevent solvent entrainment, making manifolds essential for aggregating multiple cylinders into banks. A typical setup divides cylinders into two banks: one active (primary) and one standby (reserve).

The core mechanism relies on differential pressure sensing. In automatic systems, sensors detect when the primary bank’s pressure falls, triggering a switchover. This can be mechanical (using springs and diaphragms) or electronic (with solenoids and controllers). The principle of continuity is governed by fluid dynamics: gas flow follows Bernoulli’s principle, where pressure drops correlate with velocity, but manifolds prioritize pressure stability over flow dynamics.

For acetylene, additional principles apply due to its reactivity. Flashback arrestors are integrated to prevent flame propagation back into the system, adhering to safety standards like those from OSHA or ISO. The changeover also accounts for temperature effects, as colder environments can reduce acetylene vapor pressure, affecting switchover timing.

Manual systems depend on operator intervention, while automatic ones use feedback loops similar to control systems in engineering, where input (pressure) leads to output (valve switch) via a controller. Two-stage pressure reduction is common in auto manifolds to minimize variations, ensuring outlet pressure remains consistent despite source changes.

In essence, these principles ensure reliability, with acetylene’s specifics demanding robust designs to handle its hazards.

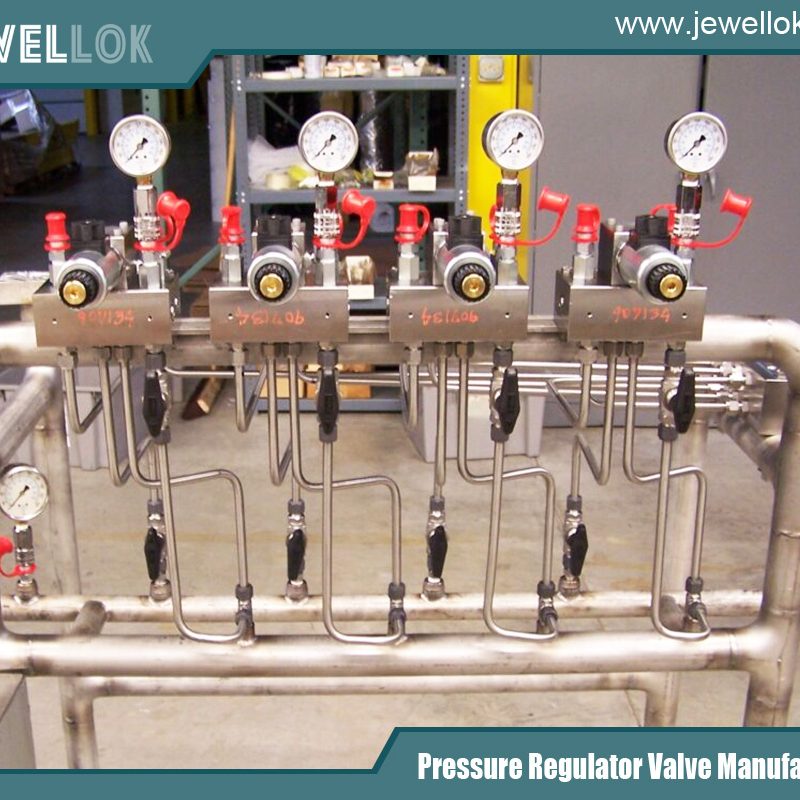

Key Components of an Acetylene Changeover Manifold

An acetylene changeover manifold comprises several integral components that collaborate to monitor, control, and distribute gas safely.

Central to the system is the switchover valve or controller, often a 4-way valve that directs flow from one bank to another. This valve determines which bank is primary and manages the transition. Pressure regulators are key: an intermediate regulator reduces cylinder pressure to a manageable level (e.g., 100-150 psi), while a line regulator fine-tunes the final outlet pressure (typically 5-15 psi for acetylene torches).

Pressure gauges are essential, with one for each bank to monitor supply levels and another for line pressure. A changeover pressure switch detects low pressure in the primary bank, triggering the switch. Safety features include excess pressure relief valves to vent overpressure and flashback arrestors to prevent ignition travel.

Headers connect multiple cylinders in each bank via pigtails (flexible hoses), ensuring even distribution. For automatic systems, an electronic controller or pneumatic actuator automates the process, often with alarms (visual/auditory) for low pressure or switchover events.

In acetylene-specific manifolds, components like automatic shut-off valves (ASV) prevent unsafe discharge rates. Materials are typically brass or stainless steel to resist corrosion from acetylene’s byproducts.

Additional elements might include filters to remove impurities and isolation valves for maintenance. These components form a cohesive unit, with redundancy built-in for reliability.

Step-by-Step Mechanism of Operation

The operation of an acetylene changeover manifold can be dissected into clear steps, varying slightly between manual and automatic types. Let’s focus on an automatic system first.

- Setup and Initialization: Cylinders are connected to headers in two banks via pigtails. The 4-way valve is set to designate one bank as primary and the other as reserve. Regulators are adjusted: intermediate for bank pressure reduction, line for final output. Cylinder valves are opened, and the system is pressurized.

- Normal Operation: Gas flows from the primary bank through the intermediate regulator, switchover valve, and line regulator to the outlet. Pressure gauges show stable readings. The system monitors primary bank pressure via the changeover switch.

- Depletion Detection: As the primary bank depletes, its pressure drops below the preset threshold (e.g., 100 psi, set above the reserve regulator’s output to avoid backflow). The pressure switch detects this and signals the controller.

- Switchover Activation: The controller actuates the 4-way valve (or solenoids in electronic models), closing the path from the primary bank and opening the reserve. Simultaneously, the valve on the primary closes, and the secondary opens, redirecting flow seamlessly. Alarms alert operators to replace the empty bank.

- Post-Switchover: The former reserve becomes primary. Operators replace depleted cylinders, reset the system by adjusting the 4-way valve or controller to redesignate banks, ensuring no interruption.

For manual systems:

- Monitoring: Operators watch gauges. When primary pressure nears low, they manually close the primary isolation valve and open the reserve’s.

- Switch: Flow shifts manually, potentially with brief interruption unless a multi-cylinder setup allows overlap.

In acetylene setups, the mechanism includes checks for flow rates to stay within safe limits, with ASVs shutting off if exceeded. Two-stage reduction in auto systems minimizes pressure fluctuations during switch.

This process ensures continuous supply, with acetylene’s volatility managed through integrated safeties.

Types of Acetylene Gas Changeover Manifolds and Their Applications

Changeover manifolds for acetylene are classified by automation level and configuration.

- Manual Changeover Manifolds: Cost-effective, requiring operator intervention. Single-cylinder types cause downtime during changes; multi-cylinder allow switching without full stop. Suitable for low-volume operations like small workshops.

- Semi-Automatic Manifolds: Switch to reserve automatically on pressure drop but require manual reset. Offer balance of cost and convenience.

- Fully Automatic Manifolds: Electronic switching back and forth without manual input, with two-stage regulation for stability. Ideal for high-demand settings.

Applications include:

- Welding and Cutting: Continuous acetylene for torches in shipbuilding or automotive repair. Chemical Industry: Stable supply for synthesis processes.

- Laboratories: Precise delivery for analytical equipment.

Specialized types like IBEDA’s with ASV allow dual-side withdrawal for higher flows.

Safety Considerations and Maintenance

Safety is critical with acetylene manifolds. Install in ventilated areas to prevent accumulation, use flashback arrestors, and never exceed 15 psi in lines without oxygen mixing. Regular inspections for leaks using soapy water are essential.

Maintenance includes checking regulators and valves monthly, replacing pigtails yearly, and professional servicing annually. After switchover, reset systems and purge lines to remove air. Compliance with standards like NFPA ensures safe operation.

Conclusion

Acetylene gas changeover manifolds are vital for uninterrupted, safe gas delivery, leveraging pressure sensing and valve controls to switch sources seamlessly. From manual to fully automatic types, they cater to diverse needs, enhancing productivity in acetylene-dependent industries. Proper understanding and maintenance unlock their full potential, safeguarding operations against disruptions.

For more about how does an acetylene gas changeover manifold work, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Five Key Considerations When Choosing a TMA Gas Changeover Manifold

How to Prevent Contamination in High Purity Xenon Gas Systems

Regulators for High Purity Krypton in Laser and Lighting Applications

Tags

Recommended Products

-

768LN Stainless Steel Male Pipe Tube Butt Weld Connector And Tube Fittings Supplier

-

Fully Automated Gas Cabinet For Precise UHP Gas Delivery And High Purity Gas Delivery Systems JW-300-GC

-

Low Pressure High Flow Line Pressure Regulators And Control Valves JSR-4L Series For Laboratory Pressure Control

-

Stainless Steel 316L Single Stage Regulator Pressure Control Panels JSP-1E Series For Semiconductor Fluid Control

-

High Purity Semi-Auto Stainless Steel Changeover Manifold System, Nitrogen High Pressure Control Panel With Semiconductor Valve Manifold Box Diaphragm Valves

-

Stainless Steel High-Purity High Temperature Metal Seated Ball Valves JBV3 Series

-

762L Stainless Steel High Purity Union High-Purity Gas System Fittings

-

Semi Automatic Gas Cabinet Gas Panels High Purity Gas Delivery Systems JW-200-GC