Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Ultra High Purity Nitrogen Gas Regulator: Precision Control for Critical Applications

- Pressure Regulator Valve Manufacturer

- additive manufacturing inert atmosphere, analytical instrumentation regulators, CGA 580 nitrogen connection, diaphragm gas regulator, electropolished regulator design, gas chromatography carrier gas, helium leak tested regulators, high flow nitrogen regulator, high pressure nitrogen gas regulator, high pressure nitrogen regulator, high pressure nitrogen regulator manufacturer, High Purity Gas Regulators, inert gas blanketing, low droop pressure regulator, nitrogen cylinder pressure regulator, nitrogen gas pressure regulator, nitrogen pressure reducing valve, PCTFE seat regulator, pharmaceutical gas control, pressure relief in gas regulators, regulator maintenance protocols, SEMI compliant regulators, semiconductor nitrogen regulator, Single Stage High Pressure Nitrogen Regulator, Stainless steel gas regulators, UHP nitrogen regulator, ultra high purity nitrogen gas regulator, ultra low pressure nitrogen regulator

- No Comments

Ultra High Purity Nitrogen Gas Regulator: Precision Control for Critical Applications

In the realm of industrial and scientific applications, the management of gases with extreme purity is paramount. Ultra high purity (UHP) nitrogen gas regulators stand at the forefront of this technology, ensuring that nitrogen gas is delivered with minimal contamination and precise pressure control. These devices are essential in sectors where even trace impurities can compromise processes, such as semiconductor manufacturing, pharmaceutical production, and analytical instrumentation. This article delves into the technical aspects of UHP nitrogen gas regulators, exploring their design, functionality, applications, and maintenance requirements. By understanding these regulators, engineers and technicians can optimize their systems for reliability and efficiency.

Nitrogen gas, being inert and non-reactive, is widely used as a carrier gas, purging agent, or blanketing medium. However, for ultra high purity applications, the gas must maintain purity levels often exceeding 99.9999% (6N grade). Any regulator handling such gas must prevent ingress of contaminants like oxygen, moisture, or particulates. UHP nitrogen gas regulators are engineered with specialized materials and features to achieve this, making them indispensable in high-stakes environments.

Design and Components

The design of an ultra high purity nitrogen gas regulator is a testament to advanced engineering principles. Unlike standard regulators, UHP models incorporate materials that minimize outgassing and corrosion. Primary components include the body, diaphragm, seat, poppet, and adjustment mechanisms, all crafted from high-grade stainless steel, such as 316L or electropolished variants, to ensure surface smoothness and reduce particle adhesion.

The body of the regulator is typically a single-piece or welded construction to eliminate potential leak paths. Electropolishing removes microscopic burrs and imperfections, achieving a surface roughness often below 10 Ra (roughness average). This is crucial for preventing particle generation during gas flow.

The diaphragm, a key sealing element, is usually made from Hastelloy or other alloys resistant to fatigue and chemical attack. It isolates the process gas from the spring mechanism, preventing contamination from lubricants or atmospheric gases. In some designs, a tied-diaphragm configuration enhances sensitivity and response time.

The seat and poppet assembly controls the flow. Soft seats made from PCTFE (polychlorotrifluoroethylene) or similar polymers provide bubble-tight shutoff, essential for maintaining purity. Hard seats, using metal-to-metal contact, are employed for higher pressure applications but require precise machining to avoid leaks.

Pressure adjustment is facilitated by a hand knob or T-handle connected to a spring-loaded mechanism. This allows for fine-tuning of outlet pressure, often in ranges from 0-25 psi up to 0-500 psi, depending on the model. Gauges, if included, are bourdon-tube type with helium leak-tested connections to preserve integrity.

Inlet and outlet connections are standardized to CGA (Compressed Gas Association) specifications, such as CGA 580 for nitrogen, ensuring compatibility and safety. Additional features like integral filters (e.g., 0.003-micron sintered metal) trap particulates, while purge ports allow for system evacuation before use.

Working Principle

The operation of a UHP nitrogen gas regulator follows the principles of pressure reduction and control. Incoming high-pressure nitrogen from a cylinder or supply line enters the inlet port. The regulator reduces this pressure to a stable, user-set outlet pressure.

At the core is a balanced force system. The inlet pressure acts on the poppet, attempting to open it, while the diaphragm senses the outlet pressure and counters it via the spring force. When outlet pressure drops (due to demand), the diaphragm moves, compressing the spring and opening the poppet to allow more gas flow. Conversely, if pressure rises, the diaphragm pushes back, closing the poppet.

For UHP applications, this process must occur without introducing impurities. The regulator’s dead volume is minimized to reduce trapped gas that could mix with contaminants. Flow coefficients (Cv) are optimized for low to medium flow rates, typically 0.02 to 0.5, to maintain laminar flow and prevent turbulence-induced particle entrainment.

Pressure droop, or the variation in outlet pressure with flow changes, is a critical performance metric. UHP regulators exhibit low droop, often less than 1% of setpoint, thanks to large diaphragm areas and precise spring rates. Helium leak rates are specified at 1×10^-9 cc/sec or better, ensuring no atmospheric ingress.

Temperature effects are mitigated through compensated designs, maintaining performance across -40°C to 60°C. In cryogenic applications, special variants handle liquid nitrogen vaporization, incorporating heat exchangers to prevent freezing.

Applications in Industry

Ultra high purity nitrogen gas regulators find extensive use across various industries. In semiconductor fabrication, they supply nitrogen for wafer processing tools, where impurities could cause defects in microchips. For instance, in photolithography, UHP nitrogen purges optical systems to prevent moisture-induced haze.

In pharmaceuticals, these regulators control nitrogen blanketing in reactors and storage tanks, preserving drug integrity by displacing oxygen and preventing oxidation. Analytical laboratories rely on them for gas chromatography and mass spectrometry, where carrier gas purity directly impacts detection limits and accuracy.

Aerospace applications involve UHP nitrogen for inerting fuel tanks and testing hydraulic systems. In food and beverage, modified atmosphere packaging uses regulated nitrogen to extend shelf life without preservatives.

Emerging fields like additive manufacturing (3D printing) employ these regulators to maintain inert atmospheres in metal powder beds, preventing oxidation during laser sintering. In research, particle accelerators and fusion experiments demand UHP nitrogen for cooling and insulation.

Benefits and Advantages

The primary benefit of UHP nitrogen gas regulators is contamination prevention, which translates to higher yields and reduced downtime in processes. Their robust construction ensures longevity, with mean time between failures often exceeding 10 years.

Precision control enhances process stability, critical for reproducible results in R&D. Safety features, like pressure relief valves and burst discs, protect against overpressurization. Compliance with standards such as SEMI (Semiconductor Equipment and Materials International) and ISO ensures global interoperability.

Economically, while initial costs are higher than standard regulators (ranging from $500 to $5000), the reduction in scrap and rework justifies the investment. Energy efficiency is improved by minimizing gas waste through tight shutoff.

Maintenance and Safety Considerations

Proper maintenance is vital for sustaining performance. Regular inspections for leaks using helium mass spectrometry are recommended. Cleaning protocols involve ultrasonic baths with isopropyl alcohol, followed by nitrogen purging and baking to remove moisture.

Safety practices include using regulators only with compatible gases and pressures. Operators should wear PPE (personal protective equipment) and ensure proper ventilation. Cylinder handling must follow DOT (Department of Transportation) guidelines to prevent accidents.

In case of malfunction, symptoms like pressure creep (slow rise in outlet pressure) indicate seat wear, necessitating replacement. Calibration every 6-12 months maintains accuracy.

Conclusion

Ultra high purity nitrogen gas regulators represent a pinnacle of gas handling technology, blending materials science, fluid dynamics, and precision engineering. Their role in safeguarding process purity cannot be overstated, enabling advancements in technology and science. As industries push for higher efficiencies, these regulators will evolve, incorporating smart sensors for real-time monitoring and IoT integration for predictive maintenance. Understanding and utilizing UHP nitrogen gas regulators effectively ensures optimal performance in demanding applications.

For more about ultra high purity nitrogen gas regulator: precision control for critical applications, you can pay a visit to Jewellok at https://www.specialtygasregulator.com/product-category/ultra-high-purity-gas-regulators/ for more info.

Recent Posts

How Does the Two-Stage Nitrogen Regulator Work?

How Does a Single-Stage Oxygen Regulator Work?

What is Exhaust Gas Cleaning System?

How Does A Low-Pressure Back Pressure Regulator Work?

How Does An Oxygen Gas Changeover Manifold Work?

How Does An Argon Gas Changeover Manifold Work?

How Does A Helium Gas Changeover Manifold Work?

How Does A Carbon Dioxide Gas Changeover Manifold Work?

How Does A Nitrogen Gas Changeover Manifold Work?

Tags

Recommended Products

-

771L Male Run Tee | Stainless Steel High Quality High Purity Male Run Tee Branch Tee Pipe Fittings

-

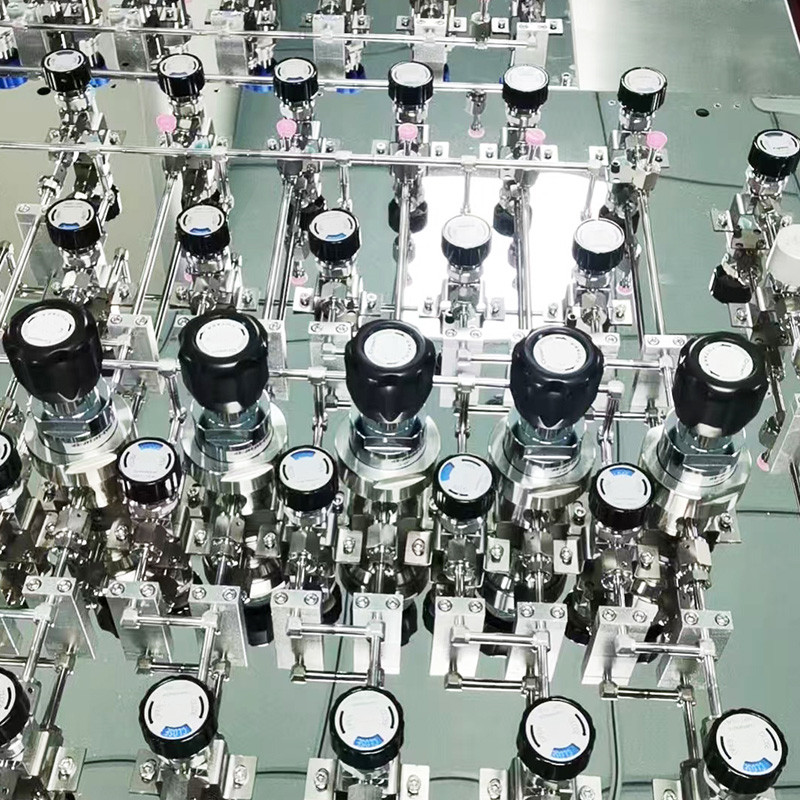

High Purity High Flow Pressure Control Regulators & Valves Gas Stick Assemblies JSR-2TG Series

-

Stainless Steel 316L Single Stage Regulator Pressure Control Panels JSP-1E Series For Semiconductor Fluid Control

-

771LF Female Run Tee | Stainless Steel Tube Fitting Compression Fittings 1/4 In 3-Way Tee Female Run Tee

-

High Purity High Pressure Gas Cylinder Pressure Regulators Pressure Reducing Valve JSR-1E Series

-

Ultra High Purity Trimethylaluminum TMA Gas Cabinet Liquid Delivering Cabinet Used For Specialty Gas Delivery System In Semiconductor

-

Semi Automatic Oxygen Nitrogen Helium Argon Gas Changeover Manifold Manual Gas Changeover Manifold Panel For Gas Cylinders

-

Scrubber Tail Gas Treatment Cabinet Waste Gas Treatment Wet Scrubber Exhaust Gas Treatment Spray Tower