Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

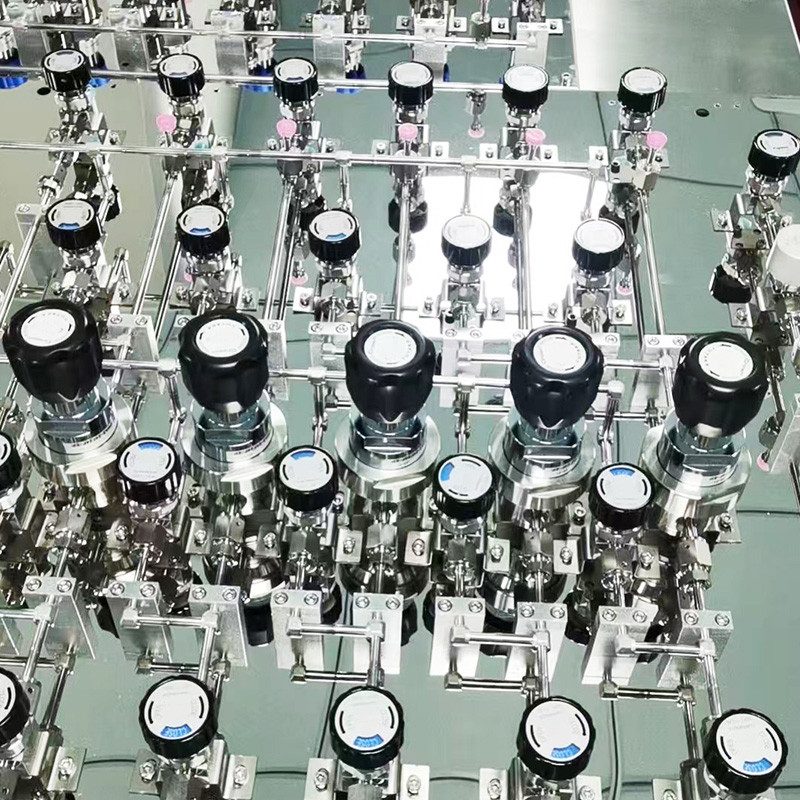

Ultra High Purity Stainless Steel Valves: Precision Engineering for Critical Applications

- Pressure Regulator Valve Manufacturer

- 316L stainless steel UHP valves, advantages of stainless steel purity valves, applications of UHP valves, ASME BPE compliant valves, bellows valves for pharmaceuticals, biotechnology UHP valve solutions, cleanroom assembly stainless steel valves, corrosion resistant stainless steel valves, cryogenic UHP valves, diaphragm valves ultra high purity, electropolished stainless steel valves, electropolishing process for valves, helium leak testing for valves, high purity gas delivery valves, high purity valves for semiconductors, ISO 14644 cleanroom standards valves, maintenance UHP stainless steel valves, manufacturing ultra high purity valves, orbital welding in UHP valves, particle-free stainless steel valves, precision engineering UHP valves, SEMI standards for high purity valves, UHP stainless steel valves, ultra high purity stainless steel valve, vacuum compatible stainless steel valves

- No Comments

Ultra High Purity Stainless Steel Valves: Precision Engineering for Critical Applications

In industries where contamination can lead to catastrophic failures or compromised product quality, the role of specialized components cannot be overstated. Ultra high purity (UHP) stainless steel valves stand at the forefront of this precision engineering, designed to handle fluids and gases with minimal risk of impurity introduction. These valves are essential in sectors such as semiconductor manufacturing, pharmaceuticals, biotechnology, and high-purity gas delivery systems. This article delves into the technical aspects of UHP stainless steel valves, exploring their composition, design principles, manufacturing processes, applications, and benefits. By understanding these valves, engineers and technicians can better appreciate their contribution to maintaining stringent purity standards in demanding environments.

UHP valves are engineered to operate in conditions where even trace levels of contaminants—measured in parts per billion (ppb) or parts per trillion (ppt)—can disrupt processes. Stainless steel, particularly austenitic grades like 316L, forms the backbone of these valves due to its excellent corrosion resistance and mechanical properties. However, achieving ultra high purity requires enhancements beyond standard stainless steel, including specialized surface treatments and assembly protocols.

Material Composition and Properties

The foundation of any UHP stainless steel valve is its material. Typically, 316L stainless steel is selected for its low carbon content, which minimizes carbide precipitation during welding and enhances corrosion resistance. This alloy contains approximately 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, providing a robust passive oxide layer that protects against oxidation and chemical attack.

For ultra high purity applications, the steel must undergo electropolishing or passivation to achieve surface roughness values as low as 0.25 micrometers Ra (roughness average). Electropolishing removes microscopic peaks and valleys on the surface, reducing areas where particles or bacteria could adhere. Additionally, the material is often specified with controlled sulfur content (less than 0.005%) to prevent pitting corrosion.

Key properties include high tensile strength (around 515 MPa), yield strength (205 MPa), and elongation (40%), ensuring durability under pressure. Thermal conductivity (about 16 W/m·K) and a coefficient of thermal expansion (16.5 × 10^-6 /K) make it suitable for cryogenic to high-temperature operations, ranging from -196°C to 400°C. These valves are also non-magnetic in the annealed state, which is crucial in sensitive electronic manufacturing environments.

Design Principles

Designing UHP stainless steel valves involves balancing flow efficiency, leak-tightness, and purity maintenance. Common types include diaphragm valves, bellows valves, and ball valves, each tailored for specific uses.

Diaphragm valves, for instance, use a flexible metal diaphragm to isolate the process media from the actuator, preventing contamination from stem seals. The diaphragm, often made from 316L or Hastelloy, ensures zero dead volume, minimizing fluid entrapment.

Bellows valves employ a welded metal bellows to seal the stem, offering high cycle life (up to 1 million cycles) and low particle generation. Ball valves in UHP configurations feature orbital welding and purged ports to eliminate crevices.

Key design features include:

– Welded Construction: Orbital welding ensures smooth, crevice-free joints with minimal heat-affected zones.

– Surface Finish: Internal surfaces are electropolished to reduce outgassing and particle shedding.

– Actuation Mechanisms: Pneumatic or manual actuators with position indicators for precise control.

– Pressure Ratings: Up to 350 bar, with vacuum compatibility down to 10^-9 mbar.

Finite element analysis (FEA) is often used in design to simulate stress distribution and ensure compliance with standards like ASME BPE (Bioprocessing Equipment).

Manufacturing Processes

Manufacturing UHP valves demands cleanroom environments (ISO Class 5 or better) to prevent airborne contamination. The process begins with raw material inspection using techniques like X-ray fluorescence (XRF) for composition verification and ultrasonic testing for defects.

Forging or bar stock machining shapes the valve body, followed by precision CNC machining for tight tolerances (±0.01 mm). Welding is performed using tungsten inert gas (TIG) or orbital methods under argon purge to avoid oxidation.

Post-machining, electropolishing immerses the parts in an electrolytic bath, removing 10-20 micrometers of material for a mirror-like finish. Passivation with nitric acid further enhances the chrome oxide layer.

Assembly occurs in laminar flow hoods, with components cleaned ultrasonically in deionized water and dried with filtered nitrogen. Helium leak testing verifies integrity, aiming for rates below 10^-9 mbar·L/s.

Quality control involves particle counting, total organic carbon (TOC) analysis, and extractables testing to ensure the valve meets SEMI (Semiconductor Equipment and Materials International) standards.

Applications in Industry

UHP stainless steel valves are indispensable in semiconductor fabrication, where they control the flow of ultrapure gases like nitrogen, argon, and silane in chemical vapor deposition (CVD) and etching processes. Any impurity could lead to defects in microchips, costing millions in yield losses.

In pharmaceuticals, these valves manage sterile fluids in bioreactors and filling lines, complying with FDA regulations for current good manufacturing practices (cGMP). They prevent cross-contamination in vaccine production or monoclonal antibody synthesis.

Biotechnology applications include cell culture media delivery, where pH and oxygen levels must be precisely controlled without introducing metals or organics.

High-purity gas industries use them in cylinder filling stations and analytical instrumentation, ensuring gases meet ISO 8573 purity classes.

Emerging uses include hydrogen fuel cells and photovoltaic manufacturing, where UHP valves handle corrosive electrolytes and precursors.

Advantages and Challenges

The primary advantage of UHP stainless steel valves is their reliability in maintaining process integrity. They offer low maintenance, with mean time between failures (MTBF) exceeding 10,000 hours. Corrosion resistance extends service life, reducing downtime.

Compared to plastic valves, stainless steel provides superior pressure and temperature handling, while being recyclable for sustainability.

However, challenges include high initial costs (often 2-5 times that of standard valves) and the need for specialized installation. Improper handling can introduce contaminants, necessitating trained personnel.

To mitigate, manufacturers provide clean-packaged valves with certificates of conformance.

Maintenance and Standards

Maintenance involves regular visual inspections, leak checks, and actuator calibration. Cleaning protocols use ultrapure water or isopropyl alcohol, avoiding abrasive methods.

Standards governing UHP valves include:

– ASME B31.3 for process piping.

– SEMI F1 for gas distribution systems.

– ISO 14644 for cleanrooms.

Compliance ensures interoperability and safety across global supply chains.

Conclusion

Ultra high purity stainless steel valves represent the pinnacle of materials science and engineering, enabling advancements in high-tech industries. Their meticulous design and fabrication underscore the importance of purity in modern manufacturing. As demands for smaller, faster, and purer processes grow, these valves will continue to evolve, incorporating smart sensors for predictive maintenance and advanced alloys for even harsher environments. Engineers must stay abreast of these developments to harness their full potential, ensuring innovation without compromise.

For more about ultra high purity stainless steel valve, you can pay a visit to Jewellok at https://www.specialtygasregulator.com/product/ for more info.

Recent Posts

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

How to Select the Right Valve Manifold Box for Your Application

316L Stainless Steel Ultra High Purity Regulator for PH3 Service

How to Safely Operate a TMA Gas Changeover Manifold

Tags

Recommended Products

-

Stainless Steel High Purity High Temperature Pneumatic Actuated Ball Valves JBV2 Series

-

763L Stainless Steel High Purity Pressure Reducing Union Fittings And Tubing Pressure Reducing Valve Adjustment

-

Low Pressure High Flow Line Pressure Regulators And Control Valves JSR-4L Series For Laboratory Pressure Control

-

Stainless Steel Fully Automatic Gas Switchover Manifold System Automatic Gas Cylinder Switchover Co2 Cylinder Auto Changeover Controller

-

JR1300 Series Ultra High Purity Single Stage Regulator High Flow Line Regulator For Ultra High Purity Intermediate Flow

-

Ultra High Purity Gas Delivery Systems And Liquid Chemical Delivery Systems JW-300-LDS

-

Semi Automatic Gas Cabinet Gas Panels High Purity Gas Delivery Systems JW-200-GC

-

Stainless Steel 316L Single Stage Regulator Pressure Control Panels JSP-1E Series For Semiconductor Fluid Control