Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

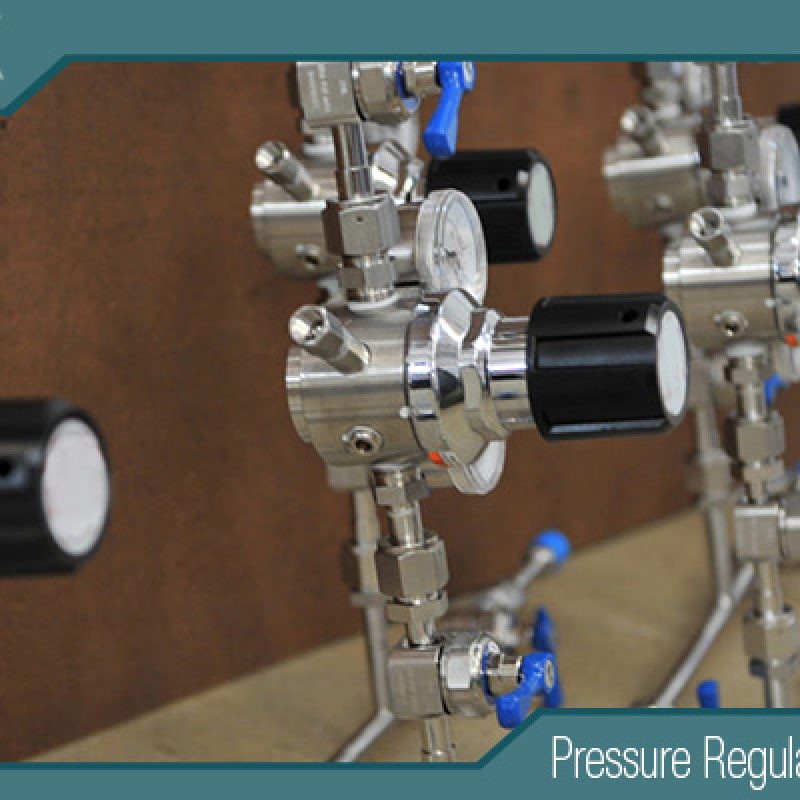

The Unseen Guardian: Why UHP 316L Stainless Steel Defines Modern Gas Pressure Regulators

- Pressure Regulator Valve Manufacturer

- 316 SS ball valves manufacturer, 316L Stainless Steel Seamless High Purity System Tube, Best high purity stainless steel gas fittings, China Ultra High Purity Fittings Factory, China Ultra High Purity Fittings Manufacturers, China Ultra High Purity Fittings Suppliers, compression tube fittings, Fittings for High Purity Piping, high pressure compression fittings, high purity fittings, high purity stainless steel fitting, high purity stainless steel tubing, hydrogen pipe valves and fittings, ISO 14644 cleanroom standards valves, maintenance UHP stainless steel valves, manufacturing ultra high purity valves, orbital welding in UHP valves, particle-free stainless steel valves, precision engineering UHP valves, SEMI standards for high purity valves, stainless steel butt weld pipe fittings, stainless steel compression fittings, stainless steel tubing fittings, Tubing and Fittings for Compressed Gas Systems, uhp 316l stainless steel gas pressure regulators, UHP stainless steel valves, Ultra High Purity Coaxial Stainless Steel Tube Fittings, ultra high purity fittings, ultra high purity fittings manufacturers in china, ultra high purity stainless steel tubing, ultra high purity stainless steel valve, Ultra-High-Purity Tube Fittings, vacuum compatible stainless steel valves

- No Comments

The Unseen Guardian: Why UHP 316L Stainless Steel Defines Modern Gas Pressure Regulators

In the intricate ecosystems of high-tech manufacturing, scientific research, and medical advancement, the purity and precise control of process gases are not mere conveniences—they are absolute imperatives. A single part-per-billion of contamination, a microscopic fluctuation in pressure, can scrap a billion-dollar semiconductor wafer, invalidate critical pharmaceutical research, or compromise the safety of a medical procedure. At the heart of safeguarding this delicate balance lies a critical component: the gas pressure regulator. And when the application demands the utmost in reliability, corrosion resistance, and cleanliness, one material reigns supreme: Ultra-High Purity (UHP) 316L stainless steel. This article delves into the world of UHP 316L stainless steel gas pressure regulators, exploring the material science behind them, their critical design features, and the demanding applications they serve.

The Material Monarch: Why 316L, and Why Ultra-High Purity?

To understand the regulator, one must first understand the material. 316L stainless steel is an austenitic chromium-nickel alloy renowned for its excellent corrosion resistance, a property derived from its key constituents: molybdenum (2-3%), nickel (10-14%), and chromium (16-18%). The “L” denotes a low carbon content (<0.03%), which is crucial. By minimizing carbon, the formation of chromium carbide precipitates at grain boundaries during welding is drastically reduced. This prevents “sensitization,” a condition that can lead to intergranular corrosion and subsequent failure—an unacceptable risk in gas systems.

But standard 316L is not enough for sensitive applications. Ultra-High Purity (UHP) 316l stainless steel gas pressure regulators take the material to an entirely new level. It undergoes specialized melting processes, such as Vacuum Induction Melting (VIM) followed by Electro-Slag Remelting (ESR) or Vacuum Arc Remelting (VAR). These methods meticulously reduce non-metallic inclusions (sulfides, oxides), control interstitial elements (carbon, oxygen, nitrogen), and ensure a homogeneous, defect-free microstructure. The result is a material with superior mechanical properties, enhanced corrosion resistance (particularly against chlorides and acidic gases), and, most importantly, a surface that can be finished to exceptional smoothness and cleanliness.

This inherent cleanliness is the cornerstone of a UHP regulator’s function. It prevents the material itself from being a source of particulate, moisture, or hydrocarbon outgassing contamination, which could poison sensitive processes downstream.

Anatomy of Precision: Design and Features of UHP Regulators

A UHP 316L regulator is more than just a standard regulator made from a better alloy. It is a system engineered from the ground up for integrity, cleanliness, and control. Key design aspects include:

- All-Metal, Diaphragm-Sealed Construction: Unlike elastomer-sealed regulators, which can outgas, degrade, and introduce contaminants, UHP regulators use a metal (often 316L) diaphragm to separate the process gas from the spring and atmospheric side. This hermetically sealed design eliminates a major source of permeation and contamination.

- Electropolished Internal Surfaces: After machining, all wetted internal components undergo a rigorous electropolishing process. This electrochemical treatment removes the thin, fragmented “Beilby layer” left by machining, smoothing micro-peaks and valleys to create a passive, ultra-smooth surface (often achieving Ra < 15 µin). This minimizes surface area where moisture or particles can adhere, facilitates easier cleaning and gas purging, and strengthens the passive chromium oxide layer for better corrosion resistance.

- High-Integrity Welding: All joints are made using Orbital Tungsten Inert Gas (TIG) welding under an inert atmosphere (argon). This automated, precision technique produces consistent, full-penetration, spatter-free welds with no internal crevices—critical for maintaining a leak-tight, contaminant-free flow path. Autogenous welds (no filler metal) are often used to preserve material homogeneity.

- Purge and Vent Configurations: UHP regulators are frequently configured with additional purge and vent valves (also UHP). These allow for proper purging of the regulator body before connecting to a sensitive system and safe venting during changeout, preventing atmospheric backstreaming.

- Specialized Pressure Elements: Springs are typically made from corrosion-resistant alloys like Inconel® and are electropolished. The seats may use soft metals like silver or specialized polymers like PCTFE (Kel-F) that are selected for their low outgassing and compatibility with specific gases.

- Particulate Control: Outlet filters (often 0.01µm or 0.003µm sintered 316L metal frits) are sometimes integrated to provide a final barrier against particulate migration downstream.

Where Failure is Not an Option: Critical Applications

The significant investment in material and manufacturing for UHP 316L regulators is justified only by the extreme demands of the applications they serve.

- Semiconductor Fabrication: This is the quintessential UHP environment. Processes like chemical vapor deposition (CVD), etching, and ion implantation use highly reactive, toxic, and corrosive gases (silane, arsine, hydrogen chloride, tungsten hexafluoride). Any moisture, oxygen, or particulate contamination can create defects, alter doping profiles, and cause catastrophic yield loss. UHP 316L regulators are mandatory on gas cabinets and tool inlets to ensure gas purity from the source to the wafer.

- Pharmaceutical and Biotechnology: In drug discovery, fermentation, and biopharmaceutical production, gases are used for incubation, sparging, and as reactants. Contamination can alter cell cultures, introduce endotoxins, or cause unwanted chemical reactions, jeopardizing product safety and efficacy. UHP systems are used for critical processes involving high-purity oxygen, nitrogen, and carbon dioxide.

- Analytical and Research Laboratories: Advanced analytical instruments like Gas Chromatography-Mass Spectrometry (GC-MS), Inductively Coupled Plasma (ICP) systems, and laser research are highly sensitive to trace contaminants. Impurities in carrier or calibration gases can create ghost peaks, baseline drift, and erroneous results, compromising data integrity.

- Medical and Specialty Gases: In medical applications like lung function testing, laser surgery, and in the delivery of specialty gas mixtures for calibration and therapy, gas purity is directly linked to patient safety and accurate diagnostics.

- Fuel Cells and New Energy Research: Hydrogen fuel cell research and production require ultra-pure hydrogen. Trace impurities like carbon monoxide can “poison” the expensive platinum catalysts, dramatically reducing efficiency and lifespan. UHP regulators ensure the integrity of the fuel stream.

Selection, Handling, and Maintenance: A Holistic Approach

Specifying a UHP 316L regulator is just the first step. Its performance depends on proper system design and handling.

Selection Criteria:

- Gas Compatibility: Ensure compatibility with the specific gas, including corrosiveness and tendency to adsorb (e.g., use Monel® for hydrofluoric acid).

- Pressure Ratings: Inlet (P1) and outlet (P2) ranges must suit the cylinder and process requirements.

- Flow Capacity (Cv): Must be adequate for the application to avoid droop or excessive heating.

- Cleanliness Specifications: Look for certifications like ASTM G93 levels (e.g., Level B/O for oxygen service) or specific particle count data.

- Connections: UHP VCR®/VCO® metal gasket face seal fittings are standard, providing a leak-tight, clean, and reusable connection.

Installation and Use:

- Proper Purging: Always purge the regulator slowly after installation to remove any installation contaminants.

- Gentle Operation: Open cylinder valves slowly; adjust the delivery pressure gradually.

- Controlled Environment: Use in a clean environment to prevent external contamination during changeout.

Maintenance and Certification: UHP regulators should be periodically recertified. This involves a complete leak test (helium mass spectrometry to very low levels, e.g., 1 x 10^-9 atm-cc/sec), internal inspection, and cleaning. They should only be serviced by specialists with cleanroom facilities and the correct tooling to preserve their integrity.

Conclusion

In an age defined by technological precision, the margin for error shrinks continually. UHP 316L stainless steel gas pressure regulators represent the confluence of advanced metallurgy, precision engineering, and a deep understanding of contamination control. They are not simple mechanical pressure-reducing devices; they are active guardians of process integrity. By providing a stable, reliable, and immaculately clean interface between a high-pressure gas source and an ultra-sensitive process, they enable the innovations that define modern science and industry. From the microchips in our devices to the medicines that heal us, the unseen work of these meticulously crafted components is, in fact, fundamental to the fabric of advanced society. Specifying, installing, and maintaining them with the care they demand is not just good practice—it is an investment in certainty, quality, and success.

For more about the unseen guardian: why UHP 316L stainless steel defines modern gas pressure regulators, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Choose the Krypton Gas Ultra High Purity (UHP) Regulator

Troubleshooting Common Failures in TMA Gas Changeover Manifolds

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

Tags

Recommended Products

-

High Pressure High Flow Specialty Gas Control Panel With Diaphragm Valve , 3000Psig Oxygen Control Medical Changeover Manifold Panel

-

Fully Automated Gas Cabinet For Precise UHP Gas Delivery And High Purity Gas Delivery Systems JW-300-GC

-

Stainless Steel Low Pressure Seal Pneumatic Diaphragm Control Valve For For HP & UHP Gases

-

Manual Gas Rack High Purity Gas Delivery Systems JW-100-GR

-

Stainless Steel Mini Elbow Mini Tee Mini Cross Mini Tribow Ultrahigh Purity Mini Butt Weld Fittings

-

Specialty Gas Valves Ultra High Purity Gas Valves Ultra High Purity Gas Cylinder Valves UHP Cylinder Valve Ultra High Purity Gas Regulator

-

Fully Automated Gas Cabinet Gas Rack Gas Delivery Systems JW-300-GR

-

767LT Reducer Pressure Reducing Valve Adjustment High purity Pressure Reducing Union Fittings And Tubing