Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

An Overview of Stainless Steel Industrial Diaphragm Valve Manufacturers in Italy

- Pressure Regulator Valve Manufacturer

- 3000psi High Pressure Stainless Steel Diaphragm Valve, Diaphragm Valve 1/2" MNPT Inlet x 1/2"FNPT Outlet, italy block and bleed ball valve suppliers, italy diaphragm valve factory, italy industrial diaphragm valve manufacturer, italy industrial diaphragm valve supplier, italy pressure reducing control valve factory, italy ss diaphragm valve factory, italy ss diaphragm valve manufacturer, italy ss diaphragm valve manufacturers, italy ss diaphragm valve supplier, italy stainless steel diaphragm valve, italy stainless steel diaphragm valve factory, italy stainless steel diaphragm valve manufacturer, italy stainless steel diaphragm valve manufacturers, italy stainless steel diaphragm valve supplier, Sanitary Stainless Steel 316 Diaphragm Valve, SS316L Stainless Steel Sanitary Diaphragm Valve, stainless steel industrial diaphragm valve manufacturers

- No Comments

An Overview of Stainless Steel Industrial Diaphragm Valve Manufacturers in Italy

Introduction to Diaphragm Valves

Diaphragm valves are vital components in numerous industrial processes, renowned for their ability to provide precise control over fluid flow while ensuring exceptional hygiene and reliability. These valves operate using a flexible diaphragm that seals against a valve body to regulate the passage of liquids, gases, or slurries. This design makes them particularly suitable for applications where contamination must be strictly avoided, such as in pharmaceuticals, food and beverage production, biotechnology, and chemical processing. The material chosen for these valves is critical to their performance, and stainless steel has become the preferred option due to its outstanding corrosion resistance, durability, and ease of maintenance. This article offers a comprehensive overview of stainless steel industrial diaphragm valve manufacturers in Italy, exploring their significance, key players, applications, and the innovations shaping the industry.

The importance of diaphragm valves lies in their ability to isolate the process media from the valve’s moving parts, reducing the risk of contamination and wear. This feature is especially valuable in industries requiring sterile or hygienic conditions. Stainless steel enhances these benefits, making it an ideal material for environments where reliability and cleanliness are paramount. Italy, with its rich industrial heritage and reputation for engineering excellence, hosts several leading manufacturers that produce these specialized valves, catering to both domestic and international markets.

Why Stainless Steel is Used in Diaphragm Valves

Stainless steel, particularly grades such as 304, 316, and 316L, is the material of choice for diaphragm valves due to its exceptional properties. Its primary advantage is its resistance to corrosion, which allows it to withstand exposure to a wide range of chemicals and aggressive media without degrading. This durability is crucial in industries handling corrosive substances like acids, solvents, or saline solutions. Additionally, stainless steel’s strength enables the construction of valves capable of operating under high pressures and temperatures, ensuring consistent performance in demanding conditions.

The material’s smooth, non-porous surface further enhances its suitability by minimizing bacterial adhesion and facilitating thorough cleaning and sterilization—key requirements in hygienic applications. For instance, in pharmaceutical manufacturing, where even trace contamination can compromise product safety, stainless steel diaphragm valves provide a reliable solution. Moreover, stainless steel is inert, meaning it does not react with process media or impart unwanted flavors or odors, making it safe for food and beverage production. These combined attributes—corrosion resistance, mechanical strength, and hygienic properties—position stainless steel diaphragm valves as indispensable tools across multiple sectors.

Overview of the Italian Valve Manufacturing Industry

Italy has long been a global leader in precision manufacturing, and its valve industry exemplifies this expertise. Known for engineering excellence, innovative designs, and strict adherence to quality standards, Italian valve manufacturers have earned a stellar reputation worldwide. The country’s strategic location in Europe, coupled with a highly skilled workforce and advanced technological infrastructure, has made it a hub for industrial valve production. Italy’s valve sector includes a diverse range of companies, from large multinational subsidiaries to specialized firms focusing on niche markets like sanitary and aseptic applications.

The Italian valve industry benefits from a strong emphasis on research and development, allowing manufacturers to stay ahead of global trends and meet evolving customer needs. This focus is particularly evident in the production of diaphragm valves, where precision and quality are critical. Italian companies are also recognized for their craftsmanship, often blending traditional manufacturing techniques with modern innovations to produce valves that meet international standards such as ISO 9001, ASME BPE, and EHEDG. As a result, Italy has become a key supplier of high-quality industrial valves, including stainless steel diaphragm valves, to markets across Europe and beyond.

Leading Italian Manufacturers of Stainless Steel Industrial Diaphragm Valves

Italy hosts several prominent manufacturers specializing in stainless steel industrial diaphragm valves. Below is a detailed look at some of the leading companies, their histories, product offerings, and unique contributions to the industry:

GEMÜ Italia

GEMÜ Italia, a subsidiary of the German-based GEMÜ Group, is a significant player in the Italian valve market. While its parent company is headquartered in Germany, GEMÜ Italia operates manufacturing and distribution facilities in Italy, producing high-quality diaphragm valves tailored to industries such as pharmaceuticals, biotechnology, and food processing. GEMÜ is renowned for its innovative approach, offering valves with features like minimal deadleg design—reducing areas where fluids can stagnate—and EHEDG-certified diaphragm sealing systems. These attributes ensure superior hygiene and ease of cleaning, making GEMÜ valves a top choice for sterile and aseptic processes. The company’s commitment to customization and technological advancement has solidified its presence in Italy’s competitive valve sector.

Alfa Laval Italy

Alfa Laval, a global leader in process equipment, maintains a strong manufacturing presence in Italy through Alfa Laval Italy. The Italian division produces a range of sanitary valves, including diaphragm valves, designed for the food, beverage, and pharmaceutical industries. Alfa Laval’s diaphragm valves are engineered for reliability and compliance with stringent hygiene standards, such as those set by the FDA and EHEDG. They excel in applications involving high-purity water, bioprocessing pipelines, and other sensitive processes, ensuring product integrity and operational efficiency. With a legacy of innovation and a focus on sustainable solutions, Alfa Laval Italy combines global expertise with local manufacturing capabilities to serve diverse markets.

Bardiani Valvole

Bardiani Valvole, headquartered in Fornovo di Taro, is a family-owned Italian company with decades of experience in producing sanitary valves. Specializing in valves for the food, beverage, and pharmaceutical sectors, Bardiani offers diaphragm valves designed for optimal performance in hygienic applications. Their products feature self-draining capabilities and compatibility with Clean-in-Place (CIP) and Sterilize-in-Place (SIP) processes, which are essential for maintaining cleanliness in production lines. Bardiani’s dedication to quality, coupled with its deep understanding of industry-specific needs, has earned it a strong reputation among customers seeking reliable and efficient valve solutions.

Valve Engineering Srl

Valve Engineering Srl is a prominent Italian manufacturer focused on hygienic valves for the pharmaceutical industry. Based in Italy, the company designs and produces diaphragm valves that meet the rigorous demands of sterile processing. Their products are engineered to minimize contamination risks, with features such as smooth internal surfaces and easy-to-maintain designs. Valve Engineering emphasizes 100% Italian-made solutions, reflecting a commitment to quality craftsmanship and responsiveness to client requirements. Their expertise in pharmaceutical applications makes them a key contributor to Italy’s diaphragm valve market.

Sesto Valves

Sesto Valves is another leading Italian manufacturer known for its premium sanitary valves, including diaphragm valves. Catering to industries like food and beverage, biotechnology, and pharmaceuticals, Sesto Valves prioritizes hygiene and performance in its product designs. Their diaphragm valves are built to meet the highest standards, offering flexibility and customization to address specific customer needs. With a focus on precision engineering and durability, Sesto Valves has established itself as a trusted supplier of high-quality valve solutions, both domestically and internationally.

OMB Valves

OMB Valves, based in Italy, is primarily recognized for its ball and gate valves but also offers a range of diaphragm valves for specialized applications. These valves are designed to handle aggressive chemicals, high temperatures, and abrasive slurries, making them suitable for chemical processing and industrial environments. OMB combines robust engineering with innovative design to produce valves that meet the rigorous demands of heavy-duty applications. While diaphragm valves may not be their primary focus, OMB’s inclusion in this category highlights the versatility and breadth of Italian valve manufacturing.

These manufacturers represent the pinnacle of Italy’s stainless steel diaphragm valve industry, blending quality, innovation, and industry-specific expertise to deliver world-class products.

Applications and Industries Served

Stainless steel diaphragm valves serve a wide range of industries, each benefiting from their unique properties:

Pharmaceuticals

In the pharmaceutical industry, diaphragm valves are critical for maintaining sterile conditions and preventing contamination. They are used in bioreactors, fermentation tanks, and the production of injectable drugs, where hygiene is non-negotiable. The ease of cleaning and sterilization, combined with stainless steel’s corrosion resistance, ensures compliance with standards like ASME BPE, making these valves indispensable.

Food and Beverage

The food and beverage sector relies on diaphragm valves to ensure hygiene and meet stringent safety regulations. Applications include dairy processing, brewing, and bottling lines, where the valves’ inert stainless steel construction prevents contamination and preserves product quality. Their ability to withstand frequent cleaning cycles enhances their utility in this industry.

Chemical Processing

In chemical processing, diaphragm valves handle corrosive and hazardous materials safely. Stainless steel’s resistance to acids, solvents, and other aggressive chemicals ensures reliable operation, while the valve’s design minimizes leaks and maintenance needs. This makes them ideal for processes involving harsh media.

Water Treatment

Water and wastewater treatment facilities use diaphragm valves to control the flow of water and chemicals in filtration systems, sludge handling, and chemical dosing units. Their durability and resistance to wear ensure long-term performance in demanding conditions, supporting efficient treatment processes.

These diverse applications underscore the versatility and importance of stainless steel diaphragm valves across critical industries.

Innovations and Trends in the Industry

The Italian diaphragm valve industry is characterized by ongoing innovation, driven by technological advancements and market demands:

– Smart Valves and Automation: Manufacturers are integrating sensors and automation into diaphragm valves, enabling real-time monitoring and control. This is particularly valuable in pharmaceuticals and chemical processing, where precision and data tracking enhance operational efficiency.

– Advanced Materials: New diaphragm materials, such as high-performance elastomers and PTFE composites, improve chemical resistance and temperature tolerance. These advancements extend valve lifespan and reduce maintenance in challenging environments.

– Hygienic Design Improvements: Innovations like reduced dead space and optimized flow paths enhance cleanability and drainability, critical for hygienic applications. These designs minimize contamination risks and improve process reliability.

– Sustainability: Italian manufacturers are adopting eco-friendly production methods and materials, aligning with global sustainability goals. This focus reduces environmental impact while maintaining product quality.

These trends demonstrate Italy’s commitment to advancing valve technology and meeting the needs of modern industries.

Conclusion

Italy’s stainless steel industrial diaphragm valve manufacturers are leaders in the global market, offering high-quality, innovative solutions for critical applications. Companies like GEMÜ Italia, Alfa Laval Italy, Bardiani Valvole, Valve Engineering Srl, Sesto Valves, and OMB Valves exemplify the country’s engineering prowess and dedication to excellence. These valves play a vital role in pharmaceuticals, food and beverage, chemical processing, and water treatment, supported by Italy’s reputation for craftsmanship and adherence to international standards. As industries evolve and demand grows, Italian manufacturers are poised to remain at the forefront, leveraging innovations like smart valves and sustainable practices to shape the future of the sector. With their blend of tradition and technology, Italy continues to set the standard for diaphragm valve manufacturing worldwide.

For more about the overview of stainless steel industrial diaphragm valve manufacturers in italy, you can pay a visit to Jewellok at https://www.jewellok.com/stainless-steel-diaphragm-valve-manufacturer/ for more info.

Recent Posts

How to Choose the Krypton Gas Ultra High Purity (UHP) Regulator

Troubleshooting Common Failures in TMA Gas Changeover Manifolds

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

Tags

Recommended Products

-

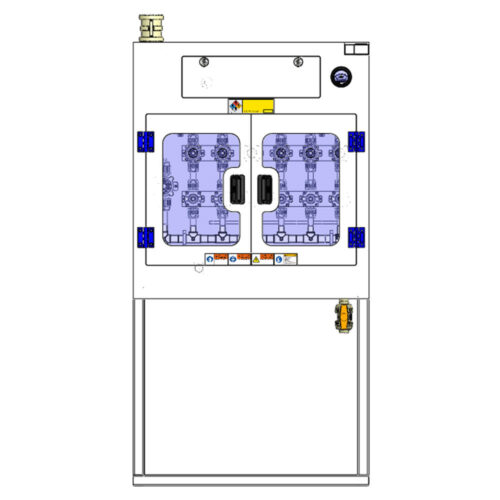

Clean Connection Cabinet JW-300-CCB Valve Manifold Box And Control Valve Box

-

Semi Automatic Oxygen Nitrogen Helium Argon Gas Changeover Manifold Manual Gas Changeover Manifold Panel For Gas Cylinders

-

Stainless Steel Ultra High Purity Mini Butt Weld Mini Tee Reducer MTRW Series Fittings

-

7121L Plug High Purity Plug Fitting And Blanking Plug

-

High Purity Configurable Systems VMB Valve Manifold Box JW-200-VMB-C & JW-100-VMB-C

-

UHP Metal Gasket Face Seal Fittings Vacuum Coupling Metal Face Seal Join Long Gland And Short Gland

-

High Purity Stainless Steel Mini Tube Butt Weld Fittings For Semiconductor

-

High Pressure High-Purity Welded Check Valves And Low Cracking Pressure Check Valve JCV1 Series