Blog

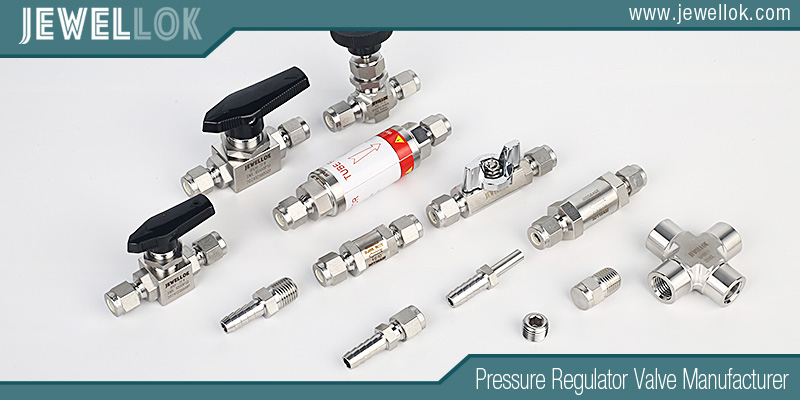

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Best High Purity Stainless Steel Gas Fittings In The Oil & Gas Industry

- Pressure Regulator Valve Manufacturer

- 316L Stainless Steel Seamless High Purity System Tube, Best high purity stainless steel gas fittings, China Ultra High Purity Fittings Factory, China Ultra High Purity Fittings Manufacturers, China Ultra High Purity Fittings Suppliers, compression tube fittings, Fittings for High Purity Piping, high pressure compression fittings, high purity fittings, high purity stainless steel fitting, high purity stainless steel tubing, hydrogen pipe valves and fittings, stainless steel butt weld pipe fittings, stainless steel compression fittings, stainless steel tubing fittings, Tubing and Fittings for Compressed Gas Systems, Ultra High Purity Coaxial Stainless Steel Tube Fittings, ultra high purity fittings, ultra high purity fittings manufacturers in china, ultra high purity stainless steel tubing, Ultra-High-Purity Tube Fittings

- No Comments

Best High Purity Stainless Steel Gas Fittings In The Oil & Gas Industry

In the oil and gas industry, the integrity of gas systems is paramount. A single failure in a gas fitting can lead to costly downtime, environmental damage, or even catastrophic accidents. This is why choosing the right high purity stainless steel gas fittings is crucial. These fittings are not just components; they are the backbone of safe and efficient operations in an industry that demands precision, reliability, and durability. High purity stainless steel gas fittings are essential for maintaining the purity of gases, preventing contamination, and ensuring the longevity of the systems they are part of. But what makes a fitting “the best” in this context? This article delves into the world of high purity stainless steel gas fittings, exploring their importance, types, and the factors that distinguish the top performers in the oil and gas sector.

Understanding High Purity Stainless Steel Gas Fittings

High purity stainless steel gas fittings are specialized components designed for use in gas systems where the purity of the gas is critical. These fittings are made from stainless steel, a material renowned for its corrosion resistance, strength, and ability to withstand extreme temperatures and pressures. In the oil and gas industry, these fittings are indispensable because they help prevent contamination, which can compromise the quality of the final product or lead to equipment failure.

Stainless steel, particularly grades like 316L, is the material of choice due to its high resistance to corrosion, especially in environments where gases are highly reactive or corrosive. The “high purity” aspect refers to the fittings’ ability to maintain the cleanliness and integrity of the gas passing through them, which is vital in processes like refining, where even minute impurities can have significant consequences.

Importance in the Oil and Gas Industry

The oil and gas industry is one of the largest and most complex sectors globally, supplying energy to power economies and societies. Within this industry, gas systems are used in various applications, from upstream exploration and production to midstream transportation and downstream refining. Each stage requires fittings that can handle the specific demands of the environment, whether it’s high pressure, extreme temperatures, or exposure to corrosive substances.

High purity stainless steel fittings are particularly crucial in refining processes, where the purity of gases can directly impact the quality of the final product. For example, in catalytic cracking, a process used to convert heavy hydrocarbons into lighter, more valuable products, the presence of impurities in the gas can deactivate the catalyst, leading to inefficient operations and increased costs. Similarly, in gas distribution networks, fittings must ensure that the gas remains uncontaminated to meet regulatory standards and ensure safety.

Moreover, the oil and gas industry often operates in harsh environments, such as offshore platforms or remote desert locations, where equipment reliability is critical. High purity stainless steel fittings are designed to withstand these conditions, offering durability and long service life, which reduces the need for frequent replacements and minimizes downtime.

Types of High Purity Stainless Steel Gas Fittings

There are several types of high purity stainless steel gas fittings used in the oil and gas industry, each serving a specific function:

Elbows: These fittings change the direction of the gas flow, typically at angles like 45° or 90°. They are essential for navigating around obstacles or creating complex piping layouts.

Tees: Tees allow for the branching of gas lines, enabling the distribution of gas to multiple locations from a single source.

Unions: Unions are used to connect two pipes in a way that allows for easy disconnection, which is useful for maintenance or repairs.

Valves: Valves control the flow of gas, allowing operators to regulate pressure, isolate sections of the system, or shut off the gas supply entirely.

Crosses: These fittings connect four pipes, forming a cross shape, and are used in more complex gas distribution systems.

Nipples: Nipples are short sections of pipe used to connect two fittings or to extend the length of a pipe.

Flanges: Flanges are used to connect pipes to other components, such as tanks or pumps, and are common in industrial applications.

Each type of fitting is designed to meet specific operational requirements, and the choice of fitting depends on factors like the type of gas, pressure, temperature, and the layout of the piping system.

What Makes a Fitting “The Best”?

Determining the “best” high purity stainless steel gas fittings involves evaluating several key factors:

1. Material Quality

The quality of the stainless steel used is paramount. Grades like 316L are preferred because they contain molybdenum, which enhances corrosion resistance, especially in chloride-rich environments common in the oil and gas industry. Additionally, the steel should be free from impurities that could compromise its integrity or contaminate the gas.

2. Surface Finish

A smooth surface finish is critical for high purity applications. Electropolishing, a process that removes microscopic burrs and cracks, is often used to achieve an ultra-smooth surface. This reduces the risk of particle generation and contamination, ensuring the gas remains pure.

3. Manufacturing Process

Fittings produced through seamless construction are generally more reliable than welded ones because they have fewer potential leak points. Seamless fittings are made from a single piece of metal, which enhances their strength and durability. Additionally, fittings should undergo rigorous testing and quality control to ensure they meet industry standards.

4. Compliance with Standards

The best fittings comply with industry standards such as ASTM, ASME, and ISO. These standards ensure that the fittings meet specific requirements for material composition, dimensions, and performance. For example, fittings used in high-pressure applications must meet ASME B31.3 standards for process piping.

5. Design Precision

Precision in design is crucial for ensuring leak-tight connections. Fittings with tight tolerances and accurate threading or welding ends are less likely to fail under pressure. Advanced manufacturing techniques, such as CNC machining, are often used to achieve the necessary precision.

6. Certifications

Certifications like NACE MR0175/ISO15156, which address materials for use in H2S-containing environments, are important for fittings used in sour gas applications. Fittings with such certifications are designed to resist sulfide stress cracking, a common issue in the oil and gas industry.

Leading Manufacturers of High Purity Stainless Steel Gas Fittings

Several companies are renowned for producing high-quality high purity stainless steel gas fittings for the oil and gas industry. Two of the most prominent are Swagelok and Parker Hannifin.

Swagelok

Swagelok is a global leader in fluid system components, including high purity stainless steel fittings. Their products are known for their reliability, precision, and compliance with industry standards. Swagelok offers a wide range of fittings, from simple elbows and tees to complex valves and manifolds, all designed to meet the demanding requirements of the oil and gas sector. Their fittings are often used in critical applications where safety and performance are non-negotiable.

Parker Hannifin

Parker Hannifin is another major player in the industry, offering a comprehensive portfolio of high purity stainless steel fittings. Their products are designed for use in high-pressure and high-temperature environments, making them ideal for the oil and gas industry. Parker Hannifin emphasizes innovation and quality, with a focus on providing solutions that enhance system integrity and reduce maintenance costs.

Both companies provide detailed specifications and certifications for their products, ensuring that customers can select the right fittings for their specific applications. They also offer technical support and training to help users make the best use of their products.

The Importance of Proper Installation and Maintenance

Even the best high purity stainless steel gas fittings can fail if not installed or maintained correctly. Proper installation is critical to ensuring leak-tight connections and preventing system failures. This includes following manufacturer guidelines for torque, using the correct tools, and ensuring that all components are clean and free from defects before assembly.

Maintenance is equally important. Regular inspections should be conducted to check for signs of wear, corrosion, or damage. Fittings should be cleaned periodically to remove any contaminants that could affect gas purity. Additionally, worn or damaged fittings should be replaced promptly to prevent leaks or failures.

In the oil and gas industry, where safety is a top priority, investing in proper installation and maintenance can prevent accidents, reduce downtime, and extend the life of the gas system.

Conclusion

High purity stainless steel gas fittings are indispensable in the oil and gas industry, where the stakes are high, and the margin for error is slim. The best fittings are those that combine superior material quality, precision design, and compliance with industry standards to deliver reliable performance in the most demanding environments. Companies like Swagelok and Parker Hannifin set the benchmark for excellence, offering products that meet the rigorous demands of the sector. However, the effectiveness of these fittings also depends on proper installation and maintenance, which are critical to ensuring the safety and efficiency of gas systems.

When selecting high purity stainless steel gas fittings, it is essential to consider the specific application, the type of gas being handled, and the operating conditions. By choosing fittings that meet these criteria and following best practices for installation and maintenance, operators can ensure the integrity of their gas systems and contribute to the overall success of their operations.

For more about the best high purity stainless steel gas fittings in the oil & gas industry, you can pay a visit to Jewellok at https://www.jewellok.com/product-category/compression-tube-fittings/ for more info.

Recent Posts

Five Key Considerations When Choosing a TMA Gas Changeover Manifold

How to Prevent Contamination in High Purity Xenon Gas Systems

Regulators for High Purity Krypton in Laser and Lighting Applications

Tags

Recommended Products

-

767LT Reducer Pressure Reducing Valve Adjustment High purity Pressure Reducing Union Fittings And Tubing

-

Stainless Steel Ultra Clean Welding Joint Fittings TW Series TRW Series & CW Series

-

Stainless Steel 316L Single Stage Regulator Pressure Control Panels JSP-1E Series For Semiconductor Fluid Control

-

High Purity Chemical Dispense System & Packing System For Semiconductors JW-200L-CDM & JW-1000L-CDM

-

JR1300 Series Ultra High Purity Single Stage Regulator High Flow Line Regulator For Ultra High Purity Intermediate Flow

-

High Purity Gas Cylinder Semi Automatic Changeover Manifold Regulator Panel 3000psig Stainless Steel Gas Control Panel 1/8 Npt With Gauge

-

765L Stainless Steel Union Elbow Reducing High Purity Fitting Tubing Extension Tubing Connection

-

764L Stainless Steel Union Tee High Purity Fitting Union Tee Reducing Tubing Connection