Blog

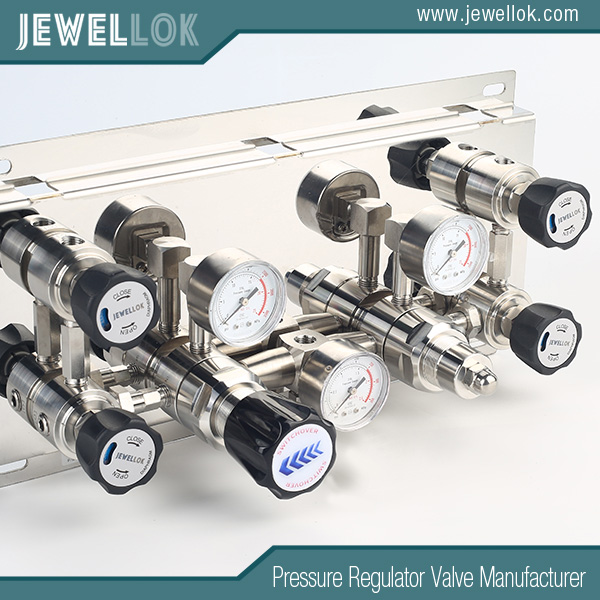

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Best High Purity Valves And Fittings For 1/4″ Tube Connections In Malaysia

- Pressure Regulator Valve Manufacturer

- China High Purity Valves Manufacturer, High Purity Ball Valves Malaysia, High Purity Ball Valves Manufacturer, High Purity Chemical Liquid Valve, High purity valves and fittings, High purity valves and fittings in malaysia, High Purity Valves Manufacturer, High Purity Valves Manufacturer In Malaysia, Pipe Fittings Manufacturers and Suppliers in Malaysia, Semiconductor Purity Valve Manufacturers, Top Industrial Valves Supplier Malaysia, UHP Ultra High Purity Gas Products Malaysia, Ultra High Purity (UHP) Fittings Malaysia, valves supplier Malaysia

- No Comments

Best High Purity Valves And Fittings For 1/4″ Tube Connections In Malaysia

In industries where the purity of fluids is non-negotiable—such as semiconductors, pharmaceuticals, and food and beverage production—the selection of valves and fittings can determine the success or failure of an entire system. High purity valves and fittings are engineered to prevent contamination, ensuring that fluids remain free from particles, chemicals, or microorganisms that could compromise quality. For 1/4″ tube connections, widely utilized for their precision and compact design, choosing the right components is especially critical. Malaysia, a growing hub for high-tech industries like semiconductor manufacturing, has an increasing demand for reliable high purity solutions. This article explores the best high purity valves and fittings for 1/4″ tube connections available in Malaysia, providing a detailed guide to help you make informed decisions for your applications.

Understanding High Purity and 1/4″ Tube Connections

High purity refers to systems designed to maintain the integrity of fluids by preventing contamination. In industries like semiconductor manufacturing, even microscopic particles can ruin a batch of microchips, while in pharmaceuticals, contamination can affect drug safety. High purity valves and fittings are typically made from non-reactive, easy-to-clean materials with smooth surfaces to minimize particle generation.

The 1/4″ tube size is a popular choice in high purity applications due to its balance of precision and practicality. It allows for accurate flow control, making it ideal for processes requiring small volumes of fluids or gases, and its compact size suits the intricate setups common in Malaysia’s high-tech sectors. Selecting the best valves and fittings for this size involves understanding their types, materials, and specific features tailored to high purity needs.

Types of High Purity Valves for 1/4″ Tube Connections

Valves control the flow, pressure, and direction of fluids in a system. In high purity applications, they must perform reliably while ensuring no contamination occurs. Below are the primary types of valves suited for 1/4″ tube connections:

1. Diaphragm Valves

Diaphragm valves are a top choice for high purity systems because they provide a hermetic seal, isolating the fluid from the valve’s moving parts. A flexible diaphragm, often made from PTFE (Polytetrafluoroethylene) or PFA (Perfluoroalkoxy), prevents contact between the fluid and components like the stem or bonnet, reducing contamination risks. Some feature a weir-type design for improved flow control and easier cleaning, while metal diaphragms are available for high-temperature or high-pressure applications. Their versatility makes them ideal for Malaysia’s pharmaceutical and semiconductor industries.

2. Ball Valves

Ball valves offer durability and quick operation, making them suitable for applications needing fast shut-off. High purity ball valves are crafted from stainless steel with polished surfaces and PTFE seats and seals. To enhance purity, they often include cavity fillers to reduce dead space where fluids might stagnate, a critical feature for maintaining system cleanliness.

3. Needle Valves

Needle valves excel in precision flow control, which is essential for processes like gas delivery in semiconductor manufacturing. Made from stainless steel with electropolished finishes, they minimize particle generation. Their packing materials are chosen for compatibility with process fluids, ensuring no contamination occurs during fine adjustments.

4. Check Valves

Check valves prevent backflow, a key factor in maintaining system purity. High purity versions feature smooth, crevice-free interiors and minimal dead space to avoid trapping particles. Often spring-loaded for reliability, they are vital in systems where contamination from reverse flow could be catastrophic.

The choice of valve depends on your application’s needs—diaphragm valves for sealing, ball valves for speed, needle valves for precision, or check valves for protection.

Types of High Purity Fittings for 1/4″ Tube Connections

Fittings connect tubes, valves, and other system components, and in high purity applications, they must minimize contamination risks. Here are the main types for 1/4″ tubes:

1. Compression Fittings

Compression fittings are favored for their secure, leak-tight connections without welding. High purity versions, often made from stainless steel, use a double-ferrule design: the front ferrule seals against the fitting body, while the back ferrule grips the tube. This dual-seal system is robust against vibration and thermal cycling, common in Malaysia’s industrial settings.

2. Welded Fittings

Welded fittings provide a permanent, crevice-free connection, perfect for ultra-high purity needs. They require skilled techniques like orbital welding to ensure welds are smooth and contaminant-free. In Malaysia, specialized welding services support industries like semiconductors, ensuring compliance with purity standards.

3. Quick-Connect Fittings

Quick-connect fittings enable fast assembly and disassembly, ideal for systems needing regular maintenance. High purity designs feature smooth surfaces and minimal dead space, with locking mechanisms to ensure secure connections without compromising cleanliness.

4. VCR Fittings

VCR (Vacuum Coupling Radiation) fittings use a metal gasket face seal for a high-integrity, leak-tight connection. Widely used in semiconductor manufacturing, they are easy to install and remove, making them suitable for Malaysia’s high-tech facilities requiring frequent system adjustments.

Your fitting choice should balance installation ease, maintenance needs, and purity level—compression for flexibility, welded for permanence, quick-connect for convenience, or VCR for ultra-high purity.

Materials for High Purity Valves and Fittings

Material selection is pivotal in high purity systems, affecting compatibility, contamination risk, and durability. Common materials include:

Stainless Steel (316L): Known for corrosion resistance and strength, 316L’s low carbon content prevents carbide precipitation during welding, making it a staple in high purity applications.

PTFE (Polytetrafluoroethylene): This chemically inert fluoropolymer is used for seats, seals, and diaphragms, offering low friction and high purity.

PFA (Perfluoroalkoxy): Similar to PTFE but stronger at higher temperatures, PFA is common in semiconductor-grade components.

PVDF (Polyvinylidene Fluoride): A cost-effective thermoplastic with good chemical resistance, suitable for less demanding applications.

Choose materials based on your process fluids, temperature, and purity requirements—316L for durability, PTFE/PFA for chemical inertness, or PVDF for economy.

Surface Finishes for High Purity Applications

Surface finish impacts cleanability and particle generation. Measured by Ra (average roughness), high purity components often have Ra values below 10 microinches, achieved through electropolishing. This process smooths and passivates surfaces, enhancing corrosion resistance and reducing contamination risks—a must for Malaysia’s stringent industries.

Standards and Certifications

Compliance with standards ensures quality and suitability:

ASME BPE: Guides biopharmaceutical equipment design, emphasizing surface finish and cleanability.

SEMI Standards: Critical for semiconductors, covering material purity and system integrity.

3-A Sanitary Standards: Ensures hygiene in food and beverage equipment.

Select products meeting standards relevant to your industry for guaranteed performance.

Installation and Maintenance Considerations

Proper handling maintains system purity:

Cleanliness: Use gloves and clean tools during installation to avoid contamination.

Torque: Apply manufacturer-specified torque for compression fittings to ensure seals without damage.

Welding: Employ orbital welding for consistent, high-quality welds in welded fittings.

Inspection: Regularly check for wear or damage to prevent failures.

Cleaning: Use CIP or approved solvents to maintain purity.

These practices are essential for long-term reliability in Malaysia’s high purity applications.

Case Study: Semiconductor Manufacturing in Malaysia

Malaysia’s semiconductor industry, a global leader, relies heavily on high purity systems. A Penang-based manufacturer uses diaphragm valves and VCR fittings for its ultra-high purity nitrogen lines. The valves, made from electropolished 316L stainless steel with PTFE diaphragms, ensure minimal particle generation, while VCR fittings provide leak-tight, maintainable connections. This setup supports the precision required for advanced chip production, showcasing the effectiveness of these components in real-world applications.

Selecting the Best Options in Malaysia

When choosing high purity valves and fittings for 1/4″ tube connections in Malaysia, consider:

Material Compatibility: Match materials to your fluids and conditions.

Surface Finish: Opt for electropolished surfaces for ultra-high purity.

Certifications: Ensure compliance with ASME BPE, SEMI, or 3-A standards.

Local Support: Select suppliers offering technical assistance and quick delivery.

Reputable brands like Swagelok, Parker, and Ham-Let offer high-quality options. In Malaysia, Fit Systems Sdn Bhd (Selangor) and Minox provide specialized components, including Swagelok’s VCR fittings and PFA tubing, supported by local expertise.

Conclusion

Selecting the best high purity valves and fittings for 1/4″ tube connections in Malaysia is a strategic decision for industries demanding contamination-free systems. By understanding valve and fitting types, material properties, surface finishes, and standards, you can optimize your setup for performance and reliability. Whether you need diaphragm valves for sealing, VCR fittings for ultra-high purity, or local support from suppliers like Fit Systems, prioritizing quality ensures success. In Malaysia’s dynamic industrial landscape, these components are your foundation for maintaining purity and achieving operational excellence.

For more about the best high purity valves and fittings for 1/4″ tube connections in malaysia, you can pay a visit to Jewellok at https://www.jewellok.com/products/ for more info.

Recent Posts

Troubleshooting Common Failures in TMA Gas Changeover Manifolds

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

How to Select the Right Valve Manifold Box for Your Application

Tags

Recommended Products

-

Ultra High Purity Trimethylaluminum TMA Gas Cabinet Liquid Delivering Cabinet Used For Specialty Gas Delivery System In Semiconductor

-

High Purity High Flow Pressure Control Regulators & Valves Gas Stick Assemblies JSR-2TG Series

-

High Purity High Pressure Specialty Gas Pressure Regulators Specialty Gases Pipeline Engineering Equipments Manufacturer And Supplier

-

High Purity And Industria Gas Stick Assemblies Precise Pressure Control Gas Systems JSR-1ETG-BV Series

-

763L Stainless Steel High Purity Pressure Reducing Union Fittings And Tubing Pressure Reducing Valve Adjustment

-

VMB Valve Manifold Panels And Boxes High Purity Configurable Systems JW-200-VMB & JW-100-VMB

-

765L Stainless Steel Union Elbow Reducing High Purity Fitting Tubing Extension Tubing Connection

-

Stainless Steel Mini Elbow Mini Tee Mini Cross Mini Tribow Ultrahigh Purity Mini Butt Weld Fittings