Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Difference of (Valve Manifold Panel) VMP Gas Cabinet and (Valve Manifold Box) VMB Gas Cabinet

- Pressure Regulator Valve Manufacturer

- gas valve manifold box, gas valve manifold box India, gas valve manifold box turkey, Gas Valve Manifold Boxes, hydrogen valve manifold box japan, nitrogen manifold panel for individual gas cabinet and valve manifold box, semiconductor valve manifold box, semiconductor valve manifold box diaphragm valves, semiconductor valve manifold box gas pressure regulators, SiH4 NF3 NH3 Gas Valve Manifold Boxes, Valve Manifold Box (VMB) gas cabinet, Valve Manifold Box for Gas System VMB, Valve manifold box/panel (VMB/VMP), Valve Manifold Panel (VMP) gas cabinet, Valve Manifold Panels and Boxes, VMB Cabinet Gas Valve Manifold Box, vmb valve manifold box, vmb valve manifold box china, vmb valve manifold box germany, vmb valve manifold box India

- No Comments

Difference of (Valve Manifold Panel) VMP Gas Cabinet and (Valve Manifold Box) VMB Gas Cabinet

Introduction

In the realm of industrial gas handling, particularly within high-purity environments such as semiconductor manufacturing, pharmaceutical production, and chemical processing, the safe and efficient distribution of gases is paramount. Gas cabinets serve as critical components in these systems, ensuring controlled delivery while mitigating risks associated with hazardous materials. Among the various configurations, Valve Manifold Panel (VMP) gas cabinets and Valve Manifold Box (VMB) gas cabinets stand out as specialized solutions for gas distribution. These systems are designed to receive gas from centralized sources, such as bulk storage or cylinder cabinets, and distribute it to multiple endpoints, like production tools or chambers.

The VMP and VMB gas cabinets, though similar in their core function of manifold-based gas splitting, differ significantly in design, application, safety features, and operational suitability. This article delves into these differences, providing a comprehensive technical analysis. We will explore the architecture, components, operational principles, advantages, limitations, and comparative aspects of each system. Understanding these distinctions is essential for engineers, facility managers, and safety professionals when selecting the appropriate gas distribution equipment for their operations. By the end of this discussion, readers will appreciate how these systems contribute to process integrity, regulatory compliance, and overall system efficiency in demanding industrial settings.

Gas distribution systems in modern facilities often involve ultra-high-purity (UHP) gases, where even minute contaminants can compromise product quality. VMP and VMB cabinets address this by incorporating precise control mechanisms, but their structural and functional variances cater to different gas types and hazard levels. For instance, while both can handle multiple “sticks” (individual gas lines), their enclosure designs and ventilation requirements set them apart. This article aims to elucidate these nuances, drawing on technical specifications and practical considerations to offer a balanced perspective.

Overview of Valve Manifold Panel (VMP) Gas Cabinet

The Valve Manifold Panel (VMP) gas cabinet is a compact, open-panel configuration primarily used for distributing inert or non-hazardous gases in controlled environments. Unlike fully enclosed systems, the VMP consists of a flat panel-mounted assembly where valves, regulators, and associated components are arranged in a linear or modular fashion. This design facilitates easy access for maintenance and monitoring, making it ideal for applications where space is limited and the gases involved pose minimal risks.

Key Components and Design

A typical VMP gas cabinet includes several essential elements:

– Manifold Assembly: The core of the VMP is a manifold that splits a single inlet gas line into multiple outlets, often referred to as “sticks.” Each stick can support independent flow control, with capacities ranging from 4 to 8 sticks in standard configurations. The manifold is constructed from high-purity materials like 316L stainless steel to prevent corrosion and contamination.

– Valves and Regulators: Pneumatic or manual valves (e.g., diaphragm valves for UHP applications) control gas flow, while pressure regulators maintain consistent output pressures, typically adjustable from 0 to 150 psi. Check valves and isolation valves ensure unidirectional flow and prevent backflow.

– Instrumentation: Pressure gauges, transducers, and flow meters are integrated for real-time monitoring. In automated variants, programmable logic controllers (PLCs) or simple relay systems enable semi-automatic operation, such as purging sequences.

– Mounting and Integration: The panel is wall-mounted or rack-integrated, often within a cleanroom or tool bay. It lacks a full enclosure, relying on the surrounding environment for ventilation. Dimensions are compact, with a standard panel measuring around 30 inches in width, allowing for seamless integration into existing piping networks.

Operational Principles

The VMP operates by receiving gas from a primary source, such as a gas cylinder cabinet or bulk tank, through an inlet port. The gas enters the manifold, where it is divided among the sticks. Each stick can be isolated, purged, or activated independently, supporting processes like tool calibration or chamber filling. For inert gases like nitrogen or argon, the system emphasizes purity preservation through electropolished surfaces and orbital welding to minimize particle generation.

Purging is a critical operation in VMP systems, typically involving vacuum-assisted cycles to remove residual gases or contaminants. Manual VMPs require operator intervention, while semi-automatic models use timers or sensors to sequence valve operations. Safety interlocks prevent accidental release, but since the system is open, it is not suited for gases requiring exhaust extraction.

Applications and Advantages

VMP gas cabinets are prevalent in semiconductor fabs for distributing purge gases, in pharmaceutical plants for inert blanketing, and in research labs for analytical instrument supply. Their advantages include:

– Cost-Effectiveness: Lower fabrication costs due to the absence of enclosure and exhaust systems.

– Ease of Maintenance: Open design allows quick component replacement without disassembly.

– Flexibility: Modular sticks enable easy expansion or reconfiguration for changing process needs.

– Space Efficiency: Ideal for tight installations where full cabinets would be impractical.

However, limitations exist: VMPs are unsuitable for hazardous gases, as they lack containment for leaks or fumes. Regulatory standards, such as those from SEMI (Semiconductor Equipment and Materials International), mandate their use only for non-toxic applications.

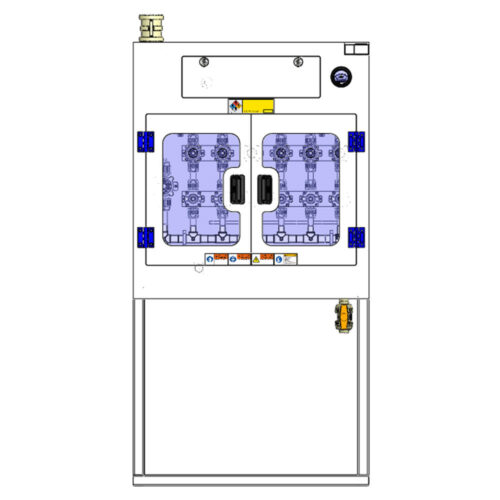

Overview of Valve Manifold Box (VMB) Gas Cabinet

In contrast, the Valve Manifold Box (VMB) gas cabinet is a fully enclosed, ventilated system designed for handling hazardous, toxic, flammable, or corrosive gases. The “box” refers to its cabinet-like structure, which provides secondary containment and integrates exhaust features to maintain a negative pressure environment. This enclosure enhances safety by capturing potential leaks and directing them to a scrubber or exhaust system.

Key Components and Design

The VMB builds on the manifold concept but encases it within a robust housing:

– Enclosure: Constructed from powder-coated steel or stainless steel, the box measures approximately 30-60 inches in width, with access doors featuring safety glass windows for visual inspection. It includes seals and gaskets to ensure airtight integrity.

– Manifold and Sticks: Similar to VMP, it supports 4 to 8 sticks, but with enhanced features like UV-IR flame detectors or toxic gas sensors for hazardous applications.

– Valves and Regulators: High-integrity valves (e.g., bellows-sealed) and regulators are used, often with pneumatic actuators for remote control. Additional check valves and excess flow valves prevent uncontrolled releases.

– Ventilation System: A key differentiator, the VMB incorporates a vacuum generator or blower for continuous exhaust, achieving airflow rates of 150-200 linear feet per minute. This maintains negative pressure, preventing gas escape.

– Control Systems: Fully automatic VMBs use advanced PLCs with touchscreen interfaces, supporting protocols like Modbus for integration with facility management systems. Alarms for pressure drops, leaks, or door openings are standard.

Operational Principles

Gas enters the VMB through a sealed inlet, distributed via the manifold to multiple outlets. For hazardous gases like silane or ammonia, the system includes automated purge cycles using inert gas or vacuum to evacuate lines before maintenance. The exhaust system continuously vents the enclosure, routing effluents to treatment units. Safety features include emergency shutdown (EMO) buttons and interlocks that halt operations if ventilation fails.

In operation, the VMB ensures compliance with codes like NFPA 55 (Compressed Gases and Cryogenic Fluids Code), which require exhausted enclosures for pyrophoric or toxic gases. The negative pressure design minimizes exposure risks, making it suitable for high-stakes environments.

Applications and Advantages

VMBs are essential in semiconductor processes involving dopant gases, LCD manufacturing with corrosive etchants, and solar panel production with flammable precursors. Benefits include:

– Enhanced Safety: Enclosure and exhaust mitigate hazards, reducing accident potential.

– Regulatory Compliance: Meets stringent standards for hazardous gas handling.

– Versatility: Handles a broader range of gases, including mixtures.

– Reliability: Automated controls minimize human error and ensure consistent delivery.

Drawbacks involve higher costs due to enclosure and ventilation, increased footprint, and more complex maintenance requiring specialized training.

Key Differences Between VMP and VMB Gas Cabinets

While both VMP and VMB systems serve gas distribution roles, their differences are rooted in design philosophy, safety requirements, and operational contexts. Below is a detailed comparison:

Design and Structure

– Enclosure: The most apparent difference is structural. VMP is an open panel, exposing components to the ambient environment, whereas VMB is a sealed box providing containment. This affects installation: VMPs are lighter (around 50-100 lbs) and easier to mount, while VMBs (200-400 lbs) require sturdy supports and ducting connections.

– Dimensions and Configuration: VMPs are slimmer, often 2-4 inches deep, suiting wall-mounted setups. VMBs are deeper (12-24 inches) to accommodate exhaust plenums and internal routing.

Safety Features

– Hazard Handling: VMPs are limited to inert gases (e.g., helium, oxygen-free nitrogen), lacking mechanisms for fume extraction. VMBs excel with hazardous gases, incorporating exhaust, sensors (e.g., for H2S or Cl2 detection), and flame arrestors.

– Ventilation: Absent in VMPs, mandatory in VMBs. VMB airflow ensures compliance with OSHA exposure limits, preventing buildup of toxic vapors.

– Interlocks and Alarms: Both have basic interlocks, but VMBs feature advanced ones, like automatic shutdown on leak detection, integrated with building fire suppression.

Operational and Control Aspects

– Automation Levels: VMPs are often manual or semi-automatic, relying on operator oversight. VMBs support full automation, with software for remote monitoring and data logging.

– Purge Capabilities: Both offer purging, but VMBs include vacuum-assisted vents for thorough evacuation, critical for corrosive gases.

– Flow and Pressure Management: Similar capacities (up to 500 slpm per stick), but VMBs handle higher pressures (up to 3000 psi inlet) due to robust construction.

Applications and Suitability

– Gas Types: VMP for non-reactive (Group A per SEMI standards); VMB for reactive/toxic (Groups B-D).

– Industries: VMP in low-risk labs; VMB in high-volume fabs where gas diversity is high.

– Cost and Maintenance: VMPs cost 20-50% less initially and require simpler upkeep. VMBs demand regular exhaust filter changes and calibration, increasing operational expenses.

Performance Metrics

|

Parameter

|

VMP Gas Cabinet

|

VMB Gas Cabinet

|

|---|---|---|

|

Enclosure Type

|

Open Panel

|

Sealed Box with Exhaust

|

|

Suitable Gases

|

Inert (N2, Ar, He)

|

Hazardous (SiH4, NH3, HF)

|

|

Ventilation

|

None

|

150-200 LFM Negative Pressure

|

|

Automation

|

Manual/Semi-Auto

|

Semi-Auto/Full-Auto

|

|

Typical Stick Count

|

4-8

|

4-8

|

|

Cost Range (USD)

|

5,000-15,000

|

10,000-30,000

|

|

Footprint (inches)

|

30W x 40H x 4D

|

30W x 40H x 18D

|

|

Safety Compliance

|

Basic (SEMI S2)

|

Advanced (NFPA 55, SEMI S6)

|

This table highlights how VMBs prioritize safety at the expense of complexity, while VMPs emphasize

Case Studies and Practical Considerations

In a semiconductor facility upgrading its etching processes, a VMB was chosen for HF gas distribution due to its corrosive nature, preventing potential leaks from affecting cleanroom air quality. Conversely, a research lab opted for a VMP to supply argon for spectroscopy, valuing its low cost and ease of integration.

When selecting between VMP and VMB, factors like gas hazard classification, facility layout, budget, and scalability must be weighed. Hybrid systems, where VMPs feed from VMB-protected sources, are emerging for optimized setups.

Conclusion

The Valve Manifold Panel (VMP) and Valve Manifold Box (VMB) gas cabinets represent tailored solutions in gas distribution technology, with VMP offering streamlined efficiency for inert applications and VMB providing robust safety for hazardous ones. Their differences in enclosure, ventilation, and control sophistication underscore the need for context-specific choices. As industries evolve toward greater automation and sustainability, these systems will continue to play vital roles, ensuring precise, safe gas delivery. Engineers must evaluate site-specific risks and requirements to leverage the strengths of each, ultimately enhancing operational reliability and compliance in high-stakes environments.

For more about the difference of (valve manifold panel) vmp gas cabinet and (valve gas box) vmb gas cabinet, you can pay a visit to Jewellok at https://www.jewellok.com/product-category/gas-cabinet/ for more info.

Recent Posts

Five Key Considerations When Choosing a TMA Gas Changeover Manifold

How to Prevent Contamination in High Purity Xenon Gas Systems

Regulators for High Purity Krypton in Laser and Lighting Applications

Tags

Recommended Products

-

Semi Automatic And Automatic Switching Speicialty Gas Changeover Manifold Panel With Semiconductor Valve Manifold Box Gas Pressure Regulators

-

Stainless Steel Single Stage Semiconductor Grade Pressure Control Module Pressure Control Panels JSP-6A Series

-

High Purity Configurable Systems VMB Valve Manifold Box JW-200-VMB-C & JW-100-VMB-C

-

7121L Plug High Purity Plug Fitting And Blanking Plug

-

770L Female Elbow | Stainless Steel High Purity Weld Fittings Female Micro Elbow Fittings

-

771LF Female Run Tee | Stainless Steel Tube Fitting Compression Fittings 1/4 In 3-Way Tee Female Run Tee

-

Stainless Steel Ultra Clean Welding Joint Fittings TW Series TRW Series & CW Series

-

Ultra High Purity Oxygen Pressure Gauge For Semiconductor Gases JG Series Pressure Instruments For Semiconductor Manufacturing