Blog

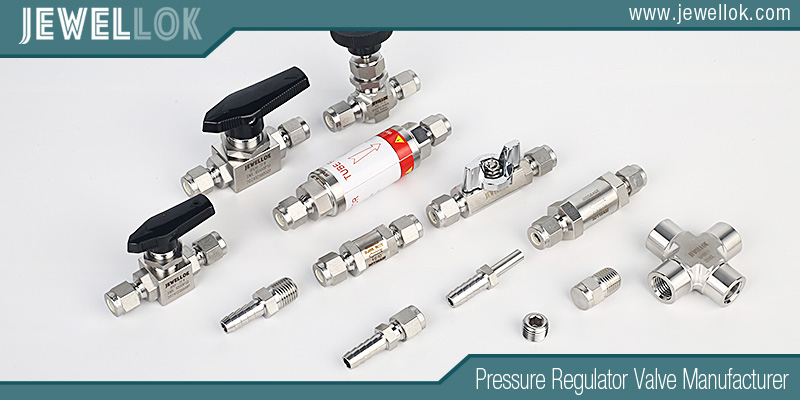

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Full Analysis of Technological Innovation and Application Scenarios of 316 Stainless Steel Diaphragm Valve

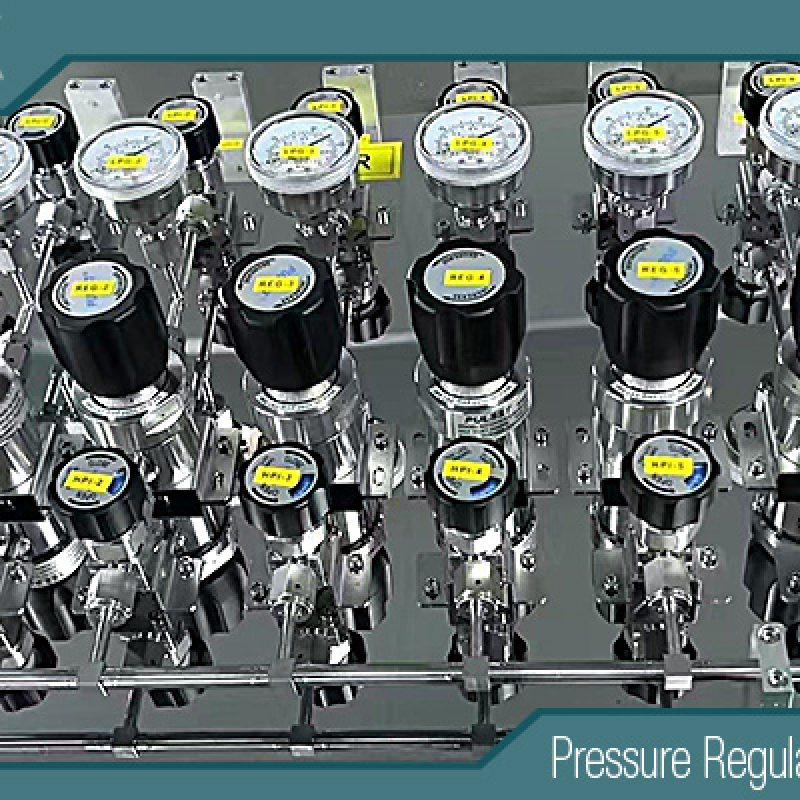

- Pressure Regulator Valve Manufacturer

- 316 SS ball valves manufacturer, 316l stainless steel diaphragm valve, 316L Stainless Steel Seamless High Purity System Tube, 316L stainless steel VIM-VAR process, 316l vim var stainless steel gas pressure reducing regulator, 316L VIM-VAR UHP High Pressure Diaphragm Sealed Valve, ASME BPE compliant valve, Best high purity stainless steel gas fittings, China Ultra High Purity Fittings Factory, China Ultra High Purity Fittings Manufacturers, China Ultra High Purity Fittings Suppliers, compression tube fittings, Diaphragm seal maintenance tips, Diaphragm sealed valve semiconductor, Electropolished 316L valve, Fittings for High Purity Piping, Helium leak tested diaphragm valve, High cycle pressure valve durability, high pressure compression fittings, High pressure fluid control valve, high purity fittings, high purity stainless steel fitting, high purity stainless steel tubing, hydrogen pipe valves and fittings, manufacturing ultra high purity valves, particle-free stainless steel valves, precision engineering UHP valves, SEMI standards for high purity valves, stainless steel butt weld pipe fittings, stainless steel compression fittings, stainless steel tubing fittings, Tubing and Fittings for Compressed Gas Systems, UHP stainless steel valves, Ultra High Purity Coaxial Stainless Steel Tube Fittings, ultra high purity fittings, ultra high purity fittings manufacturers in china, ultra high purity stainless steel tubing, ultra high purity stainless steel valve, Ultra-High-Purity Tube Fittings, vacuum compatible stainless steel valves

- No Comments

Full Analysis of Technological Innovation and Application Scenarios of 316 Stainless Steel Diaphragm Valve

The diaphragm valve, a cornerstone of fluid control in critical industries, has evolved significantly through advancements in materials science and engineering design. At the forefront of this evolution is the 316 stainless steel diaphragm valve, a paradigm of reliability, safety, and precision. This article provides a comprehensive analysis of the technological innovations that have enhanced this valve type and explores its diverse, mission-critical application scenarios. By marrying the superior material properties of ASTM 316 stainless steel with sophisticated design improvements, modern diaphragm valves offer unparalleled performance in handling corrosive, ultra-pure, and sterile fluids, solidifying their indispensable role from biopharmaceutical manufacturing to semiconductor fabrication and beyond.

Material Foundation: The Unmatched Pedigree of 316 Stainless Steel

The performance of a diaphragm valve is intrinsically linked to its material composition. 316 stainless steel (UNS S31600) is not merely a choice but a strategic engineering decision driven by its enhanced chemical and mechanical properties compared to other austenitic grades like 304.

- Molybdenum-Enhanced Corrosion Resistance: The defining innovation in 316 SS is the addition of 2-3% molybdenum. This element dramatically increases resistance to pitting and crevice corrosion in chloride-ion environments—a common challenge in chemical processing, coastal applications, and systems using saline or bleach-based CIP (Clean-in-Place) solutions.

- Superior Acid and Alkali Tolerance: 316 SS exhibits excellent resistance to a wide spectrum of corrosive media, including sulfuric acid, phosphoric acid, and various organic acids, as well as alkaline solutions, making it a versatile choice for complex chemical processes.

- Non-Reactive and Hygienic Surface: The passive oxide layer of 316 SS is inert, ensuring no leaching of contaminants into the process fluid. This is critical for maintaining product purity in food, beverage, and pharmaceutical applications. Its high polishability (to electropolished Ra<0.8 µm or better) minimizes microbial adhesion and facilitates easy, validated cleaning.

- High-Temperature Integrity: 316 SS maintains excellent structural strength and corrosion resistance at elevated temperatures, which is vital for valves involved in heat sterilization (SIP – Steam-in-Place) cycles up to 140°C+ and other high-temperature processes.

This material foundation makes 316 SS the gold standard for valve bodies, bonnets, and internal components in demanding applications.

Technological Innovations in Diaphragm Valve Design

Innovation in 316 stainless steel diaphragm valves has focused on improving sealing integrity, actuation control, cleanliness, and lifecycle efficiency.

A. Diaphragm Technology: The Heart of Innovation

The diaphragm itself is the critical sealing component, isolating the fluid path from the actuator mechanism.

- Multi-Layer Laminated Diaphragms: Modern designs often use PTFE (Teflon) diaphragms with an elastic backing layer (like EPDM or FKM). The latest innovation involves 316 SS-reinforced PTFE diaphragms. A thin, formed sheet of 316 SS is encapsulated within multiple PTFE layers. This combines the absolute chemical resistance and purity of PTFE with the mechanical strength and fatigue resistance of metal, enabling higher cycle lives and resistance to pressure pulsations.

- Diaphragm Geometry and Stress Optimization: Finite Element Analysis (FEA) is used to redesign diaphragm profiles, creating contours that evenly distribute stress during the actuation cycle. This innovation significantly reduces fatigue failure, extends service life, and allows for higher allowable pressure differentials.

- Material Advancements: Beyond standard PTFE, new perfluoroelastomer (FFKM) diaphragms offer compatibility with nearly all aggressive chemicals and solvents while maintaining elasticity, suitable for the most demanding chemical synthesis applications.

B.Body and Weir Design for Optimal Flow

- Straight-Through and Full-Bore Designs: While the traditional raised weir design is excellent for shut-off and control, innovations have led to full-bore or straight-through 316 SS body designs. These minimize pressure drop, prevent fluid entrapment, and allow for effective CIP/SIP and drainage, making them ideal for hygienic and ultra-pure applications. They are also suitable for handling slurries and viscous fluids.

- Sterile and Aseptic Connections: For biopharma, valves now feature integral 316L SS (low-carbon variant) faces for orbital welding directly into sanitary tubing, eliminating dead legs. Clamp (Tri-Clamp) connections with aseptic face seals are also standardized, ensuring a perfectly flush, cleanable interface.

C. Actuation and Control Innovations

- Pneumatic Actuator Optimization: Modern pneumatic actuators are designed for lower friction, higher efficiency, and modularity. Multi-spring fail-safe mechanisms and integrated pilot valves for sophisticated control are now common. The integration of Namur mounts and ISO 5211 mounting pads allows for easy attachment of a wide range of actuators and positioners.

- Electric Actuation Integration: The rise of Industry 4.0 has driven the development of compact, programmable electric actuators on 316 SS diaphragm valves. These enable precise flow control, digital feedback (open/close status, torque), and seamless integration into Distributed Control Systems (DCS) without the need for compressed air.

- Smart Valve Technology: The most cutting-edge innovation involves embedding sensors and IoT (Internet of Things) capabilities. Sensors can monitor:

- Diaphragm Integrity: Predicting failure by detecting micro-leaks or changes in actuation pressure.

- Position Feedback: Providing real-time, precise stem/diaphragm position.

- Pressure and Temperature: At the valve body.

This data enables predictive maintenance, reduces downtime, and ensures process integrity.

D. Surface Finish and Cleanability

Technological strides in manufacturing have standardized superior surface finishes.

- Electropolishing: This electrochemical process not only produces a mirror-like finish (Ra < 0.38 µm) but also enhances the natural passive oxide layer, further boosting corrosion resistance.

- Automated Passivation: Post-fabrication, automated nitric or citric acid passivation ensures the consistent removal of free iron and the formation of a uniform chromium oxide layer, guaranteeing the material’s full corrosion-resistant potential.

Application Scenarios: Where Innovation Meets Demand

The specific innovations in 316 SS diaphragm valves directly address the stringent requirements of these key industries:

A. Biopharmaceutical and Pharmaceutical Manufacturing

- Scenario: Production of vaccines, monoclonal antibodies, and sterile injectables.

- Requirements: Absolute sterility, cleanability, validation (FDA 21 CFR Part 11), containment of hazardous compounds.

- Valve Application: 316L SS valves with electropolished, straight-through bodies, steam-in-place (SIP) capability, and PTFE/FFKM diaphragms. Used in fermenters, bioreactors, chromatography skids, and formulation tanks. They isolate critical process zones, provide sterile sampling points, and control the flow of buffers, media, and product. Aseptic design and CIP/SIP compatibility are non-negotiable.

B. Microelectronics and Semiconductor Fabrication

- Scenario: Manufacturing of silicon wafers and microchips.

- Requirements: Ultra-high purity (UPW – Ultra-Pure Water), resistance to aggressive high-purity chemicals (acids, solvents, etchants), and metallic ion contamination control.

- Valve Application: Ultra-high-purity (UHP) 316L SS valves with electropolished interiors, diaphragm-sealed all-wetted parts, and zero internal crevices. They control the flow of UPW, slurries (CMP), hydrofluoric acid, sulfuric acid-peroxide mixtures (piranha etch), and specialty gases. Metal-ion shedding is minimized, and particulate generation is virtually eliminated.

C. Food and Beverage Processing

- Scenario: Dairy processing, brewing, juice production, and high-acid food lines.

- Requirements: Hygienic design (3-A Sanitary Standards, EHEDG), cleanability, resistance to cleaning agents (caustic, acidic detergents), and prevention of bacterial harborage.

- Valve Application: 316 SS valves with sanitary clamp ends, polished surfaces, and smooth radii. They are used for product routing, CIP system control, and aseptic processing valves. Diaphragm valves prevent product contamination from actuator lubricants.

D. Chemical and Petrochemical Processing

- Scenario: Handling of corrosive intermediates, solvents, and aggressive process streams.

- Requirements: Robust corrosion resistance, leak-tight shut-off, safety, and reliability under high-cycle or abrasive conditions.

- Valve Application: Heavy-duty 316 SS valves, often with PTFE-lined bodies or SS-reinforced PTFE diaphragms, handling acids, alkalis, chlorinated solvents, and salt slurries. Their dead-tight shut-off and leak-free design are critical for environmental protection and operational safety.

E. Water and Wastewater Treatment

- Scenario: Dosing of treatment chemicals (polymers, chlorine, sodium hydroxide, acids) and control of sludge lines.

- Requirements: Reliability with abrasive/ viscous fluids, precise metering capability, and resistance to highly variable chemical compositions.

- Valve Application: 316 SS valves, often with full-port bodies and abrasion-resistant diaphragms, are used in chemical dosing pumps and sludge control systems. Their ability to handle slurries and their clog-resistant design are key advantages.

Future Trends and Conclusion

The trajectory for 316 stainless steel diaphragm valves points towards increased intelligence, sustainability, and material synergy.

- The Rise of the Digital Twin: Smart valves with embedded sensors will feed data into digital twin models of process plants, allowing for real-time optimization and virtual testing of process changes.

- Additive Manufacturing (3D Printing): This technology will allow for the creation of optimized 316 SS valve bodies with complex internal geometries that minimize turbulence and pressure drop, which are impossible to achieve with traditional casting or machining.

- Advanced Coatings and Surface Treatments: Further enhancements, such as proprietary nanocoatings, could offer even greater protection against specific corrosive agents or reduce adhesion for sticky fluids.

- Sustainability Focus: Designs will prioritize longevity, repairability, and the use of environmentally conscious diaphragm materials without compromising performance.

Conclusion

The 316 stainless steel diaphragm valve is a testament to how incremental material and engineering innovations coalesce to solve complex industrial challenges. From the foundational superiority of molybdenum-enhanced 316 SS to the sophisticated innovations in diaphragm composites, actuation intelligence, and hygienic design, this valve type has been relentlessly optimized. It seamlessly bridges the gap between the aggressive demands of corrosive chemical processing and the pristine requirements of life sciences. As industries continue to push the boundaries of purity, efficiency, and connectivity, the 316 SS diaphragm valve, through continuous innovation, will remain an essential and evolving component in the global industrial landscape, ensuring safety, purity, and control where it matters most. Its future lies not in replacement, but in deeper integration and smarter, more predictive functionality.

For more about full analysis of technological innovation and application scenarios of 316 stainless steel diaphragm valve, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Choose the Krypton Gas Ultra High Purity (UHP) Regulator

Troubleshooting Common Failures in TMA Gas Changeover Manifolds

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

Tags

Recommended Products

-

765L Stainless Steel Union Elbow Reducing High Purity Fitting Tubing Extension Tubing Connection

-

T-BOX JW-TB-C Special Gas Delivery System Gas Valve Manifold Boxes

-

Fully Automated Gas Cabinet For Precise UHP Gas Delivery And High Purity Gas Delivery Systems JW-300-GC

-

Ultra High Purity Trimethylaluminum TMA Gas Cabinet Liquid Delivering Cabinet Used For Specialty Gas Delivery System In Semiconductor

-

Ultra High Purity Oxygen Pressure Gauge For Semiconductor Gases JG Series Pressure Instruments For Semiconductor Manufacturing

-

766L High Purity Female Connector UHP Fitting Female Connector

-

Integrated Gas System (IGS) Modular Integrated Gas Systems (TMS) Integrated Gas Supply System For Semiconductor And Laboratory

-

765LR Reducing Tee | Stainless Steel 316 High Purity Butt Weld Fittings Metal Face Seal For Welding Pipe Fitting Reducing Tee