Blog

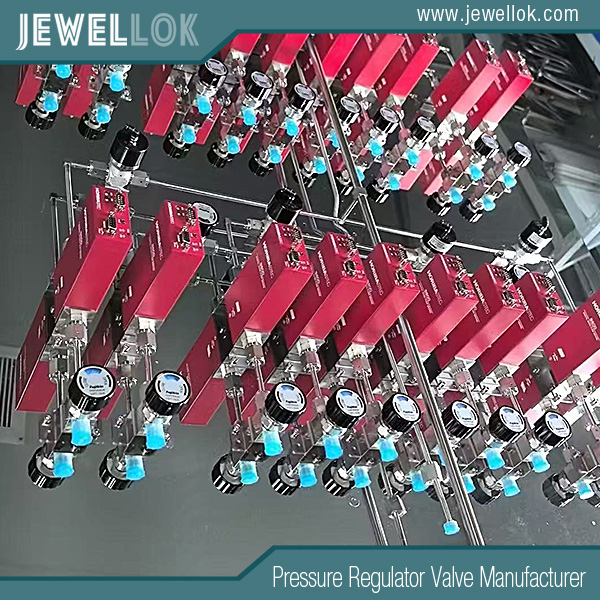

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Gas Changeover Manifold Systems: Ensuring Uninterrupted Gas Supply For Industrial And Medical Applications

- Pressure Regulator Valve Manufacturer

- Automatic Changeover Gas Manifold, Automatic Manifold Systems, automatic switchover manifold, fully automated manifold design, Gas Arc Auto Changeover Manifold Panels, gas arc auto changeover manifolds, gas changeover manifold, Gas changeover manifold system, Gas Control Panel Valves Changeover Manifold, gas cylinder manifold systems, gas manifold, gas manifold system, Gas manifold systems with automatic switch-over, gas regulator manifold, gas valve manifold box, High Purity Semi-Auto Stainless Steel Changeover Manifolds, Industrial Automatic Changeover Manifolds, Manual Changeover Manifold Systems, Pressure Changeover Manifold Regulator Panel, Specialty Gas Automatic Changeover Manifolds, specialty gas changeover manifold system, stainless steel gas manifold, Stainless Steel Semi-automatic Changeover Gas Manifold, switchover manifold, ultra high purity manifolds, valve manifold panels, vmb valve manifold box, what is a gas manifold

- No Comments

Gas Changeover Manifold Systems: Ensuring Uninterrupted Gas Supply For Industrial And Medical Applications

Gas changeover manifold systems are vital components in industries that depend on a continuous and reliable supply of gases. These systems ensure uninterrupted gas flow by seamlessly switching from a depleted gas source to a reserve one, either automatically or semi-automatically. This capability is essential in settings where even a brief interruption can lead to operational disruptions, safety hazards, or financial losses.

In this comprehensive 2000-word guide, we will explore the intricacies of gas changeover manifold systems, including their types, components, applications, benefits, and more. Whether you’re in healthcare, manufacturing, or research, understanding these systems can empower you to optimize your operations effectively. At Jewellok, we offer high-quality gas changeover manifold systems tailored to various industrial needs, and this article will showcase their value and versatility.

What is a Gas Changeover Manifold System?

A gas changeover manifold system is a sophisticated setup designed to manage gas supply from multiple sources to a single point of use. It typically comprises a manifold connecting several gas cylinders or sources, alongside pressure regulators, valves, and sensors that monitor and control gas flow. The system’s primary role is to maintain a continuous gas supply by transitioning from a primary source to a reserve one when the primary is exhausted. This switch can be manual, semi-automatic, or fully automatic, depending on the system’s design and application requirements.

Why Are Gas Changeover Manifold Systems Important?

In numerous industrial and medical environments, an uninterrupted gas supply is non-negotiable. Consider these scenarios:

– Healthcare: Medical gases like oxygen and nitrous oxide are critical for patient care, especially during surgeries or in intensive care units, where interruptions could be life-threatening.

– Manufacturing: Processes such as welding, cutting, or chemical production demand a steady flow of gases like argon, nitrogen, or hydrogen to maintain quality and efficiency.

– Research Laboratories: Experiments requiring precise gas mixtures cannot tolerate disruptions, as they could compromise results and data integrity.

Gas changeover manifold systems mitigate these risks by ensuring a seamless transition between gas sources, reducing downtime and enhancing operational reliability.

Types of Gas Changeover Manifold Systems

Gas changeover manifold systems come in three main types, each suited to different needs and budgets:

- Manual Changeover Systems

Manual systems are the simplest and most cost-effective option. They require an operator to monitor gas levels and manually switch to the reserve source when the primary one depletes. These systems suit applications with low to moderate gas consumption where brief interruptions are tolerable, such as small-scale workshops. However, they are less ideal for critical processes requiring instant switchovers.

- Semi-Automatic Changeover Systems

Semi-automatic systems strike a balance between cost and convenience. They automatically switch to the reserve source when the primary one runs out but need manual resetting once the primary source is replenished. These are perfect for moderate gas consumption scenarios, like mid-sized manufacturing units, where a short delay in resetting is acceptable.

- Fully Automatic Changeover Systems

Fully automatic systems offer the highest level of reliability and convenience. They switch between sources and reset themselves without human intervention, making them ideal for critical applications like hospitals or high-volume production lines. While more expensive, their seamless operation justifies the investment in high-stakes environments.

Choosing the right type depends on your application’s criticality, budget, and gas usage frequency. At Jewellok, our experts can guide you to the perfect gas changeover manifold system for your needs.

Components of a Gas Changeover Manifold System

A gas changeover manifold system comprises several key components working in unison to ensure a steady gas supply:

– Manifold: The central hub connecting multiple gas cylinders or sources, directing gas to the point of use.

– Pressure Regulators: These reduce high cylinder pressure to a safe, usable level while maintaining consistent output, crucial for operational stability.

– Valves: Including isolation valves (to shut off specific sources), check valves (to prevent backflow), and purge valves (to remove contaminants), these control gas flow and maintain system integrity.

– Pressure Sensors: These monitor source pressure, triggering a switchover when the primary source drops below a set threshold.

– Alarms or Indicators: Optional features that notify operators of switchovers or maintenance needs, enhancing safety and reliability.

The materials used—such as stainless steel for corrosive gases or brass for inert ones—are chosen based on the gas type to prevent corrosion or contamination. Together, these components ensure the system delivers gas efficiently and safely.

Applications of Gas Changeover Manifold Systems

Gas changeover manifold systems serve a wide array of industries, each with distinct gas supply needs:

– Healthcare: Hospitals rely on these systems for uninterrupted delivery of oxygen, nitrous oxide, and medical air, critical during emergencies or peak demand periods.

– Manufacturing: Industries like automotive and aerospace use gases for welding, cutting, and heat treatment, where consistent supply ensures product quality and process efficiency.

– Research Laboratories: Precise gas mixtures are vital for experiments, and these systems prevent disruptions that could skew results.

– Food and Beverage: Nitrogen and carbon dioxide are used in packaging and preservation, requiring steady gas flow to maintain product freshness and safety.

– Semiconductor Industry: Ultra-pure gases are essential in cleanroom settings for chip production, where even minor interruptions can halt operations.

In all these cases, gas changeover manifold systems are indispensable for maintaining operational continuity and safety.

Benefits of Using a Gas Changeover Manifold System

Investing in a gas changeover manifold system yields significant advantages:

- Reduced Downtime: Automatic switching minimizes interruptions, crucial for industries where downtime translates to lost revenue or compromised outcomes.

- Improved Safety: By reducing manual cylinder handling and incorporating safety features like alarms, these systems lower accident risks.

- Better Resource Management: They ensure cylinders are fully depleted before switching, reducing waste and optimizing gas usage.

- Enhanced Productivity: Continuous gas supply keeps processes running smoothly, boosting efficiency in high-demand settings.

- Customization: Systems can be tailored to specific gases, pressures, and flow rates, aligning perfectly with your needs.

Industry data suggests that automatic systems can cut downtime by up to 50%, significantly enhancing operational efficiency.

Selecting the Right Gas Changeover Manifold System

Choosing the best system involves evaluating several factors:

– Type of Gas: Corrosive gases require durable materials like stainless steel, while inert gases may use brass.

– Pressure and Flow Requirements: The system must handle your application’s maximum needs for consistent delivery.

– Frequency of Cylinder Changes: High-consumption settings benefit from fully automatic systems, while manual ones suit lower usage.

– Compatibility: Ensure the system integrates with existing equipment, from cylinder connections to delivery points.

– Budget: Balance functionality with cost—manual systems are cheaper, but automatic ones offer long-term value.

Consulting with Jewellok’s specialists can help you pinpoint a cost-effective, high-performing solution tailored to your operations.

Maintenance and Testing of Gas Changeover Manifold Systems

Regular maintenance ensures system reliability and safety. Key activities include:

– Function Tests: Simulate depletion to confirm switchover functionality, typically monthly.

– Leak Checks: Use soapy water or detectors to identify and fix leaks, preventing hazards and waste.

– Purging: Remove contaminants with inert gases like nitrogen, especially for hazardous or high-purity applications.

– Component Inspections: Check valves, regulators, and sensors for wear, replacing parts as needed.

A sample schedule might include monthly function tests and quarterly full inspections, adjusted based on usage intensity. Proper maintenance prevents failures and extends system lifespan.

Real-World Examples of Gas Changeover Manifold Systems

Here’s how these systems make a difference:

- Semiconductor Manufacturing: A chip producer switched to an automatic gas changeover manifold system for nitrogen supply, eliminating 30-minute downtimes per cylinder change, boosting efficiency and product consistency.

- Hospital Oxygen Supply: A hospital installed a semi-automatic system, ensuring uninterrupted oxygen during peak demand, with alarms prompting timely cylinder swaps, enhancing patient safety.

These cases highlight the tangible benefits in critical applications.

Cost Analysis of Gas Changeover Manifold Systems

While initial costs vary—manual systems being the cheapest and automatic ones the priciest—the long-term savings are compelling:

– Operational Savings: Reduced downtime and optimized gas use can save thousands annually.

– Safety and Compliance: Reliable systems avoid accidents and fines, cutting hidden costs.

– Maintenance: Routine upkeep is cheaper than repairing failures.

The return on investment often materializes within a few years, making these systems a smart financial choice.

Future Trends in Gas Changeover Manifold Systems

Advancements promise even greater efficiency:

– IoT Integration: Remote monitoring and predictive maintenance via connected devices.

– Compact Designs: Smaller systems for tight spaces like labs.

– Advanced Materials: Enhanced durability for exotic gases.

– Energy Efficiency: Lower power use in automated systems.

These innovations will solidify the role of gas changeover manifold systems in modern industries.

Conclusion

Gas changeover manifold systems are indispensable for ensuring a reliable gas supply across diverse applications. From their types and components to their benefits and future potential, these systems offer a robust solution to operational challenges.

At Jewellok, we provide top-tier gas changeover manifold systems customized to your needs. Our experts are ready to help you select and implement the ideal system, enhancing safety, efficiency, and cost-effectiveness.

Ready to optimize your gas supply? Visit https://www.jewellok.com or contact us for personalized solutions today.

Recent Posts

How to Choose the Krypton Gas Ultra High Purity (UHP) Regulator

Troubleshooting Common Failures in TMA Gas Changeover Manifolds

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

Tags

Recommended Products

-

774L Stainless Steel UHP Fittings Butt Weld Bulkhead Union For High Flow Special Gas Fluid

-

Medical Oxygen Single Stage Manual Gas Changeover Manifold Panel High-Purity Two-Stage Manual Gas Manifold Gas Pressure Control Panels

-

771LF Female Run Tee | Stainless Steel Tube Fitting Compression Fittings 1/4 In 3-Way Tee Female Run Tee

-

Manual Gas Rack High Purity Gas Delivery Systems JW-100-GR

-

High Purity High Flow Pressure Control Regulators & Valves Gas Stick Assemblies JSR-2TG Series

-

764LR Stainless Steel 316 Reducing Tee UHP Fitting Automatic Buttweld Reducing Tee

-

7102L Stainless Steel 316L SS Union Cross Ultra High Purity Long Arm Union Elbow Tee Cross Butt Weld Fittings

-

Flow Control Stainless Steel Low Pressure Manual Diaphragm Valve For High Purity And Ultra High Purity Gases