Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

High-Purity Gas Manifold Is Zero-Pollution Delivery and Precise Pressure Control Systems

- Pressure Regulator Valve Manufacturer

- adjustable low pressure propane regulator, controlling and delivering high-purity gases, Diaphragm Valves for Ultra High-Purity Gas Systems, High-Purity Cylinder Connection Valves, high-purity dual-source single-stage semiautomatic gas manifold, high-purity dual-source single-stage semiautomatic manifold, high-purity gas manifold factory, High-purity gas manifold system, high-purity gas manifold system smarket, high-purity gas manifold system supplier, high-purity gas manifold systems, high-purity gas manifold systems manufacturer, high-purity gas manisfold system, High-purity gas regulators for laboratory, High-Purity Gas Regulators for Research, high-purity gas system, High-Purity High Flow Nitrogen Regulator, High-Purity High-Flow Gas Regulators, High-Purity Hydrazine Gas Delivery System, High-purity Pressure Reducing Regulator, High-Purity Single-Source Dual-Stage Gas Manifold, High-Purity Single-Stage Gas Regulators, humming propane regulator, oxygen cylinder manifold, Oxygen Dual-Stage High-Purity Regulator, pressure relief valve vs safety valve, propane adjustable pressure regulator, propane manifold with valves, safety valve vs pressure relief valve, second stage propaneregulator, Single-Stage Ultra High-Purity Semiconductor Grade Regulator, Solenoid and Ball Valves in High-Purity Industries, Stainless Steel High-Purity Ball Valves, Ultra-High-Purity Gas Delivery Systems

- No Comments

High-Purity Gas Manifold Is Zero-Pollution Delivery and Precise Pressure Control Systems

In industries where precision and purity are non-negotiable—such as semiconductor manufacturing, pharmaceuticals, aerospace, and high-precision welding—high-purity gas manifold systems are the backbone of reliable gas delivery. These systems ensure that ultra-pure gases, like nitrogen, argon, helium, or hydrogen, reach their point of use without contamination, maintaining the integrity of sensitive processes. Whether it’s crafting microchips with nanometer precision or welding aerospace components with zero defects, the stakes are high. A single impurity or pressure fluctuation can lead to costly failures, compromised products, or even safety hazards. This is where high-purity gas manifold systems shine, offering zero-pollution delivery and precise pressure control to meet stringent industry standards.

The global demand for high-purity gases is soaring, driven by advancements in technology and manufacturing. According to industry insights, high-purity gas systems are critical in applications requiring contamination-free environments, such as cleanrooms and laboratories. These systems are not just about delivering gas; they are about delivering trust—trust that every molecule meets exact specifications and that pressure remains rock-steady under demanding conditions. In this 2000-word article, we’ll explore the intricacies of high-purity gas manifold systems, covering their design, functionality, selection criteria, safety features, and maintenance practices. By the end, you’ll understand how to choose and manage a system that ensures zero-pollution delivery and precise pressure control, leaving no room for compromise in your high-stakes operations.

Why focus on zero pollution and precise control? Contamination in high-purity applications can lead to defects costing millions, while pressure inconsistencies can disrupt processes like plasma etching or TIG welding. Regulatory bodies like the Compressed Gas Association (CGA) and standards such as ISO 9001 set strict guidelines for gas purity and system performance. A well-designed manifold system is your defense against these risks, ensuring compliance and operational excellence. Let’s dive into the world of high-purity gas manifolds and uncover how they achieve these critical goals.

Understanding High-Purity Gas Manifold Systems

A high-purity gas manifold system is a sophisticated setup designed to deliver gases with purities often exceeding 99.9999% (6N) from cylinders or bulk sources to the point of use without introducing contaminants. These systems are essential in industries where even trace impurities—measured in parts per billion (ppb)—can ruin outcomes. For example, in semiconductor fabrication, oxygen or water vapor contamination can cause defects in microchip circuits. In welding, impure shielding gases like argon can lead to weld imperfections, compromising structural integrity.

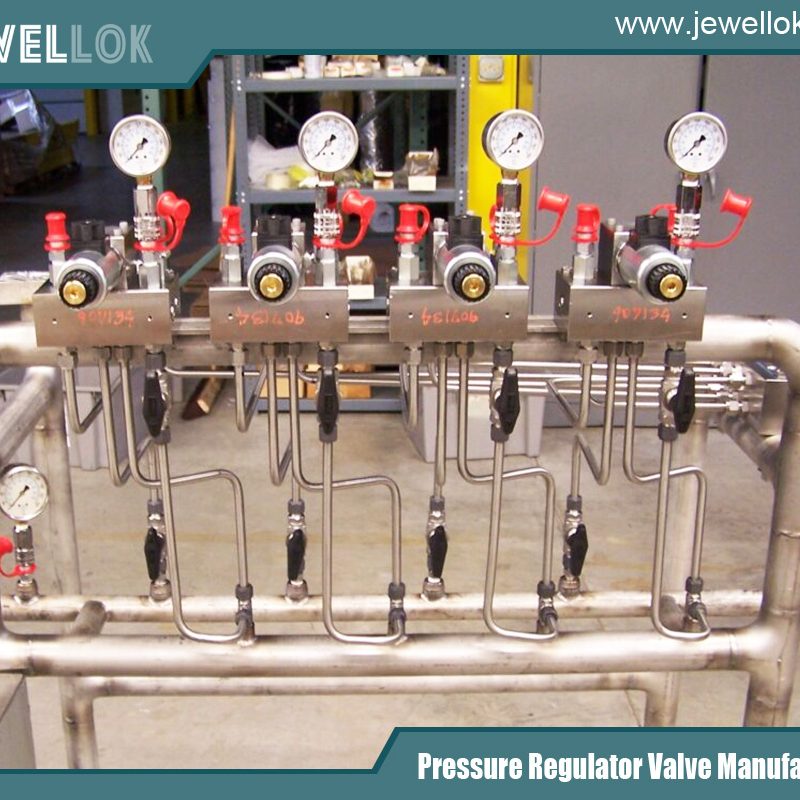

The system typically comprises several components: high-purity cylinders or bulk tanks, regulators, valves, filters, tubing, and fittings, all connected to a central manifold. The manifold acts as the control hub, managing gas flow, pressure, and purity. There are three main types: manual, semi-automatic, and fully automatic. Manual systems are simpler, requiring operator intervention to switch cylinders, suitable for low-volume labs. Semi-automatic manifolds use pressure sensors to switch between cylinders, reducing downtime while maintaining purity. Fully automatic systems, equipped with advanced controls and monitoring, are ideal for high-demand environments like semiconductor plants, ensuring seamless operation with minimal human oversight.

How do they work? Gas flows from cylinders through electropolished stainless steel tubing—often 316L grade—to prevent particle shedding or outgassing. High-purity regulators maintain precise pressure (e.g., 50-150 psi for welding or lower for analytical applications), while filters remove particulates down to 0.003 microns. Check valves and purge systems prevent backflow and flush residual contaminants, ensuring zero-pollution delivery. Advanced systems may include real-time analyzers to monitor trace impurities, providing data to maintain compliance with standards like SEMI (Semiconductor Equipment and Materials International).The design prioritizes material compatibility. For instance, corrosive gases like ammonia require Monel or Hastelloy components, while inert gases like helium use brass or stainless steel. In welding, manifolds for argon or helium must ensure consistent flow to maintain shielding gas efficacy, preventing oxidation. These systems are also scalable, allowing additional cylinders or points of use as production grows. Understanding these fundamentals sets the stage for selecting a system that meets your specific needs, balancing purity, pressure, and operational demands.

Key Selection Criteria

Choosing a high-purity gas manifold system requires careful consideration to align with your application’s demands. Here are the critical factors:

- Gas Compatibility: The system must be tailored to the gas type. Inert gases like argon require minimal corrosion resistance, but reactive gases like hydrogen demand specialized materials to prevent degradation or reactions. Verify compatibility with CGA standards for fittings and regulators.

- Purity Requirements: Different applications have unique purity needs. Semiconductor processes may demand 6N (99.9999%) purity, while welding might tolerate 5N (99.999%). The manifold must include filters and purge valves to maintain these levels. Look for systems with documented purity certifications.

- Pressure and Flow Control: Precise pressure control is vital. For example, TIG welding requires stable low-pressure delivery (10-30 psi), while industrial processes may need higher ranges. Regulators with tight tolerances (±1 psi) and flowmeters ensure consistency. Check maximum inlet and outlet pressures against your equipment’s specs.

- Material and Construction Quality: Components must resist contamination. Electropolished 316L stainless steel is standard for tubing and fittings to minimize particle generation. Diaphragm valves with low internal volume reduce dead space where contaminants can accumulate.

- Automation and Monitoring: For high-throughput environments, automatic switchover systems with alarms or digital interfaces reduce downtime and human error. Remote monitoring via IoT-enabled sensors is increasingly common in modern setups, providing real-time data on pressure and purity.

- Scalability and Flexibility: Choose a modular system that can expand with your operation. For instance, a manifold supporting additional cylinder banks is ideal for growing production lines.

- Compliance and Certifications: Ensure the system meets industry standards like CGA, SEMI, or ISO 14644 for cleanroom compatibility. Certifications from manufacturers provide assurance of quality and safety.

- Vendor Support and Maintenance: Opt for suppliers offering robust support, including installation guidance, spare parts, and service contracts. Downtime in high-purity applications is costly, so reliability is key.

Balancing these factors ensures the system delivers zero-pollution gas with precise control, tailored to your industry’s demands.

Safety and Zero-Pollution Features

Safety and purity go hand in hand in high-purity gas manifold systems. Contamination risks—such as moisture, oxygen, or particulates—can compromise processes, while gas leaks pose health and explosion hazards. Here’s how these systems mitigate risks:

- Purge Systems: Nitrogen or inert gas purges remove residual contaminants before and after cylinder changes, ensuring zero-pollution delivery.

- High-Purity Components: Electropolished surfaces and orbital welding reduce particle traps, maintaining gas integrity.

- Leak-Proof Design: VCR (Vacuum Coupling Radiation) fittings and double-seal valves prevent leaks, critical for toxic or flammable gases like hydrogen.

- Pressure Safety Devices: Relief valves and burst discs protect against over-pressurization, while sensors alert operators to anomalies.

- Gas-Specific Safety: For flammable gases, manifolds include flashback arrestors (relevant in welding) or grounding to prevent static buildup.

- Monitoring Systems: Trace gas analyzers and pressure transducers provide real-time feedback, ensuring compliance with purity and safety standards.

Regular maintenance, including leak tests and filter replacements, is essential to uphold these features. Operators must be trained on Material Safety Data Sheets (MSDS) for each gas to handle emergencies. These measures ensure no contamination or safety hazard goes undetected.

Installation and Maintenance Best Practices

Proper installation is critical for performance. Install in a clean, well-ventilated area compliant with NFPA or OSHA guidelines. Use only high-purity tubing and fittings, and follow manufacturer protocols for assembly. Purge the system thoroughly before commissioning to eliminate contaminants.

Maintenance involves:

- Daily Checks: Inspect for leaks using helium leak detectors (sensitivity down to 10^-9 atm-cc/s).

- Monthly Filter Changes: Replace high-purity filters to maintain gas quality.

- Annual Servicing: Professional inspection of regulators, valves, and sensors ensures long-term reliability.

- Documentation: Log all maintenance for regulatory compliance and traceability.

Avoid makeshift repairs or non-certified components, as they risk contamination.

Conclusion

High-purity gas manifold systems are the unsung heroes of precision industries, delivering ultra-pure gases with unwavering pressure control. By selecting a system with the right compatibility, safety features, and maintenance plan, you ensure zero-pollution delivery and operational excellence. In a world where purity is paramount, these systems are your guarantee of quality, safety, and reliability.

For more about the high-purity gas manifold is zero-pollution delivery and precise pressure control systems, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Choose the Krypton Gas Ultra High Purity (UHP) Regulator

Troubleshooting Common Failures in TMA Gas Changeover Manifolds

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

Tags

Recommended Products

-

772L Male Branch Tee | Stainless Steel High-Purity Tube Fitting Male Branch Tee

-

763L Stainless Steel High Purity Pressure Reducing Union Fittings And Tubing Pressure Reducing Valve Adjustment

-

Flow Control Stainless Steel Low Pressure Manual Diaphragm Valve For High Purity And Ultra High Purity Gases

-

FT-BOX JW-FTB-C Valve Manifold Panels And Boxes With High Purity Configurable Systems

-

Stainless Steel High Purity High Temperature Pneumatic Actuated Ball Valves JBV2 Series

-

775L Bulkhead Reducing Union | Stainless Steel High Purity Double Ferrule Bulkhead Reducing Unions

-

739 High Purity LMR Male Adapter Tube To Pipe Fittings And Adapters

-

Semiconductor High Purity High Pressure Specialty Gas Bottle Gas Cylinder Storage Cabinet And Gas Pressure Regulating Cabinet