Blog

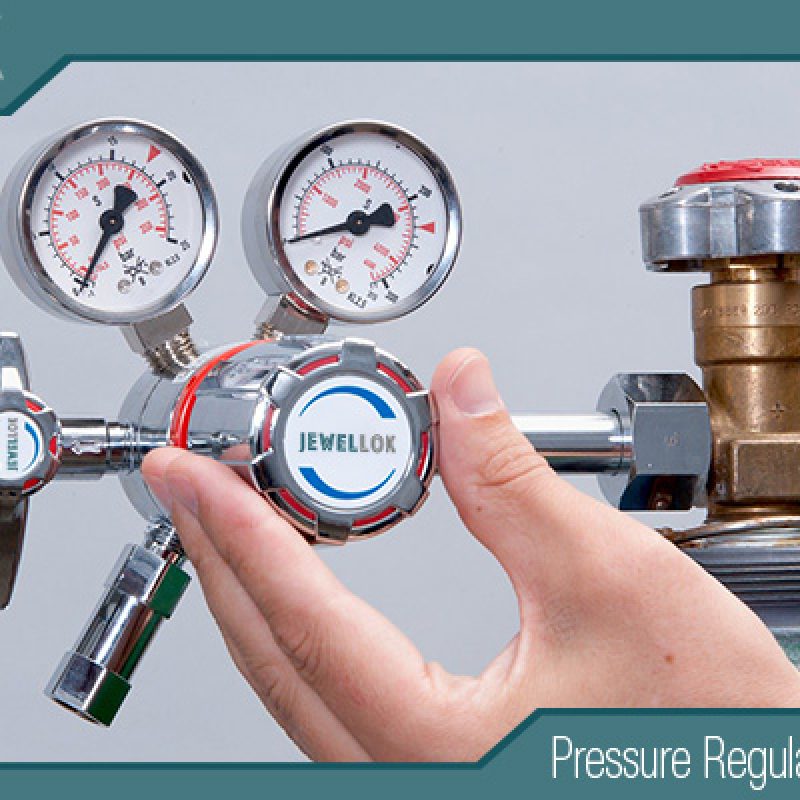

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

How Does a 316 Stainless Steel Pipe Fitting Work?

- Pressure Regulator Valve Manufacturer

- 316 Stainless Steel Pipe Fitting, 316 Stainless Steel Pipe Fitting manufacturer, 316 Stainless Steel Pipe Fitting supplier, 316 stainless steel pipe fittings, 316L Stainless Steel Seamless High Purity System Tube, 316L stainless steel UHP valves, advantages of stainless steel purity valves, applications of UHP valves, ASME BPE compliant valves, bellows valves for pharmaceuticals, Best high purity stainless steel gas fittings, biotechnology UHP valve solutions, China Ultra High Purity Fittings Factory, China Ultra High Purity Fittings Manufacturers, China Ultra High Purity Fittings Suppliers, cleanroom assembly stainless steel valves, compression tube fittings, corrosion resistant stainless steel valves, cryogenic UHP valves, diaphragm valves ultra high purity, electropolished stainless steel valves, electropolishing process for valves, Fittings for High Purity Piping, helium leak testing for valves, high pressure compression fittings, high purity fittings, high purity gas delivery valves, high purity stainless steel fitting, high purity stainless steel tubing, high purity valves for semiconductors, hydrogen pipe valves and fittings, ISO 14644 cleanroom standards valves, maintenance UHP stainless steel valves, manufacturing ultra high purity valves, stainless steel butt weld pipe fittings, stainless steel compression fittings, stainless steel tubing fittings, Tubing and Fittings for Compressed Gas Systems, Ultra High Purity Coaxial Stainless Steel Tube Fittings, ultra high purity fittings, ultra high purity fittings manufacturers in china, ultra high purity stainless steel tubing, Ultra-High-Purity Tube Fittings

- No Comments

How Does a 316 Stainless Steel Pipe Fitting Work?

Pipe fittings are the unsung heroes of industrial and commercial piping systems, performing the critical tasks of connecting, redirecting, and controlling fluid flow. Among the myriad materials available, 316 stainless steel has emerged as a gold standard for demanding applications. This article provides a comprehensive technical analysis of how a 316 stainless steel pipe fitting functions. We will explore the material science behind its superior properties, the engineering principles of its operation, the various types and their specific functions, and the real-world applications that leverage its unique capabilities. By understanding the synergy between the material’s inherent qualities and the fitting’s mechanical design, one can appreciate why 316 stainless steel fittings are indispensable in modern infrastructure.

Introduction: The Critical Role of Pipe Fittings

A piping system is more than just straight lengths of pipe. It requires direction changes, branch connections, diameter adjustments, and termination points. This is where pipe fittings come into play. They are precision-engineered components designed to join pipe sections, adapt to different sizes or shapes, and provide access for maintenance. The effectiveness of an entire system hinges on the reliability of its fittings.

The choice of material for a fitting is paramount, dictated by the fluid being transported (corrosivity, temperature, pressure), the external environment, and regulatory standards. 316 stainless steel, an austenitic chromium-nickel stainless steel containing molybdenum, has become the material of choice for highly corrosive and hygienic environments. But how does a piece of 316 stainless steel pipe fitting, shaped into an elbow, tee, or coupling, actually “work”? Its function is a combination of metallurgical excellence and mechanical engineering.

The Material Foundation: Why 316 Stainless Steel?

To understand how the fitting works, we must first understand the material it is made from. The “workings” begin at the atomic level.

- Alloy Composition and Microstructure

- Chromium (16-18%): Forms a passive, self-healing oxide layer (Cr₂O₃) on the surface. This invisible layer is the primary defense against corrosion, isolating the reactive iron in the alloy from the environment.

- Nickel (10-14%): Stabilizes the austenitic microstructure (face-centered cubic crystal structure), which provides excellent toughness, ductility, and non-magnetic properties. This makes the fitting formable and weldable.

- Molybdenum (2-3%): The key differentiator from 304 stainless steel. Molybdenum dramatically increases resistance to pitting and crevice corrosion, particularly in chloride-containing environments (seawater, salt air, chemical brines). It strengthens the passive layer.

- Carbon (Low, <0.08%): Kept low to prevent chromium carbide precipitation during welding, which can lead to “weld decay” or sensitization. The “L” grade (316L) has even lower carbon for superior weldability.

- Material Properties Enabling Function

- Corrosion Resistance: The fitting can handle aggressive fluids (acids, alkalis, chlorides) and withstand harsh atmospheric conditions without degrading, ensuring long-term system integrity.

- Strength and Pressure Integrity: High yield and tensile strength allow the fitting to contain system pressures without deforming or bursting. Its strength is maintained at both cryogenic and elevated temperatures (up to ~870°C intermittent use).

- Ductility: Allows the fitting to be forged, machined, and bent into complex shapes without cracking. It also provides some give under thermal expansion or mechanical stress.

- Hygienic and Cleanable: The smooth, non-porous surface prevents bacterial adhesion and is easily sterilized, making it ideal for food, beverage, and pharmaceutical systems.

The Mechanical Operation: Sealing and Connection Principles

A fitting works by creating a secure, leak-proof seal between itself and the pipe. The method of achieving this seal defines the fitting type. 316 stainless steel fittings are manufactured to precise dimensional standards (ASME B16.11, B16.9, ISO 4144, etc.).

- Threaded Fittings

How they work: The fitting contains tapered (NPT) or parallel (BSPT/BSPP) internal or external threads. The pipe has corresponding threads.

- Mechanical Seal (Tapered): As the male and female tapered threads are tightened, the threads wedge together, creating a metal-to-metal interference fit. The stress at the thread roots creates the seal. Thread sealant (PTFE tape, pipe dope) is often used to fill minor imperfections and lubricate.

- Gasket Seal (Parallel): In BSPP designs, a seal is achieved not by thread wedging, but by compressing an O-ring or gasket against a flat shoulder as the threads are tightened. This provides a more reliable seal for frequent disassembly.

- Role of 316 SS: The material’s strength prevents thread galling (cold-welding of threads during tightening) if properly lubricated, and its corrosion resistance ensures the threads do not seize over time, allowing for future disassembly.

- Socket Weld Fittings

How they work: The pipe is inserted into a recessed “socket” in the fitting.

- A two-stage sealing mechanism:

- Fillet Weld: A circumferential weld is made around the joint where the pipe meets the fitting’s hub. This weld provides the primary structural strength and pressure containment.

- Root Gap: A small gap (typically 1/16″) is maintained between the pipe end and the socket shoulder before welding. This gap allows for thermal expansion during welding and prevents the weld pool from cracking as it solidifies.

- Role of 316 SS: Its excellent weldability ensures a sound, corrosion-resistant weld joint. The low carbon content of 316L is particularly beneficial here to prevent sensitization in the heat-affected zone (HAZ).

- Butt Weld Fittings

How they work: The fitting (elbow, tee, reducer) has a bevelled end that is aligned with a similarly bevelled pipe end.

- Welded Joint: The two bevelled ends are welded together, typically with a full-penetration groove weld. The weld metal and the adjacent base metal (the fitting and pipe) become a continuous, homogeneous piece of 316 stainless steel.

- Result: This creates the strongest, most leak-resistant, and smoothest bore (minimizing turbulence and pressure drop) of all connection methods. It is permanent.

- Role of 316 SS: The material’s consistent metallurgy ensures the weld joint has properties nearly identical to the parent material, maintaining corrosion resistance across the entire system.

- Flanged Fittings & Unions

How they work: These fittings use a multi-component sealing system.

- The Flange: The 316 SS fitting has an integral flange or is welded to a separate flange. The flange face has a specific finish (e.g., serrated) to grip the gasket.

- The Gasket: Made from a compliant material (PTFE, rubber, graphite, metal) suited to the fluid and temperature.

- The Bolts: High-strength bolts apply massive compressive force, squeezing the gasket between the two flange faces. The gasket flows into the micro-irregularities of the flange faces, creating a perfect seal.

- Role of 316 SS: The flange provides a rigid, non-deforming surface for gasket compression. Its corrosion resistance protects the bolting area and sealing face from damage that could compromise the seal.

Types of Fittings and Their Specific Functions

Each fitting geometry serves a distinct purpose within the system, leveraging the properties of 316 SS.

- Elbows (90°, 45°): Change the direction of flow. The 316 SS withstands the increased erosion-corrosion potential at the outer radius due to fluid impingement.

- Tees (Equal, Reducing): Create branch connections. The crotch area (intersection of three bores) is a high-stress point; the toughness of 316 SS prevents cracking.

- Reducers (Concentric, Eccentric): Change pipe diameter. Eccentric reducers are used in pump suction lines to avoid air pocket formation.

- Couplings & Unions: Connect two pipes. Unions allow for easy disconnection without pipe rotation, crucial for maintenance.

- Caps & Plugs: Seal the end of a pipe. They must resist the full pressure end force and environmental corrosion.

- Crosses & Laterals: For more complex branching. Their design requires material with high structural integrity.

Application-Specific Performance

The “work” of a 316 SS fitting is defined by the challenges it overcomes in the field:

- Chemical Processing: Resists sulfuric acid, phosphoric acid, chlorides, and other corrosives at varying temperatures and pressures. Prevents catastrophic failure and product contamination.

- Marine & Offshore: Withstands constant saltwater spray, immersion, and chloride-induced pitting. Essential for ballast systems, seawater cooling, and firewater lines.

- Pharmaceutical & Bio-tech (ASME BPE): The polished, electropolished surface and crevice-free design (via orbital welding of butt weld fittings) prevent microbial harborage and allow for Clean-in-Place (CIP) and Steam-in-Place (SIP) processes.

- Food & Beverage: Non-reactive, non-toxic, and easily cleaned. Maintains product purity and meets FDA/3-A Sanitary Standards.

- High-Temperature & Cryogenic Service: Maintains strength and does not become brittle at very low temperatures (e.g., LNG). Resists scaling and oxidation at high temperatures.

Installation, Maintenance, and Failure Modes

Even the best fitting can fail if improperly installed.

- Installation Best Practices:

- Threaded: Avoid over-torquing to prevent stress cracking. Use anti-seize compound.

- Socket Weld: Ensure proper root gap. Use back-purging with argon when welding to prevent “sugaring” (oxidation) on the ID, which compromises corrosion resistance.

- General: Always ensure systems are properly supported; fittings should not bear pipe weight.

- Common Failure Modes (and how 316 SS mitigates them):

- Crevice Corrosion: Mitigated by molybdenum content and good design (avoiding stagnant zones).

- Stress Corrosion Cracking (SCC): Can occur in 316 SS under the combined action of tensile stress (from installation or operation), chlorides, and elevated temperature. Proper material selection for the specific environment is key. 316 SS is more resistant than 304.

- Galvanic Corrosion: Can occur if connected to a less noble metal (e.g., carbon steel). Use dielectric unions or ensure proper insulation.

Conclusion

A 316 stainless steel pipe fitting “works” through a sophisticated interplay of advanced material science and precision mechanical design. Its operational success is not an accident but a direct result of its molybdenum-enhanced corrosion resistance, austenitic strength and ductility, and exceptional manufacturability. Whether creating a seal via the wedging of threads, the fusion of a weld, or the compression of a gasket, the fitting relies on the inherent properties of 316 SS to maintain a secure, durable, and safe connection under some of the most challenging conditions on earth.

From guiding corrosive chemicals through a processing plant to ensuring the sterility of a life-saving drug, the humble 316 stainless steel fitting performs a vital, silent function. It is a testament to engineering innovation where the right material, shaped with purpose, becomes a fundamental component of modern industrial civilization. Understanding its workings empowers engineers and technicians to design, install, and maintain systems that are not only efficient but also safe, reliable, and long-lasting.

For more about how does a 316 stainless steel pipe fitting work, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Choose the Krypton Gas Ultra High Purity (UHP) Regulator

Troubleshooting Common Failures in TMA Gas Changeover Manifolds

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

Tags

Recommended Products

-

Ultra High Purity Pressure Gauge For Laboratory And Semiconductor JR Series

-

774L Stainless Steel UHP Fittings Butt Weld Bulkhead Union For High Flow Special Gas Fluid

-

High Pressure High Temperature Pneumatic Ultrahigh Purity Stainless Steel Diaphragm Valves

-

772 LF Female Branch Tee | Stainless Steel Tube Fitting Female Branch Tee 1/2 in. Tube OD x 1/2 in. Tube OD x 3/8 in. Female NPT

-

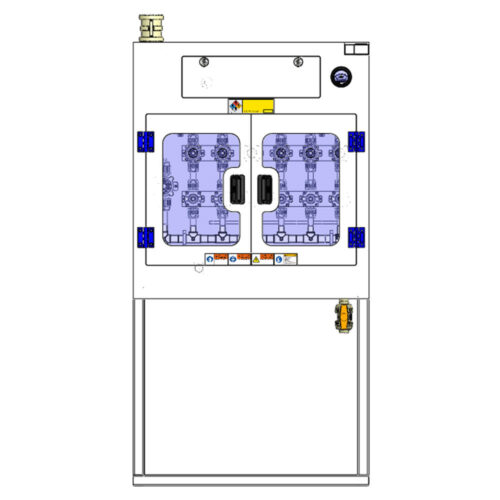

High Purity Configurable Systems VMB Valve Manifold Box JW-200-VMB-C & JW-100-VMB-C

-

Semi Automatic Gas Changeover Manifold System Manual Changeover Manifold Panel Single Stage Automatic Switchover Board

-

762L Stainless Steel High Purity Union High-Purity Gas System Fittings

-

Flow Control Stainless Steel Low Pressure Manual Diaphragm Valve For High Purity And Ultra High Purity Gases