Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

How Does a Bulk Specialty Gas Delivery System (BSGS) Work?

- Pressure Regulator Valve Manufacturer

- automatic delivery of bulk specialty gases, bsgs gas cabinet, BSGS large flow special gas supply cabinet, Bulk and Micro Bulk Gas Supply and Delivery, Bulk Gas Delivery and System Design, bulk gas distribution valves / regulators, bulk helium in thailand, Bulk Specialty Gas Delivery System, Bulk Specialty Gas Delivery System (BSGS), bulk specialty gas system, Bulk Specialty Gas Systems, Bulking up specialty gas delivery, Gas Delivery Cabinet Systems, High Purity Bulk Gas Systems, Semiconductor Gas Storage and Delivery, specialty gas cabinet, uhp bulk diaphragm valves, uhp bulk gas pressure regulators, Ultra High Purity Bulk Gas Delivery Systems

- No Comments

How Does a Bulk Specialty Gas Delivery System (BSGS) Work?

Introduction

In industries such as semiconductor manufacturing, pharmaceuticals, aerospace, and chemical production, the demand for high-purity specialty gases is paramount. These gases—nitrogen, argon, helium, hydrogen, and various gas mixtures—must be delivered with precision, reliability, and safety to support critical processes. A Bulk Specialty Gas Delivery System (BSGS) is a sophisticated infrastructure designed to store, manage, and distribute large volumes of these gases efficiently. This article provides an in-depth exploration of how a BSGS operates, detailing its components, operational principles, safety mechanisms, and applications. By understanding the workings of a BSGS, we can appreciate its vital role in enabling advanced technologies and maintaining stringent industrial standards.

What is a Bulk Specialty Gas Delivery System?

A Bulk Specialty Gas Delivery System (BSGS) is an integrated system engineered to handle the storage and distribution of high-purity specialty gases in large-scale industrial settings. Unlike small gas cylinders used for localized or low-volume applications, a BSGS is designed for high-throughput environments where a consistent, high-purity gas supply is essential. Industries like microelectronics, where even trace impurities can ruin semiconductor wafers, or medical research, where gas purity affects experimental outcomes, rely heavily on BSGS systems.

The BSGS ensures that gases are delivered at the required pressure, flow rate, and purity to various points of use (POUs) within a facility. It achieves this through a combination of storage vessels, high-purity piping, purification systems, and advanced control mechanisms. Below, we explore the key components and operational processes of a BSGS in detail.

Key Components of a BSGS

A BSGS comprises several critical components, each designed to perform specific functions in the storage, purification, and distribution of specialty gases. These components work together to ensure a reliable and contamination-free gas supply.

- Storage Vessels

The core of a BSGS is its storage system, which accommodates large quantities of specialty gases in either gaseous or liquefied form, depending on the gas type and application.

– High-Pressure Cylinders: Used for gases like nitrogen, argon, or hydrogen, these cylinders store gases at pressures ranging from 2,000 to 6,000 psig (pounds per square inch gauge). Constructed from materials like stainless steel or aluminum, they are designed to prevent corrosion and contamination.

– Cryogenic Tanks: For gases such as liquid nitrogen or helium, which require low-temperature storage, cryogenic tanks maintain gases in a liquid state to maximize storage capacity. These tanks are insulated with vacuum jackets to minimize heat transfer and evaporation losses.

– Tube Trailers: For facilities requiring frequent gas replenishment, tube trailers—large, transportable gas containers—are used to deliver and store bulk gases on-site.

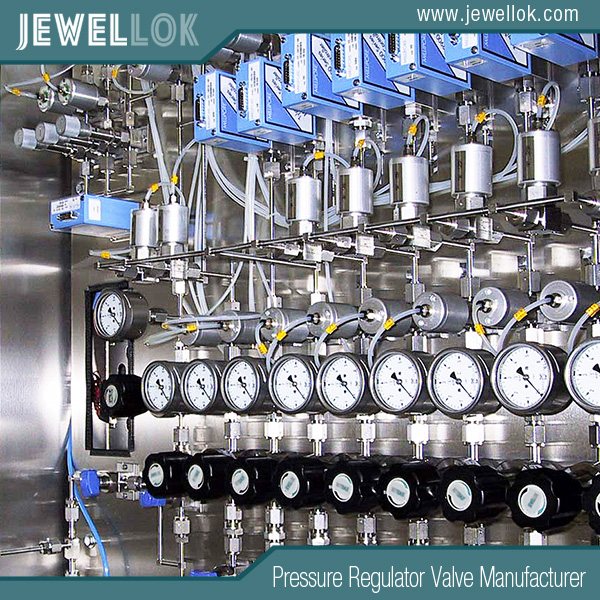

- Piping and Distribution Network

The piping network transports gases from storage vessels to points of use across a facility. This network is designed to maintain gas purity and deliver precise flow rates and pressures.

– High-Purity Piping: Made from electropolished stainless steel or other non-reactive materials, the piping minimizes contamination by reducing surface roughness where particles or moisture could accumulate.

– Valves and Regulators: High-precision valves (manual or automated) and pressure regulators control gas flow and pressure, ensuring they meet the specific requirements of each point of use.

– Manifolds: These connect multiple storage vessels to the distribution network, enabling seamless switching between vessels to maintain a continuous gas supply.

- Purification Systems

Specialty gases often require ultra-high purity levels (e.g., 99.9999% or better) to meet industry standards. Purification systems within a BSGS remove impurities such as moisture, oxygen, or hydrocarbons. Common purification methods include:

– Adsorption: Using materials like molecular sieves or activated carbon to trap impurities.

– Catalytic Purification: Employing catalysts to react with and remove specific contaminants.

– Filtration: Using fine filters to remove particulate matter.

Purifiers are strategically placed at various points, such as near storage vessels or at the point of use, to ensure gas purity is maintained throughout the delivery process.

- Control and Monitoring Systems

Advanced control and monitoring systems ensure the BSGS operates efficiently and safely. These include:

– Programmable Logic Controllers (PLCs): Automated systems that regulate gas flow, pressure, and temperature based on real-time data.

– Sensors: Pressure, temperature, and flow sensors monitor system performance and detect anomalies like leaks or pressure drops.

– Human-Machine Interfaces (HMIs): Touchscreen panels or software interfaces allow operators to monitor and adjust system parameters remotely.

– Alarms and Interlocks: Safety mechanisms that alert operators to issues like low gas levels or system malfunctions and automatically shut down the system if critical thresholds are breached.

- Safety Systems

Given the hazardous nature of some specialty gases (e.g., flammable hydrogen or toxic ammonia), BSGS systems incorporate robust safety features:

– Leak Detection Systems: Gas detectors monitor for leaks and trigger alarms if hazardous gases are detected.

– Emergency Shutoff Valves: Automatically isolate sections of the system in case of a leak or other emergencies.

– Ventilation Systems: Ensure proper air circulation in storage and delivery areas to prevent the accumulation of hazardous vapors.

– Fire Suppression Systems: Mitigate risks associated with flammable gases in storage and delivery areas.

Operational Process of a BSGS

The operation of a BSGS involves several stages, from gas storage to delivery at the point of use. Here’s a detailed look at the process:

- Gas Storage and Supply

Specialty gases are delivered to the facility in bulk via high-pressure cylinders, cryogenic tanks, or tube trailers. The BSGS stores large quantities of gas to ensure a continuous supply, minimizing downtime. For example, a semiconductor fabrication plant may require thousands of cubic feet of nitrogen daily, necessitating large-scale storage solutions. The storage vessels are connected to a manifold, which manages the transition between vessels to maintain uninterrupted supply. - Gas Purification

Before entering the distribution network, gases often pass through purification systems to remove impurities. This step is critical in applications like semiconductor manufacturing, where even parts-per-billion (ppb) levels of contaminants can cause defects. Purifiers may be located at the storage site, within the piping network, or at the point of use, depending on the system design and gas requirements. - Gas Distribution

Once purified, gases are transported through the high-purity piping network to various points of use. The distribution system is designed to maintain consistent pressure and flow rates, often using pressure regulators and flow controllers. Manifolds and automated valves allow the system to switch between storage vessels or adjust flow paths to meet demand fluctuations. - Point-of-Use Delivery

At the point of use, gases are delivered to equipment such as deposition chambers, reactors, or analytical instruments. Point-of-use purifiers or filters may be installed to ensure the gas meets the exact purity requirements of the application. Control systems monitor and adjust gas parameters in real-time to maintain optimal conditions. - Monitoring and Maintenance

Throughout the process, control and monitoring systems collect data on gas pressure, flow, and purity. Operators use HMIs to oversee system performance and respond to alarms or alerts. Regular maintenance, including leak checks, filter replacements, and vessel inspections, ensures the BSGS remains reliable and safe.

Applications of BSGS

BSGS systems are integral to several industries, each with unique gas requirements:

– Semiconductor Manufacturing: Ultra-high-purity gases like nitrogen, argon, and silane are used in processes such as chemical vapor deposition (CVD) and etching. BSGS systems ensure these gases are delivered without contamination to prevent defects in microchips.

– Pharmaceuticals: Gases like nitrogen and carbon dioxide are used in drug manufacturing and packaging. BSGS systems provide a stable supply for processes requiring inert atmospheres or precise gas mixtures.

– Aerospace: High-purity gases are used in testing, welding, and propulsion systems. BSGS systems support large-scale operations with consistent gas delivery.

– Chemical Manufacturing: Specialty gases are used as reactants or carriers in chemical synthesis. BSGS systems ensure safe handling and delivery of reactive or hazardous gases.

– Medical and Research: Gases like helium and oxygen are used in medical imaging and laboratory experiments. BSGS systems deliver high-purity gases to maintain experimental integrity.

Safety Considerations

Safety is a top priority in BSGS design and operation due to the hazardous nature of many specialty gases. Key safety considerations include:

– Gas Compatibility: Ensuring materials used in the BSGS (e.g., piping, valves) are compatible with the gases to prevent reactions or corrosion.

– Leak Prevention: Regular inspections and advanced leak detection systems minimize the risk of gas leaks.

– Operator Training: Personnel must be trained to handle specialty gases and respond to emergencies.

– Regulatory Compliance: BSGS systems must adhere to industry standards and regulations, such as those set by OSHA, NFPA, or SEMI.

Advancements in BSGS Technology

Recent advancements have improved the efficiency, safety, and sustainability of BSGS systems:

– Smart Monitoring: IoT-enabled sensors and cloud-based analytics provide real-time insights into system performance, enabling predictive maintenance.

– Energy Efficiency: Improved insulation in cryogenic tanks and optimized distribution systems reduce energy consumption.

– Automation: Fully automated BSGS systems minimize human intervention, reducing the risk of errors and improving reliability.

– Sustainable Practices: Some facilities are exploring gas recycling and recovery systems to minimize waste and environmental impact.

Challenges and Solutions

Despite their advantages, BSGS systems face challenges such as high initial costs, complex maintenance, and the need for stringent purity control. Solutions include modular system designs for scalability, advanced purification technologies, and comprehensive maintenance programs to ensure long-term reliability.

Conclusion

A Bulk Specialty Gas Delivery System (BSGS) is a cornerstone of modern industrial processes, enabling the safe and efficient delivery of high-purity gases to support critical applications. By integrating advanced storage, purification, distribution, and control systems, a BSGS ensures that industries like semiconductor manufacturing, pharmaceuticals, and aerospace can meet their stringent requirements for gas quality and reliability. As technology advances, BSGS systems continue to evolve, incorporating smarter, more sustainable solutions to meet the growing demands of global industries. Understanding how a BSGS works highlights its critical role in powering innovation and maintaining high standards across diverse sectors.

For more about how does bulk specialty gas delivery system (bsgs) work, you can pay a visit to Jewellok at https://www.jewellok.com/product/bulk-specialty-gas-systems-bsgs-gas-cabinets-and-scrubber-tail-gas-treatment-cabinets-for-high-purity-bulk-specialty-gas-delivery/ for more info.

Recent Posts

Five Key Considerations When Choosing a TMA Gas Changeover Manifold

How to Prevent Contamination in High Purity Xenon Gas Systems

Regulators for High Purity Krypton in Laser and Lighting Applications

Tags

Recommended Products

-

High Purity High Pressure 316 Stainless Steel Ball Valves JBV1 Series From High Pressure Ball Valve Manufacturer And Supplier In China

-

Flow Control Stainless Steel Low Pressure Manual Diaphragm Valve For High Purity And Ultra High Purity Gases

-

Stainless Steel Low Pressure Seal Pneumatic Diaphragm Control Valve For For HP & UHP Gases

-

FT-BOX JW-FTB-C Valve Manifold Panels And Boxes With High Purity Configurable Systems

-

DPR1 Ultra High Purity Two Stage Dual Stage Pressure Reducing Regulator Semiconductor Grade Regulators

-

Stainless Steel 316L Single Stage Regulator Pressure Control Panels JSP-1E Series For Semiconductor Fluid Control

-

Clean Connection Cabinet JW-300-CCB Valve Manifold Box And Control Valve Box

-

7121L Plug High Purity Plug Fitting And Blanking Plug