Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

How Does a Nitrogen Gas Cylinder Pressure Regulator Work?

- Pressure Regulator Valve Manufacturer

- 000 psi, best high pressure nitrogen gas regulator, high flow nitrogen regulator, high flow rate nitrogen regulator, high pressure nitrogen gas regulator companies, high pressure nitrogen gas regulator companies in uk, high pressure nitrogen gas regulator factory, high pressure nitrogen gas regulator hotsale, high pressure nitrogen gas regulator manufacturer, high pressure nitrogen gas regulator manufacturer in turkey, high pressure nitrogen gas regulator OEM, high pressure nitrogen gas regulator supplier, high pressure nitrogen gas regulator wholesale, high pressure nitrogen regulator, high pressure nitrogen regulator 1000 psi, high pressure nitrogen regulator 2000 psi, high pressure nitrogen regulator 3000 psi, high pressure nitrogen regulator 4, high pressure nitrogen regulator 6000 psi, high pressure nitrogen regulator manufacturer, high pressure nitrogen regulator manufacturer in turkey, how to adjust nitrogen regulator, low pressure nitrogen regulator, nitrogen bottle pressure regulator, nitrogen cylinder pressure regulator, nitrogen cylinder pressure regulator factory, nitrogen cylinder pressure regulator manufacturer, nitrogen gas cylinder pressure regulator, nitrogen pressure control valve, nitrogen pressure reducing valve, nitrogen tank pressure regulator, pressure reducing valve for nitrogen gas, Single Stage High Pressure Nitrogen Regulator, ultra low pressure nitrogen regulator, ultra low pressure nitrogen regulator manufacturer in turkey

- No Comments

How Does a Nitrogen Gas Cylinder Pressure Regulator Work?

Introduction

Pressure regulators are essential devices in various industrial, medical, and scientific applications where compressed gases like nitrogen are used. A nitrogen gas cylinder pressure regulator specifically controls the pressure of nitrogen gas released from a high-pressure cylinder, ensuring it is delivered at a safe and consistent lower pressure suitable for downstream equipment or processes. Understanding how these regulators function is crucial for engineers, technicians, and users who handle compressed gases to maintain safety, efficiency, and precision.

Nitrogen, an inert gas making up about 78% of Earth’s atmosphere, is commonly stored in cylinders at pressures ranging from 2,000 to 3,000 psi (pounds per square inch) or higher. Direct use of gas at such high pressures can be dangerous, leading to equipment damage, leaks, or even explosions. The pressure regulator acts as a gatekeeper, reducing and stabilizing the output pressure. This article delves into the mechanics, components, types, and operational principles of nitrogen gas cylinder pressure regulators, providing a comprehensive technical overview.

Fundamentals of Pressure Regulation

At its core, a pressure regulator operates on the principle of balancing forces to maintain a constant output pressure despite variations in input pressure or flow demand. For nitrogen cylinders, the regulator must handle the decreasing cylinder pressure as gas is depleted while keeping the delivery pressure steady.

The basic physics involved stems from Boyle’s Law, which states that the pressure of a gas is inversely proportional to its volume at constant temperature. However, regulators focus more on force equilibrium using springs, diaphragms, or pistons. When gas enters the regulator from the cylinder, it encounters a valve mechanism that restricts flow. The output pressure is sensed and compared to a setpoint, adjusting the valve opening accordingly.

In a typical setup, the regulator connects to the cylinder valve via a threaded inlet. The user sets the desired output pressure using an adjustment knob, which compresses a spring. This spring force opposes the gas pressure on a sensing element, like a diaphragm, to control the valve poppet or seat.

Key Components of a Nitrogen Pressure Regulator

A standard nitrogen gas cylinder pressure regulator consists of several critical components, each playing a role in pressure reduction and control:

- Inlet Port and Connection: This is where the regulator attaches to the nitrogen cylinder. It typically features a CGA (Compressed Gas Association) fitting, such as CGA-580 for nitrogen, ensuring a secure, leak-proof connection. The inlet port handles high pressures up to 3,000 psi.

- High-Pressure Gauge: Mounted on the regulator body, this gauge displays the cylinder’s internal pressure, allowing users to monitor gas levels. It’s usually calibrated in psi or bar.

- Adjustment Knob or Screw: This user-interface component allows setting the output pressure. Turning it clockwise increases pressure by compressing the main spring, while counterclockwise reduces it.

- Main Spring: A helical compression spring that provides the reference force for the desired output pressure. Its tension determines the setpoint.

- Sensing Element (Diaphragm or Piston): The diaphragm, often made of rubber, neoprene, or stainless steel, senses the downstream pressure. In piston-type regulators, a piston replaces the diaphragm for higher pressure applications. This element moves in response to pressure changes, actuating the valve.

- Valve Assembly (Poppet and Seat): The poppet is a movable plug that seals against the seat to control gas flow. When the downstream pressure drops below the setpoint, the sensing element moves the poppet away from the seat, allowing more gas to flow.

- Low-Pressure Gauge: This measures the regulated output pressure, ensuring it matches the setpoint.

- Outlet Port: Where the regulated gas exits, often connected to hoses or equipment. It may include a needle valve for fine flow control.

- Bonnet or Housing: The outer casing that encloses the internal components, providing protection and structural integrity.

- Relief Valve (Optional): In some designs, a safety relief valve vents excess pressure to prevent over-pressurization.

These components work in harmony to achieve precise pressure control. Materials like brass, stainless steel, or aluminum are chosen for corrosion resistance, especially since nitrogen is non-corrosive but may be used in humid environments.

Operational Principles: Single-Stage vs. Two-Stage Regulators

Pressure regulators for nitrogen cylinders come in single-stage and two-stage configurations, each suited to different applications based on precision needs.

Single-Stage Regulators

A single-stage regulator reduces pressure in one step from cylinder pressure to delivery pressure. Here’s how it works:

– Gas enters the inlet at high pressure and flows into the valve chamber.

– The downstream pressure acts on the diaphragm, pushing it upward against the main spring.

– If the output pressure is below the setpoint, the spring force dominates, pushing the diaphragm down. This movement, via a stem or linkage, lifts the poppet off the seat, allowing gas to flow into the low-pressure chamber.

– As pressure builds downstream, it equalizes with the spring force, closing the valve slightly to maintain equilibrium.

– This feedback loop ensures constant output pressure.

However, single-stage regulators suffer from “droop” or “supply pressure effect,” where output pressure decreases as cylinder pressure drops or flow increases. For nitrogen applications requiring stable pressure, like chromatography, this can be a limitation.

Two-Stage Regulators

For greater accuracy, two-stage regulators use a sequential reduction process. The first stage reduces cylinder pressure to an intermediate level (e.g., 200-500 psi), and the second stage further reduces it to the final output (e.g., 0-100 psi).

– The first stage operates like a single-stage regulator but with a fixed setpoint.

– Its output feeds into the second stage, which has an adjustable setpoint.

This design minimizes droop because the second stage sees a relatively constant input pressure from the first stage. Two-stage regulators are ideal for nitrogen in precision welding, laboratory gas supply, or beverage dispensing.

The advantage is evident in performance curves: single-stage shows a steeper pressure decay, while two-stage maintains flat output over a wide input range.

Types of Nitrogen Pressure Regulators

Beyond stages, regulators vary by design and application:

- Diaphragm-Type: Common for general use, offering good sensitivity and low contamination risk. The flexible diaphragm isolates the spring from the gas path.

- Piston-Type: Used for high-pressure or high-flow applications. A piston slides in a cylinder, providing robustness but potentially introducing more friction.

- Back-Pressure Regulators: These maintain upstream pressure by venting excess gas, useful in nitrogen blanketing systems.

- Line Regulators: Installed downstream for fine control in distribution lines.

- Specialty Regulators: For ultra-high purity nitrogen, featuring electropolished surfaces and metal-to-metal seals to prevent contamination.

Selection depends on factors like maximum inlet pressure, outlet range, flow rate (in SCFM – standard cubic feet per minute), and material compatibility.

Fluid Dynamics and Flow Characteristics

The flow through a regulator involves orifice dynamics. The valve opening creates a restriction, and gas expands adiabatically, cooling slightly (Joule-Thomson effect for nitrogen).

For nitrogen, being ideal gas-like, compressibility effects are minimal at room temperature.

Regulators must handle sonic flow if pressure ratios exceed critical values, leading to choked flow where velocity reaches Mach 1 at the throat.

Safety Considerations and Maintenance

Safety is paramount with high-pressure nitrogen. Regulators include features like burst discs or relief valves set at 1.5 times maximum working pressure.

Users must:

– Inspect for leaks using soapy water.

– Avoid oil or grease, as nitrogen can support combustion in enriched oxygen scenarios (though pure N2 is inert).

– Store cylinders upright and secure regulators when not in use.

Maintenance involves periodic gauge calibration, diaphragm replacement, and cleaning. Over time, seats can wear, causing creep (slow pressure rise).

In hazardous areas, explosion-proof regulators with ATEX certification are used.

Applications of Nitrogen Pressure Regulators

Nitrogen’s inertness makes it versatile:

– Industrial: In welding (e.g., TIG) to shield arcs, regulated to 20-50 psi.

– Medical: For cryosurgery or gas mixing, with precise low-pressure delivery.

– Food and Beverage: Purging lines or carbonating, at 30-60 psi.

– Laboratories: Gas chromatography requires stable 10-100 psi.

– Aerospace: Testing systems at high flows.

In each case, the regulator ensures consistent performance, preventing fluctuations that could ruin processes.

Advanced Features and Innovations

Modern regulators incorporate digital gauges, pressure transducers for remote monitoring, and automatic shut-off valves.

Smart regulators with IoT integration allow predictive maintenance via vibration or pressure sensors.

For high-purity applications, vacuum-jacketed designs minimize outgassing.

Research into microfluidic regulators promises miniaturization for portable devices.

Challenges and Troubleshooting

Common issues include:

– Regulator freeze-up: Due to rapid expansion cooling, mitigated by heated regulators.

– Chatter: Valve oscillation from instability, fixed by damping or flow restrictors.

– Leakage: From worn seals, requiring replacement.

Troubleshooting involves checking gauges, listening for hisses, and verifying setpoints.

Conclusion

A nitrogen gas cylinder pressure regulator is a sophisticated device that transforms high-pressure stored gas into a usable, controlled flow through mechanical force balance and feedback. From basic single-stage models to advanced two-stage systems, they ensure safety and reliability across industries. By understanding their components, principles, and applications, users can optimize performance and mitigate risks. As technology evolves, these regulators continue to adapt, supporting innovations in gas handling.

For more about how does a nitrogen gas cylinder pressure regulator work, you can pay a visit to Jewellok at https://www.jewellok.com/product/high-purity-high-pressure-gas-cylinder-pressure-regulators-pressure-reducing-valve-jsr-1e-series/ for more info.

Recent Posts

The Inner Workings of a 316L VIM-VAR Stainless Steel Pressure Regulator

How Ultra-High Purity Stainless Steel Tubing Powers Critical Industries

How Does a UHP 316L Stainless Steel Bellows Valve Work?

How Does a 316 Stainless Steel Pipe Fitting Work?

A Comprehensive Guide to 316L VIM VAR UHP Gas Regulator

Tags

Recommended Products

-

Ultra High Purity Oxygen Pressure Gauge For Semiconductor Gases JG Series Pressure Instruments For Semiconductor Manufacturing

-

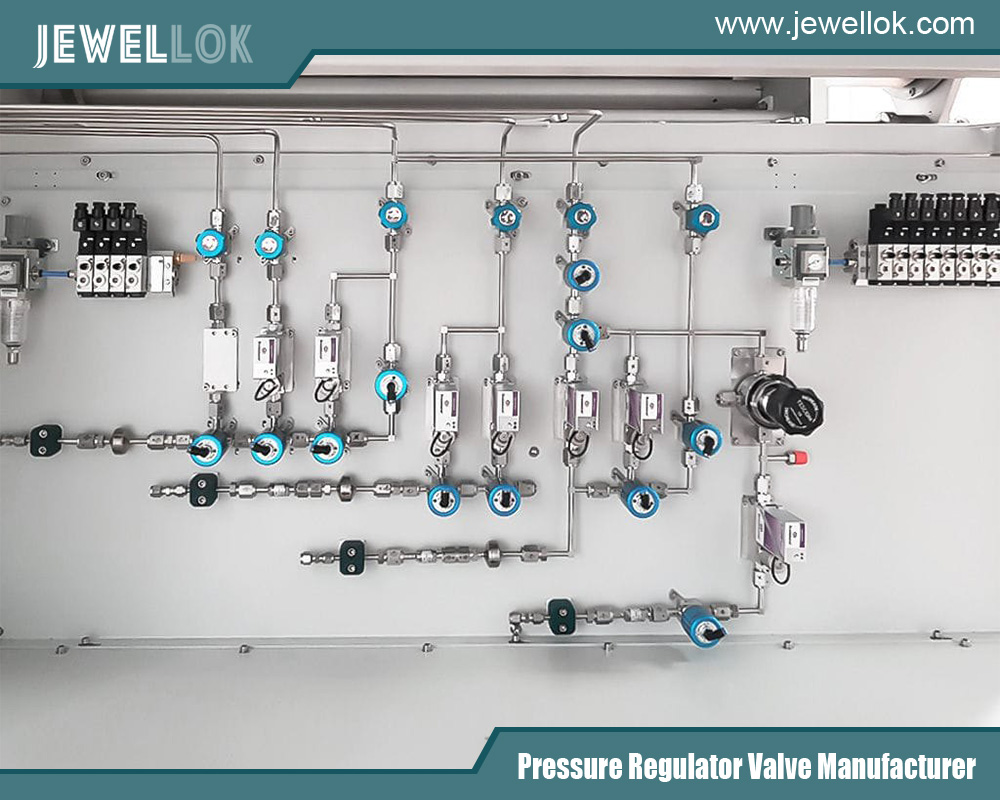

Stainless Steel Single Stage Semiconductor Grade Pressure Control Module Pressure Control Panels JSP-6A Series

-

764LR Stainless Steel 316 Reducing Tee UHP Fitting Automatic Buttweld Reducing Tee

-

Low Pressure High Flow Line Pressure Regulators And Control Valves JSR-4L Series For Laboratory Pressure Control

-

Semi Automatic And Automatic Switching Speicialty Gas Changeover Manifold Panel With Semiconductor Valve Manifold Box Gas Pressure Regulators

-

Ultra High Purity Gas Delivery Systems And Liquid Chemical Delivery Systems JW-300-LDS

-

Semi Automatic Oxygen Nitrogen Helium Argon Gas Changeover Manifold Manual Gas Changeover Manifold Panel For Gas Cylinders

-

VMB Valve Manifold Box And Panel Gas Cabinet, BSGS Gas Cabinets, TMA Gas Cabinets, Scrubber Tail Gas Treatment Cabinets