Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

How Does A Propane Gas Pressure Regulator Work?

- Pressure Regulator Valve Manufacturer

- 0-30 psi propane regulator with gauge, 1 1 2 gas pressure regulator, 1 2 propane regulator, 1/2 Gas Pressure Regulator manufacturer, 2 stage propane regulator vs single stage, 2-stage auto changeover lp propane gas regulator, 2-stage propane regulator for home, 316L Stainless Steel Gas Pressure Regulators, Acetylene Gas Pressure Regulator, adjustable high pressure propane regulator, adjustable low pressure propane regulator, adjustable low pressure propane regulator with gauge, adjustable low pressure propane regulators, adjustable low pressure propane regulators manufacturer, adjustable propane pressure regulator, adjustable propane regulator, adjustable propane regulator with gauge, argon gas pressure regulator, BA Grade High Purity Gas Pressure Regulators, best high purity gas pressure regulator, gas pressure regulator, high flow UHP gas pressure regulator industry in Italy, propane, Propane Gas Pressure Regulator, propane gas pressure regulator manufacturer, Two-Stage Propane Gas Pressure Regulator, Two-Stage Propane Gas Pressure Regulator Campany, Two-Stage Propane Gas Pressure Regulator Manufacturer, Two-Stage Propane Gas Pressure Regulator Supplier

- No Comments

How Does A Propane Gas Pressure Regulator Work?

Propane gas, chemically represented as C3H8, is a versatile hydrocarbon fuel derived from natural gas processing and petroleum refining. It is widely utilized in residential, commercial, and industrial applications, including heating homes, powering grills, fueling vehicles, and serving as a backup energy source in remote areas. Propane is stored as a liquid under moderate pressure in tanks, where it vaporizes into gas when released, providing a clean-burning flame with high energy efficiency. However, the pressure inside a propane tank can vary significantly—typically between 100 to 200 psi depending on temperature and fill level—making direct use hazardous without proper control.

This is where the propane gas pressure regulator plays a pivotal role. Acting as a gatekeeper, the regulator reduces the high, variable inlet pressure from the tank to a stable, low outlet pressure suitable for appliances, usually around 11 inches of water column (about 0.4 psi) for household uses. Without it, excessive pressure could damage equipment, cause leaks, or lead to explosions. Regulators ensure consistent gas flow, enhancing safety and performance. For instance, in a typical residential setup, a two-stage regulator first drops the pressure to about 10 psi, then further to the appliance level, compensating for pressure fluctuations.

Understanding the mechanics of a propane regulator involves exploring its design principles, components, and operational dynamics, tailored to propane’s unique properties. This article delves into these elements, drawing from engineering insights and industry practices. We’ll cover the fundamentals of gas regulators, propane-specific attributes, key parts, the step-by-step functioning, safety mechanisms, and upkeep strategies. By the conclusion, readers will grasp the engineering behind this essential device, empowering safer and more efficient propane usage.

Basics of Gas Pressure Regulators

Propane gas pressure regulators are essential in managing the delivery of gases like propane, natural gas, oxygen, and others across various sectors. Their core function is to maintain a constant outlet pressure despite variations in inlet pressure or flow demand, operating on a balance of forces to achieve this stability.

Regulators come in single-stage and multi-stage varieties. Single-stage models reduce pressure in one step and are compact, ideal for applications with stable inlet pressures, such as portable propane grills. However, they may experience “droop” or pressure drop under high demand. Two-stage regulators, common in propane systems, perform reduction in phases: the first stage lowers tank pressure to an intermediate level (e.g., 5-10 psi), and the second refines it to the final low pressure. This design minimizes fluctuations, making it suitable for whole-home systems where distance from tank to appliance affects pressure.

The underlying principle involves a diaphragm-spring mechanism. High-pressure gas enters, pressing against a flexible diaphragm. A spring, adjusted via a screw or knob, opposes this force. When balanced, a valve connected to the diaphragm regulates gas passage. Increased demand lowers outlet pressure, allowing the spring to open the valve more; decreased demand does the opposite. This feedback loop ensures steady output.

Materials are selected for durability and compatibility: brass or aluminum bodies resist corrosion, while diaphragms might be nitrile rubber or stainless steel. Seals use Viton or similar for gas resistance. Standards like those from the Underwriters Laboratories (UL) or Canadian Standards Association (CSA) certify regulators for safety, including burst tests and leak resistance.

In propane contexts, regulators often include integral features like excess flow valves. Selection criteria include gas type, inlet/outlet pressure ranges, flow capacity (measured in BTU/hour), and environmental factors. For example, a regulator for a 100-pound propane tank might handle up to 200,000 BTU/hr at 10 psi inlet. These basics highlight regulators’ role in safe gas handling, setting the foundation for propane-specific adaptations.

Properties of Propane and Special Considerations

Propane’s physical and chemical traits necessitate tailored regulator designs. As a liquefied petroleum gas (LPG), propane is stored as a liquid at pressures of 60-200 psi, vaporizing to gas above its boiling point of -42°C (-44°F). Vapor pressure rises with temperature—doubling from 100 psi at 70°F to over 200 psi at 100°F—requiring regulators to handle these swings without compromising output.

Unlike compressed gases, propane’s two-phase nature (liquid and vapor) means regulators connect to the vapor space in tanks. In cold climates, rapid vaporization can cause tank frosting and pressure drops, potentially leading to regulator freezing from moisture condensation. To counter this, some regulators feature vent orientations or heating elements, and larger tanks or vaporizers are used for high-demand scenarios.

Safety considerations are critical due to propane’s flammability (ignition range 2.1-9.5% in air) and asphyxiation risk in enclosed spaces. Regulators must prevent over-pressurization, with designs incorporating relief mechanisms. Connections follow standards like CGA (Compressed Gas Association) types, such as POL (Prest-O-Lite) left-hand threads for propane to avoid mix-ups with other gases.

Environmental factors influence performance: high humidity can corrode parts, while dust might clog vents. For automotive or marine uses, regulators must withstand vibrations. In residential installations, two-stage systems are preferred to reduce “lock-up” pressure variations and enhance efficiency over long piping runs.

Regulatory bodies like NFPA (National Fire Protection Association) mandate proper sizing and installation. For instance, a regulator undersized for demand could starve appliances, while oversizing wastes resources. Propane’s odorant (ethyl mercaptan) aids leak detection, but regulators themselves don’t add it. Overall, these properties drive innovations in regulator technology, focusing on stability, safety, and adaptability to ensure reliable operation across diverse applications.

Components of a Propane Regulator

A propane pressure regulator consists of several key elements working in unison to control gas flow safely. The body, often made of die-cast zinc or aluminum for lightweight strength and corrosion resistance, houses the internal mechanisms and provides inlet and outlet ports.

The inlet connection attaches to the tank valve, typically a POL fitting with a left-hand thread and plastic handwheel for easy, tool-free installation. It includes a filter screen to trap debris from the tank, preventing clogs. For two-stage regulators, the first stage might have a high-pressure gauge, though many residential models omit gauges for simplicity.

Central to operation is the diaphragm, a flexible membrane (often rubber or fabric-reinforced) that senses pressure changes. Attached is the spring, which sets the outlet pressure; in adjustable models, a screw or knob compresses it. The valve assembly includes a poppet or disk that seats against an orifice, controlling gas passage. The seat is typically soft material like rubber for tight sealing at low pressures.

The low-pressure chamber leads to the outlet, often a 3/8-inch flare or NPT thread for hose connections. Vents allow atmospheric pressure reference and excess gas release; they must point downward to prevent water ingress. In integral two-stage units, a second diaphragm-spring-valve set follows the first.

Safety components include an internal relief valve that opens at excessive pressures (e.g., 2-3 psi above set point) and excess flow devices that shut off flow during sudden surges, like a line break. Some models have pigtail hoses with built-in checks.

For high-capacity regulators, like those for commercial grills, additional features might include pressure taps for testing. A typical model, such as the Marshall Excelsior MEGR-6120, integrates these for flows up to 950,000 BTU/hr. These parts ensure the regulator’s robustness, with materials chosen to withstand propane’s solvency and environmental exposures.

Working Principle

The operation of a propane gas pressure regulator relies on a dynamic balance of mechanical forces to deliver consistent low-pressure gas. Let’s outline the process step by step.

Upon connection to the tank and opening the service valve, high-pressure propane vapor (100-200 psi) enters the inlet chamber. In a closed state, the poppet valve presses against the seat, blocking flow, due to a light closing spring.

To activate, if adjustable, the user turns the knob to compress the main spring, exerting downward force on the diaphragm. This displaces the poppet, opening the orifice and allowing gas into the outlet chamber. As pressure builds there, it pushes upward on the diaphragm, opposing the spring.

Equilibrium occurs when forces equalize at the desired outlet pressure (e.g., 11 inches WC). The valve stabilizes partially open, maintaining flow. The delivery remains constant as the diaphragm adjusts instantaneously to changes.

For demand variations: igniting an appliance increases flow, dropping outlet pressure. The spring dominates, opening the valve more until balance restores. Shutting off reduces demand, raising pressure; the diaphragm lifts, closing the valve.

In two-stage regulators, the first stage reduces to 5-10 psi via its own diaphragm-spring-valve, then the second fine-tunes to final pressure, minimizing effects from tank pressure drops or long lines.

Propane’s temperature-sensitive pressure means regulators compensate automatically, though extreme cold may require manual adjustments or accessories. Issues like “creep” (slow pressure rise) indicate worn seats, while “hunting” (oscillations) suggests improper sizing.

This principle ensures safe, efficient delivery, adapting to real-time conditions for applications from stoves to furnaces.

Safety Features and Maintenance

Safety is integral to propane gas pressure regulators, with built-in mechanisms protecting against hazards. Overpressure relief valves vent excess gas if pressure exceeds safe limits, preventing bursts. Lock-up features ensure the valve closes tightly when no flow is demanded, stopping leaks in non-pilot appliances. Vents release pressure but include screens to block insects.

Excess flow valves detect sudden surges (e.g., hose rupture) and shut off supply. Some regulators have thermal shut-offs that melt and close at high temperatures. Compliance with ANSI Z21.18 standards ensures these features.

Maintenance preserves functionality: inspect monthly for corrosion, leaks (using soapy water), or vent blockages. Replace every 5-10 years or after incidents. Purge air from lines during installation to avoid lockouts. Store spares in dry areas; avoid oil on threads as it can degrade seals.

Common troubleshooting: low pressure might mean frozen regulator—warm gently; no flow could indicate tripped excess valve—reset by turning off, then on slowly. Professional servicing ensures adherence to codes like NFPA 58. Regular care minimizes risks, extending system life.

Conclusion

In summary, a propane gas pressure regulator is a vital engineered component that safely modulates high tank pressures for everyday use. Through its components and balanced operation, it exemplifies reliability in gas handling. Mastering its workings enables users to optimize propane systems, promoting safety and efficiency in diverse settings.

For more about how does a propane gas pressure regulator work, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Five Key Considerations When Choosing a TMA Gas Changeover Manifold

How to Prevent Contamination in High Purity Xenon Gas Systems

Regulators for High Purity Krypton in Laser and Lighting Applications

Tags

Recommended Products

-

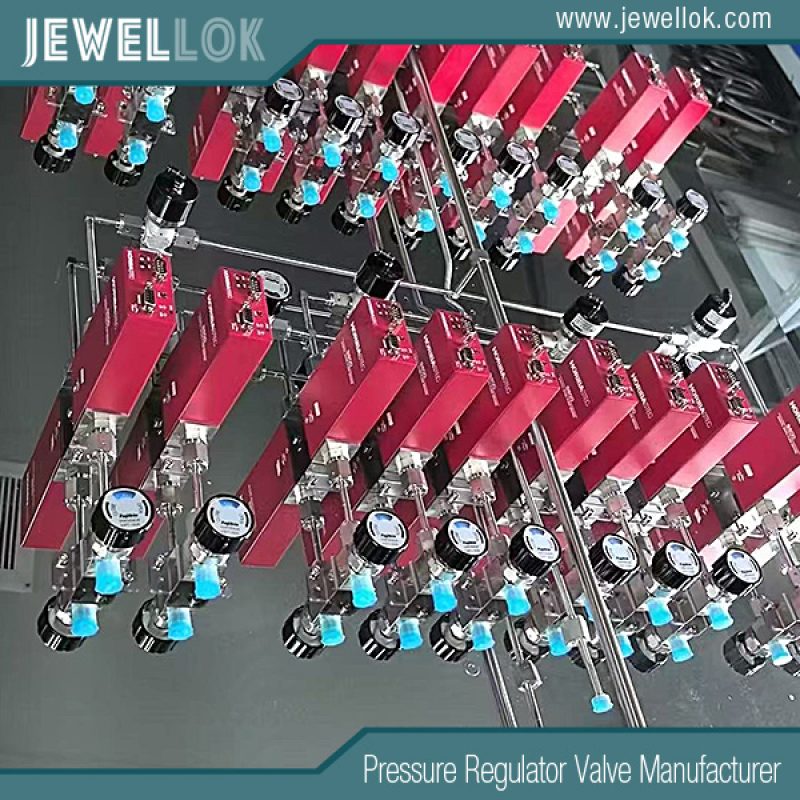

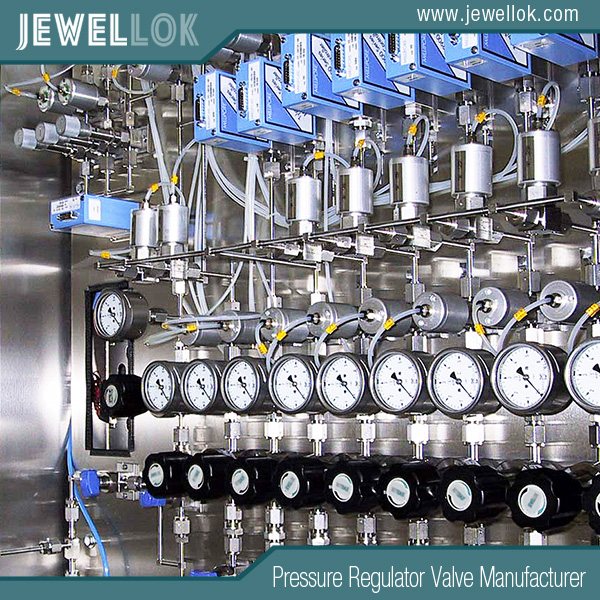

Automatic Gas Switchover System Automatic Switchover Manifold Automatic Gas Cylinder Switchover

-

Hydrogen Manifold Argon Gas Manifold System Oxygen Manifold Propane Gas Manifold With Valves In Gas Manifold Changeover System

-

DPR1 Ultra High Purity Two Stage Dual Stage Pressure Reducing Regulator Semiconductor Grade Regulators

-

Integrated Gas System (IGS) Modular Integrated Gas Systems (TMS) Integrated Gas Supply System For Semiconductor And Laboratory

-

Clean Connection Cabinet JW-300-CCB Valve Manifold Box And Control Valve Box

-

T-BOX JW-TB-C Special Gas Delivery System Gas Valve Manifold Boxes

-

Stainless Steel Ultra High Purity Mini Butt Weld Mini Tee Reducer MTRW Series Fittings

-

High Purity High Pressure Stainless Steel Needle Valve Natural Gas Flow Control Valve JNV Series