Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

How Does a Scrubber Tail Gas Treatment Cabinet for Gas Delivery Systems in Semiconductor Manufacturing Work?

- Pressure Regulator Valve Manufacturer

- Exhaust Gas Scrubber Systems, gas abatement scrubbers, gas scrubber manufacturers in china, gas scrubber manufacturers in india, Gas scrubber oil and gas, Gas scrubber system, Gas Scrubber System for Fume Hoods, Gas Scrubbers for Display Cabinet, gas scrubbers manufacturer, Gas scrubbing systems for drying and cleaning processes, How does a gas scrubber work?, Industrial gas scrubber manufacturers in india, Laboratory gas scrubbers, Laser Gas Cabinet, Scrubber for butyric vapor acid, scrubber gas cabinet, scrubber tail gas treatment cabinet, Scrubbers for Specialty Gases Filling Stations, Specialty gas scrubber manufacturers, Top Wet Scrubber Manufacturer in India, Tower Gas Scrubber for Gas Treatment Wet Scrubber, Toxic Gas Cabinet, Waste gas and process gas scrubbing systems, waste gas scrubbers, Waste Gas Treatment Equipment, Waste-gas and exhaust gas treatment, Wet Scrubber Exhaust Gas Treatment Spray Tower

- No Comments

How Does a Scrubber Tail Gas Treatment Cabinet for Gas Delivery Systems in Semiconductor Manufacturing Work?

Introduction

The semiconductor industry is a cornerstone of modern technology, powering everything from smartphones to advanced computing systems. However, the manufacturing processes involved in producing semiconductors generate hazardous and toxic gases that pose significant risks to human health, equipment, and the environment. To mitigate these risks, scrubber tail gas treatment cabinets are employed as critical components of gas delivery systems in semiconductor fabrication plants (fabs). These specialized systems are designed to neutralize, capture, and remove harmful pollutants from exhaust gas streams before they are released into the atmosphere or further processed. This article explores how scrubber tail gas treatment cabinets function, their role in semiconductor manufacturing, key design considerations, and their importance in ensuring safety and regulatory compliance.

The Role of Gas Delivery Systems in Semiconductor Manufacturing

Semiconductor manufacturing involves complex processes such as deposition, etching, doping, and cleaning, all of which rely heavily on a variety of gases. These gases include:

– Pyrophoric gases (e.g., silane, phosphine) used in deposition processes.

– Corrosive gases (e.g., hydrogen chloride, fluorine) for etching.

– Toxic gases (e.g., arsine, diborane) for doping.

– Atmospheric gases (e.g., nitrogen, argon) for purging and maintaining process purity.

These gases are delivered through sophisticated gas delivery systems that ensure precise control over flow, pressure, and temperature to meet the stringent requirements of semiconductor fabrication. However, the exhaust gases (or tail gases) produced during these processes often contain hazardous byproducts, such as volatile organic compounds (VOCs), acid gases, and particulate matter. These tail gases must be treated to prevent environmental contamination, comply with regulatory standards, and protect workers and equipment.

This is where scrubber tail gas treatment cabinets come into play. Integrated into the gas delivery system, these cabinets are designed to treat exhaust gases at the point of use (POU) or within centralized exhaust treatment facilities, ensuring that harmful substances are neutralized or removed before release.

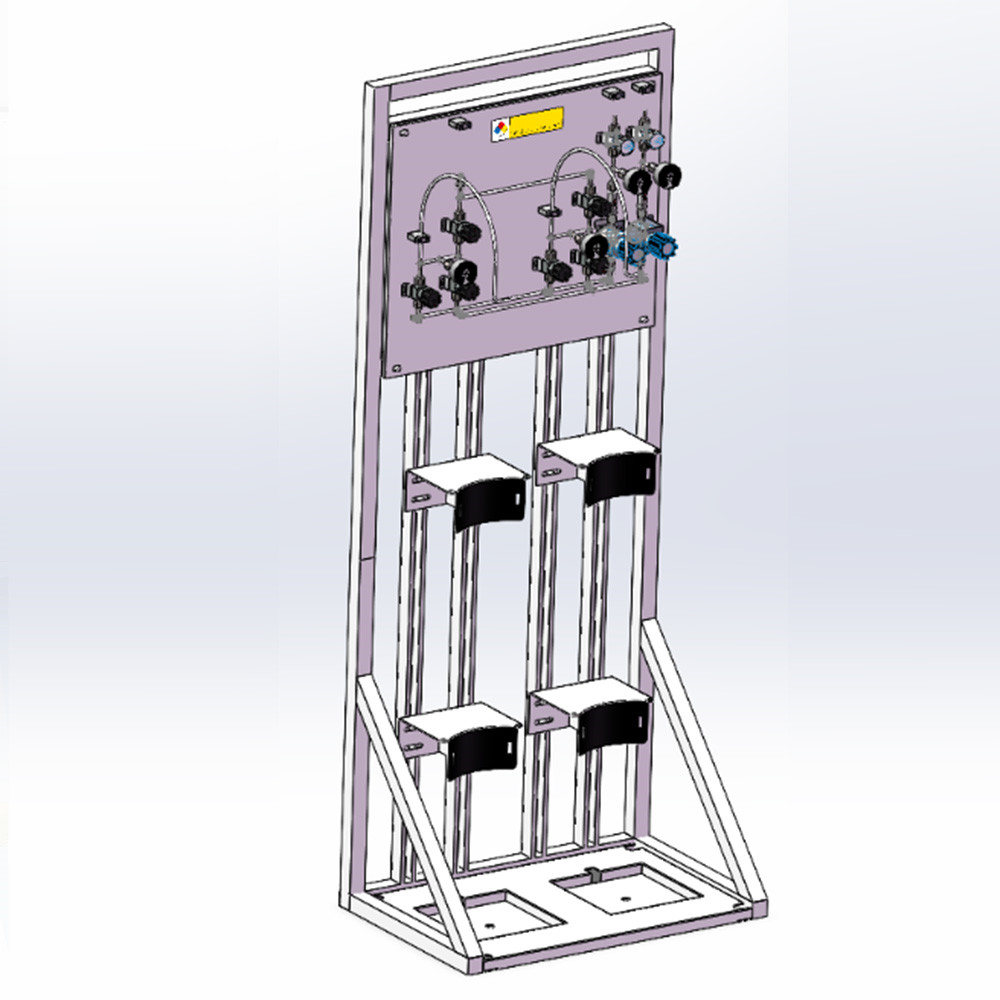

What Is a Scrubber Tail Gas Treatment Cabinet?

A scrubber tail gas treatment cabinet is a specialized piece of equipment used to purify exhaust gases generated during semiconductor manufacturing. It is typically a self-contained unit that houses components such as scrubbers, pumps, sensors, and control systems, all enclosed within a robust cabinet designed to handle hazardous gases safely. The term “tail gas” refers to the residual gases exiting a process after the primary reactions have occurred, which may still contain pollutants that need to be treated.

Scrubbers within these cabinets operate using various techniques, including absorption, adsorption, chemical neutralization, and combustion, to remove or neutralize harmful components. The cabinets are often customized to address specific gas compositions and process requirements, making them versatile solutions for the semiconductor industry.

How Does a Scrubber Tail Gas Treatment Cabinet Work?

The operation of a scrubber tail gas treatment cabinet can be broken down into several key stages, each designed to ensure effective pollutant removal. Below is a detailed explanation of the process, incorporating insights from industry practices and technical sources.

1.Gas Inlet and Pre-Treatment

The process begins with the entry of contaminated tail gas into the scrubber cabinet through an inlet zone, typically located at the bottom of the unit. In semiconductor manufacturing, these gases may originate from processes such as chemical vapor deposition (CVD), etching, or ion implantation, and may contain substances like hydrochloric acid (HCl), ammonia (NH3), hydrogen fluoride (HF), or silane (SiH4).

To protect downstream components, some systems include a pre-wet scrubbing section to remove highly corrosive or soluble gases, such as hydrogen halides (HCl, HBr) or metal halides (WF6). This pre-treatment reduces the risk of corrosion in the system and prevents clogging in subsequent stages. For example, a pre-washer may dissolve corrosive gases into a liquid medium, protecting the burner or other components in the cabinet.

2.Primary Treatment: Scrubbing Mechanisms

The core of the scrubber tail gas treatment cabinet is the scrubbing process, which can involve one or more of the following techniques:

a.Wet Scrubbing

Wet scrubbers use a liquid medium, typically water or a chemical solution (e.g., caustic soda or sodium hydroxide), to capture and neutralize pollutants. The tail gas is brought into contact with the scrubbing liquid through spray nozzles, packed beds, or foam layers, which maximize the surface area for gas-liquid interaction. This process involves:

– Absorption: Soluble gaseous components, such as acid gases (HCl, HF) or ammonia, dissolve into the liquid phase.

– Chemical Neutralization: Harmful substances react with the scrubbing solution to form inert or less hazardous compounds. For instance, acidic gases like HCl react with caustic solutions to form salts, while ammonia may be neutralized with acidic solutions.

– Particulate Removal: Fine aerosols or solid particles are captured through mechanisms like inertial impaction or interception.

After treatment, the cleaned gas passes through a demister or mist eliminator to remove entrained liquid droplets, ensuring minimal carryover into the exhaust stream. The used scrubbing liquid is collected in a recirculation tank for treatment, reuse, or disposal.

b.Dry Scrubbing

In some cases, dry or semi-dry scrubbers are used, particularly for gases that do not require liquid-based neutralization. Dry scrubbers inject a dry reagent, such as hydrated lime or sodium bicarbonate, into the gas stream to react with acid gases like sulfur dioxide (SO2) or HCl. These systems are advantageous because they do not produce wastewater, reducing disposal requirements. However, they are less common in semiconductor applications due to the prevalence of water-soluble pollutants.

c.Combustion (Burn-Wet Systems)

For pyrophoric or flammable gases like silane or hydrogen, the scrubber cabinet may include a burn chamber where gases are oxidized at high temperatures to break down toxic compounds into less harmful byproducts. For example, silane can be combusted to form silicon dioxide (SiO2) and water vapor. The combustion process is followed by a wet scrubbing stage to capture any residual soluble gases or dust generated during oxidation.

3.Gas-Liquid Contact Optimization

The efficiency of a scrubber depends on the contact time and surface area between the gas and the scrubbing liquid. To enhance this interaction, scrubber cabinets often incorporate:

– Packed Beds: These consist of materials like Raschig rings or Intalox saddles, which increase the surface area for gas-liquid contact. The packing material is typically made of corrosion-resistant materials like polypropylene (PP) or polyvinylidene fluoride (PVDF).

– Spray Nozzles: These distribute the scrubbing liquid evenly, creating fine droplets that enhance absorption.

– Counter-Flow Design: In many scrubber cabinets, the gas flows upward while the liquid flows downward, maintaining a concentration gradient that improves pollutant removal efficiency.

4.Post-Treatment and Exhaust

After scrubbing, the treated gas is directed through an outlet, where it is either released into the atmosphere (if it meets regulatory standards) or sent to a centralized exhaust system for further processing. The scrubber cabinet may include sensors and monitoring systems to ensure that emission levels comply with environmental regulations, such as those set by the U.S. Environmental Protection Agency (EPA) or local authorities like Cal/OSHA.

The used scrubbing liquid, now containing captured pollutants, is collected in a recirculation tank or sent to a wastewater treatment system. In some cases, valuable materials can be recovered from the liquid for reuse, adding an economic benefit to the process.

5.Safety and Automation Features

Scrubber tail gas treatment cabinets are equipped with advanced safety and automation systems to handle the hazardous nature of semiconductor gases. These include:

– Sensors: Monitor parameters like pH, flow rate, and gas concentration to ensure optimal operation.

– Backup Systems: Dual scrubber systems or bypass mechanisms ensure continuous operation during maintenance.

– Leak Prevention: Short connections between the scrubber and vacuum pumps reduce the risk of leaks, as seen in integrated pump and abatement solutions (IPAS).

– Compliance with Standards: Systems are designed to meet safety standards like SEMI S2 for semiconductor manufacturing equipment.

Key Design Considerations for Scrubber Tail Gas Treatment Cabinets

The design of scrubber cabinets for semiconductor applications is highly specialized to address the unique challenges of the industry. Key considerations include:

- Material Selection: Cabinets are typically constructed from corrosion-resistant materials like fiber-reinforced plastic (FRP), polypropylene (PP), or stainless steel to withstand corrosive gases. For example, FRP is preferred for its durability and low maintenance requirements.

- Capacity and Flow Rate: The cabinet must handle the specific gas flow rates of the semiconductor process, which can range from 100 to 1,200 standard liters per minute (slm) for point-of-use systems.

- Pollutant Specificity: The scrubbing solution and design are tailored to the target pollutants. For instance, caustic solutions are used for acidic gases, while oxidizing agents may target hazardous compounds like hydrogen sulfide (H2S).

- Space Constraints: In semiconductor fabs, space is at a premium. Compact designs, such as those offered by companies like Quimipol, are optimized for laboratory or sub-fab environments.

- Energy Efficiency: Modern scrubber cabinets incorporate automation to reduce chemical and energy consumption. For example, linking the scrubber to the process tool via ethernet can optimize burner capacity and reduce fuel use by over 20%.

- Regulatory Compliance: Scrubbers must meet stringent environmental regulations, such as the EPA’s Greenhouse Gas Mandatory Reporting Rule, which requires semiconductor fabs to monitor and report emissions.

Applications in Semiconductor Manufacturing

Scrubber tail gas treatment cabinets are used across various semiconductor processes, including:

– Chemical Vapor Deposition (CVD): Treats gases like silane, ammonia, and dichlorosilane used in thin-film deposition.

– Etching: Removes acid gases (HCl, HF) and fluorine compounds from plasma or reactive ion etching processes.

– Ion Implantation: Neutralizes toxic gases like arsine and phosphine used for doping.

– Wafer Cleaning: Purifies exhausts containing acidic or alkaline cleaning agents.

For example, the SALIX scrubber by DAS Environmental Experts is designed for single-wafer cleaning processes, directly treating exhaust gases from process chambers to ensure safe disposal.

Advantages and Challenges

Advantages

– High Removal Efficiency: Scrubbers can achieve near-complete removal of targeted pollutants, ensuring compliance with environmental standards.

– Versatility: Customizable for a wide range of gases and processes.

– Safety: Protects workers and equipment by neutralizing hazardous gases.

– Resource Recovery: Some systems allow recovery of valuable materials from the scrubbing liquid.

Challenges

– Maintenance: Components like packing media or nozzles may degrade when handling aggressive gases, requiring regular replacement.

– Wastewater Management: Wet scrubbers generate wastewater that must be treated or disposed of properly.

– Cost: Initial installation and ongoing maintenance can be costly, with prices ranging from $5,000 for small units to millions for large-scale systems.

Industry Trends and Innovations

The semiconductor industry is evolving, with increasing focus on sustainability and emission reduction. Innovations in scrubber technology include:

– Catalytic DeNOx Systems: To address nitrogen oxide (NOx) emissions, companies like DAS Environmental Experts are developing catalytic solutions for semiconductor fabs.

– Compact Designs: Systems like GEA’s Compact Gas Scrubbers eliminate the need for mechanical fans, reducing energy consumption.

– Integration with Sub-Fab Systems: Point-of-use scrubbers are increasingly integrated with vacuum pumps to minimize gas line length and improve efficiency.

Conclusion

Scrubber tail gas treatment cabinets are indispensable in semiconductor manufacturing, ensuring the safe handling of hazardous exhaust gases while maintaining compliance with environmental and safety regulations. By employing wet scrubbing, dry scrubbing, or combustion techniques, these systems effectively neutralize and remove pollutants like acid gases, VOCs, and particulates. Their design, tailored to the specific needs of semiconductor processes, incorporates corrosion-resistant materials, automation, and safety features to optimize performance. As the industry continues to innovate, scrubber cabinets will play a critical role in supporting sustainable and efficient semiconductor manufacturing, protecting both the environment and the workforce.

For more about how does a scrubber tail gas treatment cabinet for gas delivery systems in semiconductor manufacturing work, you can pay a visit to Jewellok at https://www.jewellok.com/product/bulk-specialty-gas-systems-bsgs-gas-cabinets-and-scrubber-tail-gas-treatment-cabinets-for-high-purity-bulk-specialty-gas-delivery/ for more info.

Recent Posts

How to Select the Right Valve Manifold Box for Your Application

316L Stainless Steel Ultra High Purity Regulator for PH3 Service

How to Safely Operate a TMA Gas Changeover Manifold

How to Choose an Ultra High Purity CO2 Pressure Reducing Valve

Tags

Recommended Products

-

764L Stainless Steel Union Tee High Purity Fitting Union Tee Reducing Tubing Connection

-

Semiconductor High Purity High Pressure Specialty Gas Bottle Gas Cylinder Storage Cabinet And Gas Pressure Regulating Cabinet

-

768L Stainless Steel Male Tube Butt Weld Connector | Clean Weld Fittings And Ultra-High Purity Fittings

-

770L Female Elbow | Stainless Steel High Purity Weld Fittings Female Micro Elbow Fittings

-

774L Stainless Steel UHP Fittings Butt Weld Bulkhead Union For High Flow Special Gas Fluid

-

FT-BOX JW-FTB-C Valve Manifold Panels And Boxes With High Purity Configurable Systems

-

767LP Port Connector Ultra High Purity VCR Metal Gasket Face Seal Tube Fittings

-

DPR1 Ultra High Purity Two Stage Dual Stage Pressure Reducing Regulator Semiconductor Grade Regulators