Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

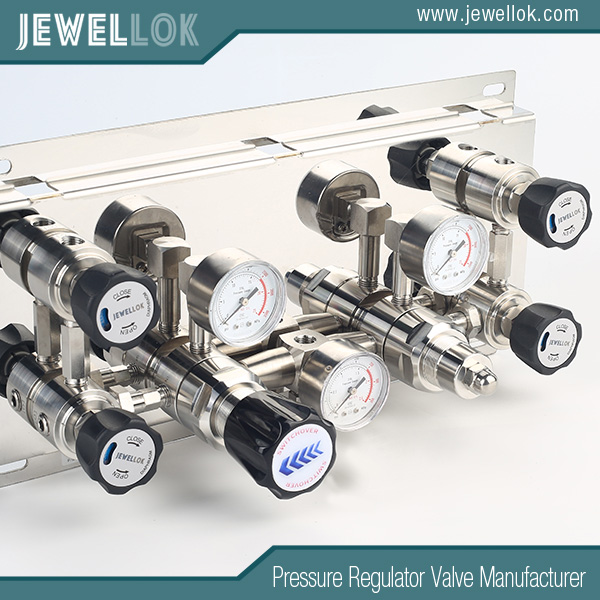

How Does a Gas Cylinder Manifold System Work? Ensuring Continuous, Safe, and Reliable Gas Supply

- Pressure Regulator Valve Manufacturer

- 316L Stainless Steel Gas Pressure Regulators, 316L stainless steel regulator, ba grade high purity pressure regulator, Back Pressure Regulator, Bulk Specialty Gas Delivery System, CGA 580 connection, cleanroom assembly regulator, dual stage gas regulator, Gas Cylinder Manifold System, gas pressure regulator, gas purity 99.9999%, helium leak testing regulator, high flow gas regulator, high purity pressure regulator, high purity pressure regulator manufacturer, high purity valves for semiconductors, inert gas pressure control, ISO 14644 cleanroom standards valves, Laboratory And Specialty Gas Delivery System, maintenance UHP stainless steel valves, manufacturing ultra high purity valves, particle-free stainless steel valves, precision engineering UHP valves, SEMI standards gas equipment, semiconductor gas regulator, single stage pressure regulator, specialty gas delivery system, stainless steel gas pressure regulator, Stainless Steel Gas Pressure Regulator Work, Stainless Steel Gas Pressure Regulators, Stainless Steel Pressure Regulator, uhp 316l stainless steel gas pressure regulators, uhp 316l stainless steel gas pressure regulators manufacturer in thailand, UHP gas regulator, UHP Stainless Steel Gas Pressure Regulators, UHP stainless steel valves, ultra high purity gas pressure regulator, ultra high purity pressure regulator, ultra high purity pressure regulator manufacturer, ultra high purity stainless steel valve, vacuum compatible stainless steel valves

How Does a Gas Cylinder Manifold System Work? Ensuring Continuous, Safe, and Reliable Gas Supply

In industrial, medical, and laboratory environments, a continuous and reliable supply of gases—such as oxygen, nitrogen, argon, or medical-grade air—is often critical. Individual gas cylinders have limited capacity and require frequent replacement, causing operational interruptions and potential safety risks. A gas cylinder manifold system solves this challenge by linking multiple cylinders into a unified supply network, allowing seamless transition between sources and ensuring an uninterrupted flow. This technical article explores the design, components, working principles, and applications of gas cylinder manifold systems, providing a comprehensive understanding of their operation and importance.

- What Is a Gas Cylinder Manifold System?

A gas cylinder manifold system is an arrangement that connects two or more gas cylinders to a common header or pipeline, which then supplies gas to the end-use points. The system is designed to automatically or manually switch from an active (or “duty”) set of cylinders to a reserve set when the former are exhausted. This setup is essential in applications where gas supply cannot be interrupted, such as in hospitals (for patient oxygen), semiconductor manufacturing, or welding operations.

Manifold systems can be configured for:

- High-purity gases (e.g., in labs or electronics fabrication).

- High-pressure gases (industrial gases stored at up to 300 bar).

- Hazardous or non-hazardous gases, with safety provisions tailored accordingly.

The core purpose is to increase capacity, enhance safety, and reduce manual cylinder handling, thereby minimizing downtime and human error.

- Key Components of a Manifold System

A typical gas cylinder manifold system consists of the following components:

2.1 Gas Cylinders

Cylinders are the source vessels, usually color-coded and labeled according to the gas they contain. They are equipped with a cylinder valve and often a pressure relief device.

2.2 Manifold Header

The header is a central pipe or tube that collects gas from all connected cylinders. It is made from materials compatible with the gas (e.g., copper for oxygen, stainless steel for corrosive gases). The header includes:

- Inlet connections for each cylinder (via pigtails or flexible hoses).

- Pressure gauges to monitor inlet pressures.

- Isolation valves for each inlet to allow servicing.

2.3 Changeover Device

This is the intelligence of the system. It monitors pressure in the active supply and automatically switches to the reserve bank when the active pressure falls below a set point. In manual systems, changeover is initiated by an operator.

2.4 Pressure Regulators

Cylinder pressure is often too high for end-use equipment. Primary regulators reduce the pressure from cylinder pressure (e.g., 200 bar) to an intermediate level, and sometimes a secondary regulator further adjusts it to working pressure.

2.5 Safety Valves and Relief Devices

- Non-return valves (check valves): Prevent backflow between cylinders.

- Pressure relief valves: Protect the system from overpressure.

- Emergency shut-off valves: Allow rapid isolation in case of a leak or fire.

2.6 Alarm and Monitoring Systems

Advanced manifolds include:

- Pressure switches to trigger audible/visual alarms when changeover occurs.

- Gas detectors (for hazardous gases) to alert staff to leaks.

- Remote monitoring capability for centralized control rooms.

2.7 Distribution Piping

From the manifold header, gas is delivered through pipelines to various points of use, with additional local valves and regulators as needed.

- How the System Works: Step-by-Step Operation

3.1 Configuration and Setup

Cylinders are grouped into two banks: Duty (or Active) and Reserve (or Standby). Each bank consists of one or more cylinders connected in parallel. The number of cylinders per bank depends on flow rate requirements and desired backup duration.

3.2 Normal Operation Phase

During normal operation, gas is drawn from the duty bank. All cylinders in this bank are opened, and gas flows through their individual pigtails into the common header. The pressure regulator adjusts the output to the required delivery pressure. The reserve bank remains isolated but ready, with its cylinders also opened but blocked by a closed valve or changeover mechanism.

3.3 Changeover Trigger

As the duty bank depletes, its pressure drops. A pressure-sensitive switch in the changeover device detects this drop (typically set at a predetermined level, e.g., 10% above the minimum required delivery pressure). This triggers the changeover sequence.

3.4 Automatic Changeover Process

In an automatic system:

- The changeover valve closes the duty bank supply.

- Simultaneously, it opens the reserve bank supply.

- Gas flow is now sourced from the reserve bank without interruption.

- An alarm may activate to notify personnel that the duty bank is exhausted and requires replacement.

3.5 Cylinder Replacement and Reconfiguration

Once the duty bank is empty, operators replace the cylinders. After replacement, that bank becomes the new reserve, and the system continues operating seamlessly. This swing-over method ensures that one bank is always online.

3.6 Pressure Regulation and Flow Control

Throughout the process, pressure regulators maintain stable output pressure regardless of fluctuating inlet pressures. If flow demand exceeds the capacity of one cylinder, drawing from multiple cylinders in parallel ensures sufficient volume.

- Types of Manifold Systems

4.1 Manual Manifolds

Operators monitor pressure gauges and manually switch valves to change banks. These are lower cost but require human intervention and risk interruption if not monitored closely.

4.2 Semi-Automatic Manifolds

These use a manual changeover valve but include alarms to prompt operator action. They offer a balance between cost and reliability.

4.3 Fully Automatic Manifolds

Equipped with an automatic changeover valve and pressure switches, these systems switch banks without human intervention. Common in critical applications like medical gas supply in hospitals.

4.4 Hydraulic vs. Pneumatic vs. Electronic Control

- Hydraulic: Uses gas pressure itself to operate the changeover mechanism.

- Pneumatic: Employs compressed air or gas for actuation.

- Electronic: Uses solenoids and electronic sensors, allowing integration with building management systems.

4.5 High-Purity and Specialty Gas Manifolds

For ultrapure gases (e.g., in pharmaceutical or electronics industries), manifolds are constructed from electropolished stainless steel, with diaphragm seals and purging provisions to prevent contamination.

- Safety Considerations and Design Standards

Gas manifold systems handle potentially hazardous materials under high pressure, making safety paramount.

5.1 Gas Compatibility

Materials must be compatible with the gas. For example, oxygen manifolds require oxygen-clean components to prevent fire hazards from ignition of contaminants.

5.2 Leak Prevention

- Use welded joints or sealed fittings where possible.

- Regular leak tests with approved solutions or detectors.

- Installation in well-ventilated areas, especially for toxic or asphyxiant gases.

5.3 Pressure Integrity

Systems are designed and tested to withstand maximum cylinder pressure with a safety factor. Pressure relief valves protect against regulator failure.

5.4 Standards and Regulations

Manifold systems must comply with industry standards such as:

- ISO 7396-1 for medical gas pipeline systems.

- NFPA 99 (Health Care Facilities Code).

- ASME BPVC for pressure vessel and piping design.

- Regional regulations (e.g., UK’s HTM 02-01 for medical gases).

5.5 Venting and Emergency Shutdown

Vent lines may be installed to safely discharge gas during maintenance or emergencies. Emergency shutoff valves are often located at accessible points.

- Applications of Manifold Systems

6.1 Medical Gases

Hospitals use manifold systems for oxygen, nitrous oxide, medical air, and nitrogen. These are life-support systems, requiring absolute reliability and often duplicate (“duplex”) or triplicate manifolds with additional backup.

6.2 Industrial Manufacturing

- Welding and cutting: Supply of acetylene, oxygen, argon.

- Heat treatment: Nitrogen and hydrogen atmospheres.

- Pneumatic controls: Instrument air manifolds.

6.3 Laboratories

Research labs use manifolds for carrier gases (GC, MS), calibration gases, and reactant gases. Manifolds may be housed in gas cabinets for safe handling of toxic gases.

6.4 Semiconductor and Electronics Industry

High-purity manifolds deliver argon, nitrogen, helium, and specialty gases like silane. These systems often include gas detection, auto-purge, and toxic gas monitoring.

6.5 Beverage Industry

CO₂ manifolds supply carbonation systems in breweries and soft-drink plants, ensuring continuous operation during cylinder swaps.

- Installation and Maintenance Best Practices

7.1 Site Selection and Preparation

- Install in a secure, accessible, and ventilated location.

- Ensure adequate spacing for cylinder handling.

- Avoid areas with extreme temperatures or corrosive atmospheres.

7.2 Professional Installation

Qualified personnel should install and pressure-test the system before commissioning. Piping should be clearly labeled according to gas identity and flow direction.

7.3 Routine Maintenance

- Daily/Weekly: Check pressure gauges, inspect for leaks, verify alarm function.

- Monthly: Test changeover operation, examine hoses and fittings.

- Annually: Comprehensive inspection, regulator servicing, relief valve testing.

7.4 Record Keeping

Maintain logs of cylinder changes, maintenance activities, and alarm events for compliance and troubleshooting.

7.5 Training

Operators and maintenance staff must be trained in system operation, emergency procedures, and cylinder handling.

- Advantages and Limitations

Advantages:

- Uninterrupted supply critical for continuous processes and life support.

- Reduced labor as cylinders are changed less frequently.

- Enhanced safety through centralized control and reduced cylinder handling.

- Scalability – additional cylinders can be added to meet higher demand.

- Better pressure stability with multiple cylinders feeding a common regulator.

Limitations:

- Higher initial cost compared to single-cylinder use.

- Requires more space for cylinder banks and manifold cabinet.

- Maintenance complexity – more components to monitor and service.

- Gas compatibility restrictions – a manifold is typically dedicated to one gas type.

- Future Trends and Innovations

- IoT Integration: Remote monitoring of pressure, usage, and predictive maintenance alerts.

- Advanced Materials: Lightweight, corrosion-resistant composites for headers and fittings.

- Energy Efficiency: Optimized designs to reduce gas wastage during changeover.

- Modular Manifolds: Pre-fabricated, skid-mounted systems for quicker deployment.

Conclusion

A gas cylinder manifold system is an engineering solution that elegantly addresses the need for continuous gas supply by integrating multiple cylinders into a managed network. Through careful design—incorporating regulators, changeover mechanisms, and safety devices—these systems ensure reliability, safety, and operational efficiency across diverse sectors from healthcare to high-tech manufacturing. Understanding their components, working principles, and maintenance requirements is essential for engineers, facility managers, and technicians responsible for critical gas infrastructure. As technology advances, manifold systems will continue to evolve, offering smarter, safer, and more efficient ways to manage vital gas supplies.

For more about how does a gas cylinder manifold system work? Ensuring continuous, safe, and reliable gas supply, you can pay a visit to Jewellok at https://www.specialtygasregulator.com/product-category/ultra-high-purity-gas-regulators/ for more info.

Recent Posts

How to Choose the Krypton Gas Ultra High Purity (UHP) Regulator

Troubleshooting Common Failures in TMA Gas Changeover Manifolds

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

Tags

Recommended Products

-

High Purity Chemical Dispense System & Packing System For Semiconductors JW-200L-CDM & JW-1000L-CDM

-

766L High Purity Female Connector UHP Fitting Female Connector

-

739 High Purity LMR Male Adapter Tube To Pipe Fittings And Adapters

-

Ultra High Purity Oxygen Pressure Gauge For Semiconductor Gases JG Series Pressure Instruments For Semiconductor Manufacturing

-

Stainless Steel High Pressure Specialty Gas Changeover Manifold For High Purity Oxygen Nitrogen Argon Helium Hydrogen Co2

-

Semi-Automatic VMB Gas Cabinet With Semiconductor Valve Manifold Box Diaphragm Valves And Gas Pressure Regulators

-

316L Stainless Steel Tube Butt Weld Reducing Fittings Union Reducer RW Series Ultrahigh Purity Process

-

768L Stainless Steel Male Tube Butt Weld Connector | Clean Weld Fittings And Ultra-High Purity Fittings