Blog

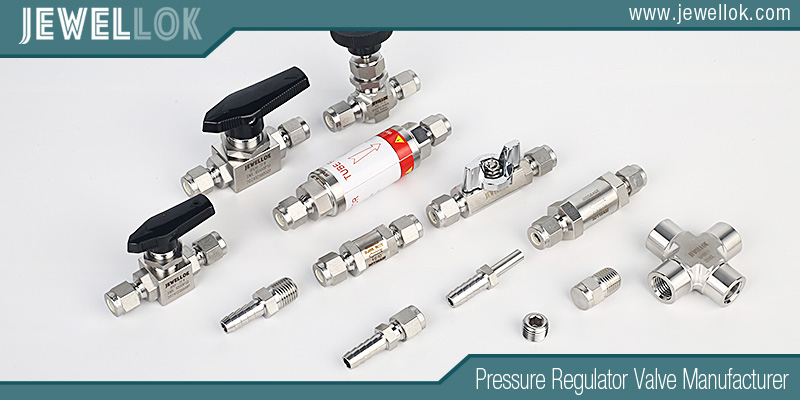

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

How to Choose the best 316L Stainless Steel Ball Valve Manufacturer

- Pressure Regulator Valve Manufacturer

- 1/4 VCR Stainless Steel Ultra High Purity Gas Regulator, 10000 Psi Needle Valve Manufacturer, 2 electric valve, 2 inch irrigation valve, 3000psi High Pressure Stainless Steel Diaphragm Valve, 316 SS ball valves factory, 316 stainless steel ball valves, 316 stainless steel pipe fittings, 316 stainless steel tube pressure rating, 316L Stainless Steel Ball Valve, 316l stainless steel ball valve manufacturer, 316L stainless steel ball valve manufacturer in thailand, 316l stainless steel diaphragm valve, 316l stainless steel diaphragm valve Thailand, 316L Stainless Steel Gas Pressure Regulators, 316l stainless steel pressure regulator, 316L Stainless Steel Seamless High Purity System Tube, actuated ball valve manufacturers, adjust gas valve pressure, adjustable high pressure propane regulator, adjustable high pressure regulator, adjustable hydraulic flow control valve, adjustable hydraulic pressure regulator, adjustable inline air regulator, adjustable low pressure propane regulator, adjustable natural gas regulator, ba grade stainless steel pressure regulator, Best high purity stainless steel gas fittings, best stainless steel diaphragm valve manufacturer, china stainless steel ball valve, High purity specialty gas stainless steel ball valves, high temperature stainless steel ball valve, Stainless Steel, Stainless Steel Ball Valve, stainless steel ball valve from china manufacturer, stainless steel ball valve malaysia

- No Comments

How to Choose the best 316L Stainless Steel Ball Valve Manufacturer

In the intricate world of industrial fluid control, selecting the right manufacturer for 316L stainless steel ball valves is a decision that can significantly impact operational efficiency, safety, and long-term cost savings. 316L stainless steel, a low-carbon variant of the austenitic 316 grade, is renowned for its exceptional corrosion resistance, particularly in chloride-rich environments, making it ideal for demanding applications in industries such as oil and gas, chemical processing, pharmaceuticals, food and beverage, and marine engineering. The “L” designation indicates lower carbon content (typically less than 0.03%), which enhances weldability and reduces the risk of intergranular corrosion during fabrication.

Ball valves made from this material feature a spherical disc that rotates to control flow, offering quick quarter-turn operation, tight shut-off, and minimal pressure drop. However, not all manufacturers produce these valves to the same standards. With the global market projected to grow amid increasing demands for durable, hygienic, and high-performance components, choosing a reliable supplier requires careful evaluation of multiple factors. This article provides a comprehensive guide on how to select a 316L stainless steel ball valve manufacturer, drawing on industry best practices, key criteria, and insights into top players as of 2025. By the end, you’ll be equipped to make an informed choice that aligns with your project’s specific needs, ensuring reliability and compliance in high-stakes environments.

Understanding 316L Stainless Steel Ball Valves

Before diving into manufacturer selection, it’s essential to grasp what makes 316L stainless steel ball valves unique. These valves consist of a body, ball, stem, seats (often PTFE for chemical resistance), and seals, all crafted from 316L alloy, which contains molybdenum (2-3%) for superior pitting and crevice corrosion resistance compared to 304 stainless steel. They come in various designs: one-piece for compact, low-cost applications; two-piece for easier maintenance; and three-piece for full disassembly and cleaning, which is crucial in sanitary industries like pharmaceuticals.

The advantages are manifold. 316L offers excellent mechanical properties, with tensile strength around 485 MPa and yield strength of 170 MPa, allowing it to withstand pressures up to 1000 psi or more, depending on size and configuration. Its temperature range spans from -196°C to 815°C, making it versatile for cryogenic to high-heat processes. In corrosive media, such as seawater or acidic chemicals, 316L outperforms standard steels, reducing downtime and maintenance costs. For instance, in offshore oil platforms, these valves prevent leaks that could lead to environmental disasters or equipment failure.

Applications abound: in petrochemical plants for handling aggressive fluids; in food processing for hygienic flow control (meeting FDA standards); in water treatment for durability against chlorides; and in biotechnology for sterile environments. However, the valve’s performance hinges on the manufacturer’s quality control. Poor forging or machining can lead to defects like porosity or improper seating, causing leaks or premature wear. Thus, understanding these basics sets the foundation for evaluating suppliers.

Key Criteria for Selecting a Manufacturer

Choosing a manufacturer isn’t just about price; it’s about ensuring the valves meet your operational demands without compromising safety or efficiency. Here are the primary factors to consider.

Certifications and Quality Standards

First and foremost, verify certifications that attest to the manufacturer’s adherence to international standards. Look for ISO 9001 for quality management systems, which ensures consistent production processes. For valves in pressure systems, API 6D certification is critical, as it covers design, manufacturing, and testing for pipeline valves. ANSI/ASME B16.34 outlines valve ratings for pressure and temperature, while ASTM A351/A182 specifies material requirements for castings and forgings. In Europe, PED (Pressure Equipment Directive) compliance is mandatory for high-pressure applications.

Additionally, for hygienic uses, seek NSF/ANSI 61 or 372 for lead-free compliance, especially in potable water systems. Material traceability is non-negotiable—reputable manufacturers provide mill test reports (MTRs) detailing chemical composition, mechanical properties, and heat treatment. Third-party inspections, such as those by Lloyd’s Register or Bureau Veritas, add credibility. Without these, you risk non-compliant products that could fail regulatory audits or cause operational hazards.

Experience and Reputation

A manufacturer’s track record speaks volumes. Opt for companies with at least 10-20 years in valve production, as they likely have refined processes and overcome common pitfalls. Research their reputation through customer reviews on platforms like ThomasNet or Alibaba, and check for case studies or references in your industry. For example, a supplier with proven success in marine applications will better understand saltwater corrosion challenges.

Engage in industry forums like Eng-Tips to gauge peer opinions. Longevity often correlates with innovation; established firms invest in R&D for features like fire-safe designs (API 607) or anti-static properties. Avoid newcomers unless they demonstrate exceptional quality through partnerships or certifications.

Manufacturing Capabilities

Assess the manufacturer’s technological prowess and production capacity. Advanced facilities with CNC machining, investment casting, and automated assembly ensure precision and consistency. For 316L valves, inquire about forging methods—hot forging enhances grain structure for better strength. Capacity matters for large orders; a supplier with multiple production lines can handle scalability without delays.

Look for in-house testing labs equipped for hydrostatic, pneumatic, and leakage tests per API 598. Integration of Industry 4.0 technologies, like IoT for quality monitoring, indicates forward-thinking operations. If your needs include custom sizes (e.g., from 1/4″ to 12″), confirm their ability to produce non-standard configurations without compromising quality.

Material Sourcing and Traceability

The quality of 316L stainless steel varies by source. Premium manufacturers source from reputable mills like Outokumpu or Nippon Steel, ensuring alloy purity. Demand full traceability from raw material to finished product to prevent counterfeits or substandard alloys. Wetted parts should be 100% 316L, while non-wetted components might use 304 for cost efficiency, but confirm compatibility.

Seals and seats are equally important; PTFE (Teflon) is standard for chemical resistance, but options like PEEK for high temperatures should be available. Ethical sourcing, free from conflict minerals, adds to sustainability credentials.

Customization and Product Range

Your application might require specific features: floating vs. trunnion balls for high-pressure; multi-port for diverting flow; or actuated valves for automation. A versatile manufacturer offers a broad range, including threaded, flanged, or welded ends, and sizes from miniature to large bore. Customization capabilities, such as extended stems for insulation or cryogenic extensions, demonstrate flexibility.

Evaluate their design engineering support—do they use CAD/CAE for prototypes? This ensures the valve fits your system seamlessly.

Pricing and Cost-Effectiveness

While tempting, the cheapest option often leads to higher lifecycle costs due to failures. Compare total cost of ownership (TCO), including maintenance, downtime, and replacement. Bulk pricing, payment terms, and warranties (typically 1-5 years) factor in. Chinese manufacturers like those in Wenzhou offer competitive rates, but balance with quality. Request quotes from multiple suppliers, factoring in shipping and tariffs.

Customer Service and After-Sales Support

Responsive support is crucial. Look for dedicated account managers, technical assistance, and global service networks. After-sales include spare parts availability, repair services, and training. Manufacturers with 24/7 helplines or on-site commissioning excel in this area.

Supply Chain Reliability and Lead Times

In a post-pandemic world, resilient supply chains are vital. Inquire about inventory levels, lead times (typically 4-12 weeks), and contingency plans for disruptions. Proximity matters—US-based for North America reduces shipping times, while Asian suppliers suit cost-sensitive projects.

Sustainability and Ethical Practices

Increasingly, buyers prioritize eco-friendly manufacturers. Check for ISO 14001 (environmental management), low-emission processes, and recyclable packaging. Ethical labor practices, per ILO standards, ensure social responsibility.

Researching Manufacturers

Start with online searches for “top 316L stainless steel ball valve manufacturers 2025.”

Use directories like Metoree or PROCAMLOCK for listings. Attend trade shows like Valve World or ACHEMA to network. Request samples for testing, visit facilities if possible, and conduct audits. Leverage RFQs on platforms like Global Sources.

Top Manufacturers in 2025

As of 2025, leading manufacturers include:

- Emerson (USA): Known for automation-integrated valves, with strong API certifications.

- Flowserve (USA): Expertise in high-pressure applications, global presence.

- IMI PLC (UK): Focus on precision engineering for critical industries.

- KITZ Corporation (Japan): High-quality, innovative designs.

- NSW (China): Cost-effective with broad ranges.

- Parker Hannifin (USA): Versatile products for instrumentation.

- Bray International (USA): Resilient seated options.

- Swagelok (USA): Premium for high-purity applications.

- L&T Valves (India): Robust for oil and gas.

Others like Powell Valves and Milwaukee Valve offer specialized lines. In America, companies like Gemini Valve and SSP stand out for domestic production.

Common Mistakes to Avoid

Don’t overlook compatibility—ensure the valve matches your fluid’s pH, temperature, and pressure. Ignoring certifications can lead to legal issues. Relying solely on price ignores TCO. Failing to check references might reveal poor service. Overlooking sustainability could harm your brand’s image.

Conclusion

Selecting a 316L stainless steel ball valve manufacturer demands a holistic approach, balancing quality, cost, and support. By prioritizing certifications, experience, and customization while researching thoroughly, you can secure a partner that enhances your operations. In 2025’s competitive landscape, the right choice not only prevents failures but drives efficiency and innovation. Invest time in evaluation—your systems depend on it.

For more about how to choose the best 316L stainless steel ball valve manufacturer, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Select the Right Valve Manifold Box for Your Application

316L Stainless Steel Ultra High Purity Regulator for PH3 Service

How to Safely Operate a TMA Gas Changeover Manifold

How to Choose an Ultra High Purity CO2 Pressure Reducing Valve

Tags

Recommended Products

-

DPR1 Ultra High Purity Two Stage Dual Stage Pressure Reducing Regulator Semiconductor Grade Regulators

-

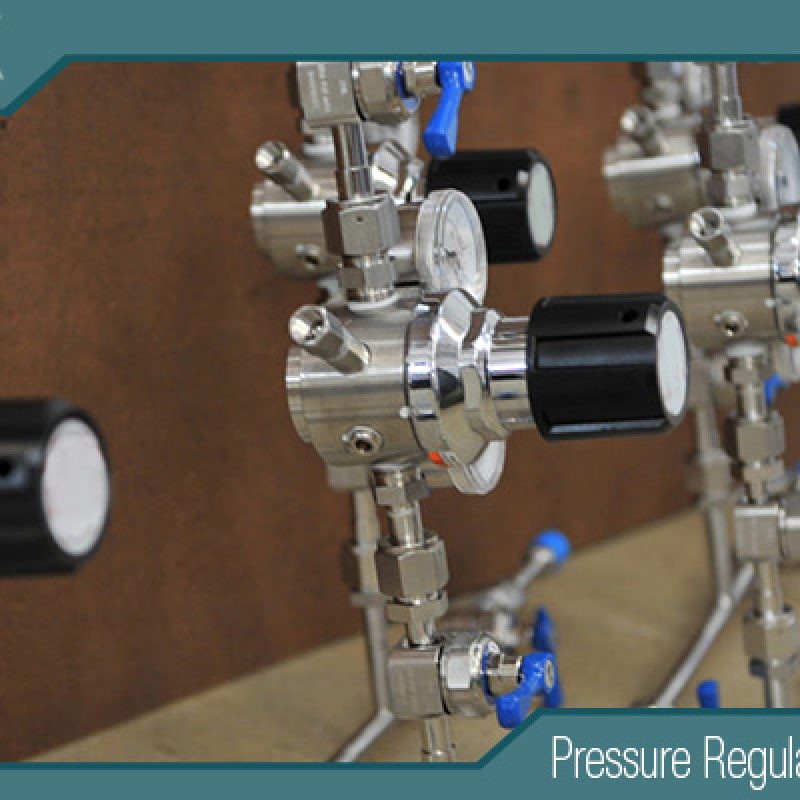

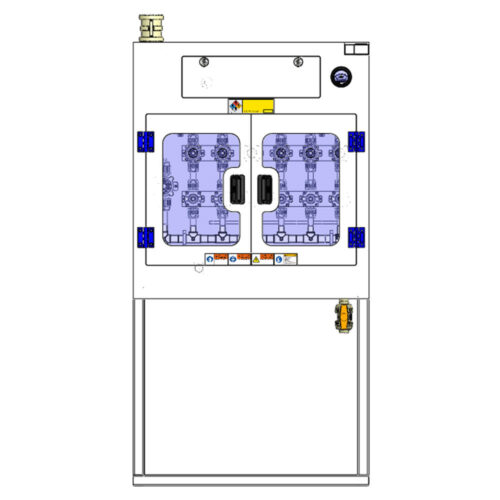

FT-BOX JW-FTB-C Valve Manifold Panels And Boxes With High Purity Configurable Systems

-

Stainless Steel Ultra Clean Welding Joint Fittings TW Series TRW Series & CW Series

-

High Purity And Industria Gas Stick Assemblies Precise Pressure Control Gas Systems JSR-1ETG-BV Series

-

766L High Purity Female Connector UHP Fitting Female Connector

-

High Purity Configurable Systems VMB Valve Manifold Box JW-200-VMB-C & JW-100-VMB-C

-

Long Gland LG Series For Ultra High Purity Gas And Chemical Delivery Systems

-

Integrated Gas System (IGS) Modular Integrated Gas Systems (TMS) Integrated Gas Supply System For Semiconductor And Laboratory