Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

How to Safely Operate a TMA Gas Changeover Manifold

- Pressure Regulator Valve Manufacturer

- argon gas manifold system, argon manifold system, Automatic Changeover Gas Manifold, automatic changeover manifold, automatic gas switchover manifold system, Best Gas Switchover Manifolds for Gas Management, best manifold valve manufacturers in india, CO2 gas changeover manifold, custom hydraulic manifolds, gas cylinder changeover manifold, gas cylinder changeover manifold malaysia, gas manifold system, Gas Manifolds Manufacturers in India, gas switchover manifold, High Pressure Nitrogen Gas Manifold System, how does a gas changeover valve work, hydraulic manifold block manufacturers in india, hydraulic manifold manufacturers in india, hydrogen valve manifold, Industrial Gas Manifold Systems India, LPG Gas Manifold System Manufacturer from New Delhi, Lpg Manifold System Manufacturer from Navi Mumbai, manifold manufacturers in india, nitrogen gas manifold system, PH3 gas changeover manifold, pressure valve manifold manufacturers, semi-automatic gas switchover manifold panel system, SiH4 gas changeover manifold, stainless steel manifold manufacturers, Stainless Steel Semi-automatic Changeover Gas Manifold, TMA gas changeover manifold, TMA gas changeover manifold manufacturer, TMA gas changeover manifold market, TMA gas changeover manifold supplier, TMA gas changeover manifold work, welding gas manifold system

- No Comments

How to Safely Operate a TMA Gas Changeover Manifold

Trimethylaluminum (TMA) is an indispensable precursor in semiconductor manufacturing and advanced materials science, particularly for Atomic Layer Deposition (ALD) and Metalorganic Chemical Vapor Deposition (MOCVD) processes. As a pyrophoric, moisture-sensitive, and toxic substance, its safe handling is non-negotiable. The heart of this safe handling system is the TMA Gas Changeover Manifold. This sophisticated piece of equipment ensures a continuous, reliable, and safe supply of TMA vapor from dual source cylinders, enabling uninterrupted production cycles.

Operating this manifold incorrectly carries severe risks: violent exothermic reactions, fires, toxic releases, and process contamination. This technical article provides a detailed, step-by-step guide on the safe operation of a standard TMA gas changeover manifold, focusing on principles, procedures, and critical safety protocols.

Understanding the System: Components and Purpose

Before touching a valve, one must understand the system’s design philosophy. A TMA gas changeover manifold is engineered for fail-safe operation and inert atmosphere integrity.

Core Components:

-

Dual Source Cylinders: Two TMA bubbler or ampoule cylinders (typically “A” and “B”) provide redundancy. One is online (supplying the process), while the other is standby.

-

Primary & Secondary Pressure Regulators: Each cylinder has its own dedicated regulator. The primary regulator controls cylinder head pressure, while the secondary (often integral) provides a stable, precise delivery pressure to the manifold header.

-

Purge Gas Inlets: Dedicated, regulated lines for high-purity inert gas (N₂ or Ar) connected to each cylinder line and the common header. These are used for purging and pressure balancing.

-

Shut-Off Valves (SOVs) & Pneumatic Actuators: Manual or automated bellows or diaphragm valves that isolate each leg. Automated systems use pneumatically actuated valves controlled by a system controller.

-

Changeover Valve/Manifold Header: The central junction where the A and B lines converge into a single delivery line to the tool. In advanced systems, this is a dedicated 3-way valve.

-

Pressure Transducers & Sensors: Monitor pressure in each cylinder line, the header, and often the purge lines. They provide critical data for automatic changeover logic and leak detection.

-

Vacuum Generator & Vent System: A crucial safety subsystem. A vacuum pump or ejector is used to safely evacuate lines before opening to atmosphere (for maintenance) or before purging. The vent line leads to an exhaust scrubber or burn-box designed to neutralize pyrophoric and toxic effluents.

-

System Controller (PLC/CPU): In automated manifolds, this brain monitors pressures, controls valve sequencing, executes purge cycles, and triggers changeovers based on predefined logic (e.g., cylinder pressure decay).

-

Exhaust/Scrubber Interface: All vented gases must be routed to a facility scrubber or point-of-use abatement system to treat toxic and pyrophoric byproducts.

The Primary Goal: To switch the gas supply from a depleted or nearly empty “online” cylinder to a full “standby” cylinder without introducing air, moisture, or pressure spikes into the process tool, and without exposing the operator to hazardous materials.

Pre-Operational Safety Checks and Preparations

Safety is established before any procedure begins.

-

Personal Protective Equipment (PPE): Mandatory wear of flame-resistant (FR) lab coat or coveralls, safety goggles or face shield, chemically resistant gloves (e.g., Butyl rubber), and closed-toe shoes. Have a compatible Class D fire extinguisher readily accessible.

-

Work Area Verification: Ensure the area is well-ventilated, clear of combustibles, and that emergency eyewash and shower are unobstructed. Post appropriate “Pyrophoric Gas” warning signs.

-

System Status Check:

-

Verify the exhaust/scrubber system is operational and has adequate flow.

-

Confirm all purge gas supplies (primary and backup) are connected, regulated, and at correct pressure (typically 20-30 psig higher than TMA delivery pressure).

-

Check for any active alarms on the system controller. Acknowledge and resolve any prior to operation.

-

Inspect all connections, valves, and the cylinders themselves for signs of corrosion, leakage, or physical damage. Never operate a compromised system.

-

-

Cylinder Integrity: Ensure new cylinders are properly labeled, have current safety data sheets (SDS), and their valve outlets are clean. Verify the cylinder heel (for bubblers) is within useable limits.

Standard Operating Procedure: Manual Changeover Example

This outlines a conservative, manual procedure. Automated systems will follow a similar logical sequence programmed into the controller.

Scenario: Cylinder “A” is online but nearing depletion. Cylinder “B” is full and on standby.

Step 1: Preparation of Standby Cylinder (“B”)

-

Ensure the TMA delivery valve and purge valve on Line B are CLOSED.

-

Slowly open the cylinder valve on the new “B” cylinder. Listen for leaks (hissing). Use a leak detector (specifically for the carrier gas) at the valve stem and connection.

-

Adjust the primary regulator on Line B to the specified head pressure (e.g., 50 psig). Allow the cylinder and line to thermally equilibrate. The secondary regulator should already be set to the tool’s required inlet pressure (e.g., 10 psig).

Step 2: Pressure Equalization (The Critical Step)

-

The goal is to bring Line B to the exact same pressure as the active manifold header before connecting it, to prevent a surge or backflow.

-

Isolate the Tool: Close the main delivery shut-off valve to the process tool. The tool should have its own isolation.

-

Purge Line B to Header: With the Line B TMA valve closed, slowly open the Line B purge valve. Allow the inert gas to fill Line B up to the closed changeover valve. Monitor the pressure gauge on Line B.

-

Equalize: Using the purge gas regulator, carefully adjust the pressure in Line B until it matches the pressure reading on the manifold header pressure gauge (which is being supplied by the still-online Cylinder A). This may take fine adjustments.

Step 3: Switching the Supply (Changeover)

-

Once pressures are equalized, slowly open the Line B TMA shut-off valve. Now, both A and B sources are connected to the header at equal pressure.

-

Switch the Changeover Valve: If a manual 3-way valve is used, carefully turn it from position “A” to position “B”. The tool should now be receiving TMA from Cylinder B. In a dual-valve system, you would now close the Line A TMA shut-off valve. Cylinder B is now online.

Step 4: Isolating and Securing the Depleted Cylinder (“A”)

-

Close the Cylinder A primary valve at the cylinder itself.

-

Purge Line A: Open the Line A purge valve to displace residual TMA vapor from the line into the vent/scrubber. Purge for a specified time or number of volume exchanges (e.g., 3x line volume).

-

Evacuate Line A: Engage the vacuum system to evacuate Line A. This removes purge gas and any residual traces.

-

Close all valves on Line A (TMA valve, purge valve). The line is now inert and under vacuum, safe for disconnection.

-

Cap the Depleted Cylinder: Close the cylinder valve, disconnect it, and immediately install the manufacturer-provided protective cap on the cylinder outlet.

-

Label the Cylinder: Mark it clearly as “Depleted” or “Heel” and date it.

Step 5: Return to Normal Operation

-

Verify the tool is receiving stable pressure and flow from Cylinder B.

-

Re-open the main delivery shut-off valve to the tool if it was closed.

-

Document the changeover in the system log: date, time, cylinder IDs (from/to), operator, and any observations.

Critical Safety Protocols and Hazard Mitigation

-

Never Break Containment Under Pressure: Always follow Evacuate-Purge-Evacuate (E-P-E) or Purge-Evacuate-Purge cycles before opening any line to atmosphere. This removes all hazardous material.

-

Slow, Deliberate Valve Operation: “Slow is smooth, and smooth is fast.” Rapid valve actuation can cause pressure hammer, create static electricity, or lead to thermal shocks in the lines.

-

Pressure Equalization is Mandatory: Switching sources without equalizing pressure can force liquid TMA into the gas lines or cause dangerous flow reversals.

-

Leak Check Continuously: Perform leak checks with a compatible detector after every connection, especially after a changeover. Pay special attention to valve stems and regulator diaphragms.

-

Understand the Control System Logic: If operating an automated manifold, know what conditions trigger an automatic changeover (e.g., low pressure, high flow time). Know how to perform a manual override safely.

-

Emergency Response: Know the location and operation of the Emergency Shut-Off (ESO) valve, which should isolate the entire gas cabinet and initiate an emergency purge. Understand the facility’s alarm response protocol for fire or toxic release.

Troubleshooting Common Issues

-

Pressure Fluctuations After Changeover: Likely due to imperfect pressure equalization or regulator instability. Isolate the tool, re-equalize, and slowly re-establish flow.

-

Unable to Achieve Pressure Equalization: Check for a clogged purge line, faulty regulator on the standby leg, or a leaking shut-off valve.

-

High Pressure Alarm: Could indicate a failed regulator (seat) or a closed valve downstream. Isolate and investigate; do not simply reset the alarm.

-

Low Flow Alarm Despite Full Cylinder: Could be a depleted cylinder (check weight), a clogged dip tube in the cylinder, or a too-low cylinder temperature (TMA vapor pressure is temperature-dependent).

-

Automatic Changeover Fails to Initiate: Verify sensor readings are accurate. The system may be in manual mode, or interlocks (like “tool in use”) may be preventing the sequence.

Conclusion

Operating a TMA gas changeover manifold is a task that blends technical understanding with disciplined procedural execution. The manifold is not just a collection of valves and gauges; it is an engineered safety system designed to control a significant hazard.

The cornerstone of safe operation is a deep respect for the material properties of TMA—its pyrophoric nature, reactivity, and toxicity—coupled with a rigorous adherence to validated procedures. Whether performing a manual changeover or supervising an automated system, the principles remain the same: maintain inert atmosphere integrity, ensure pressure stability, execute thorough purging, and never bypass safety interlocks.

Continuous training, coupled with clear, accessible standard operating procedures (SOPs) and a strong culture of safety, transforms this complex technical task from a high-risk operation into a routine, controlled process. In the world of precursor delivery, there is no room for shortcuts—only careful, knowledgeable, and safe practice ensures the protection of personnel, equipment, and the environment.

For more about how to safely operate a TMA gas changeover manifold, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Five Key Considerations When Choosing a TMA Gas Changeover Manifold

How to Prevent Contamination in High Purity Xenon Gas Systems

Regulators for High Purity Krypton in Laser and Lighting Applications

Tags

Recommended Products

-

Semiconductor High Purity High Pressure Specialty Gas Bottle Gas Cylinder Storage Cabinet And Gas Pressure Regulating Cabinet

-

High Purity And Industria Gas Stick Assemblies Precise Pressure Control Gas Systems JSR-1ETG-BV Series

-

763L Stainless Steel High Purity Pressure Reducing Union Fittings And Tubing Pressure Reducing Valve Adjustment

-

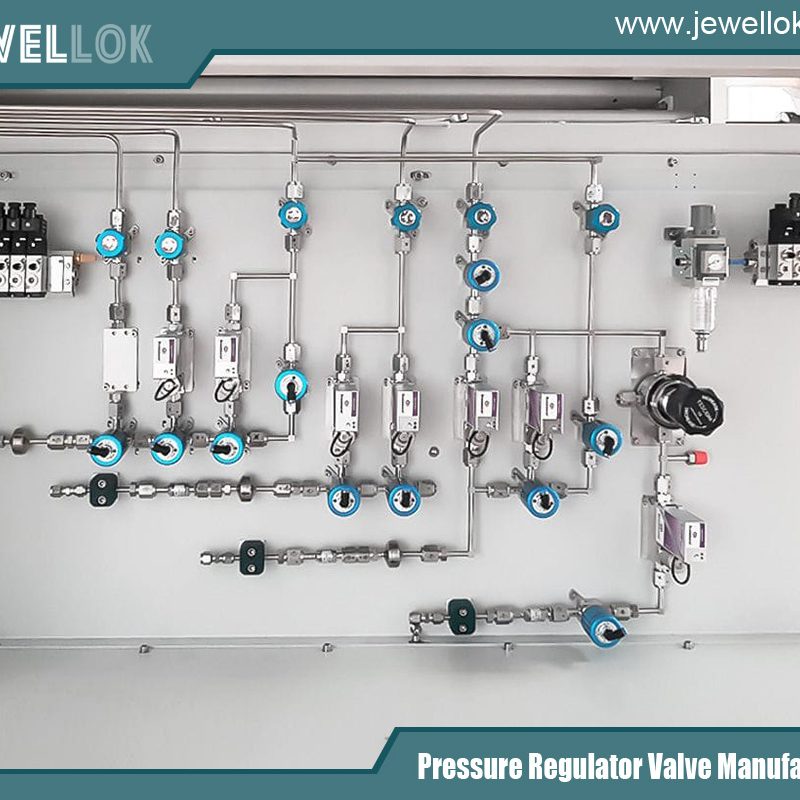

High Purity Semi-Auto Stainless Steel Changeover Manifold System, Nitrogen High Pressure Control Panel With Semiconductor Valve Manifold Box Diaphragm Valves

-

Ultra High Purity Gas Delivery Systems And Liquid Chemical Delivery Systems JW-300-LDS

-

High Pressure High-Purity Welded Check Valves And Low Cracking Pressure Check Valve JCV1 Series

-

770L Female Elbow | Stainless Steel High Purity Weld Fittings Female Micro Elbow Fittings

-

High Purity Gas Cylinder Semi Automatic Changeover Manifold Regulator Panel 3000psig Stainless Steel Gas Control Panel 1/8 Npt With Gauge