Blog

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Low-Pressure Valve Manufacturers: An In-Depth Exploration

- Pressure Regulator Valve Manufacturer

- 1/2 gas pressure regulator, 2 electric valve, 316 SS ball valves manufacturer, adjustable propane pressure regulator, back pressure regulator manufacturers, best low-pressure valve, best low-pressure valve manufacturers, Diaphragm Valve Manufacturers, Double Block and Bleed valve manufacturers, electric water valve, gas regulator valve manufacturers, high flow needle valve manufacturer, high pressure ball valve manufacturer, high pressure hydraulic needle valve manufacturer, high pressure needle valve manufacturer, high purity regulator, high purity valves manufacturers, industrial diaphragm valve manufacturers, low pressure valve manufacturer, low-pressure valve, low-pressure valve manufacturers, low-pressure valve supplier, medical oxygen pressure gauge manufacturer, needle valve 10000 psi manufacturer, pneumatic actuated ball valve manufacturer, pressure control valve manufacturers, pressure gauge manufacturers, pressure relief valve manufacturers, safety valve vs relief valve, semiconductor gas, Stainless Steel Diaphragm Valve Manufacturer

- No Comments

Low-Pressure Valve Manufacturers: An In-Depth Exploration

Valves are the unsung heroes of modern infrastructure, quietly controlling the flow of water, gas, and other fluids that power our daily lives. Among these, low-pressure valves play a pivotal role in systems where precision and safety are paramount. But what exactly are low-pressure valves, and who are the manufacturers behind these essential components? This article delves into the world of low-pressure valve manufacturing, exploring their types, materials, production processes, key industry players, market trends, challenges, and real-world applications. By the end, you’ll have a comprehensive understanding of this critical industry and its impact on our world.

Low-pressure valves are engineered to operate at pressures typically below 150 psi, making them ideal for applications where high-pressure bursts could be catastrophic. These valves are ubiquitous in industries such as water distribution, HVAC systems, and various industrial processes. Their ability to provide precise control over fluid flow ensures the efficiency and safety of these systems, making their manufacturers vital contributors to global infrastructure.

What Are Low-Pressure Valves?

Low-pressure valves are specialized devices designed to regulate the flow of fluids or gases in systems operating at relatively low pressures, generally below 150 psi. Unlike their high-pressure counterparts, which handle extreme conditions in industries like oil and gas extraction, low-pressure valves are tailored for environments requiring meticulous control without excessive force. They are essential in applications where safety, reliability, and precision are non-negotiable.

These valves find their place in everyday systems we often take for granted. For instance, in municipal water supply networks, they manage water flow to homes and businesses. In HVAC systems, they regulate air and coolant to maintain comfortable indoor environments. In industrial settings, they control processes that demand steady, low-pressure fluid management. Understanding the manufacturers behind these valves requires first appreciating the diversity and functionality they bring to these applications.

Types of Low-Pressure Valves

Low-pressure valves come in various designs, each suited to specific tasks. Here’s a breakdown of the most common types:

- Ball Valves

Ball valves are renowned for their quick shut-off capabilities. Featuring a spherical disc with a hole through its center, they allow or block flow by rotating the ball. This design ensures a tight seal, making them ideal for applications requiring immediate cessation of fluid movement, such as emergency shut-offs in water or gas lines.

- Gate Valves

Gate valves excel in on/off control, commonly used in water distribution systems. They operate by lifting a gate out of the fluid’s path, minimizing pressure drop when fully open. Their straightforward design makes them a staple in systems where flow regulation isn’t frequent but reliability is key.

- Globe Valves

Globe valves are the go-to choice for throttling flow. With a movable disk that adjusts to regulate flow rate, they offer precision in applications like HVAC systems or industrial processes where fluid volume needs fine-tuning. Their versatility comes at the cost of higher pressure drops compared to gate valves.

- Check Valves

Check valves prevent backflow, allowing fluid to move in one direction only. This feature is crucial in systems where reverse flow could cause damage or contamination, such as in pumping systems or chemical processing. Their simplicity and effectiveness make them indispensable.

Each type serves a unique purpose, and manufacturers must produce a range that meets diverse industry needs.

Materials Used in Low-Pressure Valves

The choice of material in valve manufacturing is a balancing act between durability, cost, and application-specific requirements. Here are the primary materials used:

- Brass: Valued for its corrosion resistance and ease of machining, brass is a popular choice for valves in water and gas systems. Its affordability and reliability make it a mainstay in residential and commercial applications.

- Stainless Steel: Offering superior strength and corrosion resistance, stainless steel is favored in demanding environments like chemical processing or marine applications. Its durability justifies the higher cost in settings where failure isn’t an option.

- Plastic: Lightweight and cost-effective, plastic valves (e.g., PVC or CPVC) are used where corrosion from metals is a concern, such as in certain water treatment processes. Their limitations in strength and temperature tolerance restrict them to specific uses.

Manufacturers select materials based on the valve’s intended environment, ensuring longevity and performance. For instance, a valve in a coastal water system might prioritize stainless steel to combat saltwater corrosion, while a budget-conscious HVAC system might opt for brass or plastic.

Manufacturing Processes

Producing low-pressure valves involves a series of precise steps to ensure quality and functionality:

- Casting: The process begins with casting, where molten metal or plastic is poured into molds to form the valve body. This step establishes the basic shape and structure.

- Machining: Once cooled, the cast components are machined to refine their dimensions and add features like threads or seats. Precision machining ensures the valve operates smoothly and seals effectively.

- Assembly: Components such as the valve body, stem, and sealing elements are assembled. This stage may involve manual or automated processes, depending on the manufacturer’s scale.

- Quality Control: Rigorous testing follows, including pressure tests, leak checks, and compliance with industry standards (e.g., ASME or ISO). This ensures the valve performs reliably under specified conditions.

Manufacturers invest heavily in quality control to meet regulatory and customer expectations, as a faulty valve can lead to system failures or safety hazards.

Key Manufacturers in the Industry

Several companies dominate the low-pressure valve manufacturing landscape, each bringing unique strengths to the table:

- Emerson: A global leader in automation solutions, Emerson offers a broad portfolio of valves, including low-pressure designs. Their emphasis on technological innovation—such as smart valve systems—positions them as an industry pacesetter.

- Flowserve: With over two centuries of experience, Flowserve produces high-quality valves and pumps for diverse sectors, including water treatment and energy. Their low-pressure valves are known for durability and performance.

- Crane: Specializing in fluid handling, Crane provides a range of low-pressure valves tailored to industrial and commercial needs. Their focus on sustainability appeals to environmentally conscious markets.

These manufacturers, alongside others like Parker Hannifin and Swagelok, drive competition and innovation, ensuring a steady supply of advanced, reliable valves.

Market Trends and Demands

The low-pressure valve market is evolving, fueled by growth in key industries. A 2021-2026 market report projects the global valve market to grow at a compound annual growth rate (CAGR) of 4.5%, with low-pressure valves contributing significantly. This growth is driven by:

- Water Treatment: Expanding urban populations demand robust water management systems, increasing the need for low-pressure valves in distribution and treatment plants.

- Renewable Energy: Systems like solar thermal plants or geothermal setups rely on precise fluid control, boosting valve demand.

- HVAC Growth: Rising construction and energy efficiency standards propel the use of low-pressure valves in heating and cooling systems.

Manufacturers are responding with innovations like energy-efficient designs and eco-friendly materials, aligning with global sustainability goals. Digital integration, such as valves with IoT capabilities for real-time monitoring, is also gaining traction.

Challenges Faced by Manufacturers

Despite a promising outlook, manufacturers face significant hurdles:

- Competition: Low-cost producers, especially in Asia, challenge established firms with cheaper alternatives, pressuring profit margins.

- Innovation Costs: Continuous research and development to improve valve performance or meet new standards require substantial investment, challenging smaller players.

- Regulatory Compliance: Stricter environmental laws demand low-emission production processes and recyclable materials, adding complexity and cost.

Navigating these challenges requires a blend of strategic pricing, technological advancement, and adherence to global standards.

Real-World Applications

Low-pressure valves shine in practical settings, demonstrating their value:

- Municipal Water Systems: Cities rely on gate and check valves to distribute water efficiently, preventing waste and ensuring pressure stability.

- Chemical Processing: Globe valves regulate chemical flows in plants, safeguarding workers and equipment by maintaining controlled, low-pressure conditions.

These examples underscore how manufacturers’ products underpin critical infrastructure and industrial operations.

Conclusion

Low-pressure valves may lack the spotlight, but their role in modern life is undeniable. From delivering clean water to enabling safe industrial processes, they are vital cogs in the machinery of our world. Manufacturers like Emerson, Flowserve, and Crane lead the charge, crafting these essential components with skill and innovation.

As industries grow and evolve, so too does the demand for these valves, pushing manufacturers to adapt to new trends and challenges. With a focus on quality, sustainability, and technological advancement, the future of low-pressure valve manufacturing is poised for growth. This article has journeyed through their types, production, key players, and applications, revealing an industry as dynamic as the systems it serves. The next time you turn on a tap or adjust your thermostat, spare a thought for the low-pressure valves—and the manufacturers—making it all possible.

For more about the best low-pressure valve manufacturers: an in-depth exploration, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

Five Key Considerations When Choosing a TMA Gas Changeover Manifold

How to Prevent Contamination in High Purity Xenon Gas Systems

Regulators for High Purity Krypton in Laser and Lighting Applications

Tags

Recommended Products

-

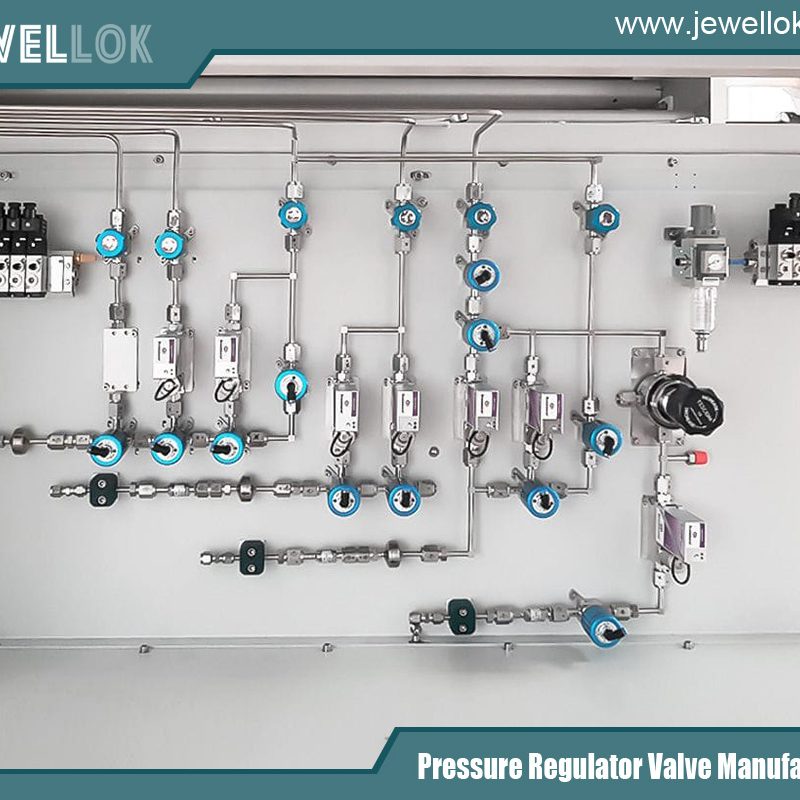

VMB Valve Manifold Box And Panel Gas Cabinet, BSGS Gas Cabinets, TMA Gas Cabinets, Scrubber Tail Gas Treatment Cabinets

-

772L Male Branch Tee | Stainless Steel High-Purity Tube Fitting Male Branch Tee

-

Hydrogen Manifold Argon Gas Manifold System Oxygen Manifold Propane Gas Manifold With Valves In Gas Manifold Changeover System

-

Ultra High Purity Trimethylaluminum TMA Gas Cabinet Liquid Delivering Cabinet Used For Specialty Gas Delivery System In Semiconductor

-

774L Stainless Steel UHP Fittings Butt Weld Bulkhead Union For High Flow Special Gas Fluid

-

Low Pressure High Flow Line Pressure Regulators And Control Valves JSR-4L Series For Laboratory Pressure Control

-

Semiconductor High Purity High Pressure Specialty Gas Bottle Gas Cylinder Storage Cabinet And Gas Pressure Regulating Cabinet

-

Scrubber Tail Gas Treatment Cabinet Waste Gas Treatment Wet Scrubber Exhaust Gas Treatment Spray Tower