Blog

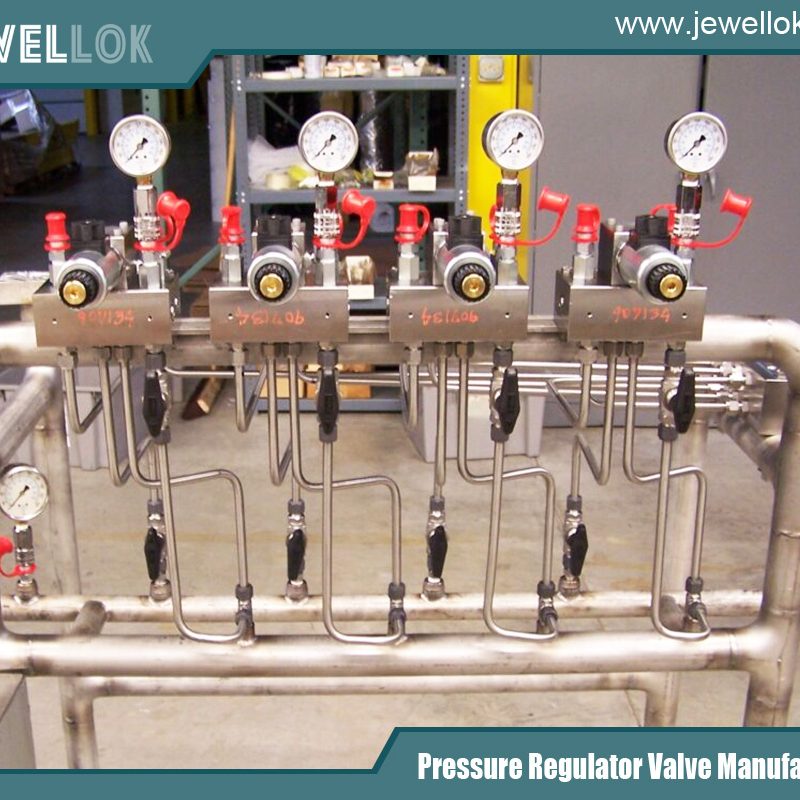

Jewellok is a professional pressure regulator and valve manufacturer and supplier.

Pressure Reducing Regulator VS Back Pressure Reducing Valve

- Pressure Regulator Valve Manufacturer

- 316 SS ball valves manufacturer, 316l vim var stainless steel gas pressure reducing regulator, back pressure reducing regulator, back pressure reducing valve, Back Pressure Reducing Valve Manufacturer, Back Pressure Regulating Valve, back pressure regulator manufacturers, back pressure regulator vs pressure reducing regulator, back pressure regulator vs pressure regulator, back pressure regulator vs pressure relief valve, back pressure regulator vs relief valve, back pressure valve manufacturers, back pressure valve vs pressure relief valve, best high purity gas pressure regulator, best high purity gas pressure regulators manufacturer, best high purity gas pressure regulators manufacturers USA, Brass Pressure Regulator, Changeover Manifold, china high pressure air regulator valve manufacturer, Diaphragm Valve Manufacturers, Double Block and Bleed valve manufacturers, gas regulator valve manufacturers, high flow back pressure regulator, high flow needle valve manufacturer, high pressure back pressure regulator, high pressure ball valve manufacturer, High-purity Pressure Reducing Regulator, how do back pressure regulators work, industrial diaphragm valve manufacturers, industrial lng pressure reducing regulator, low pressure valve manufacturer, medical oxygen pressure gauge manufacturer, needle valve 10000 psi manufacturer, pneumatic actuated ball valve manufacturer, pressure control valve manufacturers, pressure reducing regulator, pressure reducing regulator manufacturer, pressure reducing vs back pressure regulator, pressure regulator vs back pressure regulator, pressure relief valve vs back pressure regulator, Ultra High Purity Dual Stage Pressure Reducing Regulator, what is a back pressure regulator

- No Comments

Pressure Reducing Regulator VS Back Pressure Reducing Valve

In the world of fluid control systems, valves and regulators play a pivotal role in ensuring safe, efficient, and precise operation across industries such as oil and gas, chemical processing, manufacturing, and even laboratory settings. Two commonly confused yet fundamentally distinct devices are the pressure reducing regulator (PRR) and the back pressure reducing valve, often referred to as a back pressure regulator (BPR). While both are essential for managing pressure in pipelines, vessels, and equipment, they serve opposite functions in a system. Understanding their differences is crucial for engineers, technicians, and system designers to avoid misapplications that could lead to inefficiencies, equipment damage, or safety hazards.

A pressure reducing regulator is designed to lower high inlet pressure to a stable, lower outlet pressure, protecting downstream components from excessive force. In contrast, a back pressure reducing valve maintains a consistent upstream pressure by relieving excess pressure when it exceeds a setpoint, safeguarding upstream systems. This article delves into the definitions, working principles, key differences, applications, advantages, disadvantages, and selection criteria for these devices. By exploring real-world examples and comparative analyses, we aim to provide a comprehensive guide to help professionals choose the right tool for their needs. Drawing from industry insights, we’ll highlight how these regulators contribute to operational reliability in diverse scenarios.

The importance of these devices cannot be overstated. In high-stakes environments like oil production or pharmaceutical manufacturing, improper pressure control can result in leaks, explosions, or product contamination. According to industry sources, misapplying a PRR in place of a BPR, or vice versa, is a common error that leads to system failures. This comparison will equip readers with the knowledge to make informed decisions, potentially saving costs and enhancing safety.

What is a Pressure Reducing Regulator?

A pressure reducing regulator, also known as a pressure regulator or PRV (pressure reducing valve), is a control device that automatically reduces a higher inlet pressure to a lower, constant outlet pressure, regardless of fluctuations in upstream pressure or flow rate. It is typically installed at the beginning of a system or upstream of sensitive equipment to ensure that downstream processes receive a steady, safe pressure level.

How It Works

The PRR operates on a simple yet effective principle involving a sensing element, a control mechanism, and a valve body. Internally, it features a diaphragm or piston that senses the downstream pressure. When the outlet pressure drops below the setpoint—due to increased demand or flow—the regulator opens wider to allow more fluid or gas to pass through, restoring the pressure. Conversely, if the downstream pressure rises above the setpoint, the valve throttles back or closes slightly to reduce flow. This feedback loop maintains equilibrium.

Most PRRs are normally open, meaning they allow flow in their default state and adjust based on downstream conditions. For instance, in a spring-loaded design, a spring exerts force on the diaphragm, counterbalanced by the downstream pressure. Advanced models may incorporate pilots for more precise control in high-pressure applications.

Components typically include:

- Inlet and outlet ports

- Sensing line or port connected downstream

- Adjustable setpoint mechanism (e.g., a screw or knob)

- Valve seat and plug for flow control

Applications

PRRs are ubiquitous in systems where high supply pressure needs to be stepped down for safe use. In natural gas distribution, they regulate pressure from high-pressure mains to low-pressure lines for residential or industrial use. In laboratories, PRRs reduce cylinder gas pressure (often 200 bar) to workable levels like 5-7 bar at points of use.

Other applications include:

- Suction controllers on compressors

- Fuel gas supply for production equipment

- Pneumatic tools in manufacturing, where consistent air pressure prevents tool malfunction

- Hospital gas systems via changeover panels

Examples

Consider a gas meter run in an oil refinery: A PRR ensures that incoming high-pressure gas is reduced to a stable level for accurate metering and safe delivery to burners. Without it, pressure surges could damage meters or cause inconsistent combustion.

What is a Back Pressure Reducing Valve?

A back pressure reducing valve, or back pressure regulator (BPR), is a device that maintains a constant pressure upstream of itself by opening to relieve excess pressure when the inlet pressure exceeds a predetermined setpoint. It is often installed at the end of a system or downstream of vessels to protect upstream components from over-pressurization.

How It Works

Unlike the PRR, the BPR senses pressure on the upstream side (inlet). It is normally closed, creating an obstruction to flow until the upstream pressure builds to the setpoint. At that point, the valve opens proportionally to bleed off excess fluid or gas, reducing the upstream pressure back to the desired level. This continuous adjustment provides steady-state control rather than abrupt on/off relief.

Key components mirror those of PRRs but with reversed sensing: a diaphragm or piston connected upstream, a valve that opens to decrease upstream pressure, and an adjustable setpoint. In dome-loaded designs, a reference pressure in the dome controls the valve position for precision across varying flows. BPRs differ from relief valves, which are safety devices for emergency pressure release; BPRs focus on ongoing regulation.

Applications

BPRs are ideal for scenarios requiring upstream pressure maintenance, such as in closed-loop systems or vessels. In oil and gas production, they hold pressure on separators to create differentials for fluid dumping.

Other uses include:

- Chemical reactors to prevent over-pressurization

- Pump discharge lines to regulate flow

- Bypass control for positive displacement pumps

- Floating production storage and offloading (FPSO) vessels for sealing flexible hoses in oil/water lines

- Return lines before tanks to maintain back pressure

Examples

In a chemical processing plant, a BPR at the end of a return line ensures upstream pumps and reactors maintain minimum pressure, preventing cavitation or flow instability. If pressure rises too high, it dumps excess into a tank, stabilizing the system.

Key Differences

While PRRs and BPRs may look similar externally, their operational philosophies are inverted.

Here’s a detailed comparison:

Sensing and Control Orientation

- PRR: Senses and controls downstream pressure. The sense line connects to the outlet side.

- BPR: Senses and controls upstream pressure. The sense line connects to the inlet side.

- PRR: Normally open; opens to increase downstream pressure, closes to decrease it.

- BPR: Normally closed; opens to decrease upstream pressure, closes to increase it.

- PRR: At the start of a system to protect downstream equipment.

- BPR: At the end to benefit upstream components.

- PRR: Reduces high pressure for safe, consistent downstream delivery.

- BPR: Maintains minimum upstream pressure by relieving excess.

|

Aspect |

Pressure Reducing Regulator (PRR) | Back Pressure Regulator (BPR) |

| Controls Pressure | Downstream | Upstream |

| Normal State | Open | Closed |

| Installation | Upstream/start of system | Downstream/end of system |

| Opens To | Increase downstream pressure | Decrease upstream pressure |

| Closes To | Decrease downstream pressure | Increase upstream pressure |

| Typical Applications | Gas distribution, tools | Vessels, pumps, reactors |

This table summarizes the core distinctions.

Misapplication is common; using a PRR at the end of a line results in it staying open, offering no regulation, while a BPR in a PRR’s position could cause excessive back pressure.

Advantages and Disadvantages

Advantages:

- Provides precise downstream control, ideal for sensitive equipment.

- Reduces energy waste by lowering unnecessary high pressure.

- Versatile in gas and liquid systems; easy to adjust.

Disadvantages:

- Cannot maintain upstream pressure; vulnerable to inlet fluctuations.

- May require additional components for high-flow applications.

- Potential for droop (pressure drop at high flows).

Back Pressure Regulator

Advantages:

- Excellent for upstream protection and steady-state control.

- Prevents over-pressurization in vessels and loops.

- More stable than relief valves for continuous operation.

Disadvantages:

- Requires a means to handle relieved fluid (e.g., recirculation).

- Less effective for downstream regulation.

- Higher cost in precision models for varying flows.

In balanced systems, pairing both—PRR at the inlet and BPR at the outlet—optimizes performance.

Real-World Applications and Case Studies

In the oil and gas sector, Kimray highlights BPRs for pressurizing production vessels, enabling fluid transfer via differentials, while PRRs regulate compressor suction. A case study from FPSO operations shows BPRs maintaining seals in subsea hoses, preventing leaks during oil extraction. In manufacturing, Valin describes PRRs supplying air to tools, ensuring consistent torque, and BPRs in chemical tanks to avoid rupture. Equilibar’s research applications use BPRs for low-pressure flow control in labs, recirculating excess gas for precision. A Plast-O-Matic example warns against using PRRs in BPR roles: In a return line, a misplaced PRR acts as an open pipe, failing to build pressure, leading to pump issues.

Selection Criteria

Choosing between a PRR and BPR depends on several factors:

- System Requirements: Downstream control? Choose PRR. Upstream maintenance?

- Pressure Levels: Ensure the device handles inlet/outlet ranges.

- Flow Rate and Media: Gases require different sizing than liquids; consider viscosity.

- Precision Needs: Dome-loaded BPRs for variable flows.

- Installation Constraints: Space, cost, and integration with existing systems.

- Safety and Compliance: Check for certifications like ASME.

Consult manufacturers and perform calculations using Cv (flow coefficient) values.

Conclusion

Pressure reducing regulators and back pressure reducing valves are indispensable in fluid systems, yet their inverted roles—downstream reduction versus upstream maintenance—make them complementary rather than interchangeable. By understanding their mechanics, differences, and applications, engineers can design more robust systems. Whether in oil production, chemical processing, or lab work, selecting the right regulator enhances efficiency and safety. As industries evolve with smarter controls, these devices will remain foundational, adapting to new challenges like sustainable energy systems. For optimal results, always verify with site-specific data and expert advice.

For more about pressure reducing regulator vs back pressure reducing valve, you can pay a visit to Jewellok at https://www.jewellok.com/ for more info.

Recent Posts

How to Choose the Krypton Gas Ultra High Purity (UHP) Regulator

Troubleshooting Common Failures in TMA Gas Changeover Manifolds

Key Specifications: UHP Argon Valves for 99.999% Purity Gas Systems

Tags

Recommended Products

-

Medical Oxygen Single Stage Manual Gas Changeover Manifold Panel High-Purity Two-Stage Manual Gas Manifold Gas Pressure Control Panels

-

762L Stainless Steel High Purity Union High-Purity Gas System Fittings

-

JR1000 Series UHP Ultra High Purity Single Stage Pressure Reducing Regulator And Low To Intermediate Flow

-

Semi Automatic And Automatic Switching Speicialty Gas Changeover Manifold Panel With Semiconductor Valve Manifold Box Gas Pressure Regulators

-

FT-BOX JW-FTB-C Valve Manifold Panels And Boxes With High Purity Configurable Systems

-

739LF High Purity Female Adapter Tube To Pipe Fittings And Connectors

-

Ultra High Purity Stainless Steel Compressed Gas Changeover Manifold Panel System For Integrated Gas Supply System

-

Ultra High Purity Oxygen Pressure Gauge For Semiconductor Gases JG Series Pressure Instruments For Semiconductor Manufacturing